Patents

Literature

42results about How to "Shorten the heat conduction distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

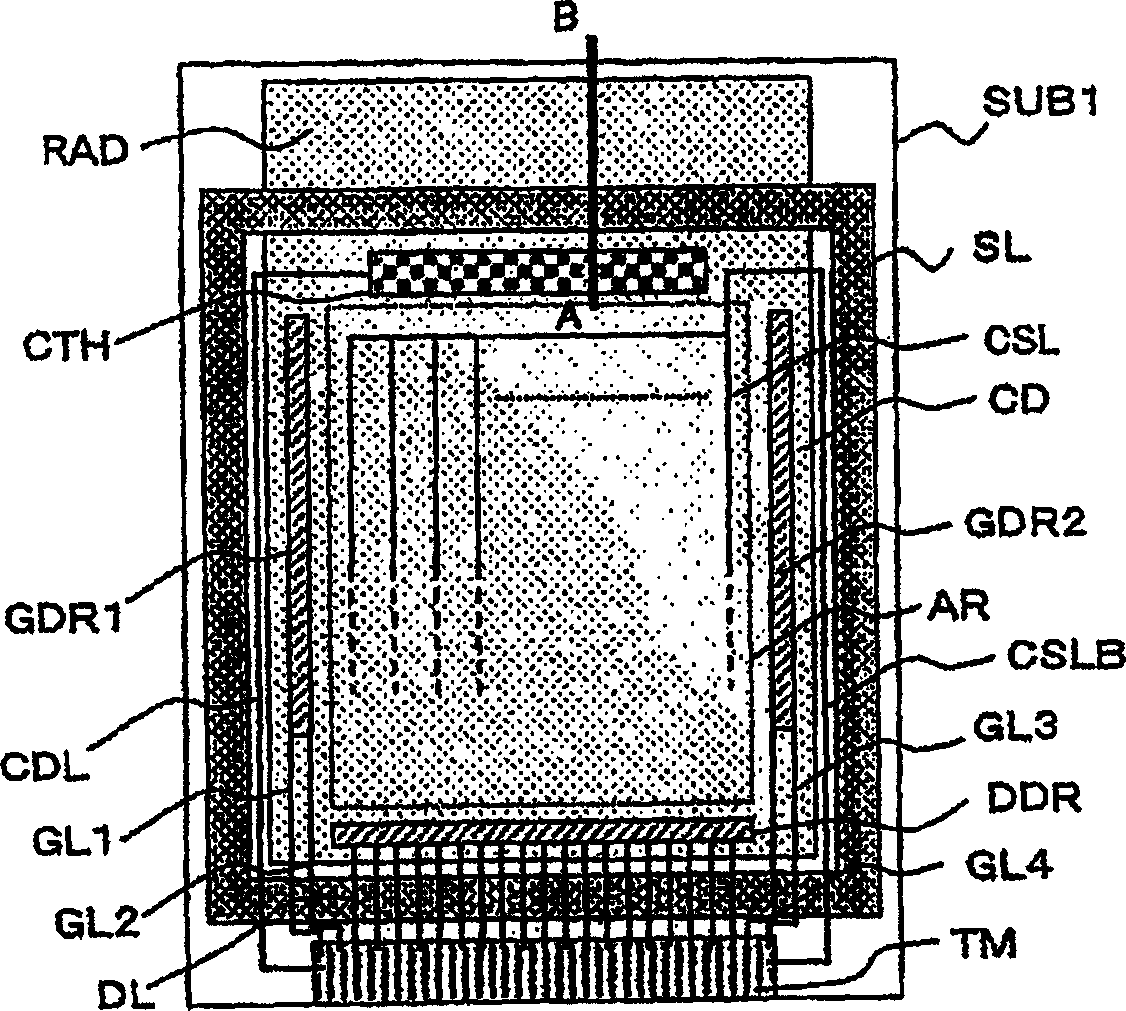

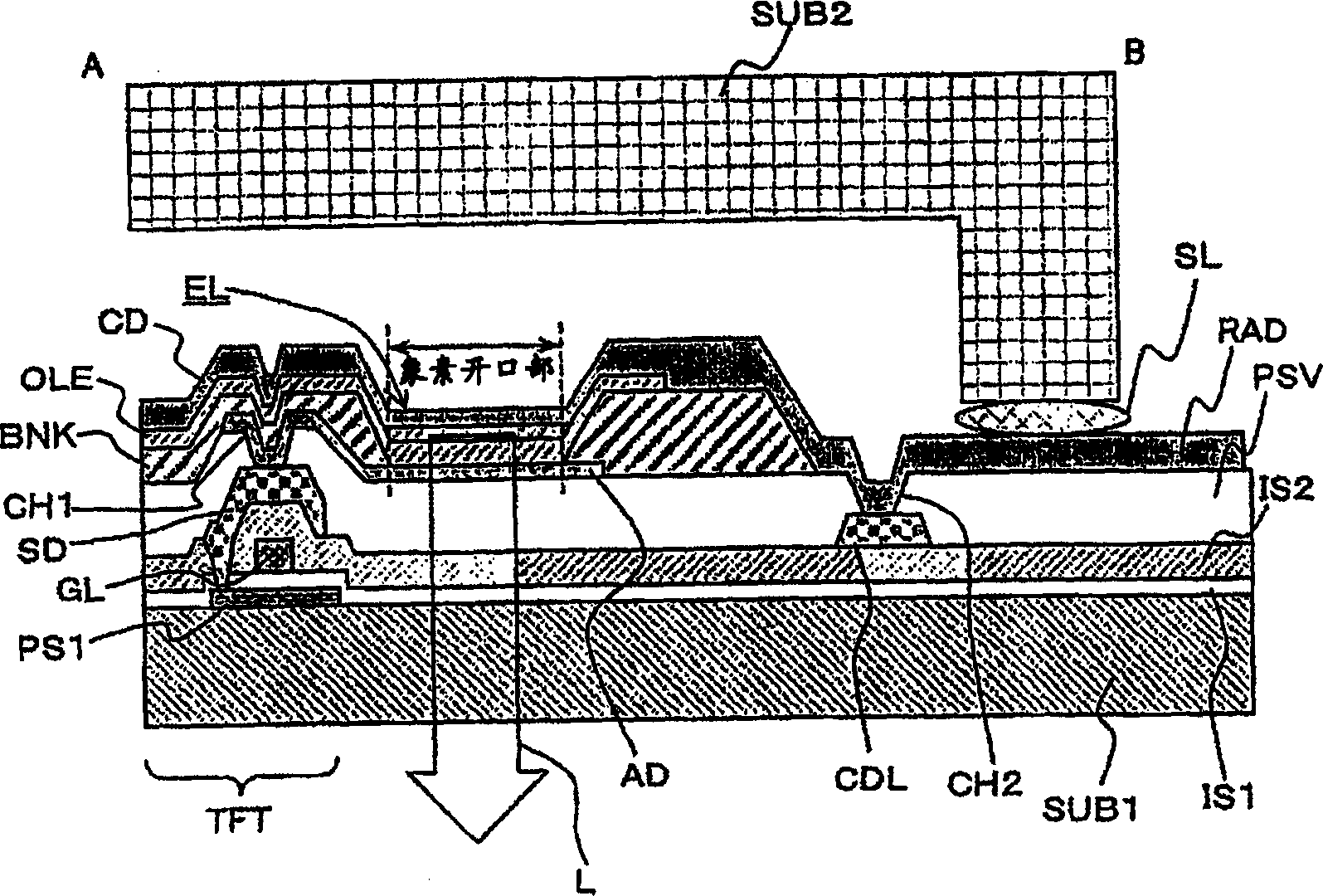

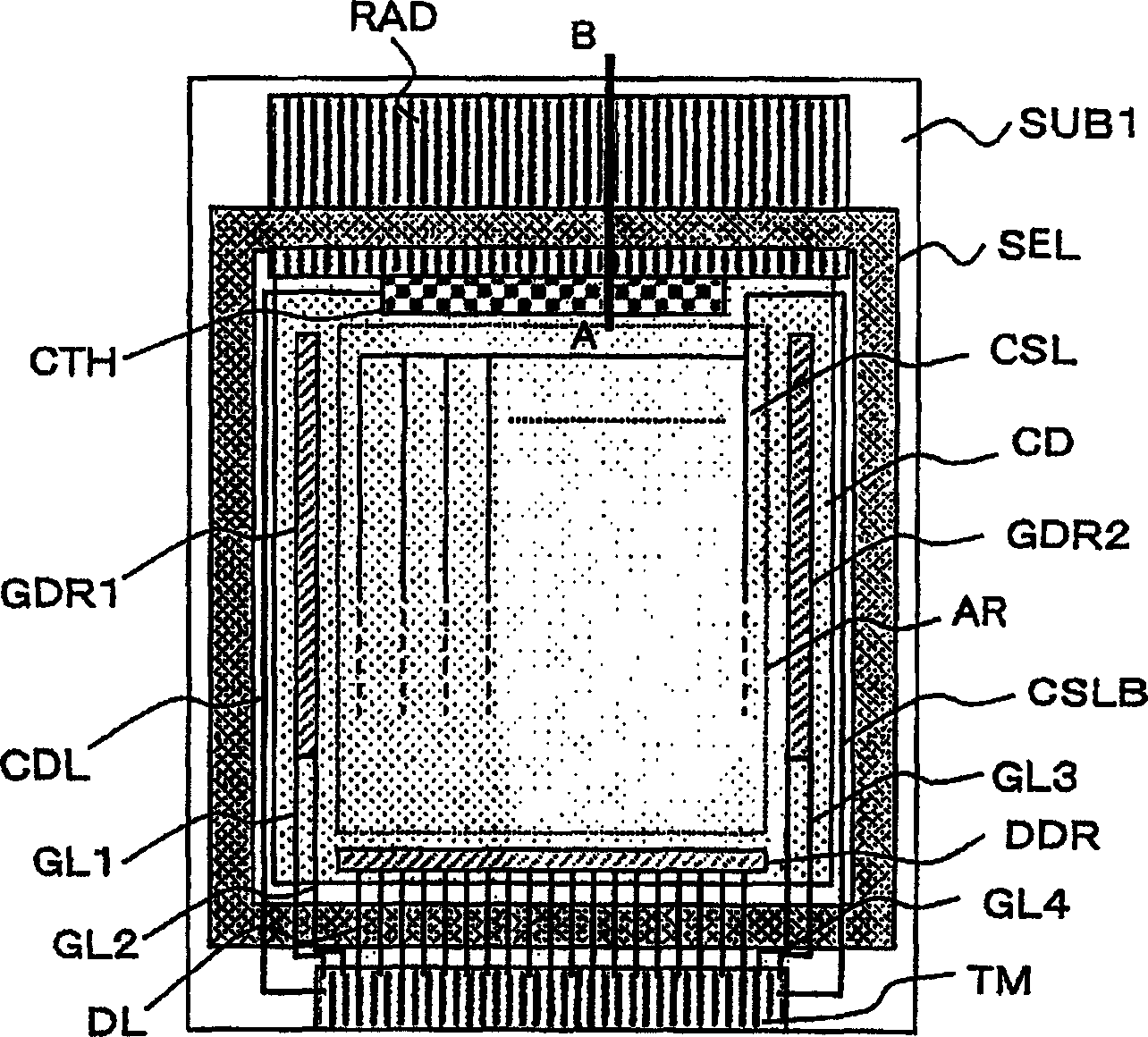

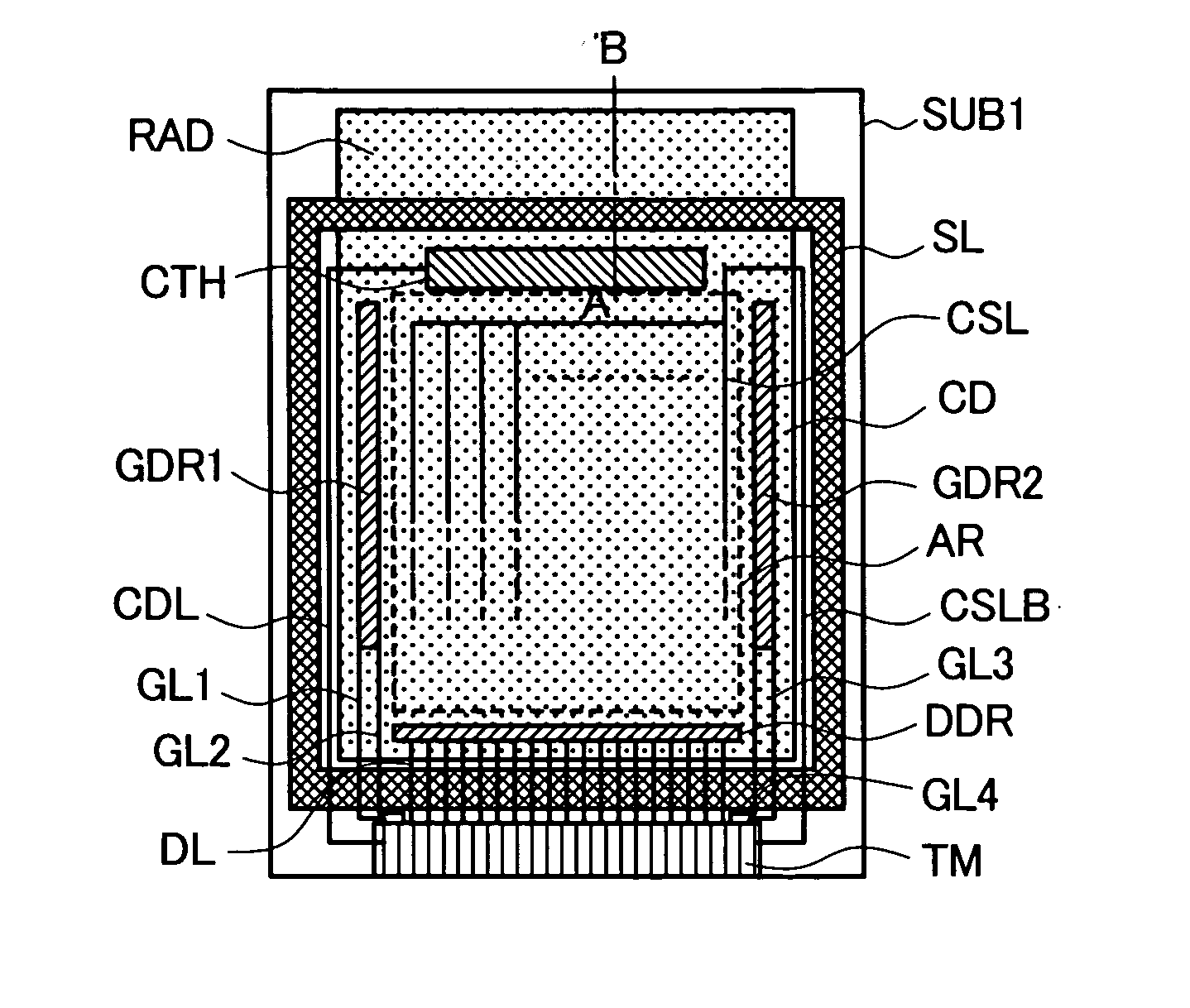

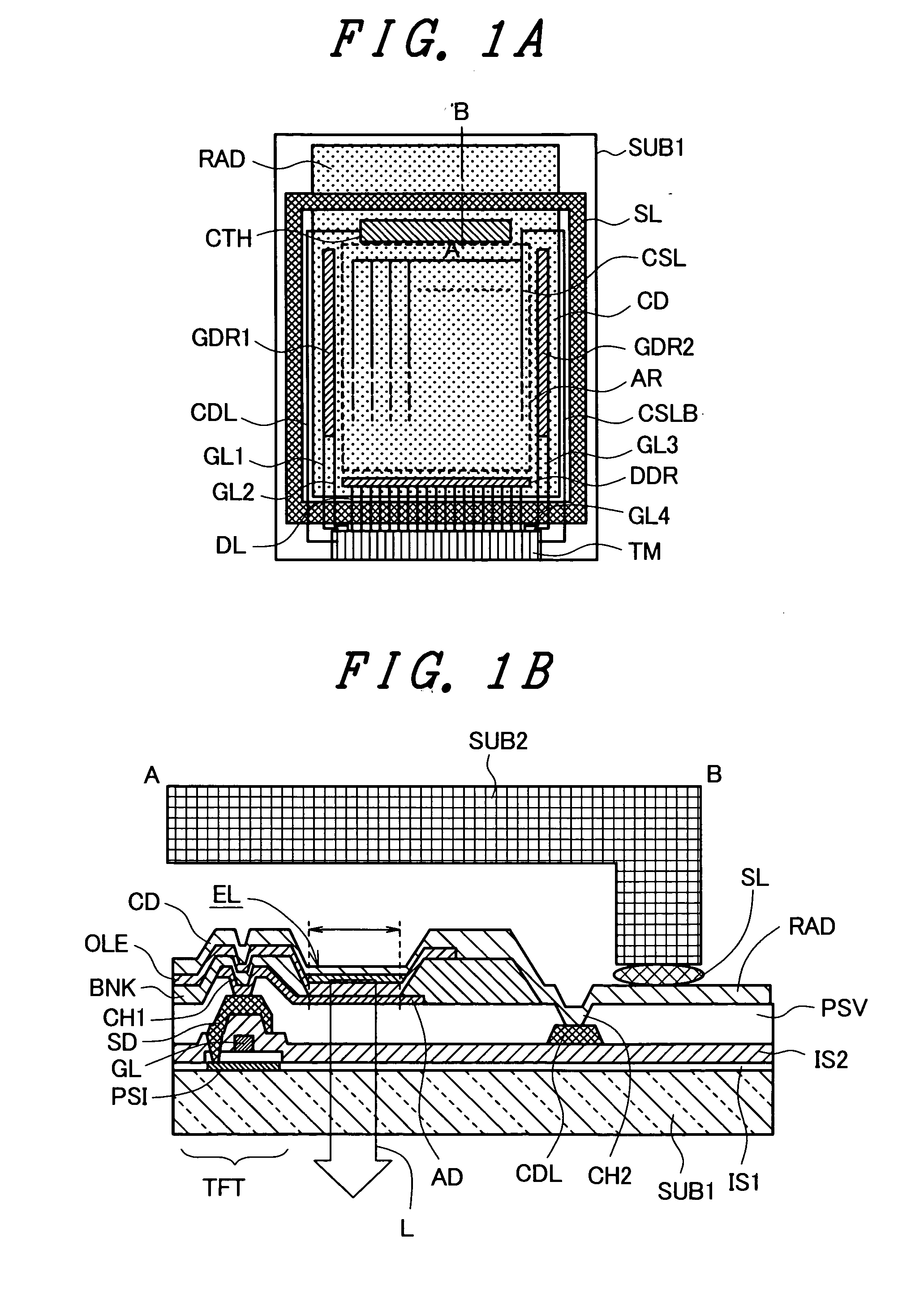

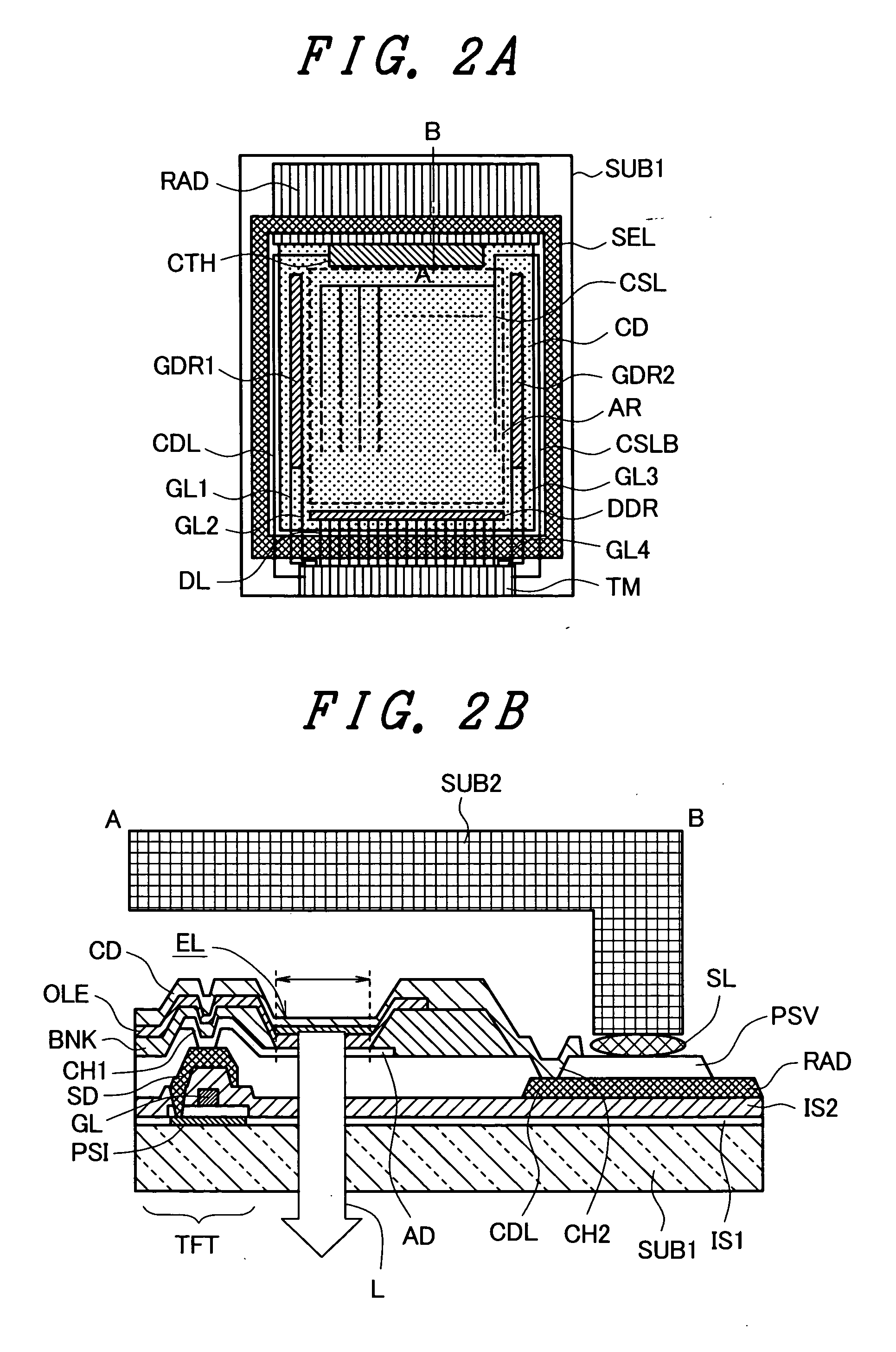

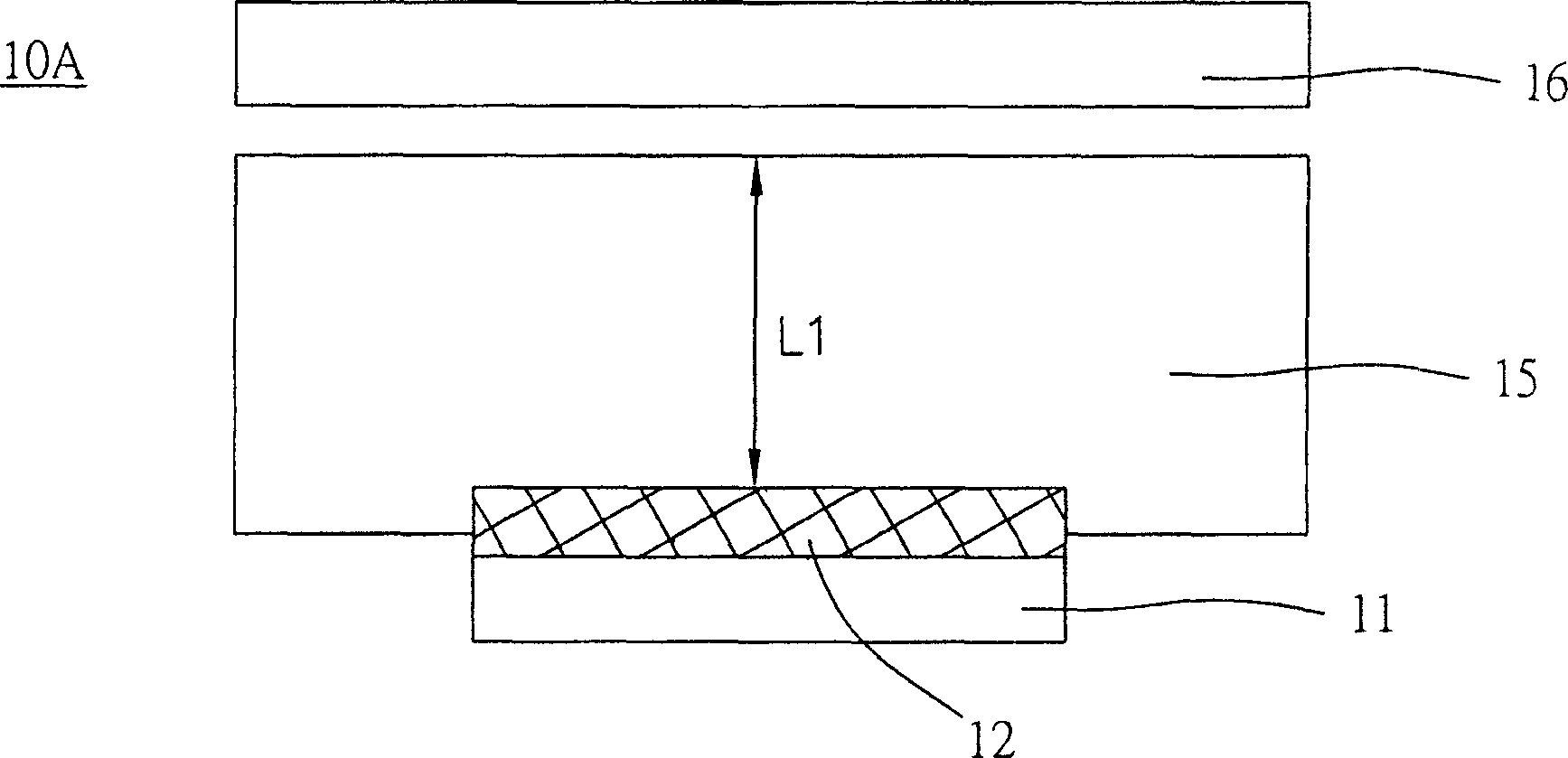

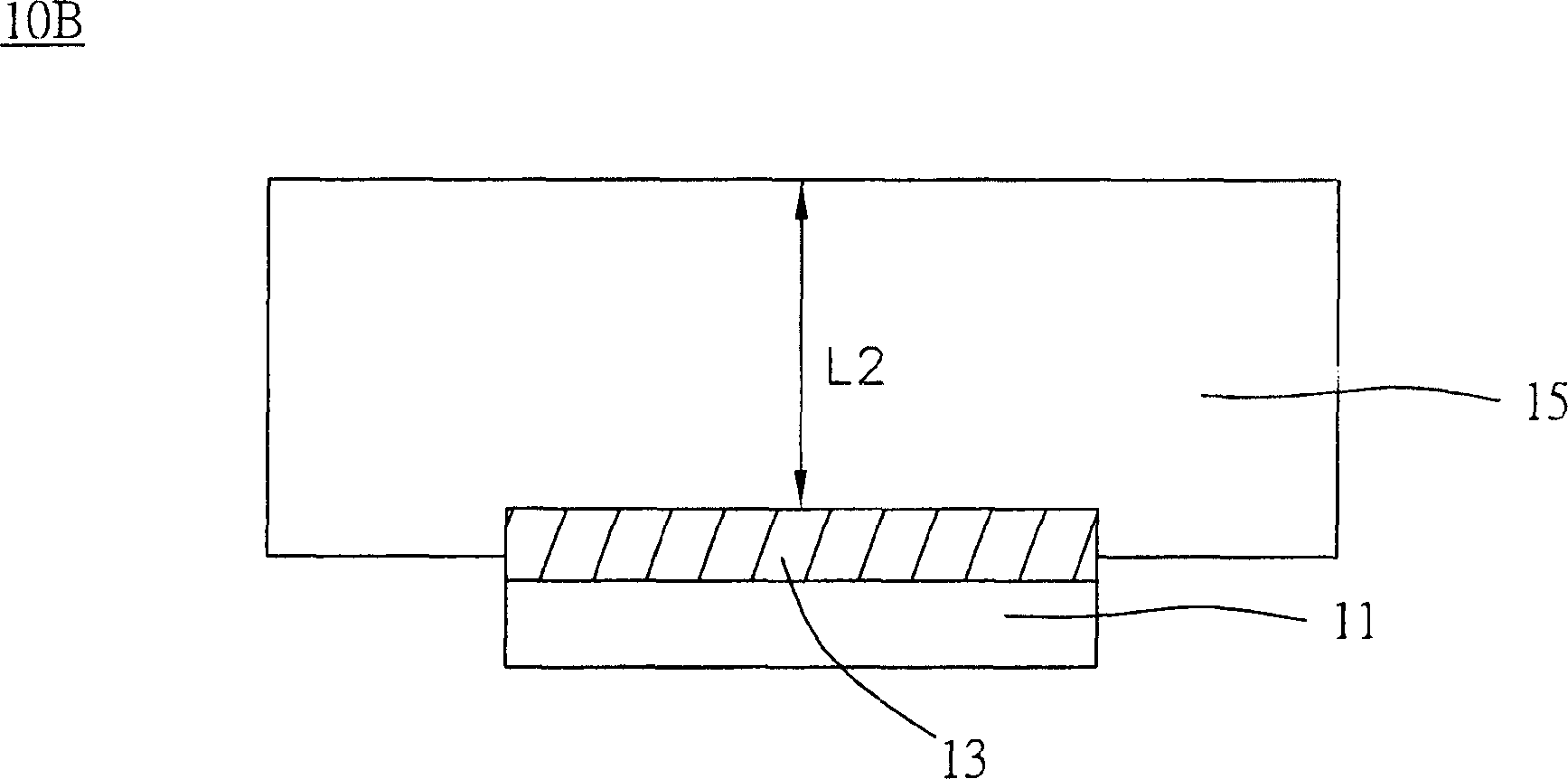

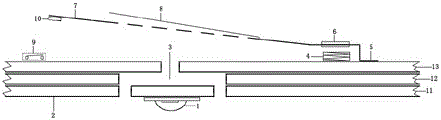

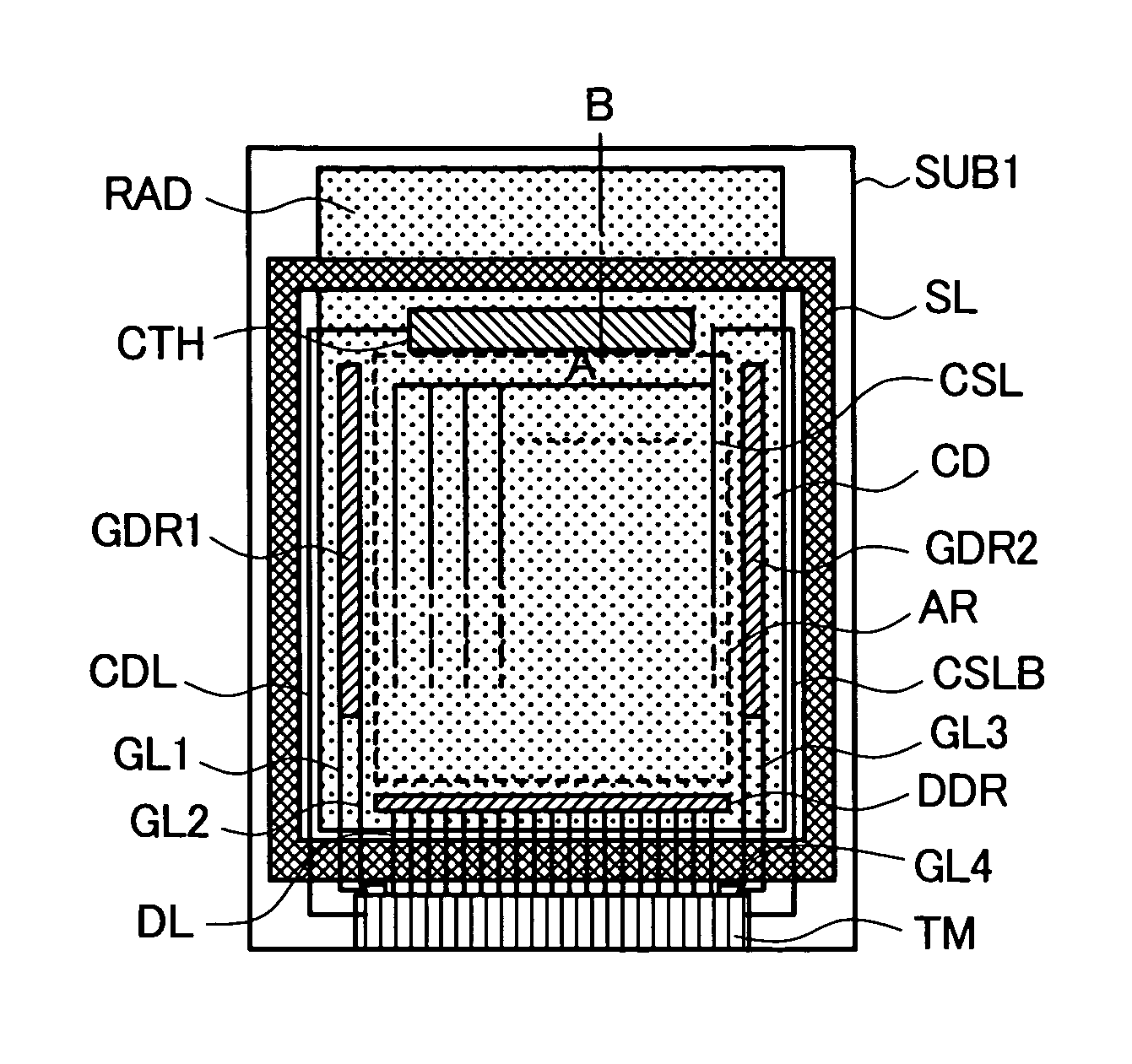

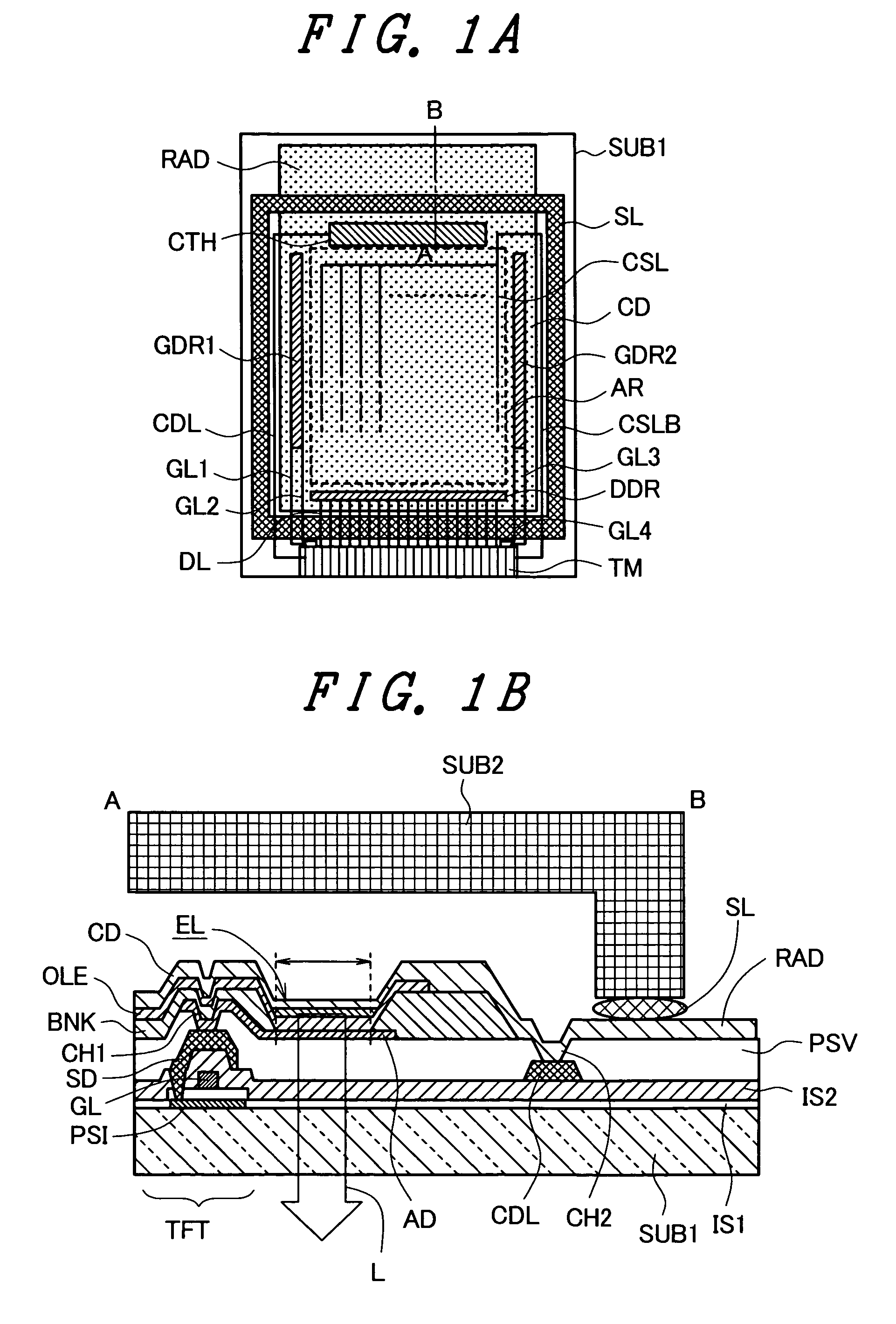

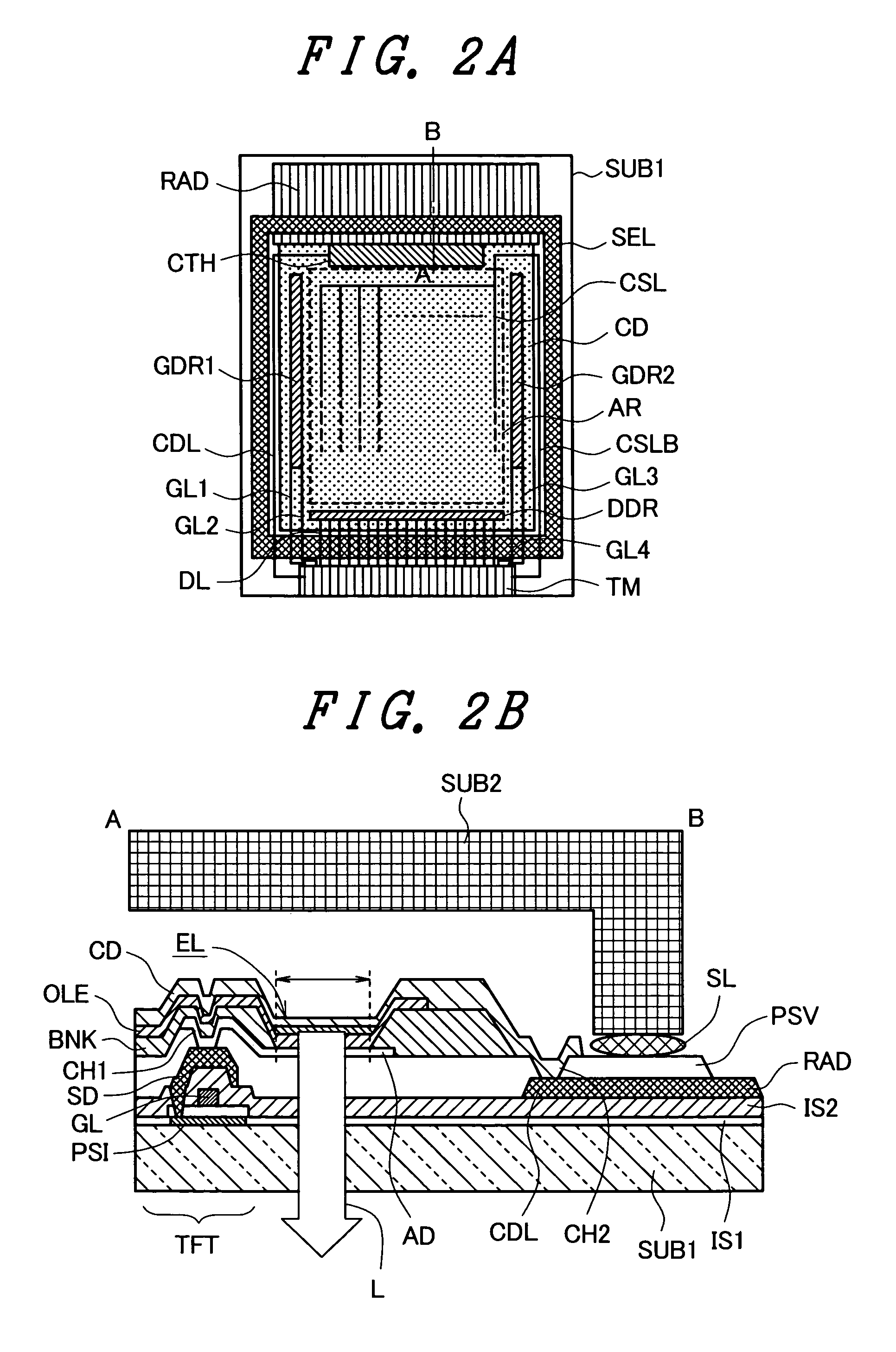

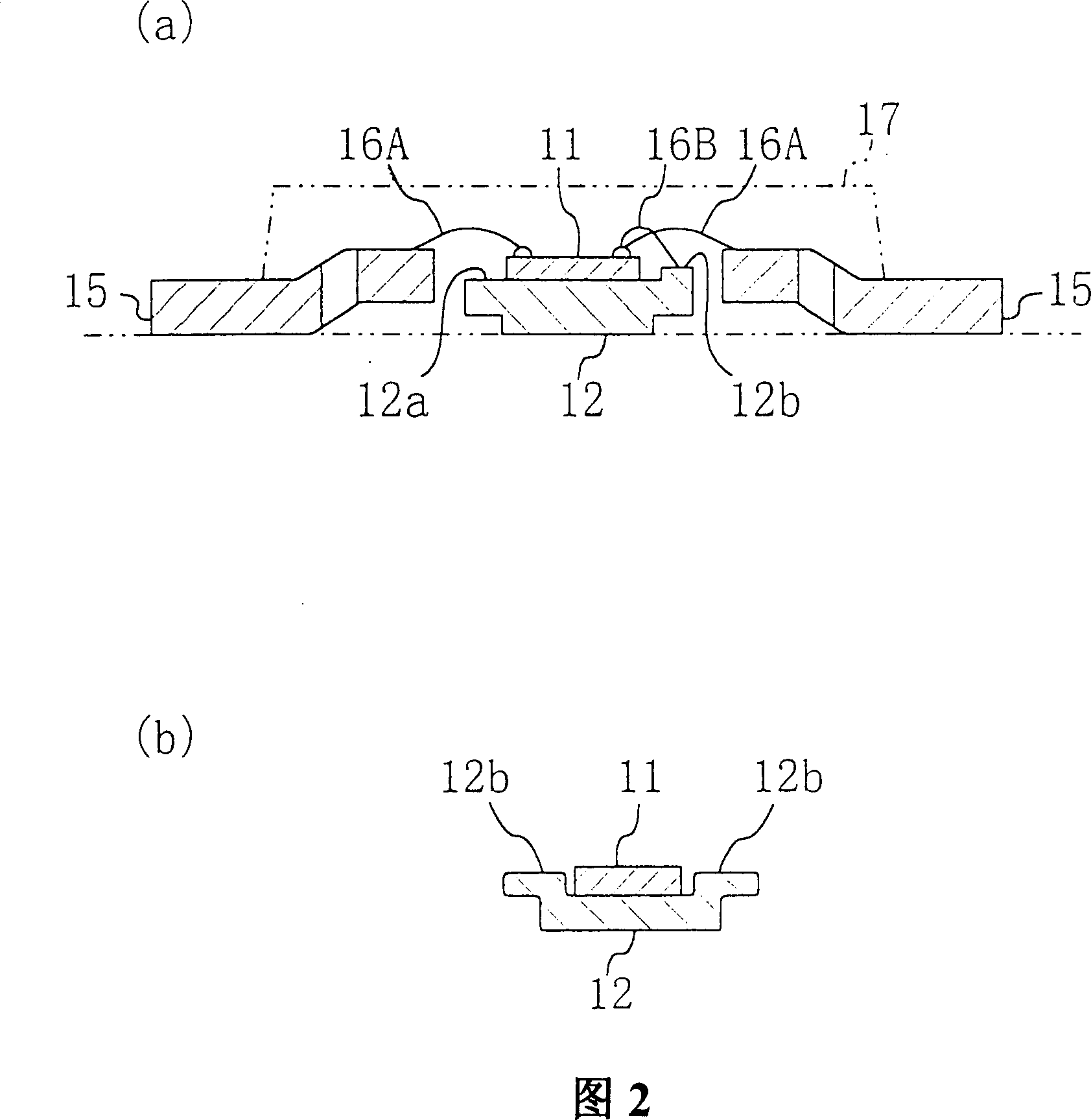

Organic light emitting display

InactiveCN1901221AExtend your lifeDissipate heat quicklySemiconductor/solid-state device detailsElectroluminescent light sourcesLight emissionRadiation

An organic light emitting display provided according to the invention maintains light emission efficiency and elongates its lifetime by radiating heat generated from organic light emitting elements to the outside of an encapsulated area. In the organic light emitting display, a part of a cathode is extended to the outside of the encapsulated area of a main substrate to form a radiation section integrally with the cathode. Heat generated from organic light emitting elements is diffused and radiated from the radiation section so that the heat can be discharged therefrom.

Owner:HITACHI DISPLAYS

Organic light emitting display

ActiveUS20070045616A1Heat conduction distanceImprove radiation efficiencySolid-state devicesSemiconductor/solid-state device manufacturingLight emissionRadiation

An organic light emitting display provided according to the invention maintains light emission efficiency and elongates its lifetime by radiating heat generated from organic light emitting elements to the outside of an encapsulated area. In the organic light emitting display, a part of a cathode is extended to the outside of the encapsulated area of a main substrate to form a radiation section integrally with the cathode. Heat generated from organic light emitting elements is diffused and radiated from the radiation section so that the heat can be discharged therefrom.

Owner:SAMSUNG DISPLAY CO LTD +1

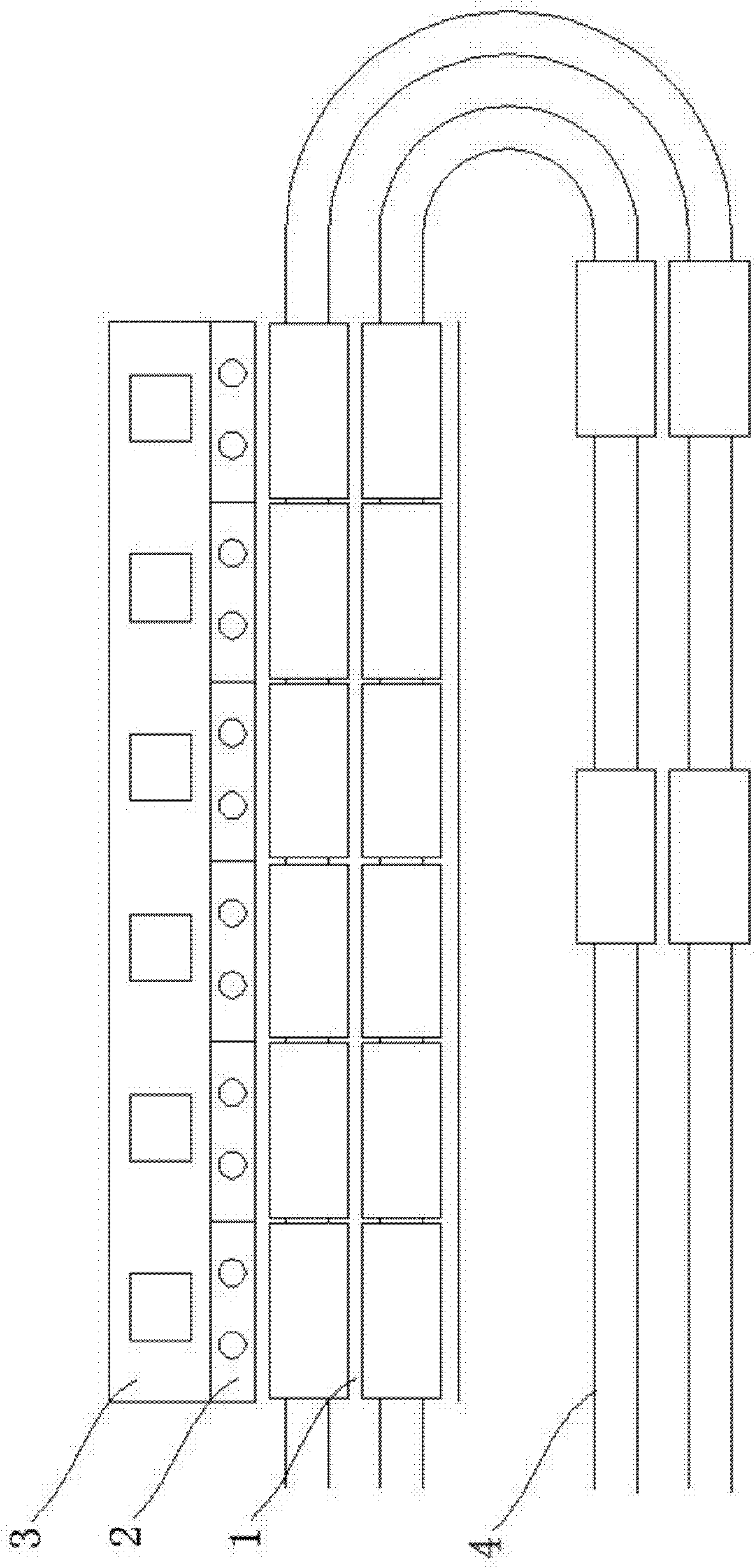

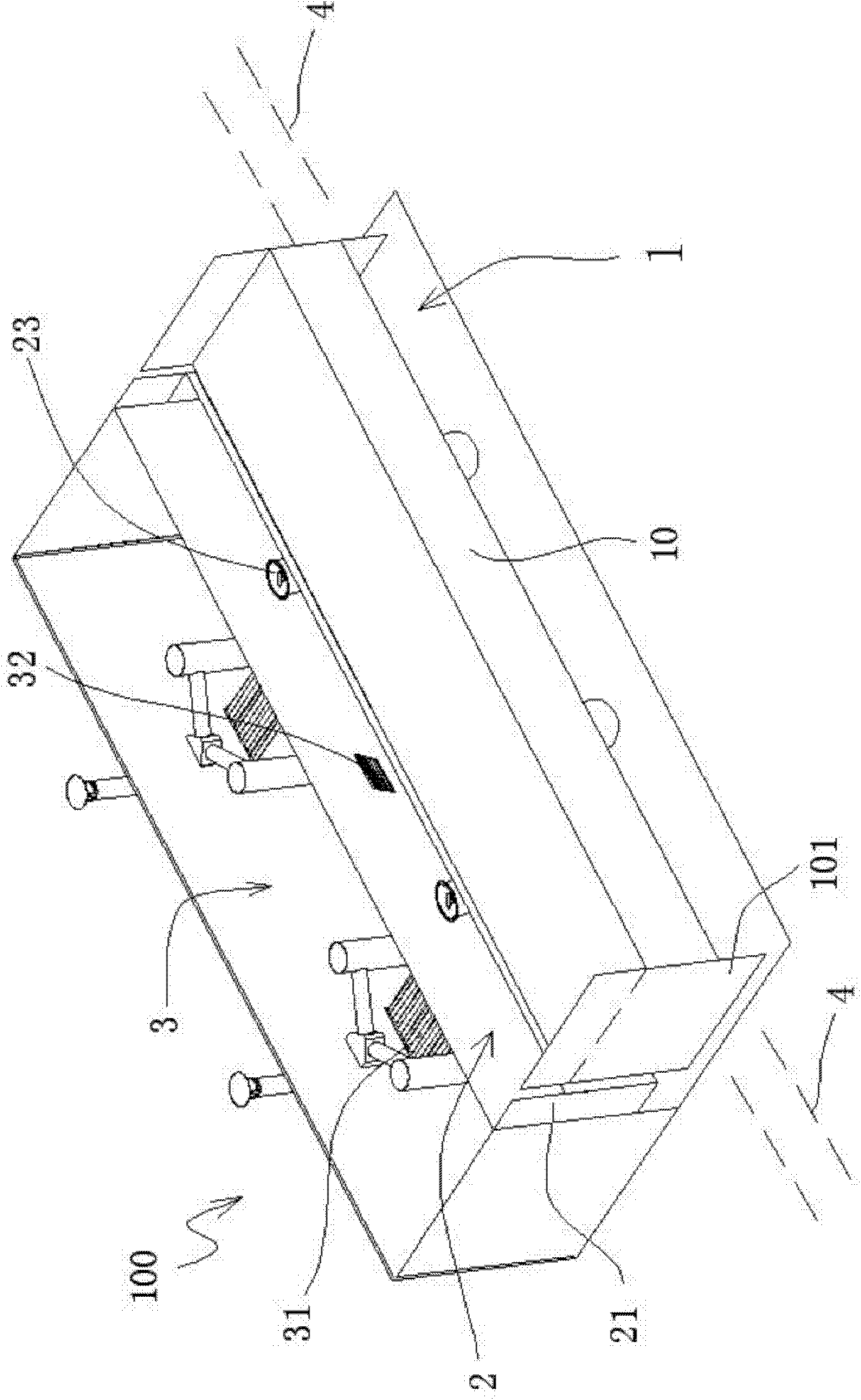

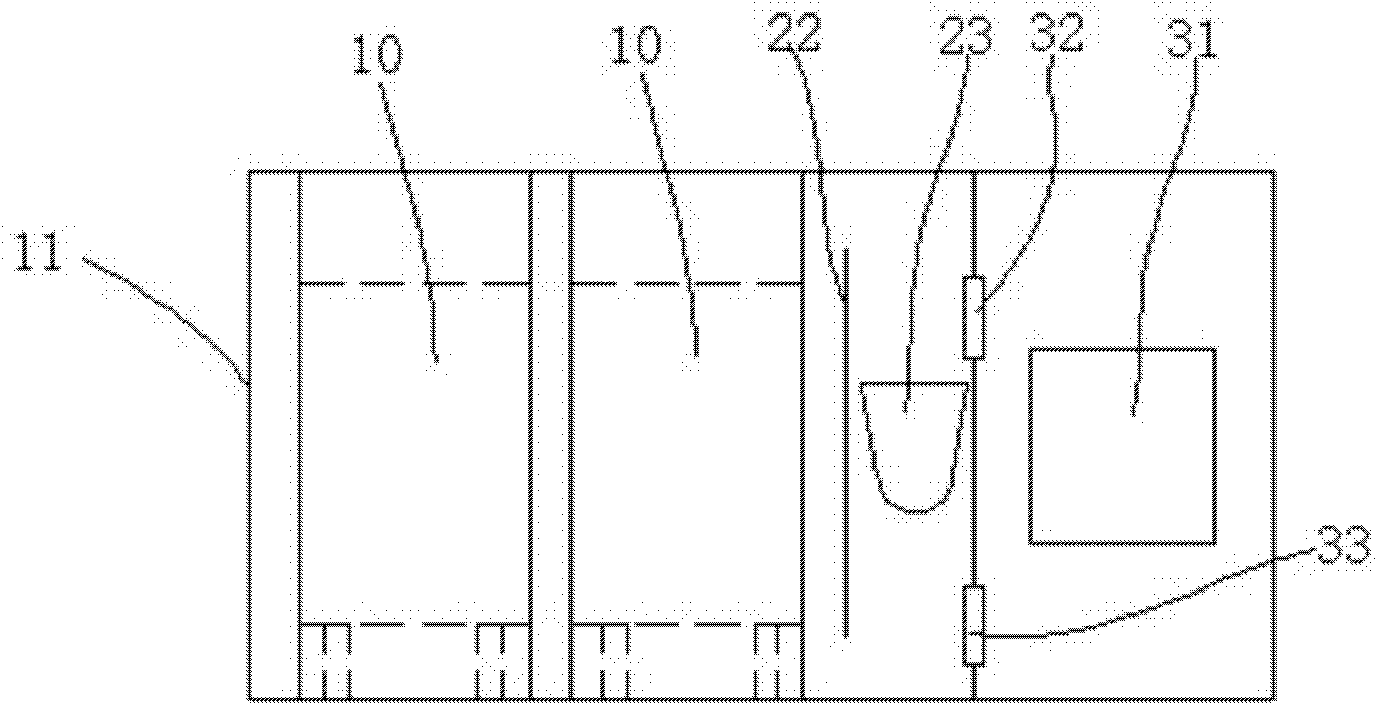

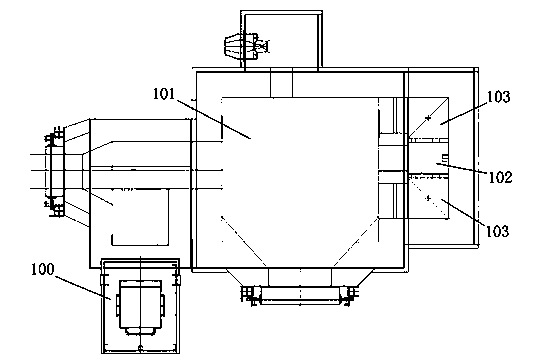

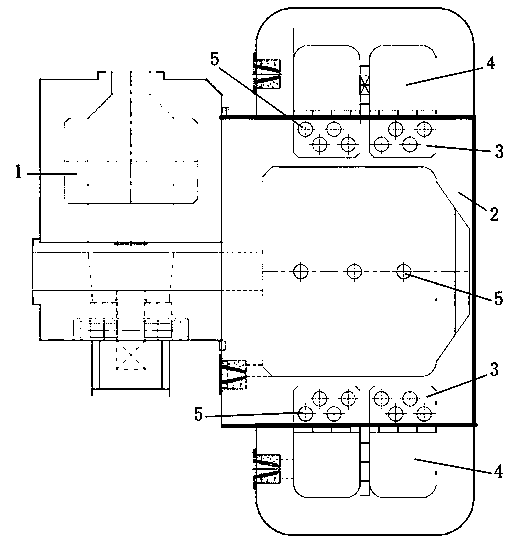

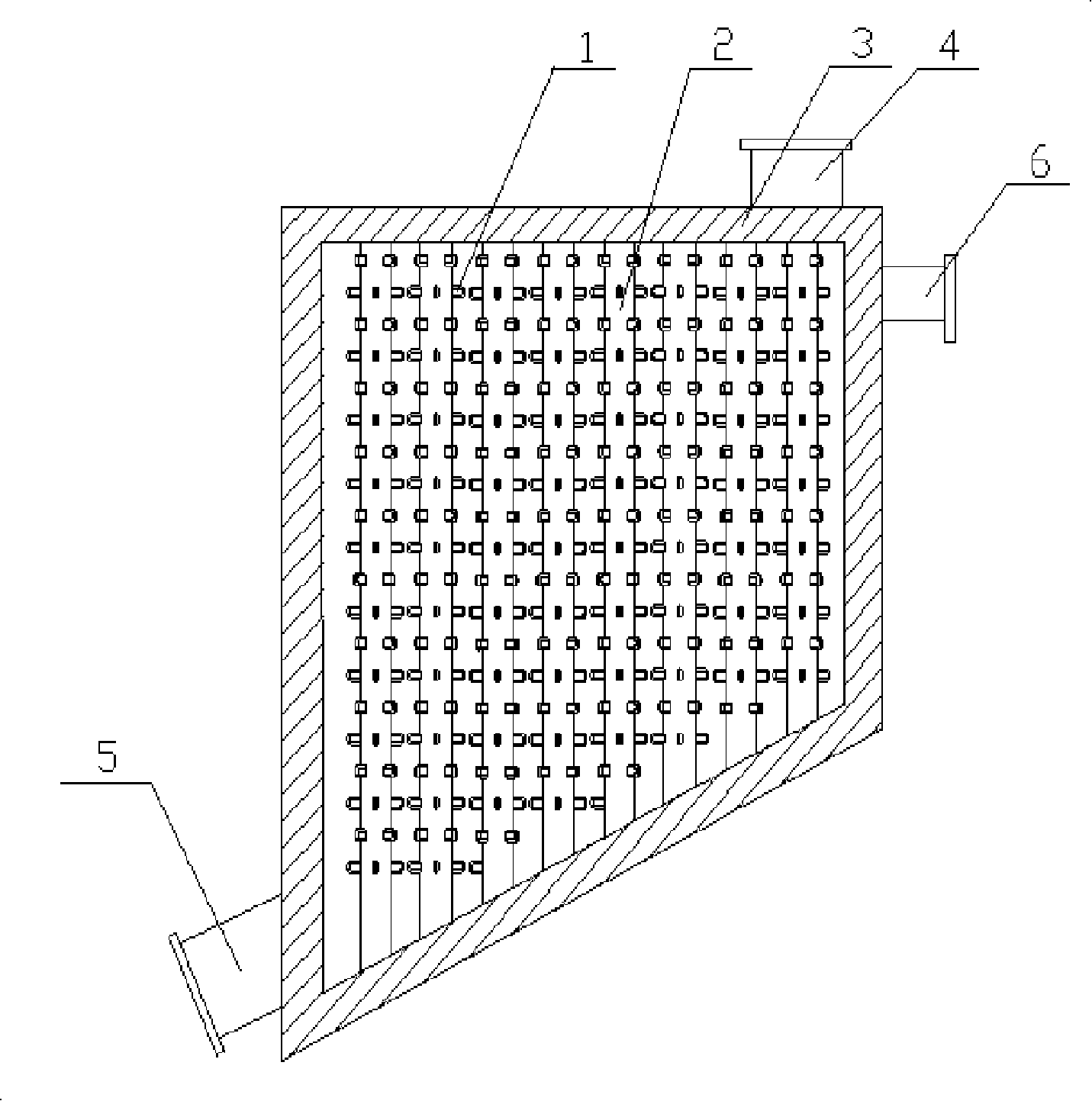

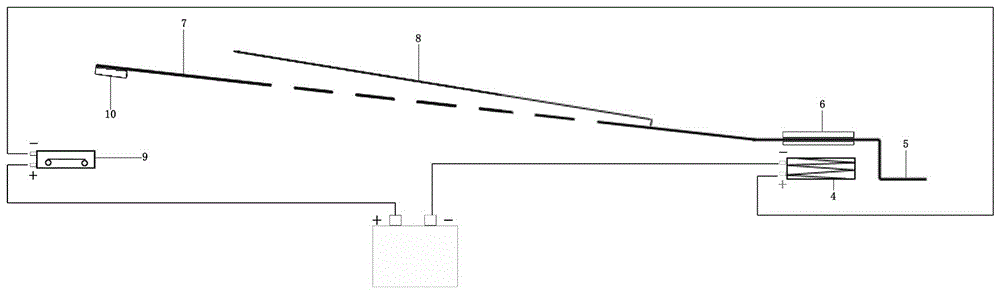

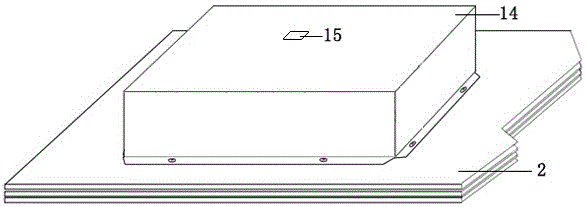

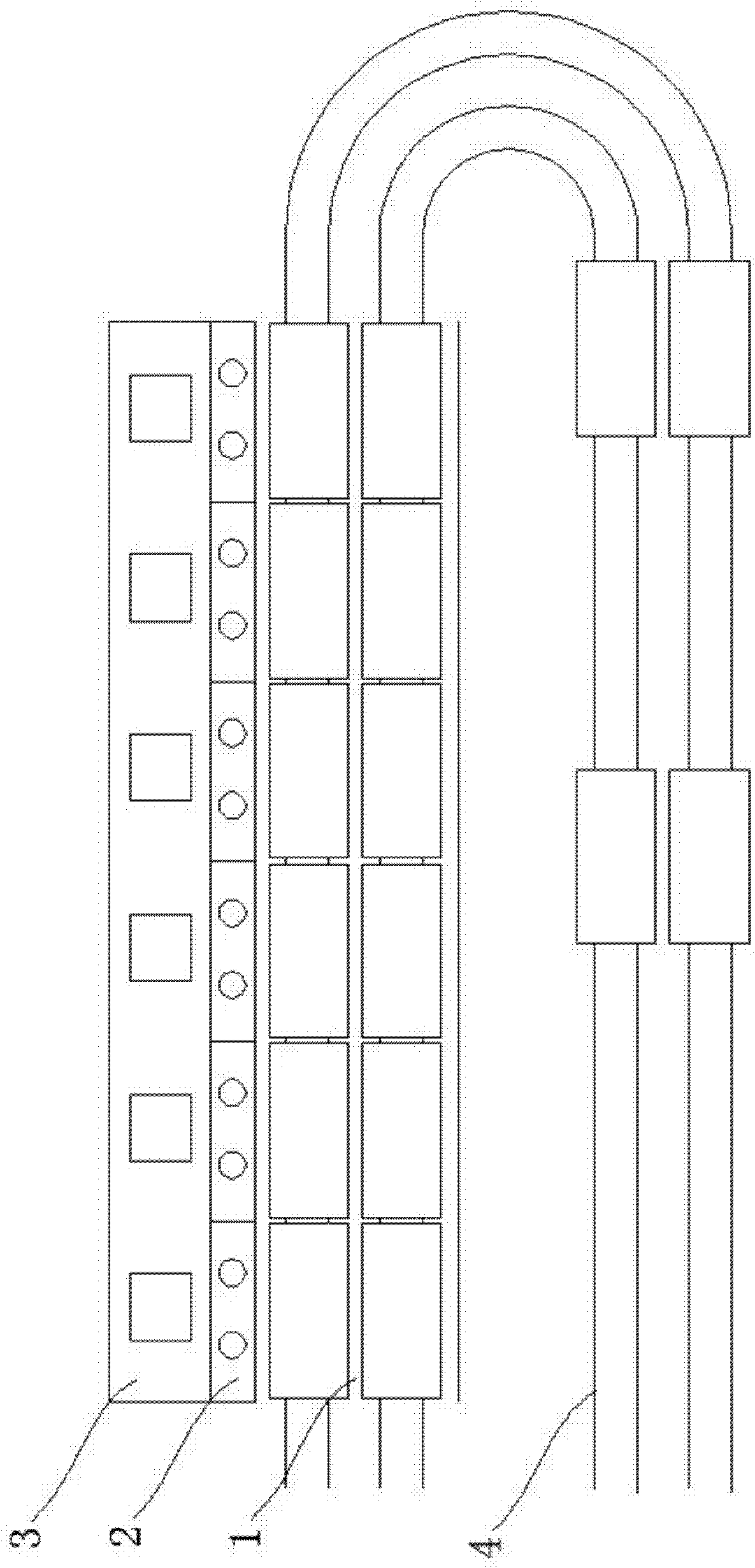

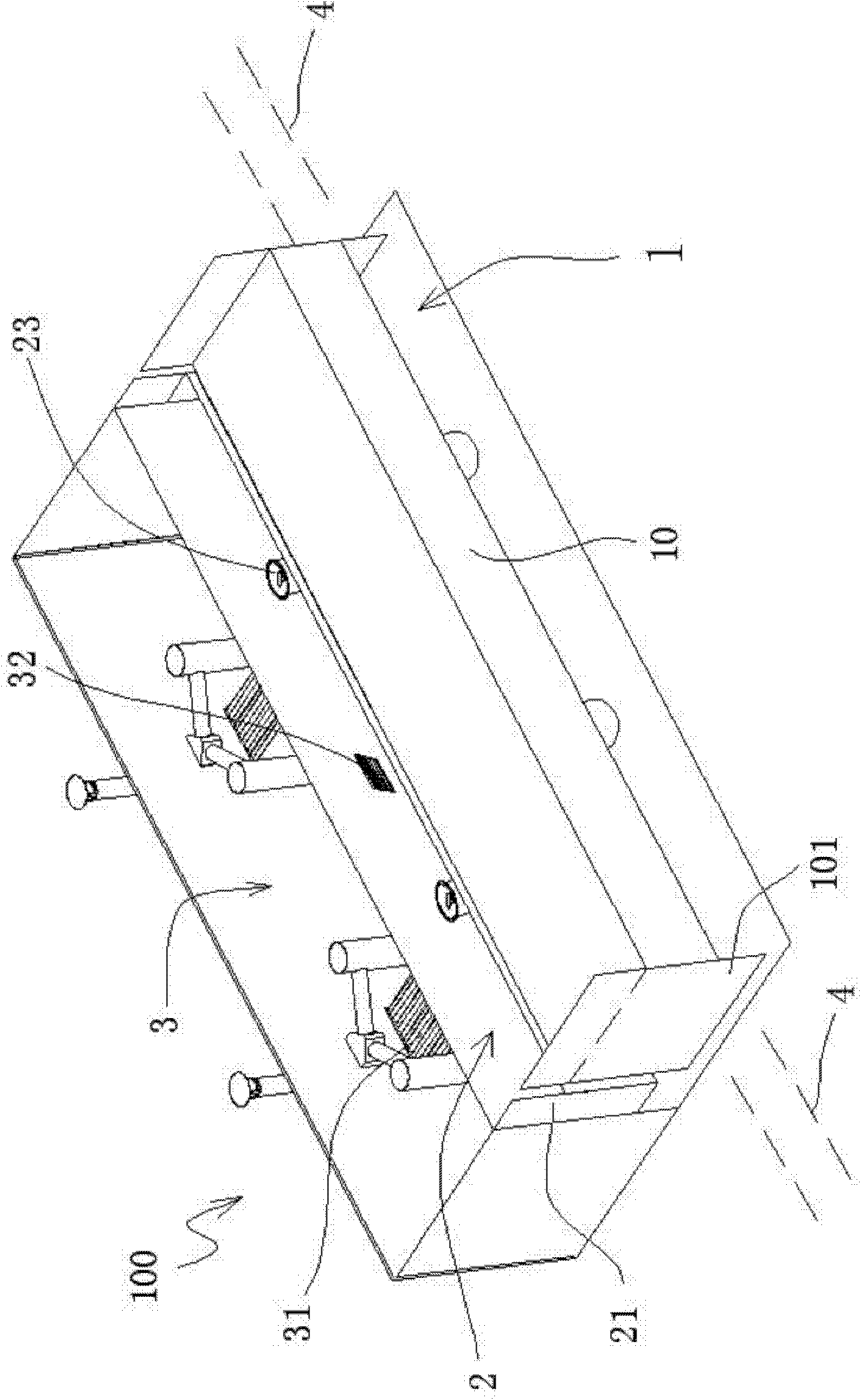

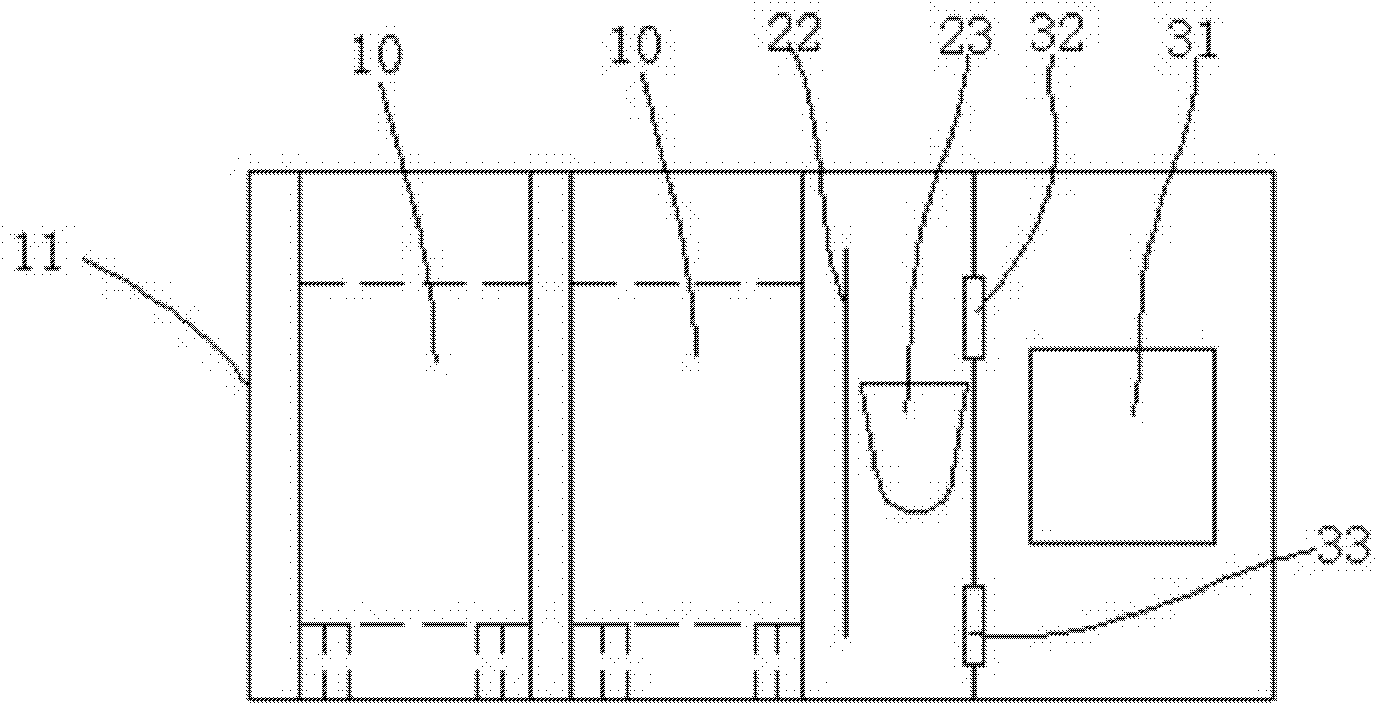

Tunnel curing barn adopting humiture subdivision control of alternate wind direction

ActiveCN102735035AEvenly heatedDrain evenlyDrying gas arrangementsDrying machines with progressive movementsAir cellOne-hot

Disclosed is a tunnel curing barn adopting humiture subdivision control of alternate wind direction, and the tunnel curing barn is formed by a plurality of work cells, which are penetrated through and connected by a track. Each work cell comprises a baking cell, an air-mixing layer and a hot air cell. Each work cell is provided with one hot air cell or the plurality of work cells share at least one hot air cell. The air-mixing layer is located between the baking cell and the hot air cell. Material trolleys which pass through the baking cells respectively move a distance of one baking cell every time, and the material trolleys are used for being filled with materials to be baked. A circulating fan is installed in the air-mixing layer to produce an ascending airflow or a descending airflow. A heating or heat exchanging device is disposed in the hot air cell. The whole tunnel curing barn is separated into a plurality of independent work cells by separating plates which are provided at the front end and the rear end of the material trolleys in the baking cells, and each work cell forms an independent hot air self-circulating system. The material trolleys on the track move forward at intervals and are capable of moving at fixed time and fixed quantity and staying in different work cells for drying according to temperature and humidity required by materials at different times.

Owner:北京华珍烘烤系统设备工程有限公司

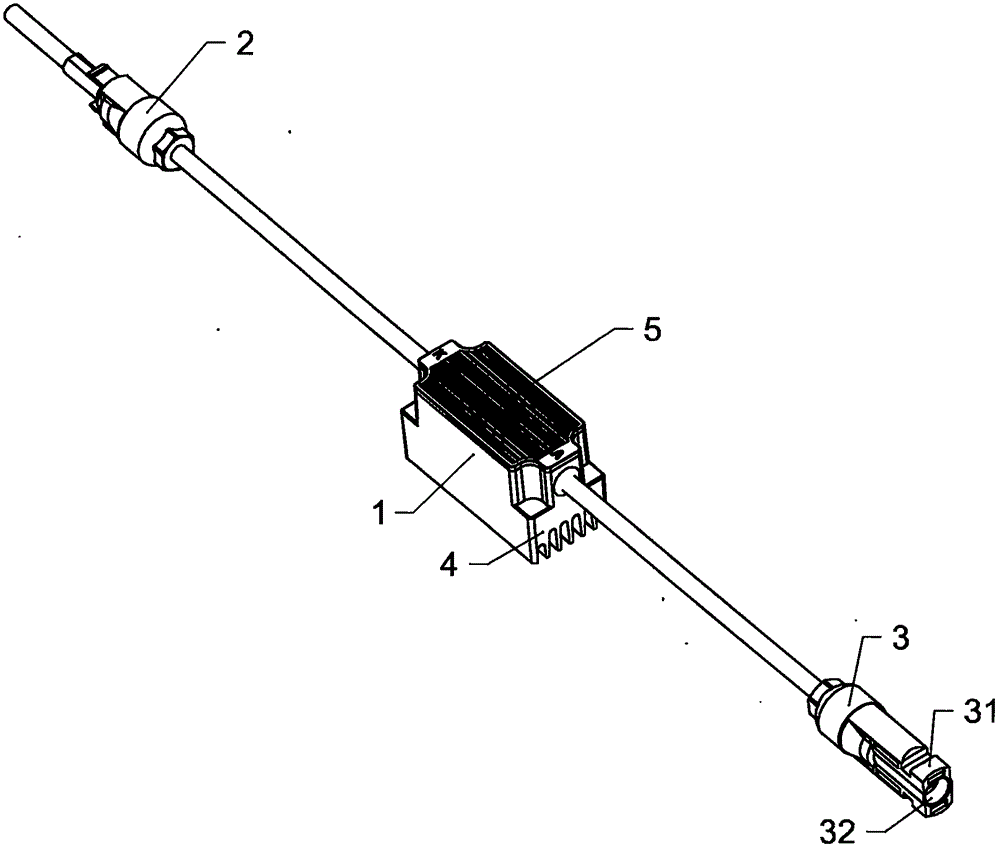

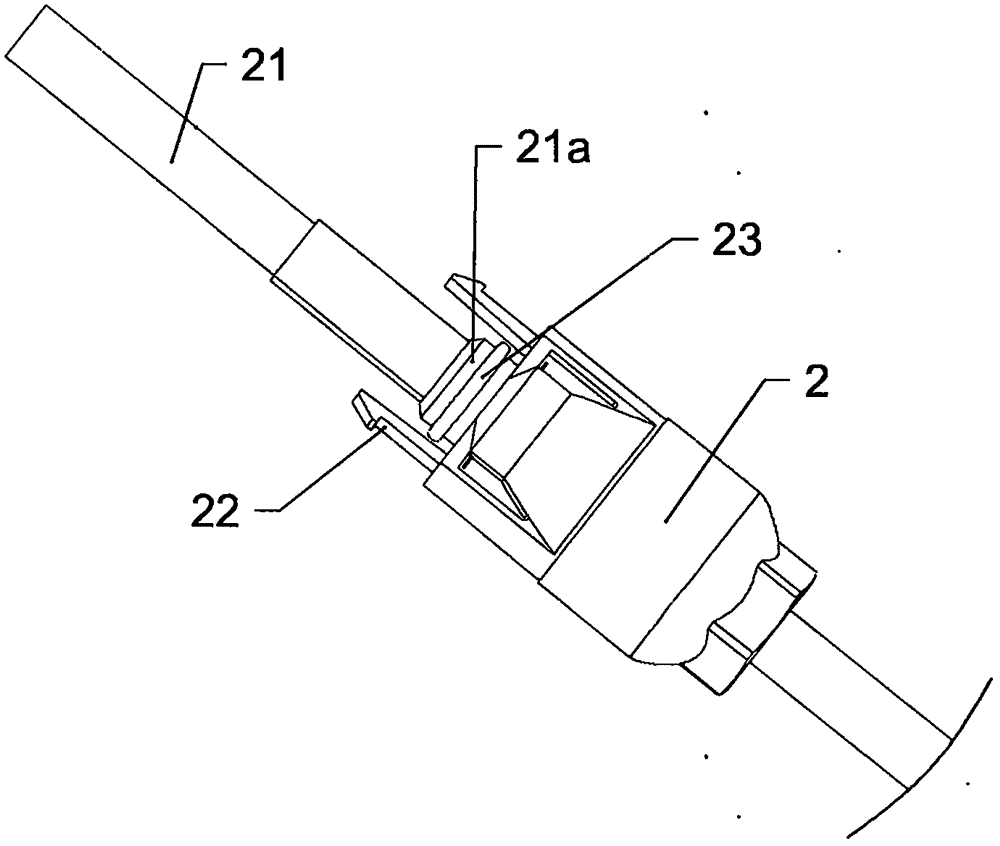

Temperature measurement assembly and electric equipment

ActiveCN107727261AImprove insulation performanceImprove thermal conductivityThermometer detailsThermometers using electric/magnetic elementsElectric equipmentElectrical equipment

The invention discloses a temperature measurement assembly and electric equipment. The temperature measurement assembly comprises a heat conduction member and a temperature measurement member. The heat conduction member is used for conducting heat of a device subjected to temperature measurement. The temperature measurement member is in heat conduction arrangement with the heat conduction member so as to measure a temperature signal of the device subjected to temperature measurement according to the heat conducted by the heat conduction member and transmit the temperature signal to an output connector. The heat conduction member and the temperature measurement member are separate and independently-formed components and can be connected to form a one body. The heat conduction member of thetemperature measurement assembly has good insulation and heat conduction performance, so that the temperature measurement assembly is especially suitable for temperature measurement of the device subjected to temperature measurement, and temperature measurement response time of the temperature measurement member can be reduced.

Owner:TYCO ELECTRONICS (SHANGHAI) CO LTD

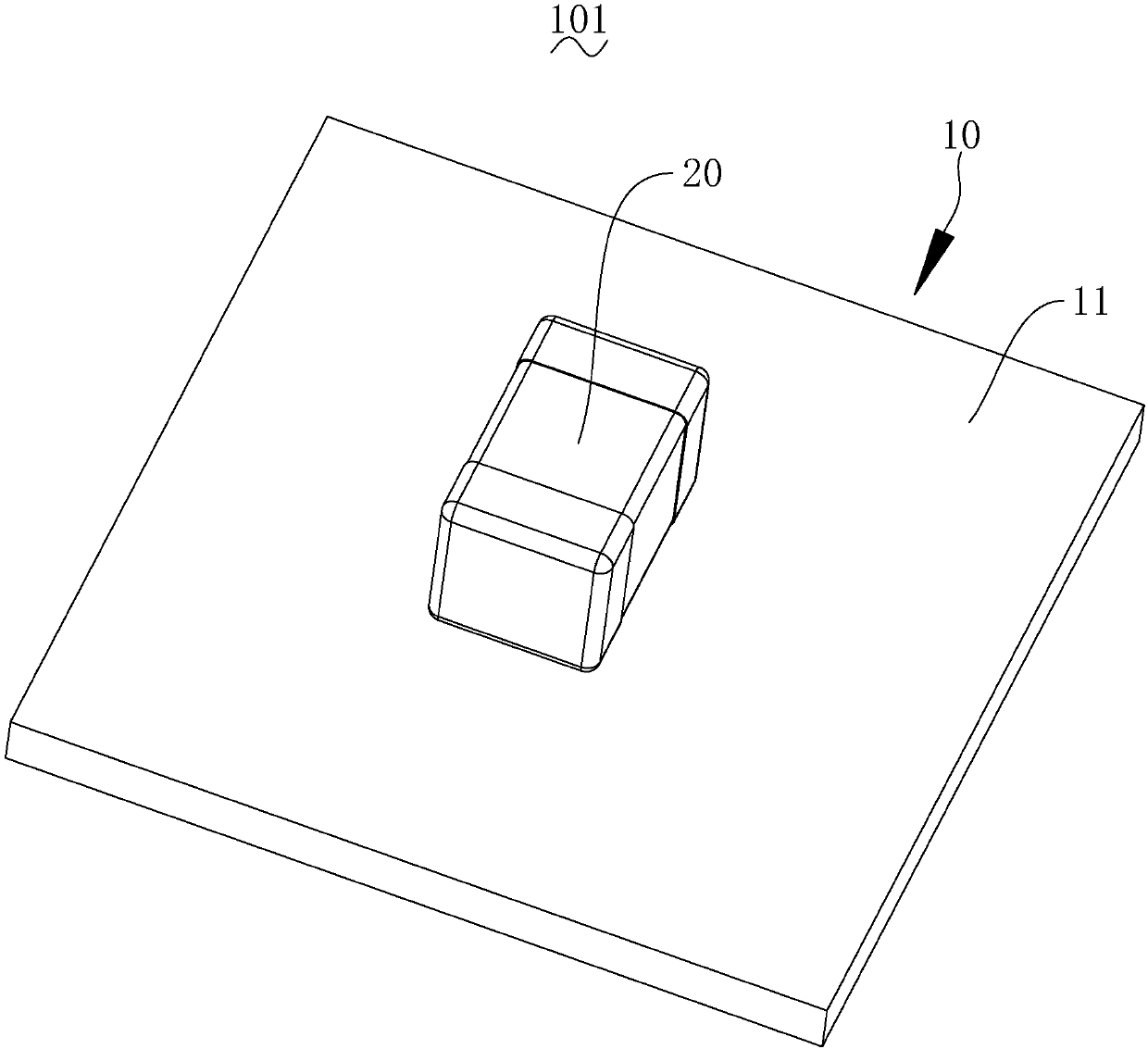

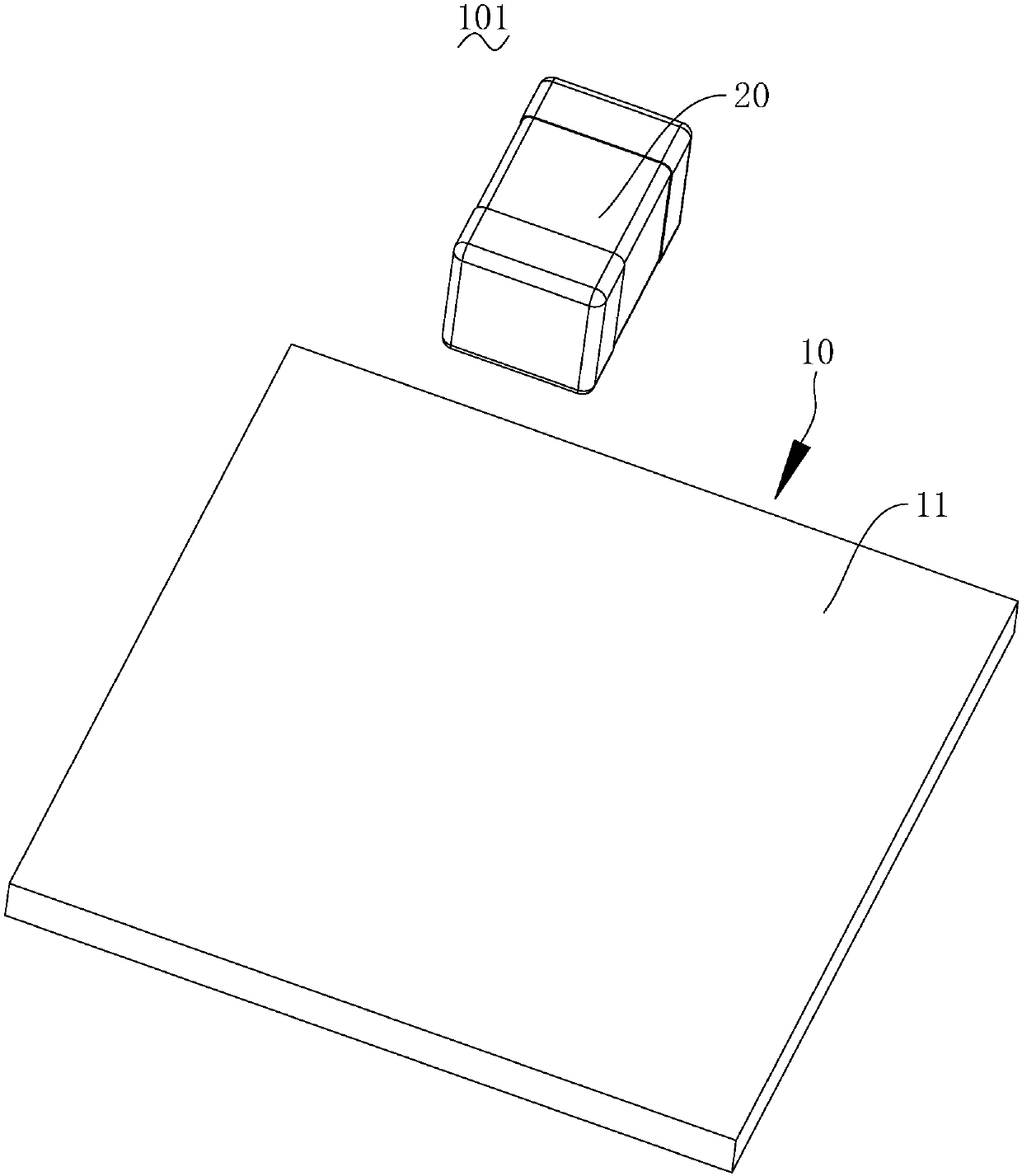

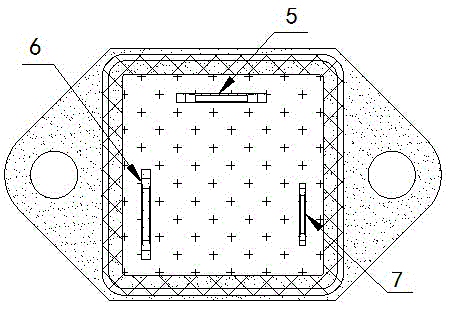

Thin film capacitor for high-cooling electric vehicle

PendingCN108735509AIncrease cooling powerShorten the heat conduction distanceMultiple fixed capacitorsThin/thick film capacitorFilm capacitorElectric vehicle

The invention relates to the technical field of a thin film capacitor, in particular to a thin film capacitor for a high-cooling electric vehicle. The thin film capacitor is compact in structure, small in size, low in cost and good in cooling effect and comprises a shell and a leading-out electrode, wherein a capacitor core and a potting material are arranged in the shell, the thin film capacitoris characterized in that the shell is a plastic shell, a cooling metal plate is arranged at the bottom of the plastic shell and is used for connecting a cooling device in the electric vehicle, the capacitor core is connected with a copper busbar via a copper plate, the copper busbar and the leading-out electrode are formed in an integrated structure, the copper busbar is arranged near to the cooling metal plate, and insulation paper is arranged between the copper busbar and the cooling metal plate.

Owner:WUXI CHENRUI NEW ENERGY TECH

Heating plate

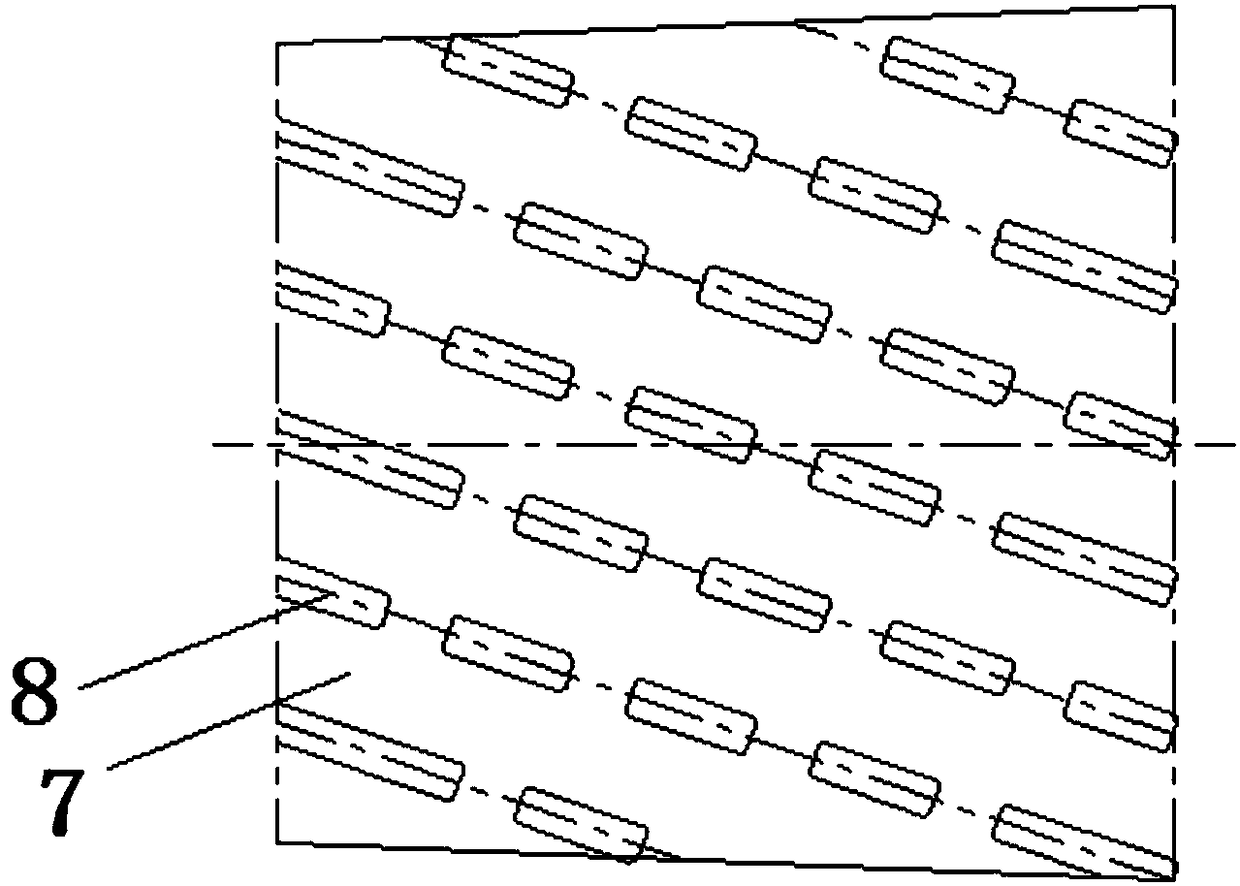

InactiveCN101158488AOvercome unsafe situations such as electric leakageShorten the heat conduction distanceLighting and heating apparatusElectric heating systemFiberCarbon fibers

The invention relates to a heating plate which belongs to the technical field of building materials. The invention arranges novel heating components like a far-infrared carbon fiber, etc., between a complex material including a surface layer and a bottom layer and is connected with the heating components through a mother-son cuttage grafting component. By adopting industrial manufacture, the invention completely overcomes the unsafe situations like creepage caused by the construction factor brought by paving the existing heating components like the far-infrared carbon fiber under or in the indoor ground tiles by manpower, thereby greatly increasing the heat efficiency, further reducing the energy consumption and greatly improving the energy saving effect. The invention relates to a novel decoration material, has an extremely large market and has extremely remarkable economic benefits and social benefits.

Owner:王雷鸣

Continuous type aluminum alloy melting furnace

Owner:厦门民兴工业有限公司

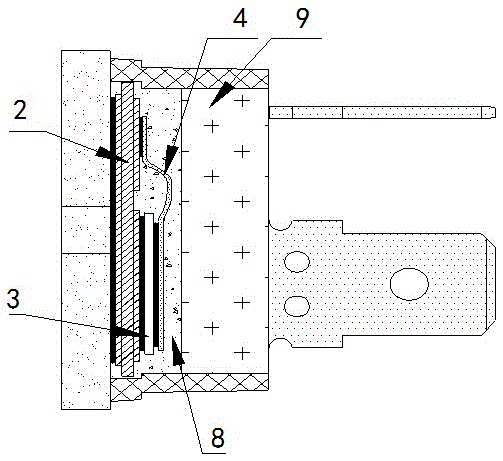

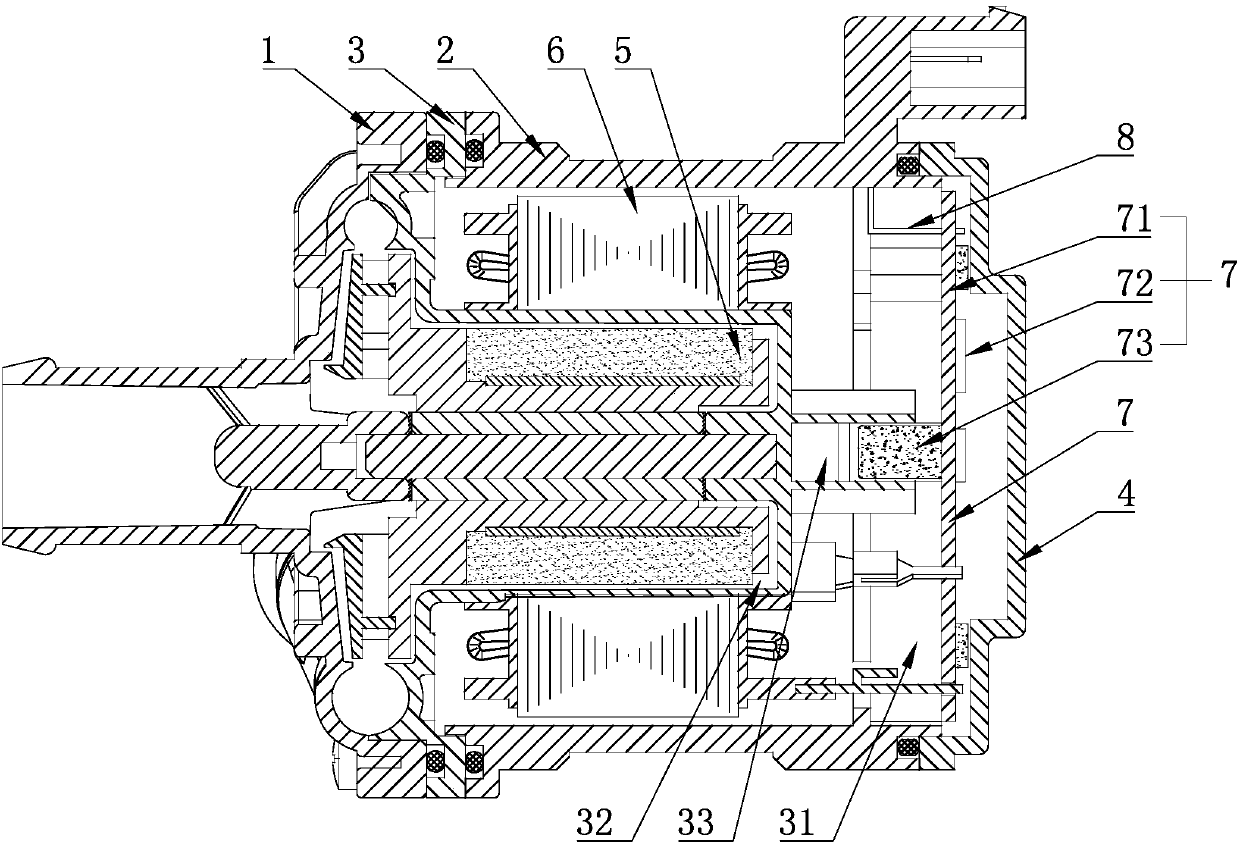

High-power thyristor package structure and manufacturing method thereof

InactiveCN105633041AShorten the heat conduction distanceEliminate the process of assembly and weldingSemiconductor/solid-state device detailsSolid-state devicesCooling effectCopper

The invention discloses a high-power thyristor package structure, which comprises a metal cooling bottom plate and a ceramic copper-clad plate, wherein the bottom surface of the ceramic copper-clad plate is welded at the upper end of the metal cooling bottom plate; a large-area copper-clad layer is arranged on the bottom surface of the ceramic copper-clad plate; a copper-clad layer divided into an anode welding region, a cathode welding region and a gate welding region is arranged on the top surface of the ceramic copper-clad plate; a thyristor chip and an anode bridging chip are sequentially welded at the upper end of the copper-clad layer on the top surface of the ceramic copper-clad plate from bottom to top; a plastic sleeve shell is also arranged on the periphery of the ceramic copper-clad plate; and a cathode electrode and a gate electrode of the thyristor chip are welded on the divided cathode welding region and gate welding region on the top surface of the ceramic copper-clad plate in a coplanar inversion manner respectively. The invention further discloses a manufacturing method of the high-power thyristor package structure. By the method that the cathode electrode and the gate electrode of the thyristor chip are welded on the divided copper-clad layer on the top surface of the ceramic copper-clad plate in the coplanar inversion manner, the cooling effect is greatly improved; and meanwhile, the process of bridging assembly welding of a control electrode is emitted, so that massive high-efficiency production can be relatively well achieved.

Owner:JIANGSU JIEJIE MICROELECTRONICS

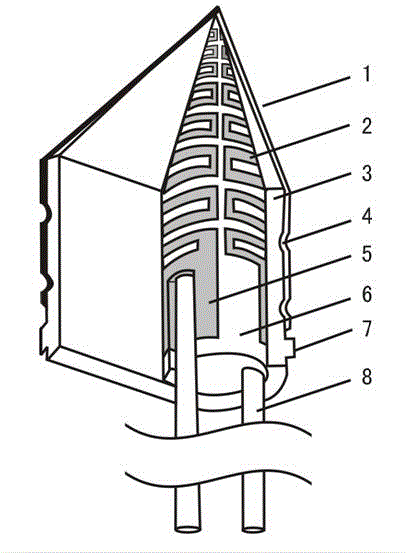

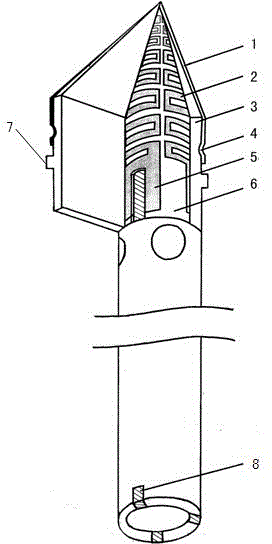

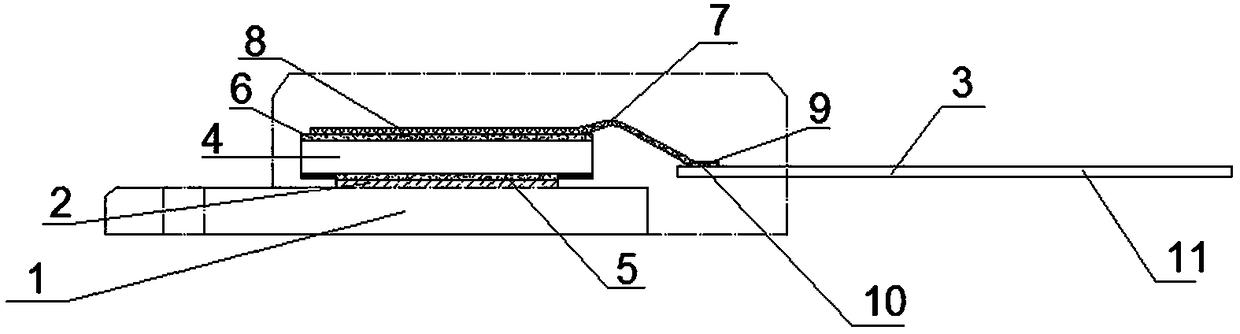

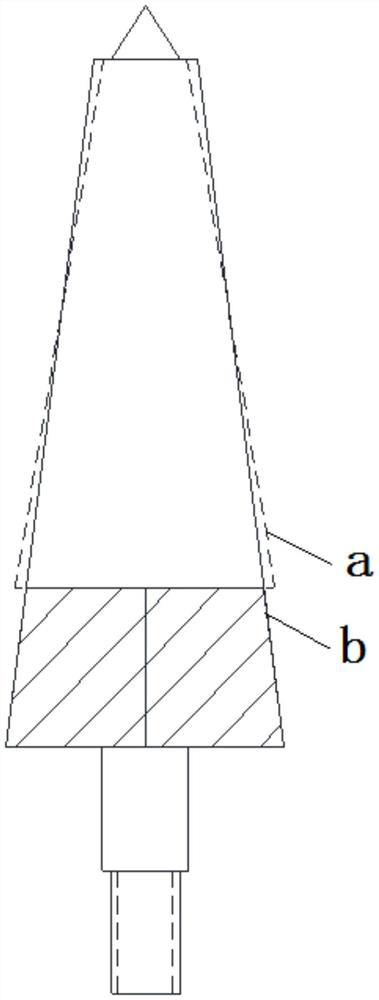

Novel tip-heated soldering iron head

InactiveCN104526102AWith self-constant temperature characteristicsShorten the heat conduction distanceSoldering ironEngineeringCeramic

The invention relates to a novel tip-heated soldering iron head. The novel tip-heated soldering iron head comprises an outer metal layer, a heating body and conductive pins and is characterized in that the heating body takes ceramics as a main body and is directly made into a soldering iron head shape, a resistive material is pre-placed inside the front tip end of the heating body, the conductive pins are arranged at the rear end of the heating body and are formed through high-temperature sintering, and the outer metal layer is arranged outside the front tip end of the heating body. According to the novel tip-heated soldering iron head, energy-accumulated tip heating is adopted, the heat conduction distance is less than 1 / 40 that of the existing external heating type electric soldering irons, the preheating is extremely fast, and tin can be melted and be used for soldering in few seconds, so that the novel tip-heated soldering iron head is energy-efficient; the novel tip-heated soldering iron head further has an automatic-thermostatic characteristic, so that high-temperature oxidation iron burning is prevented, and the service life is long; a charging soldering iron produced from the tip-heated soldering iron head disclosed by the invention is simple in structure, flexible in operation, convenient in carrying and low in power and is powerful; an automatic reset switch is mounted on a handle of the electric soldering iron, and the electric soldering iron is powered off through unclasping hands, so that the problems of the existing electric soldering irons that personal safety accidents and fires are caused due to current leakage, iron-damaged power cords and plug unplugging forgetting are thoroughly solved.

Owner:周晅民

Ice making evaporator and processing method thereof

PendingCN110285620AFast ice makingShort transmission distanceIce productionEvaporators/condensersEvaporatorEngineering

The invention discloses an ice making evaporator and a processing method thereof. The ice making evaporator comprises a base plate, an evaporation pipeline device and a plurality of partition plates, wherein the evaporation pipeline device and the partition plates are arranged on the base plate, and the partition plates are arranged on the base plate to form an ice making lattices; the evaporation pipeline device comprises a plurality of evaporation pipes arranged on the base plate, and the evaporation pipes are located on the side surfaces of the ice making lattices of the base plate. The technical scheme is adopted, the evaporation pipe is directly contacted with the side face of the corresponding ice making lattices or is used as the side face of the ice making lattices, so that heat exchange is realized through the plurality of side surfaces of the ice making lattices, refrigeration and condensation are carried out, the ice making speed is high, the ice making is conducted from the side surface of the ice making machine to the bottom surface of the ice making machine, the transferring distance is shorter, the evaporation area is greatly increased, the ice making function of the ice making lattices is realized, the refrigerating effect is better, the structure is simplified, the installation and production are convenient, and the working efficiency of the evaporator is improved.

Owner:宁波三缺一机电有限公司

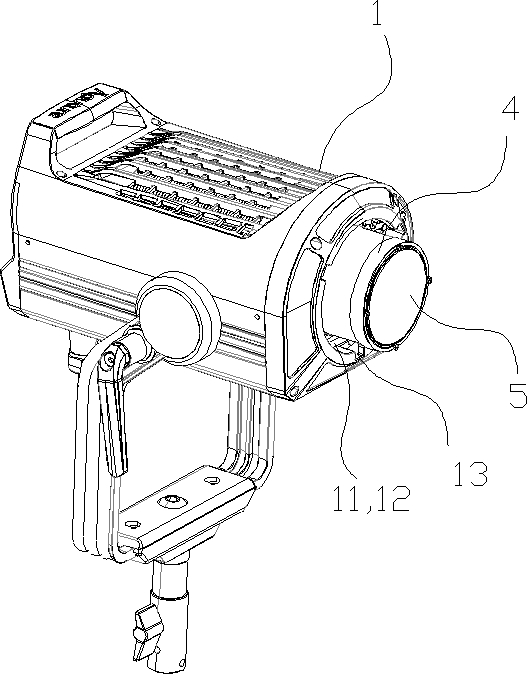

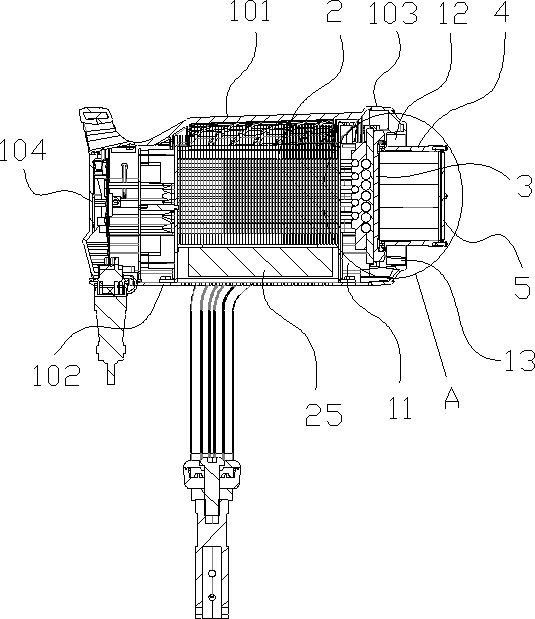

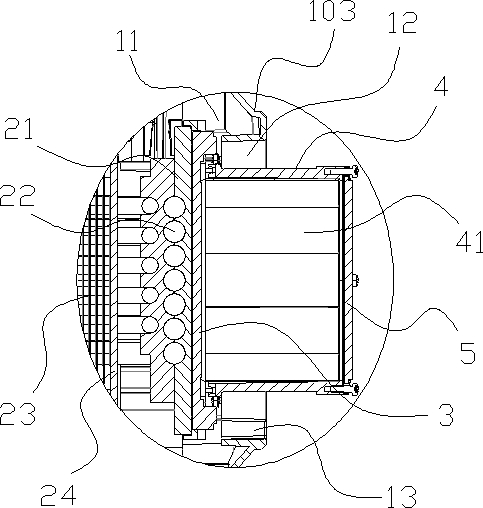

Lighting device

ActiveCN113253542AReduce lossShorten the heat conduction distanceLighting applicationsMechanical apparatusEngineeringMaterials science

The embodiment of the invention discloses a lighting device comprising a lamp main shell with a containing cavity, a heat dissipation device, a light source and a front-end shell; one end of the lamp main shell is provided with a notch communicated with the containing cavity and a bayonet structure used for being connected with an optical accessory, and the position of the notch corresponds to the position of the bayonet structure; the heat dissipation device is arranged in the accommodating cavity; the light source is in heat conduction connection with the heat dissipation device and is positioned in the accommodating cavity or the notch; the front-end shell is provided with a through hollow cavity, one end of the front-end shell covers the light source, and the other end of the front-end shell penetrates through the notch towards the outer side of the notch; and light emitted by the light source penetrates through the hollow cavity of the front-end shell to be emitted outwards. In the lighting device, the light source can form an expected light emitting effect without protruding out of the lamp main shell, the light loss is effectively reduced, the space utilization rate is high, the heat conduction efficiency is high, and the overall performance and the use experience of the lighting device are improved.

Owner:APUTURE IMAGING IND CO LTD

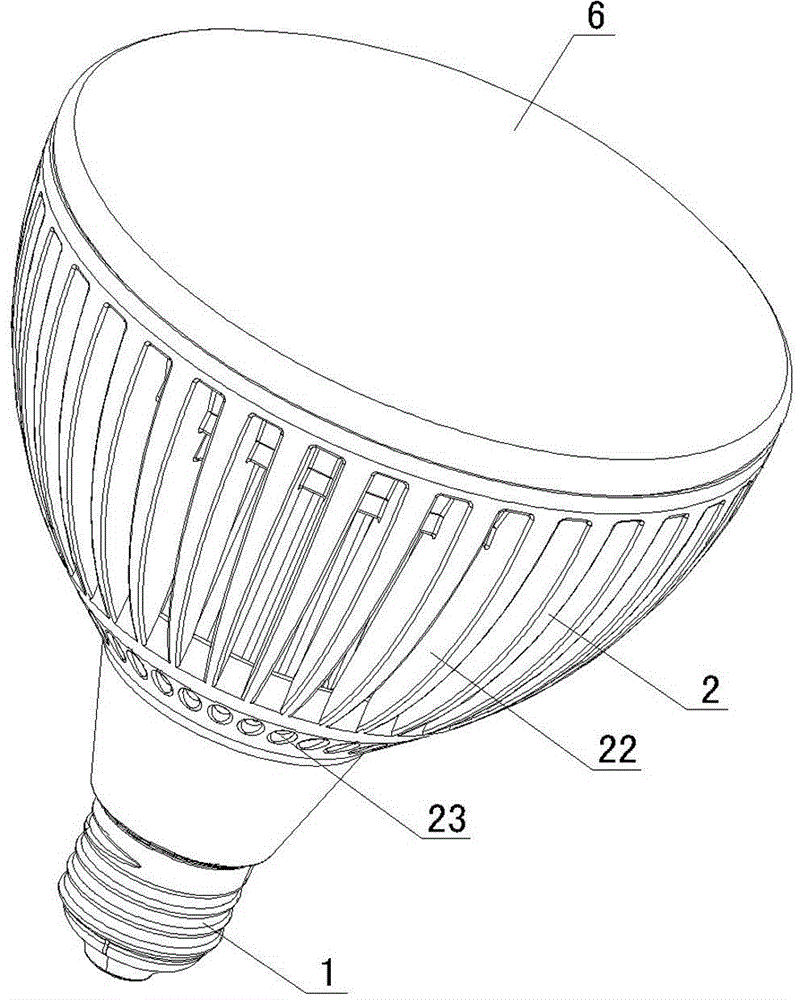

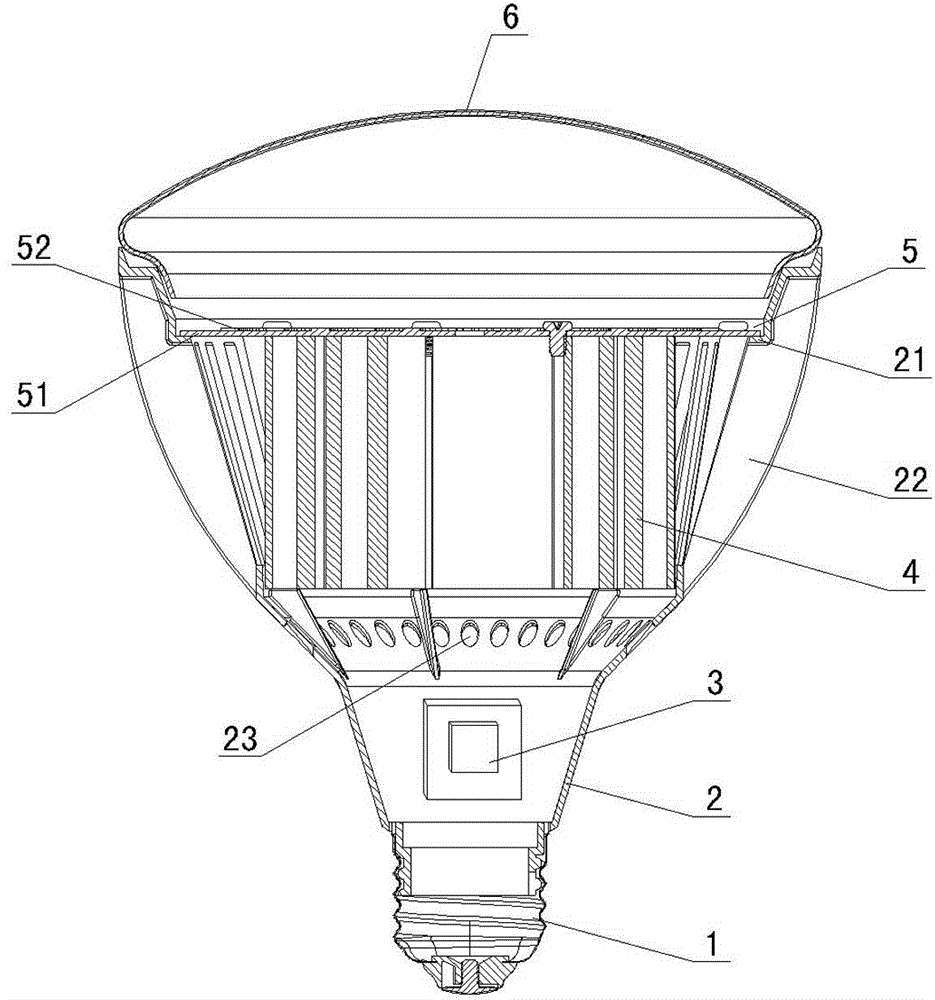

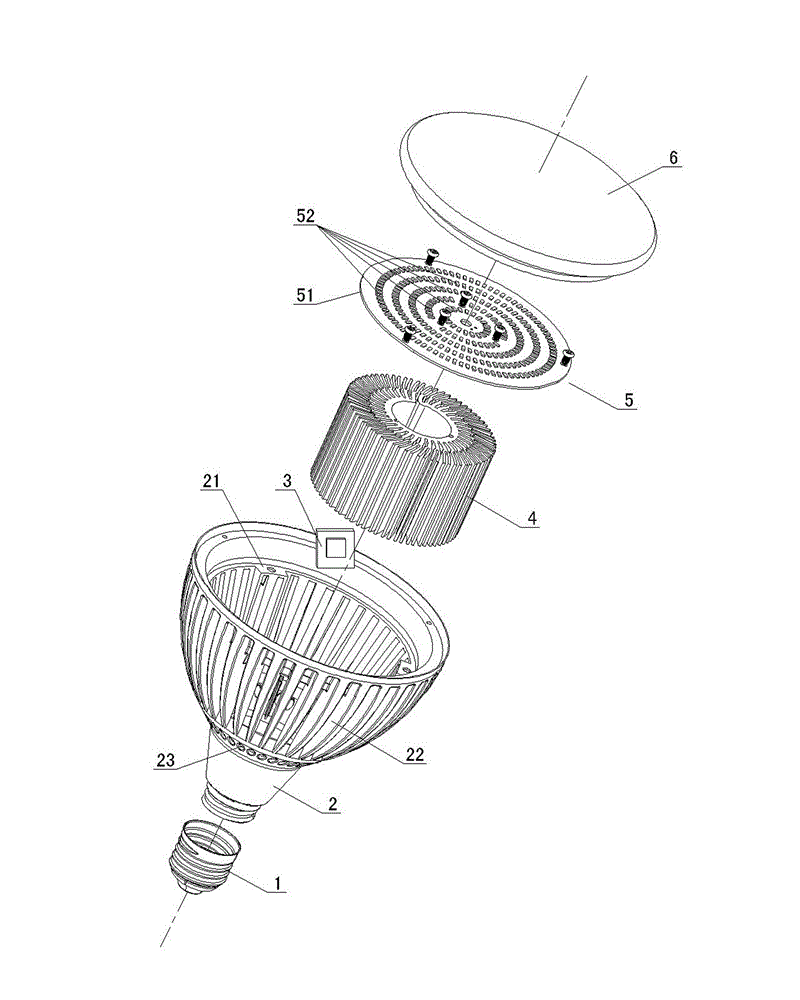

PAR (Parabolic Aluminum Reflector) light

InactiveCN104006314AEvenly distributedImprove lighting effectsPoint-like light sourceLighting heating/cooling arrangementsElectricityOptoelectronics

The invention provides a PAR (Parabolic Aluminum Reflector) light. The PAR light comprises a light holder, a plastic housing, and a light transmitting cover which are connected in sequence; a constant-current driving power supply, an aluminum profile radiator and an LED light source plate are arranged in the plastic housing; the constant-current driving power supply is electrically connected with the LED light source plate and the light holder; the LED light source plate comprises a base plate and at least one group of annularly-distributed small-power LED light beads, wherein the at least one group of annularly-distributed small-power LED light beads is arranged on the base plate; the base plate is connected and fixed to a step arranged in the plastic housing and tightly clung to the aluminum profile radiator. According to the PAR light, a plurality of LED light beads are arranged to form an annular structure, and uniform and reasonable distribution of the light within the radiating scope of the light beads is realized through the annular distribution of the LED light beads, namely, the luminance is gradually reduced from the center to the periphery, and seamless transition of light is realized, and thus light spots can be avoided during radiating, and as a result, the purpose of effectively utilizing light is reached; in addition, the PAR light is safe and reliable to use, high in light utilization rate and good of radiating effect.

Owner:蔡干强

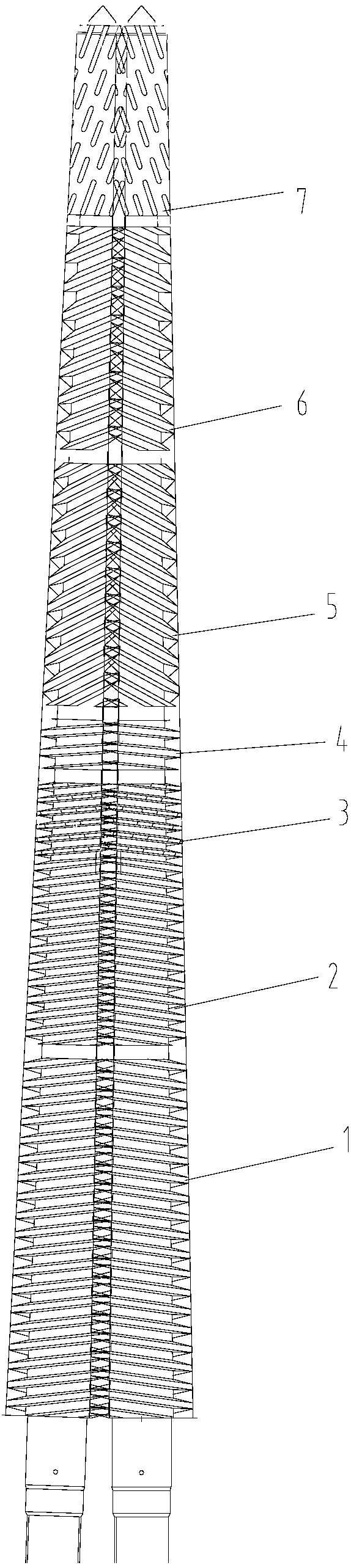

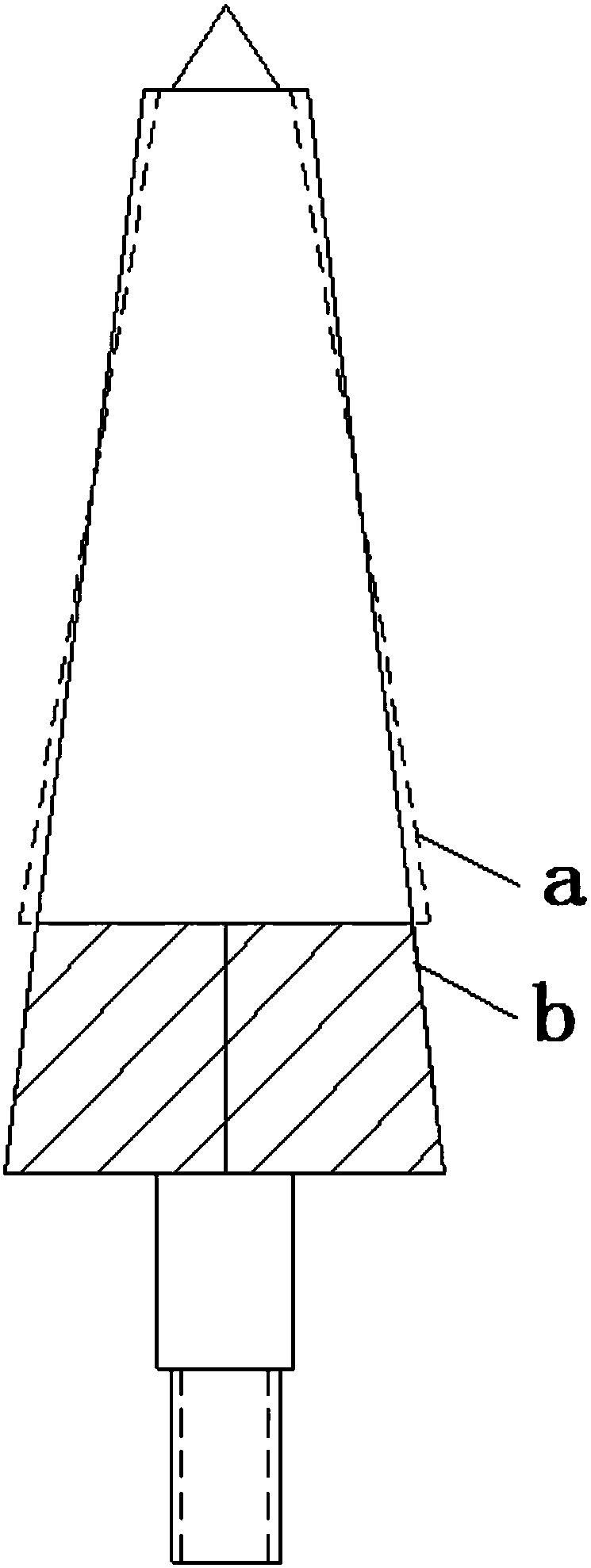

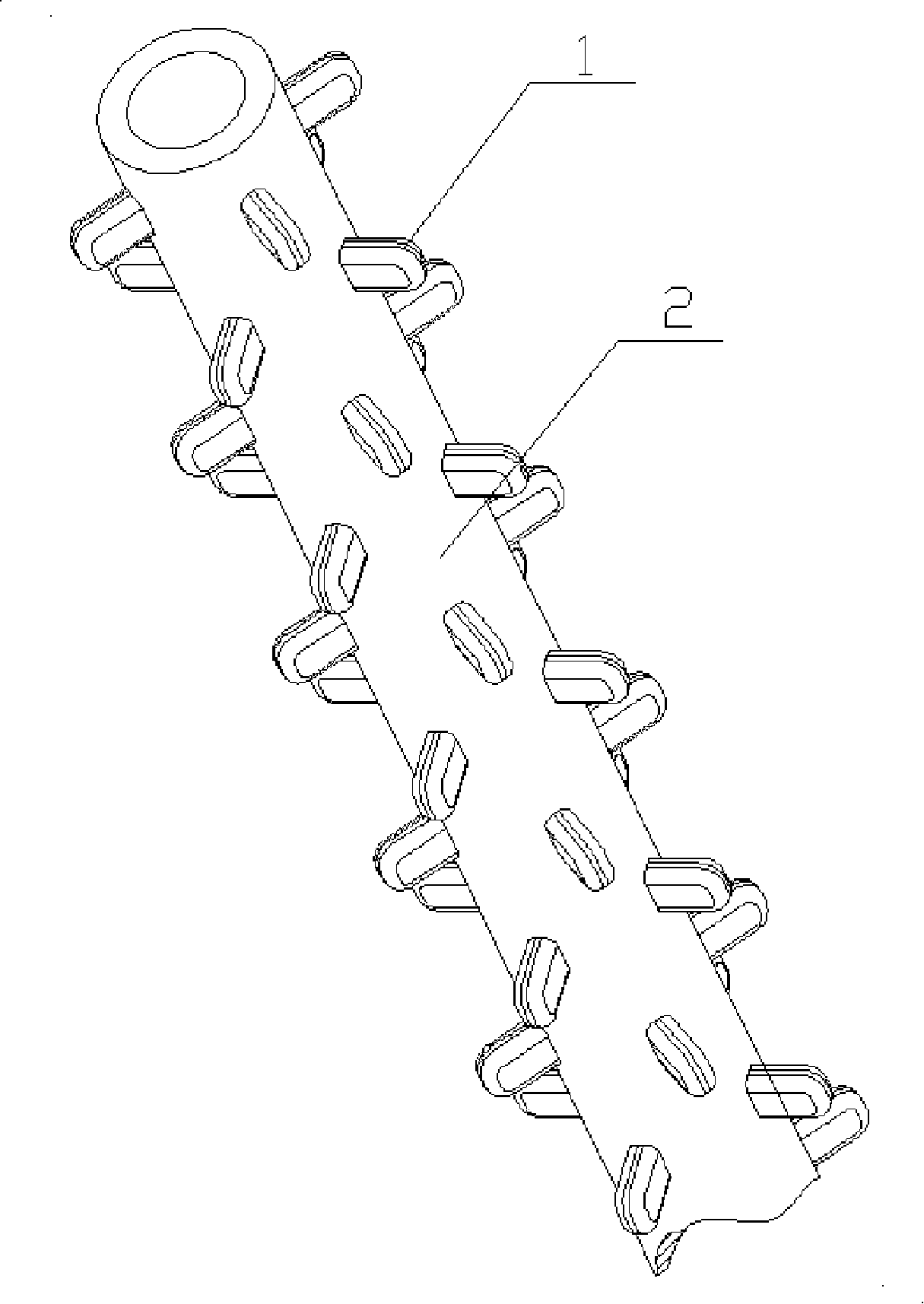

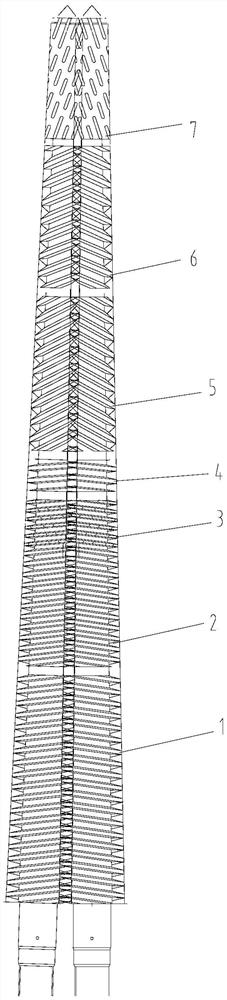

Large-scale cone double-extruder foaming screw

The invention relates to a large-scale extruder foaming cone double screw comprising a feeding section, a compression section, a metering section, an exhaust section, a mixing section, a pre-compression section and a dynamic mixing head; intermeshing screw flights are arranged in the feeding section, the pre-compression section, the compression section, the metering section, the exhaust section and the mixing section; and screw grooves are formed between the adjacent screw flights, and the dynamic mixing head is provided with intermeshing convex blocks. Compared with the prior art, according to the large-scale extruder foaming cone double screw, the compression section is separated into the pre-compression section and a compression section, the aspect ratio of the screw is improved and theresidence time of materials is prolonged, the efficiency of heat control during the processing is improved, and the plasticization of the materials is completed with minimum stress; by arranging thedynamic mixing head, quantity of heat of the materials when the materials are extruded from the screw is reduced, the temperature of the materials can be effectively prevented from rising due to shearheat, and the precipitation of foaming gas to the surface of the materials is reduced; the length of the cone double screw and the diameter of the screw are extended, the screw volume and surface area are increased to enable the interior of the screw to accommodate more materials, and the production is improved.

Owner:SHANGHAI JINHU EXTRUSION EQUIP

Plastic-encapsulated SiC Schottky diode device and manufacturing method thereof

PendingCN108538924AImprove cooling effectImprove flow capacitySemiconductor/solid-state device detailsSolid-state devicesCooling effectSolder paste

The invention discloses a plastic-encapsulated SiC Schottky diode device, which comprises a metal cooling bottom plate, an outer pin, a SiC Schottky diode chip and a connection bridge plate. The manufacturing method comprises steps: the metal cooling bottom plate is placed in a die, and an appropriate solder paste is applied to the upper surface of a boss of the metal cooling bottom plate; the anode surface of the SiC Schottky diode chip is placed on the upper surface of the boss in a downward and upside down mode, and an appropriate solder paste is applied to the upward cathode area surface of the SiC Schottky diode chip and the soldering area of the outer pin at the same time; a soldering A area and a soldering B area of the connection bridge plate are placed on the cathode area and thesoldering area of the outer pin respectively; and the product which is well assembled and the die are together subjected to one time vacuum sintering, after sintering is completed, cleaning and plastic encapsulation are carried out, encapsulation is completed and a product is formed. The chip cooling effects are greatly improved, the process is shortened, the production efficiency is improved, thedevice circulation ability is greatly improved, and the high circulation ability advantage of the SiC Schottky diode chip is thoroughly executed.

Owner:捷捷半导体有限公司

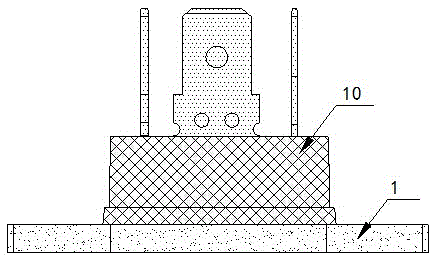

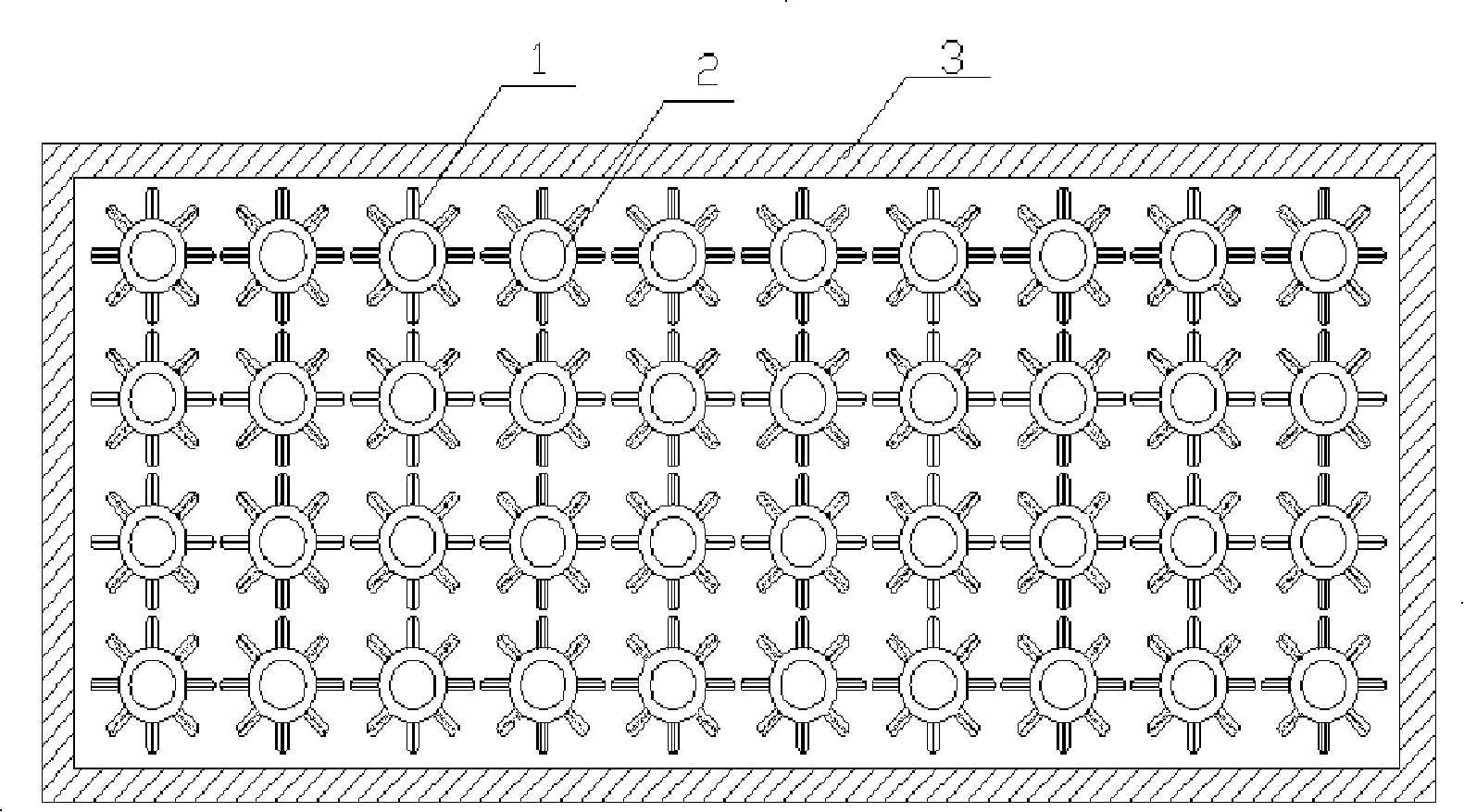

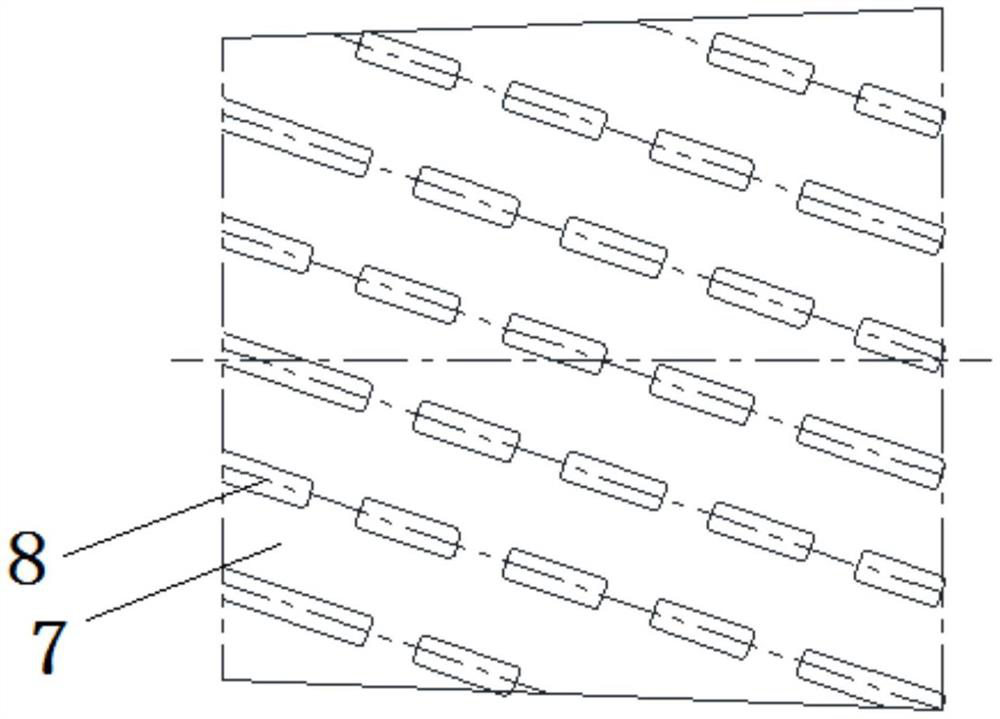

Method for increasing heating speed of material in metal vacuum smelting reduction still and reduction still

InactiveCN101210285AIncrease heat conduction areaFast heatingProcess efficiency improvementMetalUtilization rate

The invention discloses a method for improving material heating speed in a reduction kettle for vacuum metal smelting, which comprises the following steps of: arranging heat conductors (1) on the wall of a reduction kettle for vacuum metal smelting or on a radiation pipe (2) penetrating in the reduction kettle, thus increasing the contact area between the radiation pipe and a reduction material in the reduction kettle, reducing the heat conduction distance between the radiation pipe and the reduction material and improving the heating speed of the reduction material. By arranging the plurality of heat conductors on the kettle wall and on the radiation pipe connected with the reduction kettle, the invention can increase the contact heat conduction area between the radiation pipe and the reduction material in the reduction kettle for vacuum metal smelting, shorten the heat conduction distance from the reduction material and improve the heating speed of the reduction material, thus improving heat utilization rate, achieving energy saving effect, reducing reduction reaction time and improving the production capacity.

Owner:GUIZHOU SHIJI TIANYUAN MINING IND

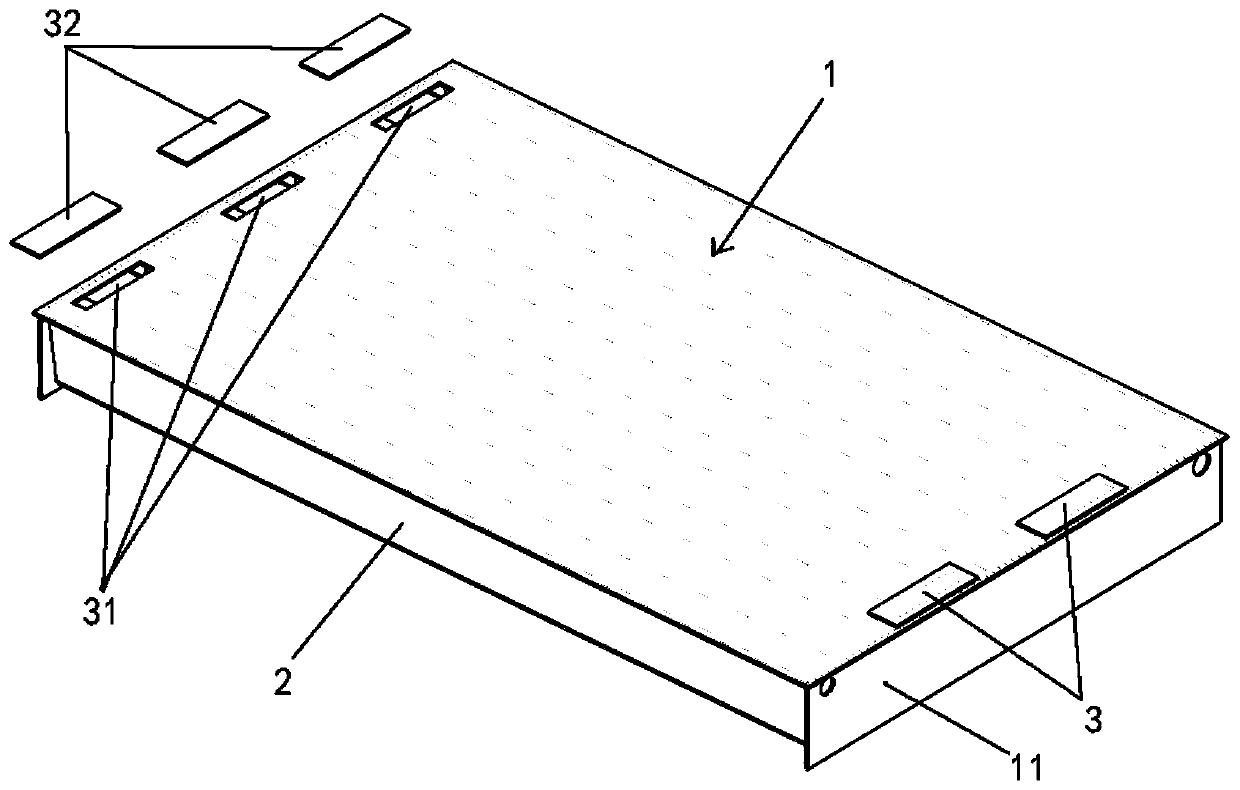

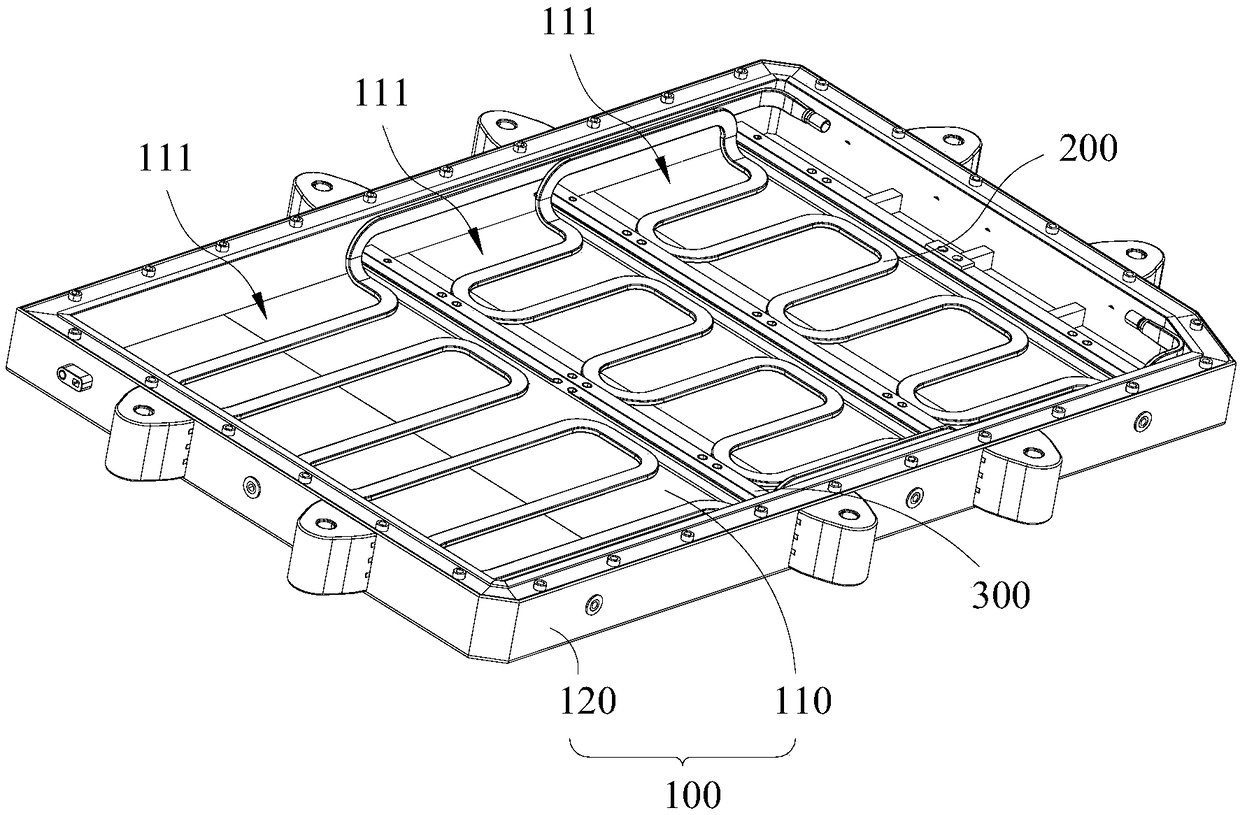

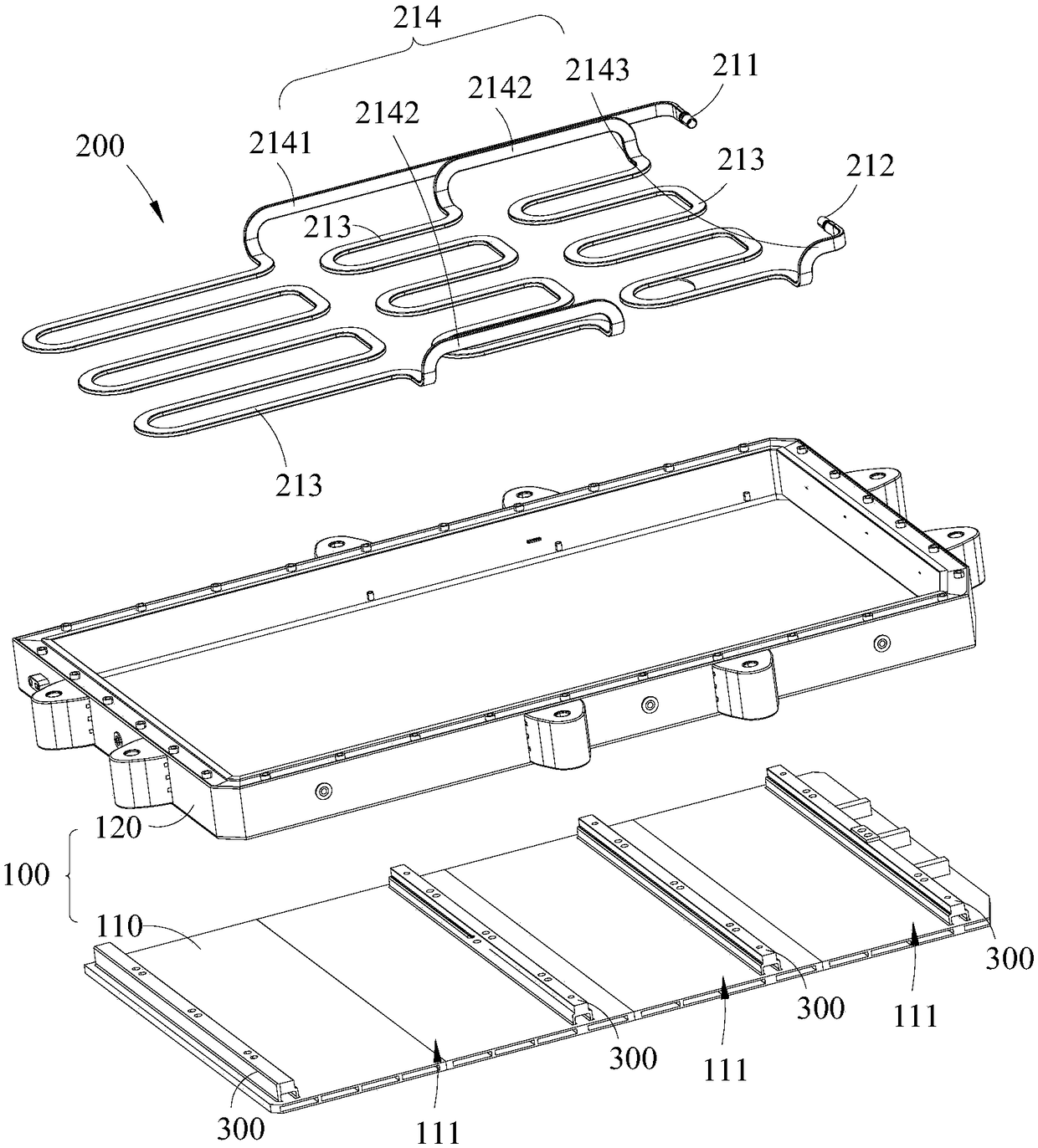

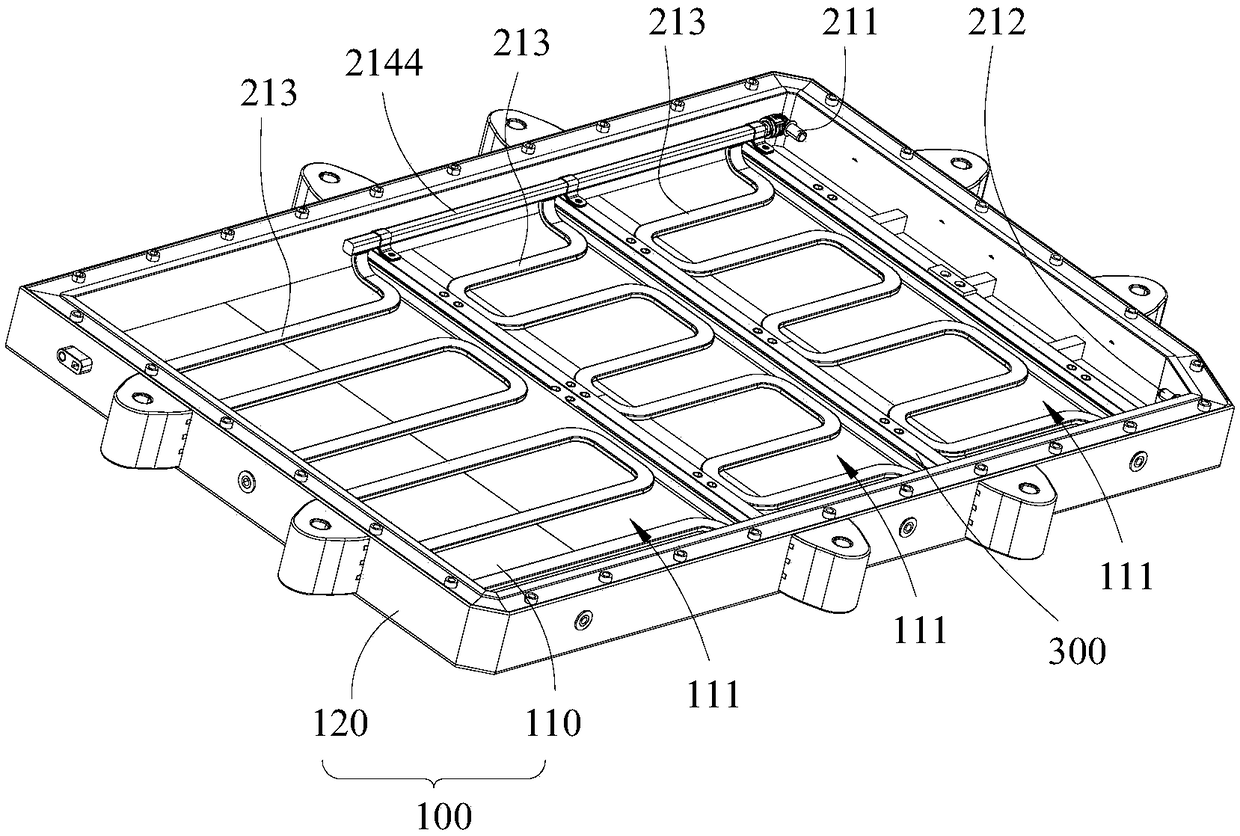

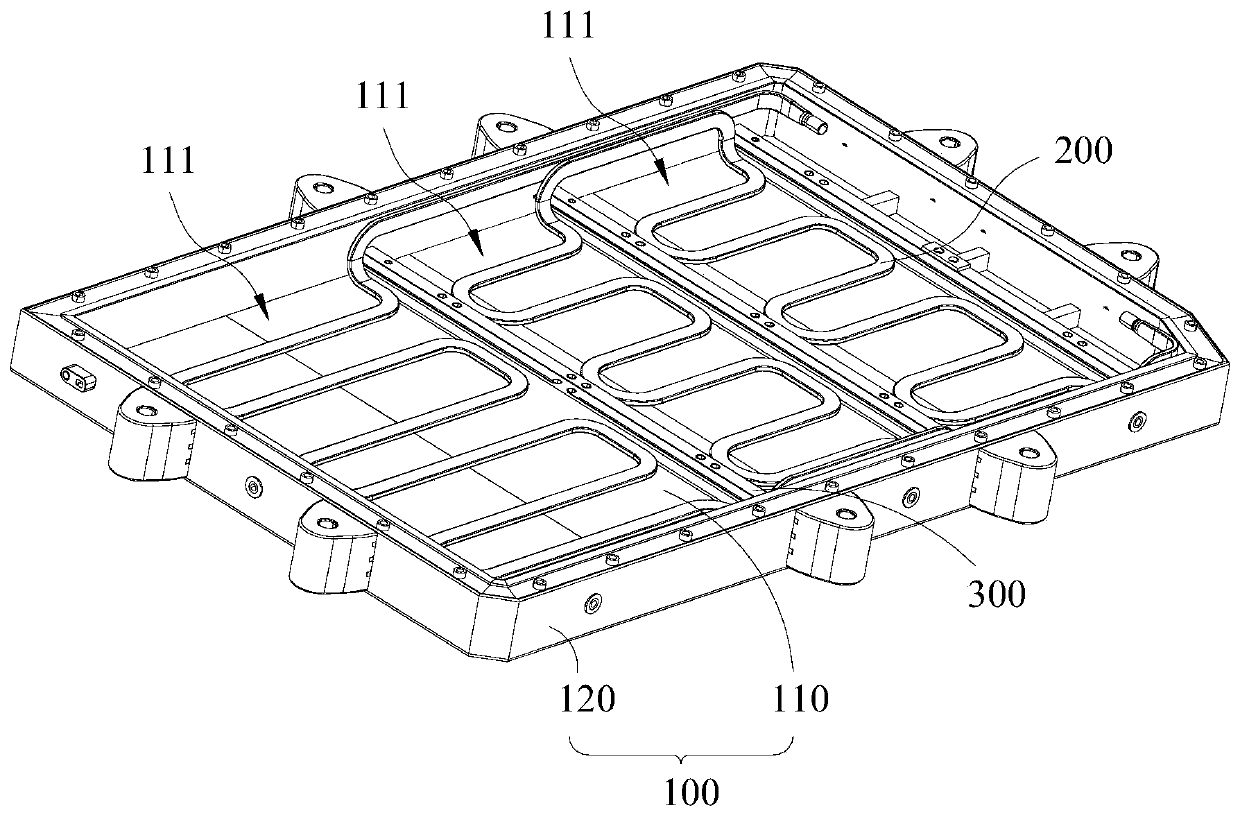

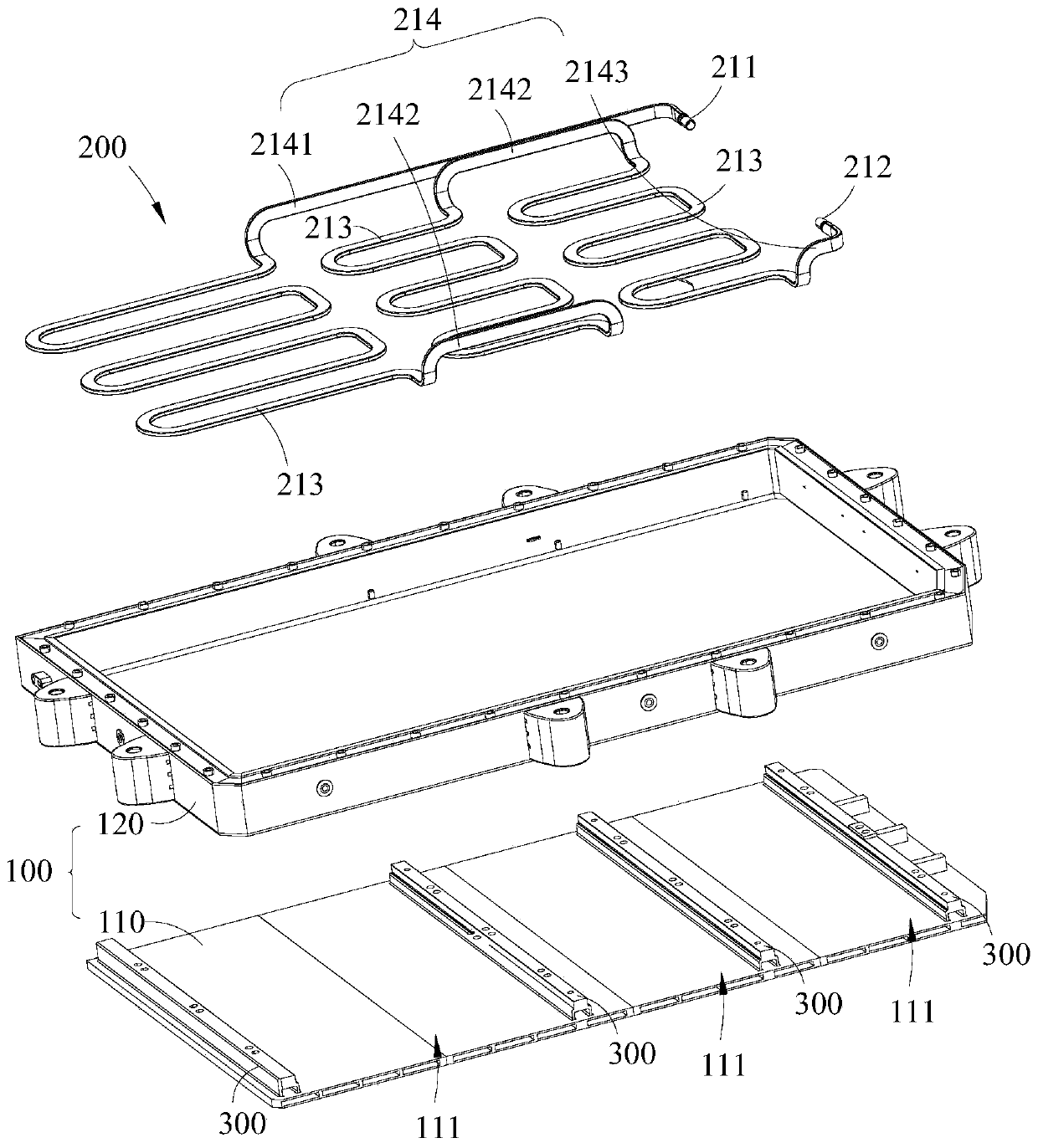

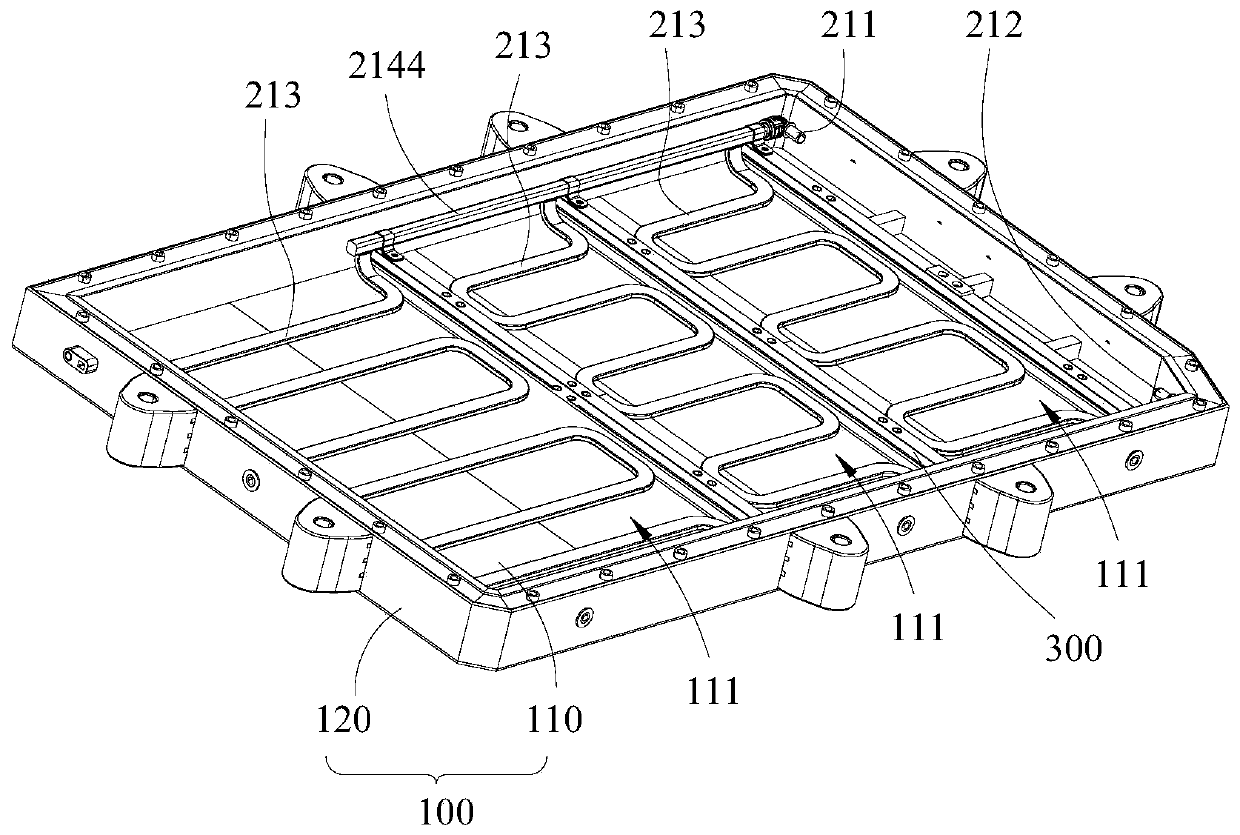

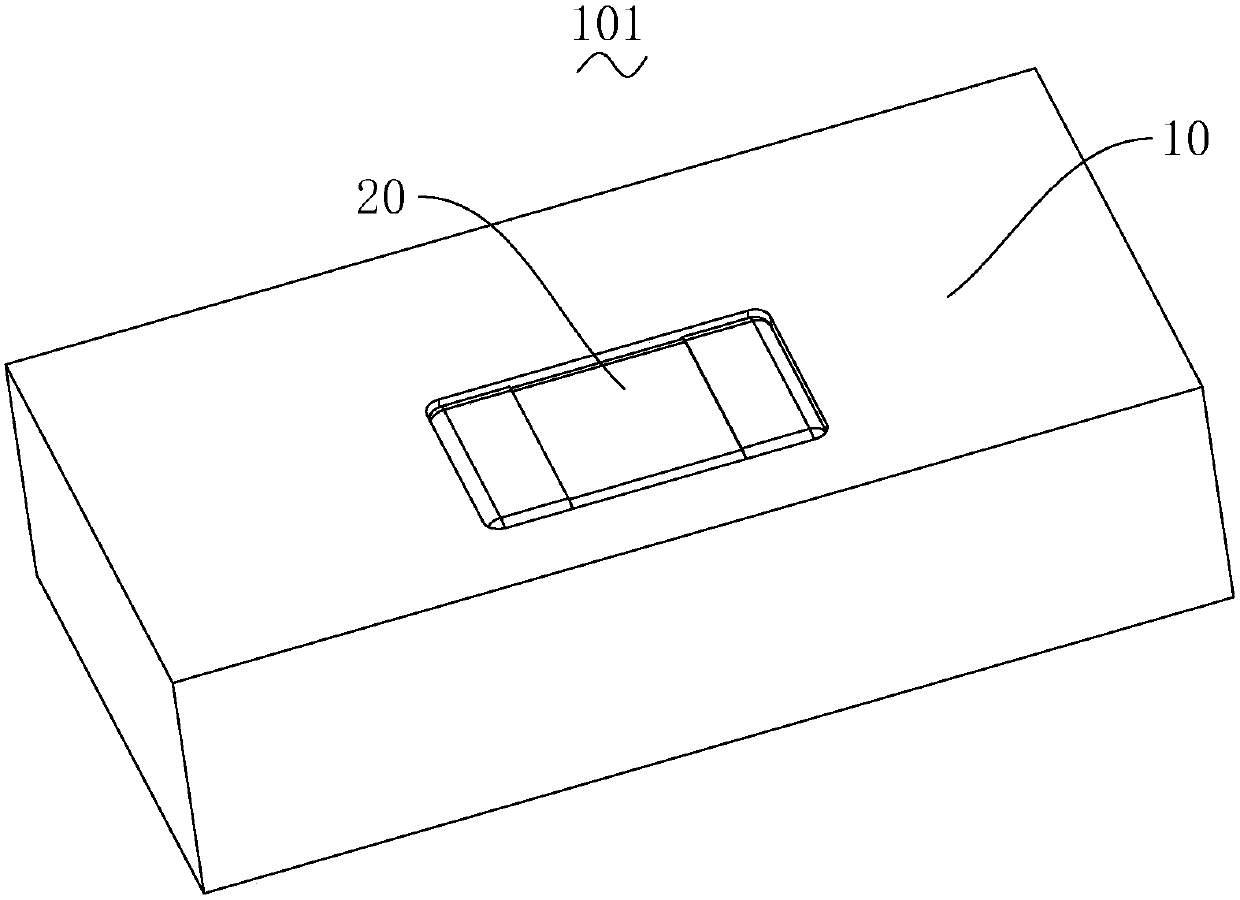

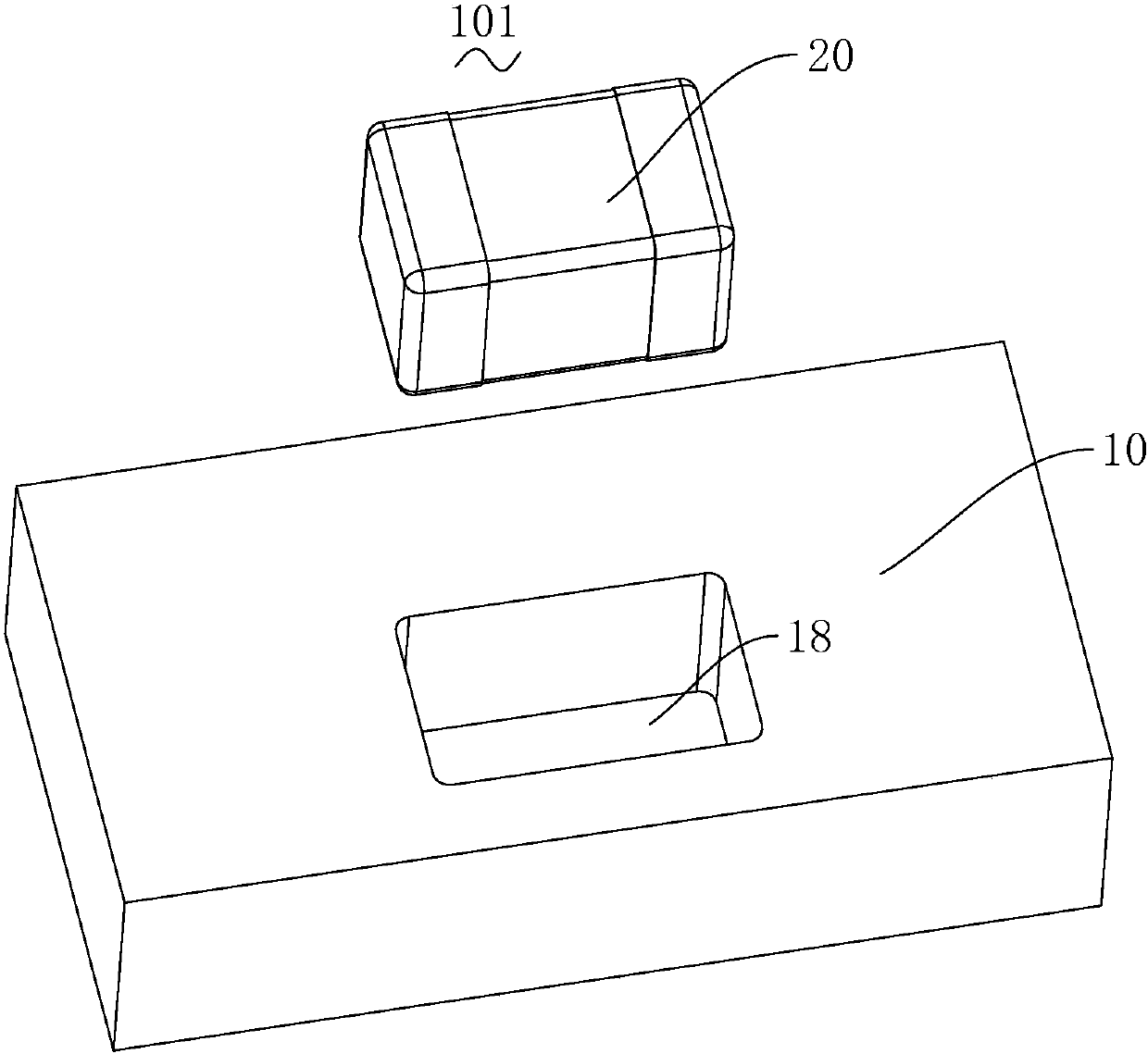

Power battery base tray and power battery module

ActiveCN108075066AImprove assembly efficiencyImprove disassembly efficiencySecondary cellsCell component detailsPower batteryBattery pack

The invention provides a power battery base tray and a power battery module, wherein the power battery base tray includes a tray and a liquid cooling tube installed on the tray. The power battery basetray and the power battery module are characterized in that the tray includes a bottom plate and side plates arranged around the bottom plate, the bottom plate and the side plates together form a receiving cavity for accommodating a power battery pack, at least one cross beam is arranged on the bottom plate, and the cross beam divides the bottom plate into at least two sub-bottom plates. The liquid cooling tube is laid on at least one of the sub-bottom plates, and the liquid cooling tube spans across the cross beam. The liquid cooling tube spans across the cross beam so that the liquid cooling tube is not need to be assembled to the tray, then the cross beam is installed on the tray, the assembly efficiency of the liquid cooling tube to the tray is improved, and the assembly efficiency ofa finished product assembly phase is facilitated. When the liquid cooling tube is disassembled, the liquid cooling tube is not needed to be disassembled after the cross beam is detached from the tray, thereby improving disassembly efficiency of the liquid cooling tube.

Owner:BYD CO LTD

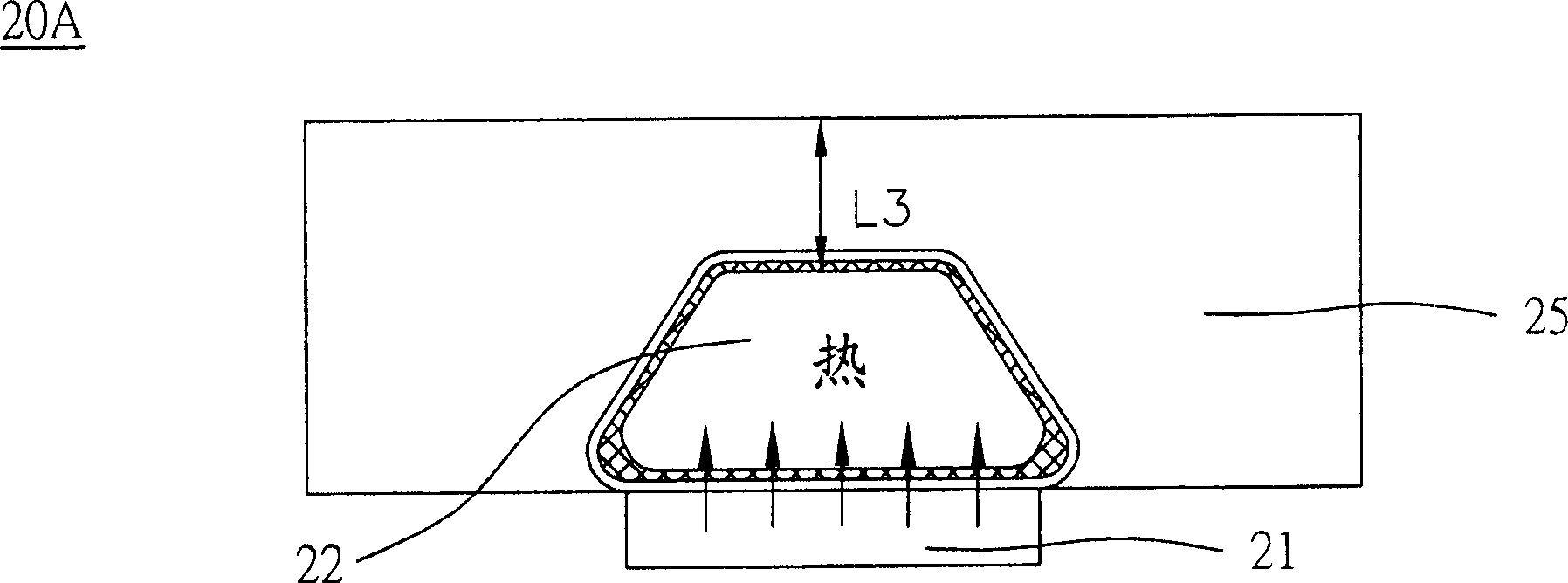

Radiator with uniform temperature hot cavity

InactiveCN1747640AShorten the heat conduction distanceReduce unit weightInstrumental cooling apparatusCooling/ventilation/heating modificationsWorking fluidEngineering

A heat dissipation device for a heat generating electronic package is composed of a heat radiator and a temp homogenizing cavity consisting of capillary structure for returning the working fluid back to heat absorbing region, heat absorbing region in contact with electronic package, heat dissipating region in contact with heat radiator, working fluid for transferring heat, and at least one buffer region able to provide a fluid storage space.

Owner:DELTA ELECTRONICS INC

LED lamp

ActiveCN105822919AReduce heat buildupImprove conversion efficiencyElectric circuit arrangementsLighting heating/cooling arrangementsFlapping wingControl switch

The invention discloses an LED lamp. The LED lamp comprises an LED lamp bead, a lampshade, a heat conduction apparatus for fixing the LED lamp bead and a radiator, wherein the heat conduction apparatus is provided with an air flue; the radiator comprises an electromagnet, a spring leaf, an armature, a fan blade with a flapping wing structure, a one-way flow auxiliary ring and a magnetic-control switch, wherein the electromagnet, the magnetic-control switch and a power supply form a circuit; one end of the armature is connected with the spring leaf, and the other end of the armature is connected with the fan blade with the flapping wing structure; the fan blade with the flapping wing structure is provided with a plurality of pores; and one end, close to the armature, of the one-way flow auxiliary ring is fixed to the fan blade with the flapping wing structure. After the power supply is switched on, the electromagnet attracts the armature to drive the fan blade with the flapping wing structure to move downwards, so that a seam capable of allowing air to pass through is formed between the fan blade with the flapping wing structure and the one-way flow auxiliary ring; a permanent magnet magnetic sheet on the fan blade with the flapping wing structure is in contact with the magnetic control switch, so that the circuit is switched off; under the action of the spring leaf, the armature drives the fan blade with the flapping wing structure to return, so that the circuit is switched on; and the processes are repeated. The LED lamp actively realizes one-way flow of air, so that the heat dissipation effect is achieved.

Owner:江苏创导光电科技有限公司

Tunnel curing barn adopting humiture subdivision control of alternate wind direction

ActiveCN102735035BEvenly heatedDrain evenlyDrying gas arrangementsDrying machines with progressive movementsCooking & bakingOne-hot

Disclosed is a tunnel curing barn adopting humiture subdivision control of alternate wind direction, and the tunnel curing barn is formed by a plurality of work cells, which are penetrated through and connected by a track. Each work cell comprises a baking cell, an air-mixing layer and a hot air cell. Each work cell is provided with one hot air cell or the plurality of work cells share at least one hot air cell. The air-mixing layer is located between the baking cell and the hot air cell. Material trolleys which pass through the baking cells respectively move a distance of one baking cell every time, and the material trolleys are used for being filled with materials to be baked. A circulating fan is installed in the air-mixing layer to produce an ascending airflow or a descending airflow. A heating or heat exchanging device is disposed in the hot air cell. The whole tunnel curing barn is separated into a plurality of independent work cells by separating plates which are provided at the front end and the rear end of the material trolleys in the baking cells, and each work cell forms an independent hot air self-circulating system. The material trolleys on the track move forward at intervals and are capable of moving at fixed time and fixed quantity and staying in different work cells for drying according to temperature and humidity required by materials at different times.

Owner:北京华珍烘烤系统设备工程有限公司

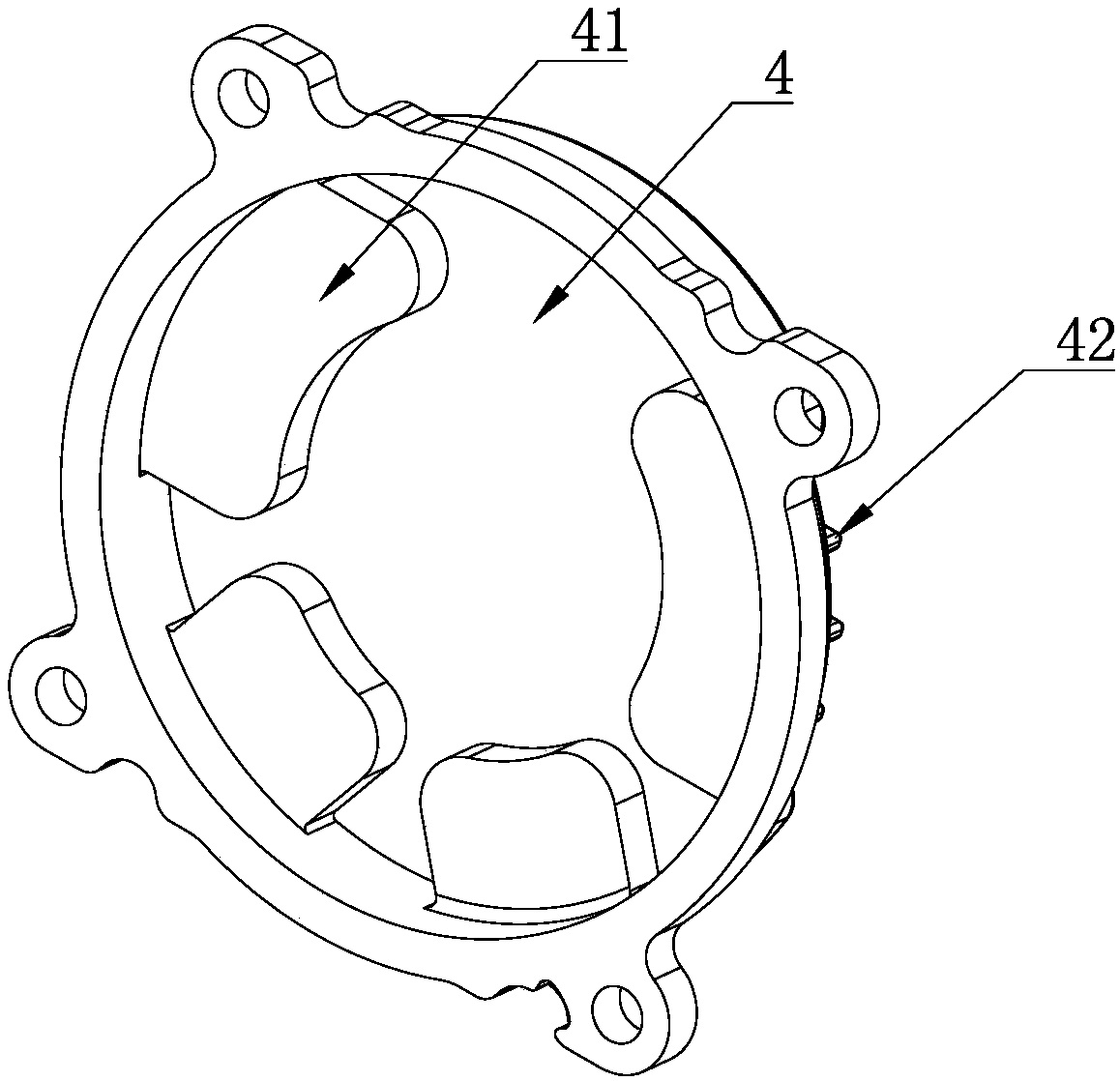

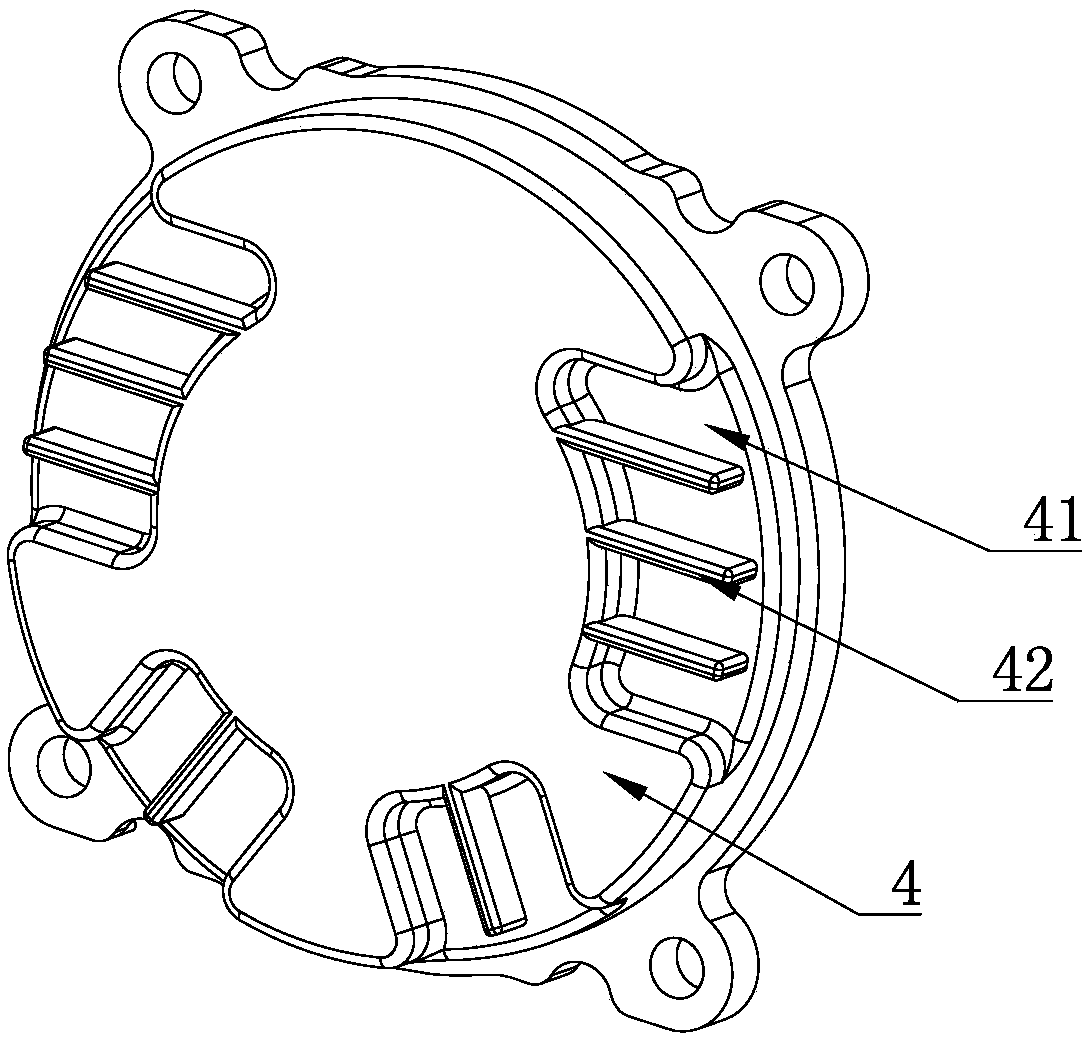

Heat radiation structure and electronic water pump

PendingCN109958660AHeat dissipation fastImprove cooling efficiencyPump componentsPump installationsEngineeringHeat sink

The invention discloses a heat radiation structure and an electronic water pump. The electronic water pump comprises the heat radiation structure, a pump head and a pump case, wherein a cavity is formed by the pump head, the pump case and the heat radiation structure. An isolation sleeve used for diving the cavity into a dry cavity and a wet cavity is connected between the pump head and the pump case. A rotor assembly is arranged in the wet cavity. A stator assembly and a control panel assembly connected with the stator assembly are arranged in the dry cavity. The control panel assembly comprises a control panel and multiple chips abutting against heat conduction bosses. According to the heat radiation structure and the electronic water pump, heat emitted by the chips is conducted out by the heat conduction bosses, then heat radiation sheets integrally formed with the heat conduction bosses emit heat rapidly, the heat conduction efficiency is increased, heat conduction of the chips ismore rapid, and the heat conduction efficiency of the water pump is greatly improved through a heat conduction cover.

Owner:DUNAN ENVIRONMENT TECH

Organic light emitting display

ActiveUS7679089B2Reduced life-timeLot of radiationDischarge tube luminescnet screensLamp detailsThermal radiationLight emission

An organic light emitting display provided according to the invention maintains light emission efficiency and elongates its lifetime by radiating heat generated from organic light emitting elements to the outside of an encapsulated area. In the organic light emitting display, a part of a cathode is extended to the outside of the encapsulated area of a main substrate to form a radiation section integrally with the cathode. Heat generated from organic light emitting elements is diffused and radiated from the radiation section so that the heat can be discharged therefrom.

Owner:SAMSUNG DISPLAY CO LTD +1

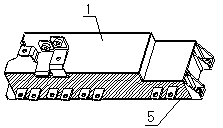

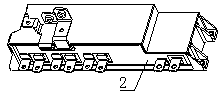

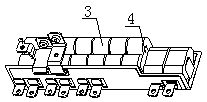

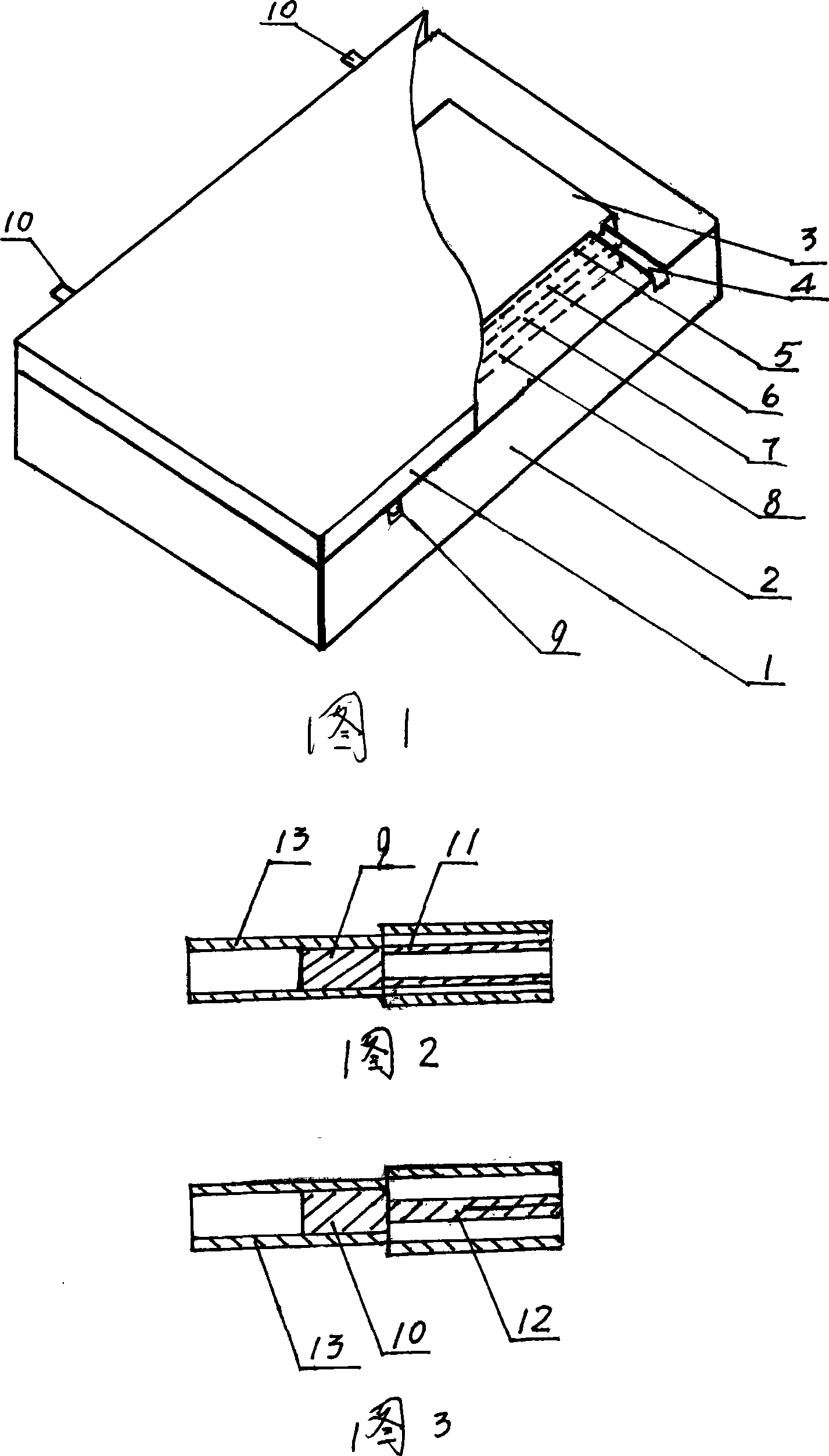

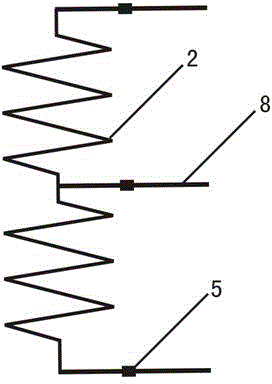

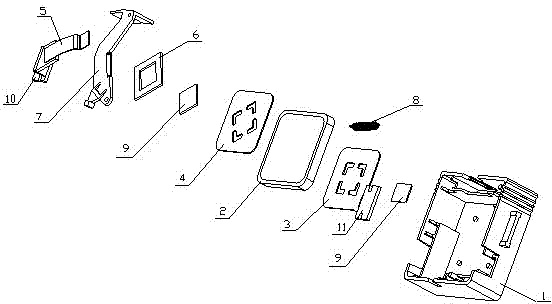

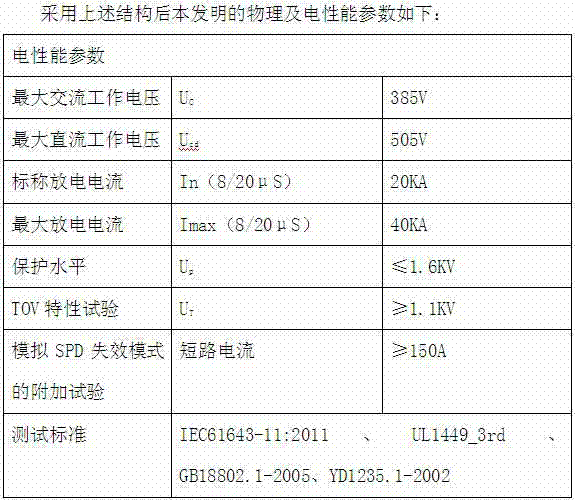

Novel High-reliability surge protector

ActiveCN103904632AIncreasing the thicknessTime does not pursueEmergency protective arrangements for automatic disconnectionEmergency protective arrangements for limiting excess voltage/currentMetal sheetElectrical current

The invention discloses a novel high-reliability surge protector which comprises a voltage-sensitive resistor (2) located in a module box (1). Two electrodes of the voltage-sensitive resistor (2) are connected with an inner electrode A (3) and an inner electrode B (4) respectively, and a heat separation elastic sheet (5) is connected to a heat separation point of the inner electrode B (4). The thickness of the inner electrode B (4) is 0.9 mm to 2 mm, or a melting-through preventing metal sheet (9) is arranged at the connecting position of the heat separation point of the inner electrode B (4) and the heat separation elastic sheet (5). Due to the fact that the thickness of the inner electrode B (4) is increased or the melting-through preventing metal sheet (9) is added between the inner electrode and the heat separation electrode, a long time is needed to melt through the melting-through metal sheet through short circuit currents formed by chip breakdown, time is gained for the response of a heat separation mechanism, and mechanism reliability is greatly improved.

Owner:贵阳高新益舸电子有限公司

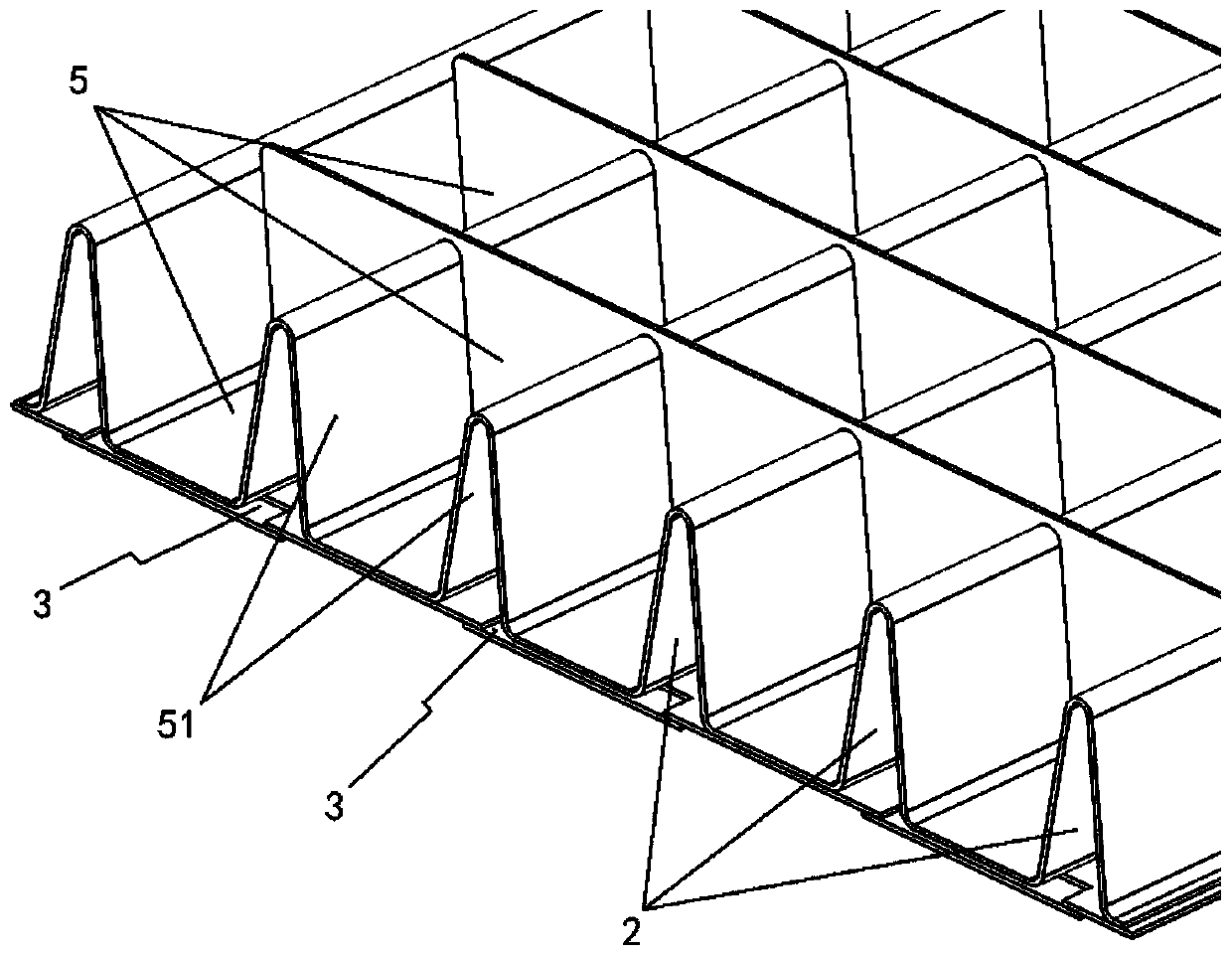

Photovoltaic anti-reversing diode of high heat radiation performance

InactiveCN105958937AImprove cooling effectReduce spacingPhotovoltaicsPhotovoltaic energy generationHigh heatDiode

The invention discloses a photovoltaic anti-reversing diode of high heat radiation performance. The diode comprises a packaging body out of which two terminals are led, a diode chip is arranged in the packaging body, and the bottom surface of the packaging body is provided with a radiating pedestal. The diode is characterized in that the packaging body is integrated with the radiating pedestal, a radiating fin group is formed in the lower side of the radiating pedestal, and the radiating fin group comprises multiple radiating fins which are arranged vertical at equivalent interval. The photovoltaic anti-reversing diode provided by the invention is high in the heat radiation performance and convenient to install.

Owner:ZHEJIANG HUAJING RECTIFIER

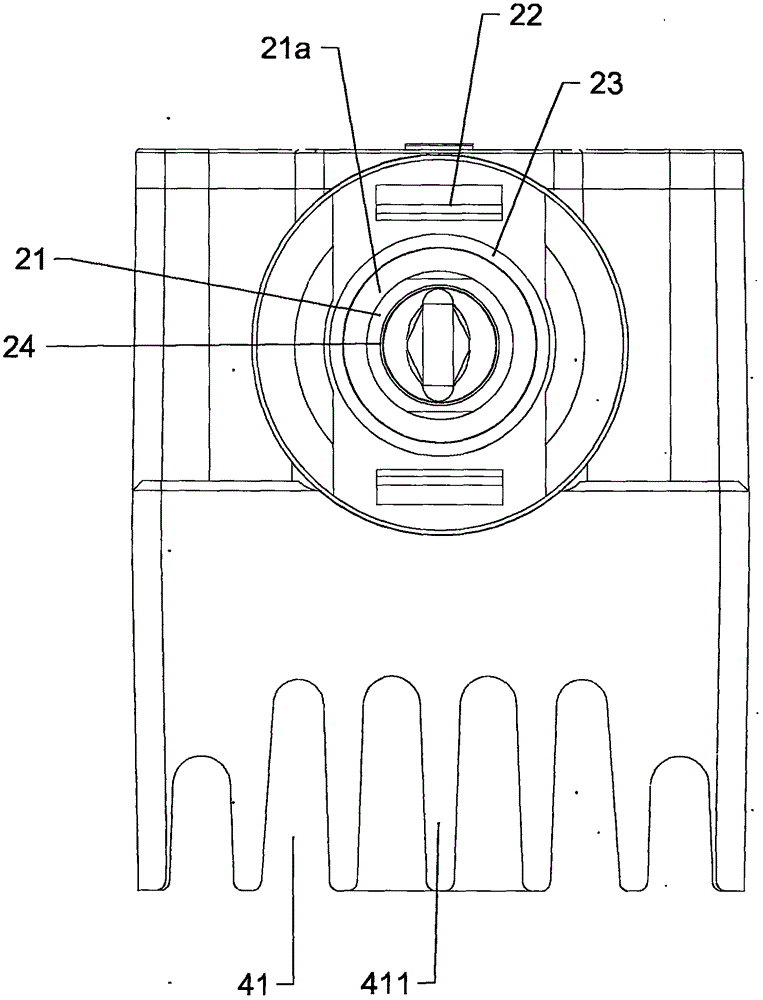

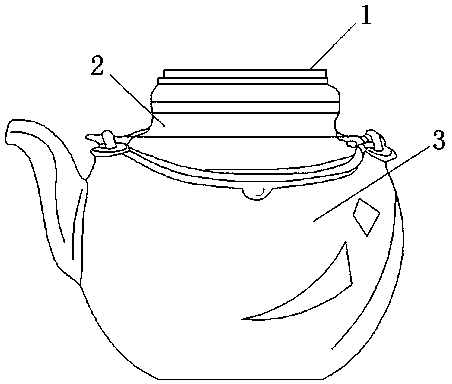

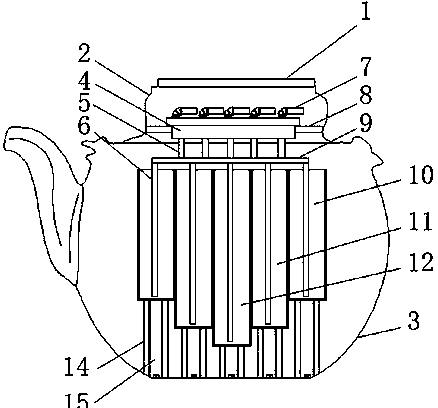

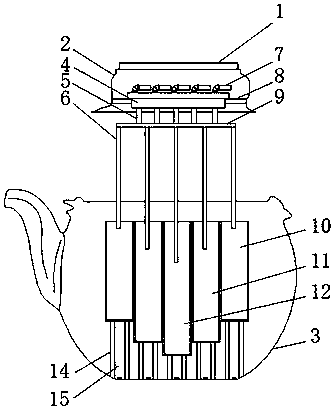

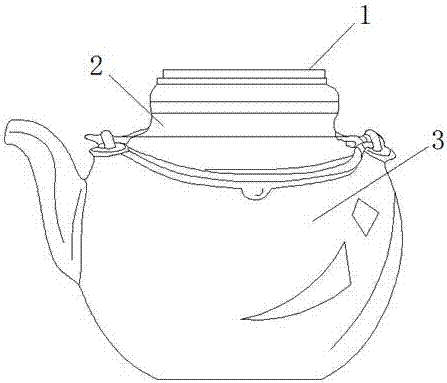

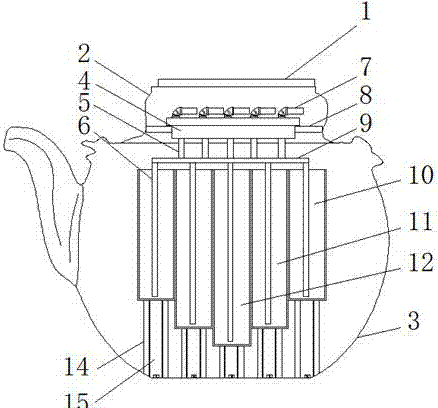

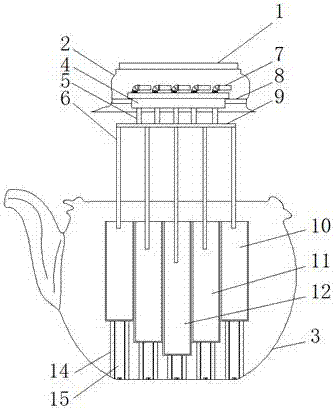

A kind of traditional Chinese medicine pot that is convenient to control the heat

InactiveCN107260545BNot easy to burnEasy to operatePharmaceutical product form changeDomestic articlesChinese drugNozzle

The invention discloses a traditional Chinese medicinal pot convenient for controlling duration and degree of heating, belonging to the field of traditional Chinese medicinal pots. The traditional Chinese medicinal pot convenient for controlling duration and degree of heating comprises a pot body with a medicine pouring nozzle, wherein a sealing cover is hinged to the medicine pouring nozzle, the upper end of the pot body is covered with a second pot cover, the upper end of the second pot cover is covered with a first pot cover, a limiting plate is fixedly connected to the interior of the second pot cover, an opening is formed in the middle of the limiting plate, a plug is arranged in the opening, a medicine decocting mechanism is arranged in the pot body, the medicine decocting mechanism comprises first heating cylinders, second heating cylinders and a third heating cylinder, and the third heating cylinder, the second heating cylinders and the first heating cylinders are sequentially arrayed from center to outer part in the pot body. With one traditional Chinese medicinal pot, different traditional Chinese medicines can be decocted separately with different durations and degrees of heating according to the types of the traditional Chinese medicines, the decoction time can be separately controlled, meanwhile, automatic stirring is realized, the sampling for checking is safe, and the operation is convenient.

Owner:SICHUAN ACADEMY OF MEDICAL SCI SICHUAN PROVINCIAL PEOPLES HOSPITAL

A large cone twin extruder foaming screw

The invention relates to a large-scale extruder foaming cone double screw comprising a feeding section, a compression section, a metering section, an exhaust section, a mixing section, a pre-compression section and a dynamic mixing head; intermeshing screw flights are arranged in the feeding section, the pre-compression section, the compression section, the metering section, the exhaust section and the mixing section; and screw grooves are formed between the adjacent screw flights, and the dynamic mixing head is provided with intermeshing convex blocks. Compared with the prior art, according to the large-scale extruder foaming cone double screw, the compression section is separated into the pre-compression section and a compression section, the aspect ratio of the screw is improved and theresidence time of materials is prolonged, the efficiency of heat control during the processing is improved, and the plasticization of the materials is completed with minimum stress; by arranging thedynamic mixing head, quantity of heat of the materials when the materials are extruded from the screw is reduced, the temperature of the materials can be effectively prevented from rising due to shearheat, and the precipitation of foaming gas to the surface of the materials is reduced; the length of the cone double screw and the diameter of the screw are extended, the screw volume and surface area are increased to enable the interior of the screw to accommodate more materials, and the production is improved.

Owner:SHANGHAI JINHU EXTRUSION EQUIP

Power battery base bracket and power battery module

ActiveCN108075066BImprove assembly efficiencyImprove disassembly efficiencySecondary cellsCell component detailsPower batteryTorch

Owner:BYD CO LTD

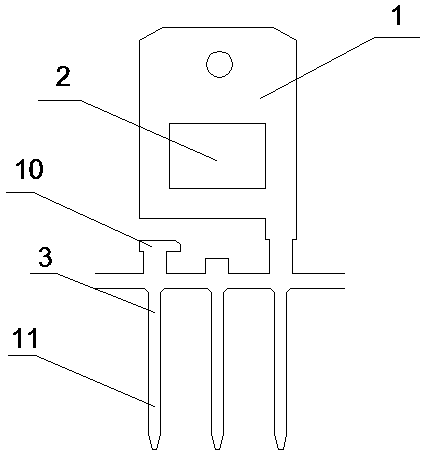

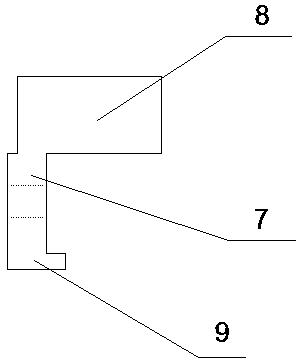

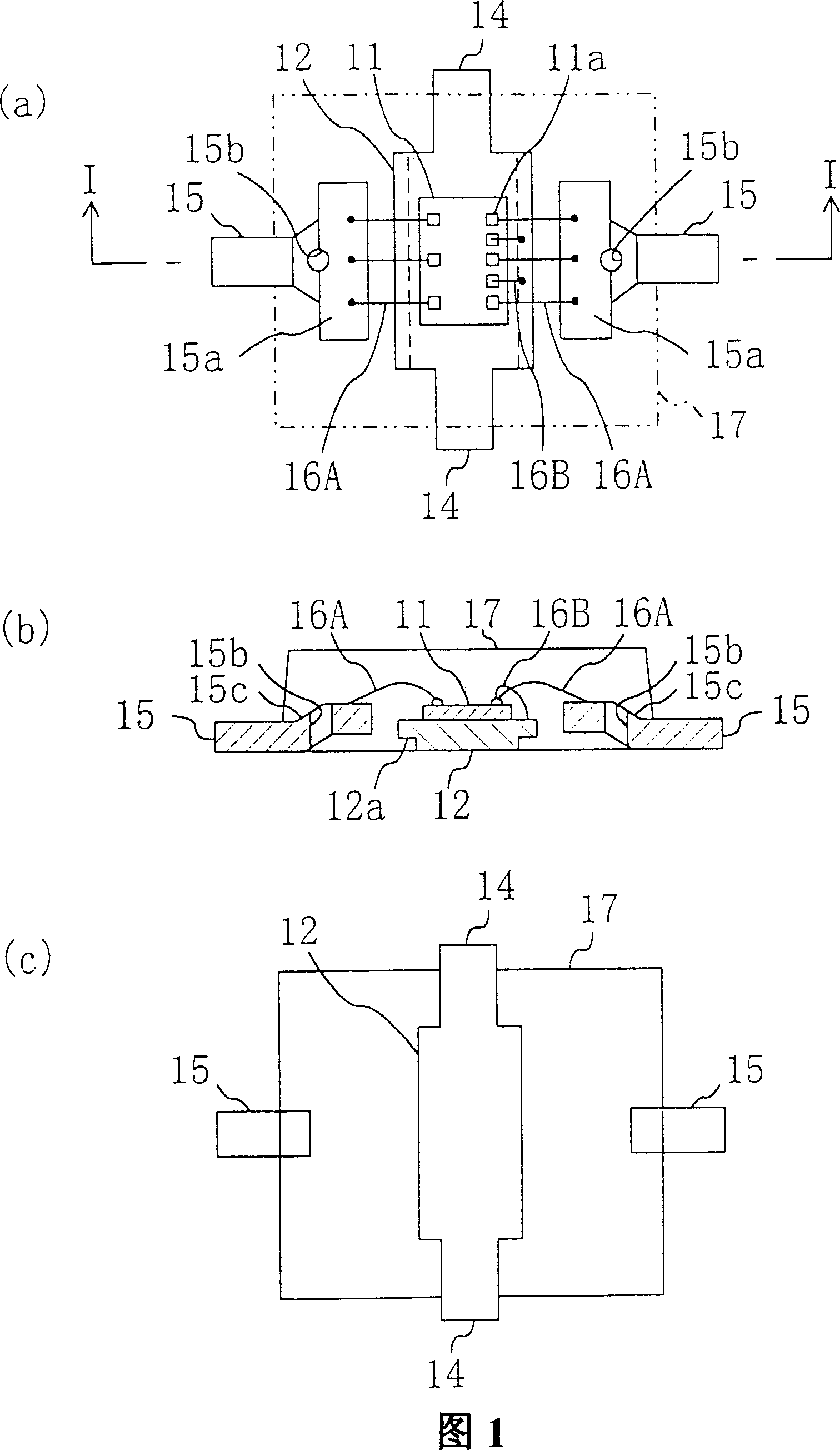

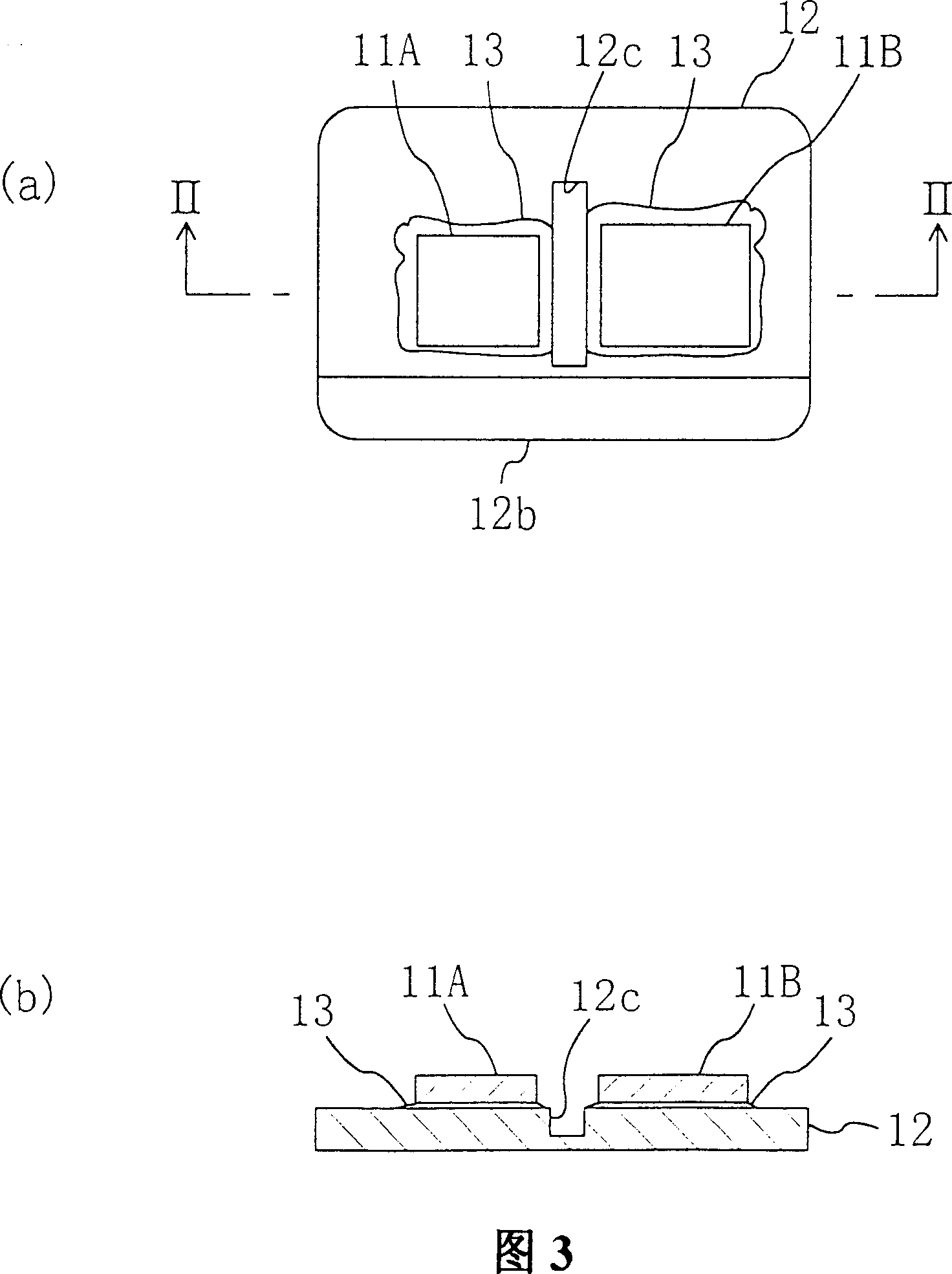

Semiconductor device and its lead frame

InactiveCN100359681CShorten the heat conduction distancePrinted circuit assemblingSemiconductor/solid-state device detailsSilver pasteSemiconductor chip

The semiconductor device of the invention includes: a square die pad, to which a semiconductor chip is adhered via a silver paste member or the like; first leads, the inner end of each of the first leads being formed continuously and integrally with an associated shorter side of the die pad; and a pair of second leads extending in an outer direction, the inner ends of the second leads interposing the die pad therebetween. The inner end of each of the second leads includes a width-increased end portion having a larger width and being formed to be parallel to an associated longer side of the die pad. A through hole is provided in a portion connecting the width-increased end portion to the outer portion of each of the second leads. The semiconductor chip is electrically connected to the second leads via wires and to the die pad via a grounding wire.

Owner:PANASONIC CORP

Traditional Chinese medicinal pot convenient for controlling duration and degree of heating

InactiveCN107260545AReduce hot air outletNot easy to be burnedPharmaceutical product form changeDomestic articlesTraditional Chinese medicineNozzle

The invention discloses a traditional Chinese medicinal pot convenient for controlling duration and degree of heating, belonging to the field of traditional Chinese medicinal pots. The traditional Chinese medicinal pot convenient for controlling duration and degree of heating comprises a pot body with a medicine pouring nozzle, wherein a sealing cover is hinged to the medicine pouring nozzle, the upper end of the pot body is covered with a second pot cover, the upper end of the second pot cover is covered with a first pot cover, a limiting plate is fixedly connected to the interior of the second pot cover, an opening is formed in the middle of the limiting plate, a plug is arranged in the opening, a medicine decocting mechanism is arranged in the pot body, the medicine decocting mechanism comprises first heating cylinders, second heating cylinders and a third heating cylinder, and the third heating cylinder, the second heating cylinders and the first heating cylinders are sequentially arrayed from center to outer part in the pot body. With one traditional Chinese medicinal pot, different traditional Chinese medicines can be decocted separately with different durations and degrees of heating according to the types of the traditional Chinese medicines, the decoction time can be separately controlled, meanwhile, automatic stirring is realized, the sampling for checking is safe, and the operation is convenient.

Owner:SICHUAN ACADEMY OF MEDICAL SCI SICHUAN PROVINCIAL PEOPLES HOSPITAL

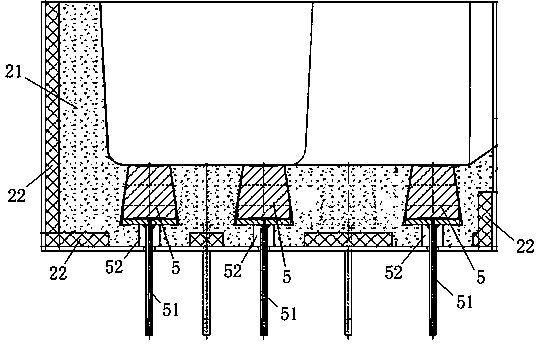

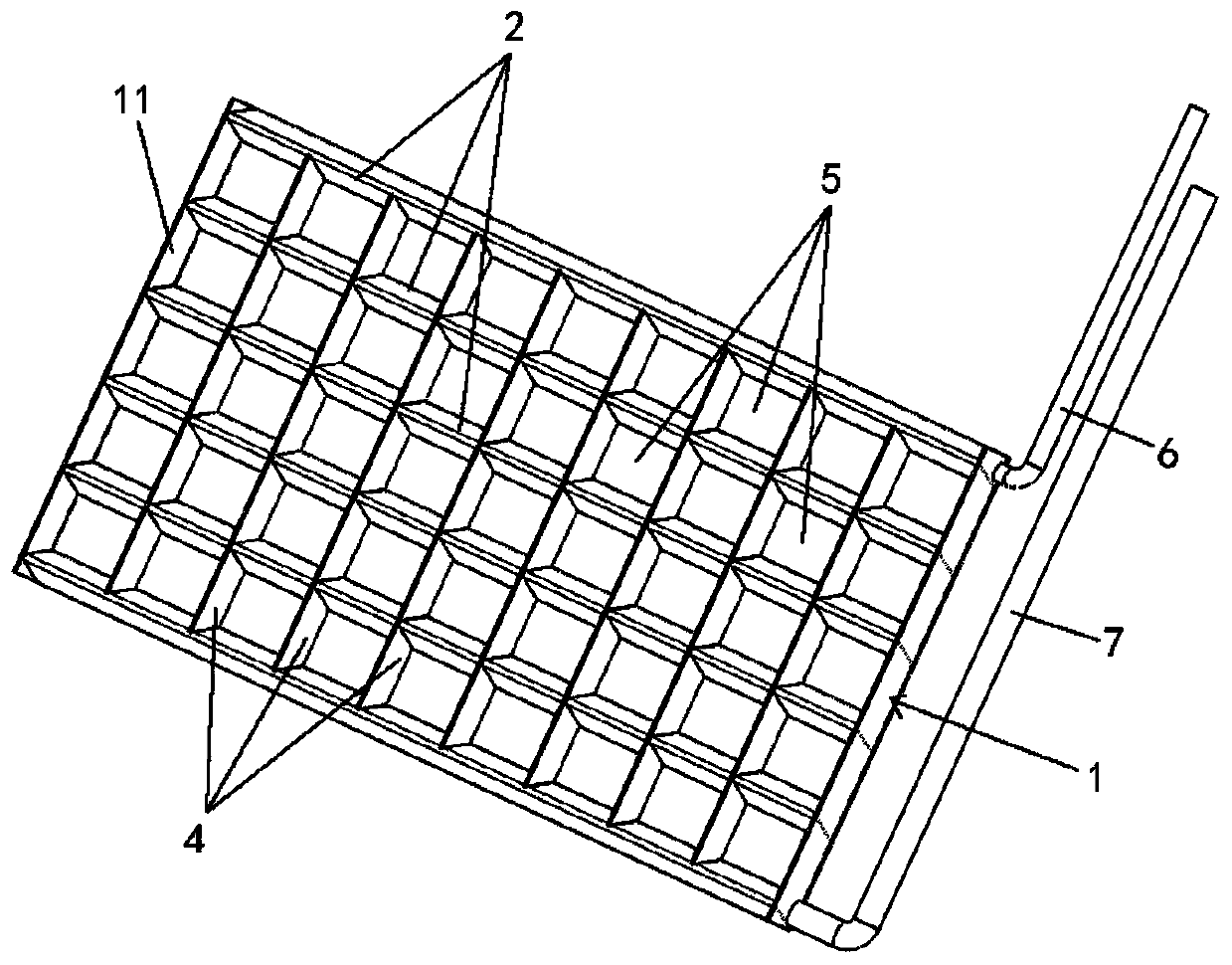

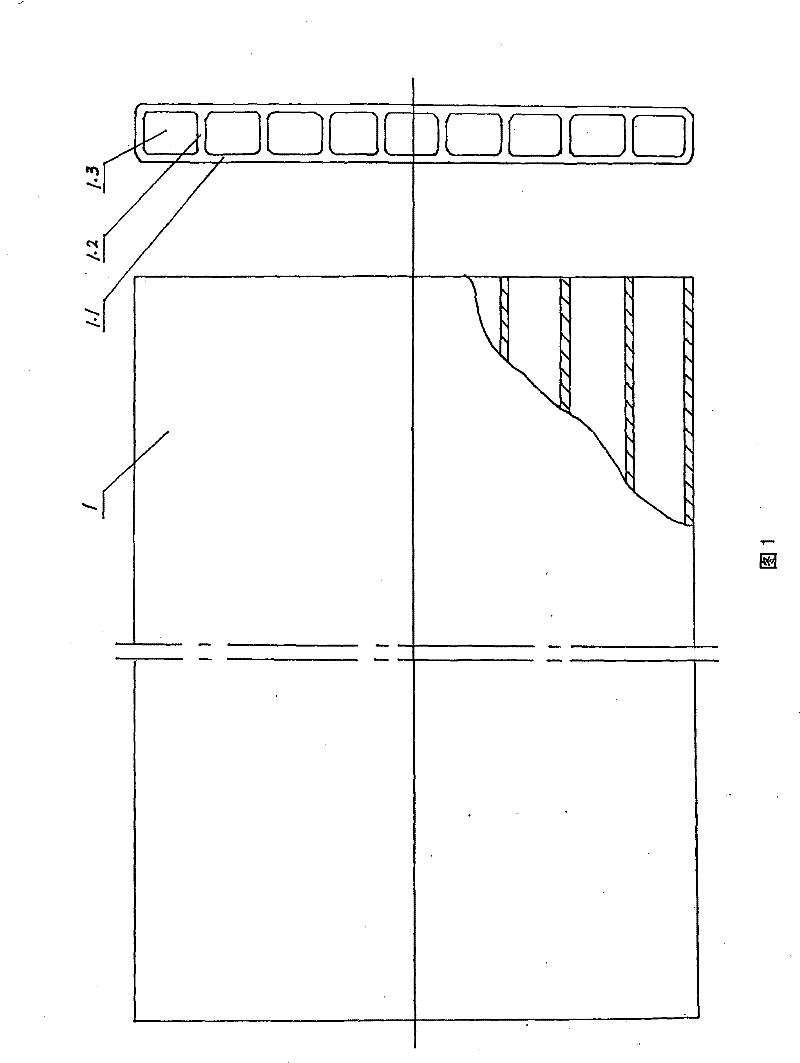

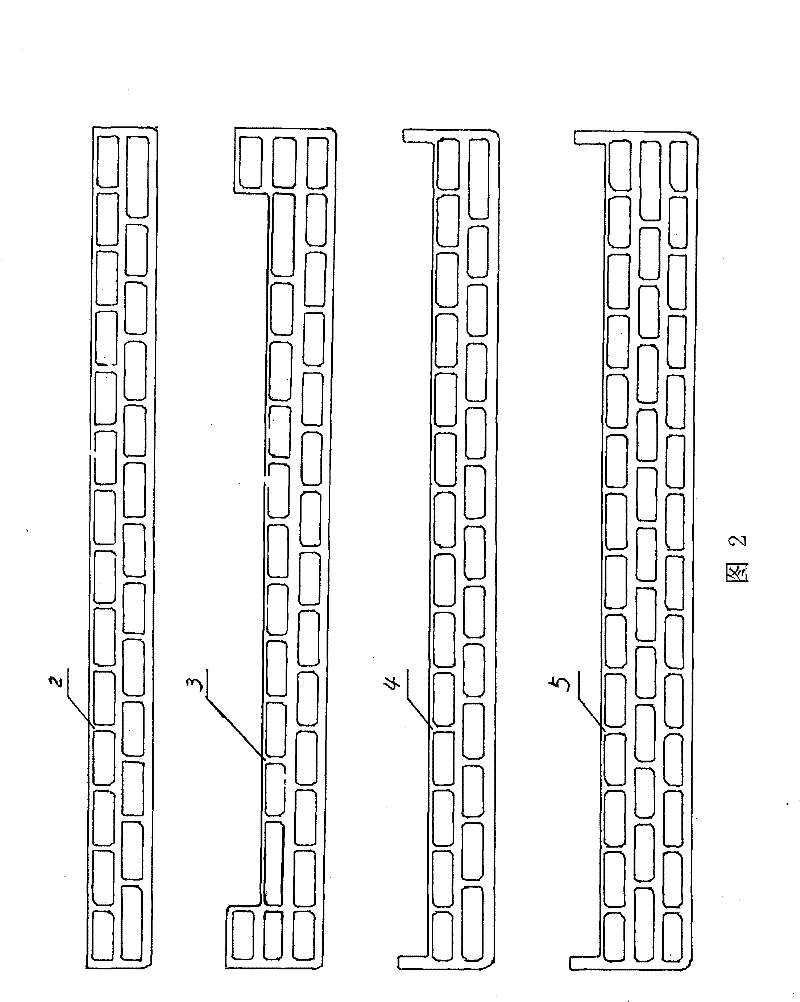

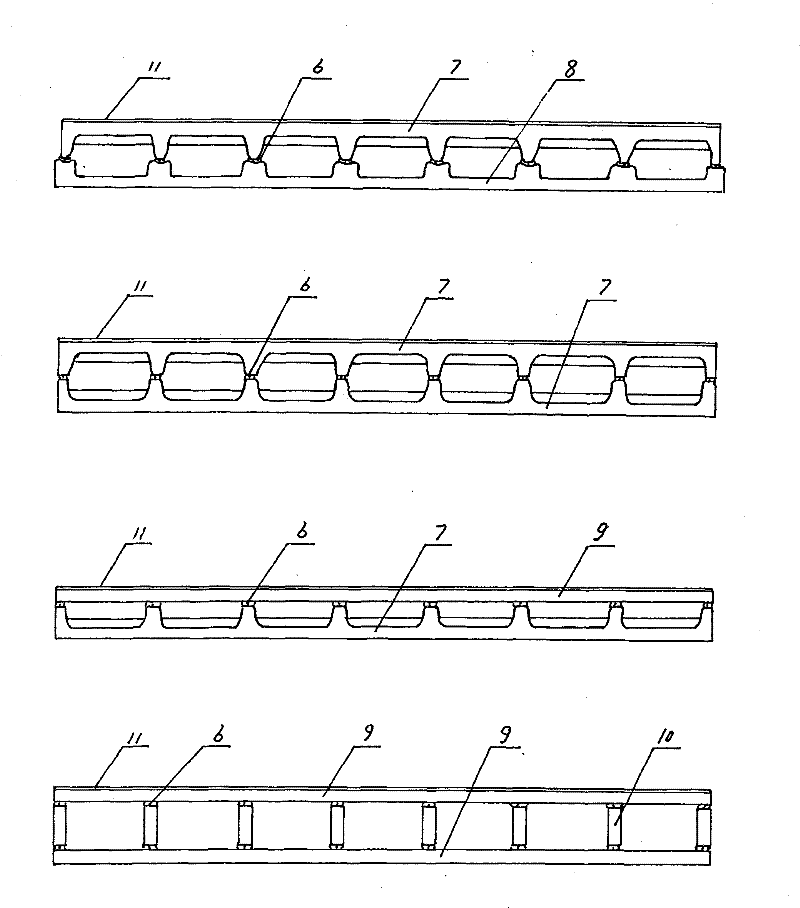

Thermal equipment for producing composite ceramic solar panel

InactiveCN101813413BIncrease productivityImprove production yieldDrying solid materials with heatDrying machines with progressive movementsHeat currentComposite ceramic

The invention relates to a structure of a solar thermal collector, ceramic industry in China, a composite ceramic solar panel production technology and thermal equipment. The invention fully utilizes the common roller kiln for drying and firing in ceramic industry; movable heat-resisting baffles are installed in the hearth of the roller kiln; the positions of the baffles can be adjusted to convert the area of the cross section of the hearth; the movable baffles in the hearth of the roller kiln are positioned by a hanger rod and a cam; the hanger rod is elevated or the cam is rotated to elevate the horizontal baffle or change the angle of the sloping baffle, thereby changing the movement path of the heat current; thus, part of the heat current enters through holes of the hollow ceramic plate blank, so that the inner surface and the outer surface of the outer wall of the hollow ceramic plate blank, and both surfaces of the support wall are in the same heating state, thereby greatly shortening the thermal conduction distance; and therefore, all parts of the hollow ceramic plate blank are in the same temperature, drying or firing state, thereby greatly enhancing the production efficiency for drying and firing the hollow ceramic plate blanks and increasing the yield.

Owner:曹树梁

Temperature measurement component, temperature measurement device and electric appliance component

PendingCN107607215ASimple structureImprove versatilityThermometer detailsThermometers using electric/magnetic elementsAppliance componentEngineering

The invention discloses a temperature measurement component, a temperature measurement device and an electric appliance component. The temperature measurement component comprises a heat conduction padand a temperature measuring element. The heat conduction pad is in thermally conductive connection with an object to be measured in temperature. The temperature measuring element is in contact with the heat conduction pad, is arranged at intervals with the object to be measured in temperature, and is used for detecting the temperature of the object to be measured in temperature. The temperature measurement component replaces a heat transfer structure made by a potting and packaging process with the heat conduction pad, thereby avoiding low efficiency caused by long potting time and the inconvenient control of glue curing time. Further, the heat conduction pad does not require complicated structural cooperation and has high universal performance.

Owner:TYCO ELECTRONICS (SHANGHAI) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com