Novel tip-heated soldering iron head

A soldering iron tip and hot tip technology, which is applied in the field of new tip hot soldering iron tips, to achieve the effect of shortening the heat conduction distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

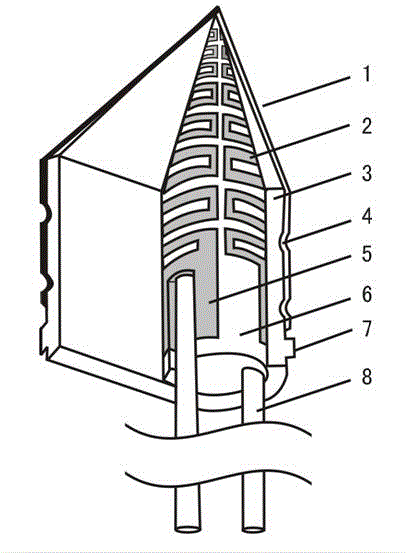

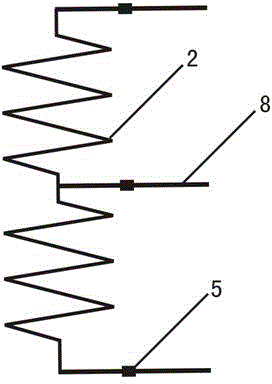

[0034] The technical solution adopted in the present invention is: this new type of pointed hot-type soldering iron head includes: heating element 3, ceramic core 6 preset in heating element 3, resistance 2, wiring area 5, conductive pin 8 and setting on heating element 3 Outer metal layer 1, concave ring 4, fixed ring 7. The heating element 3 of the present invention is mainly made of insulating ceramics, directly made into the shape of a soldering iron tip, and the material of the resistance 2 is preset in the front tip, and the concave ring 4 and the fixed ring 7 are arranged outside it, and the conductive pin 8 is arranged at the rear end. , formed by high-temperature sintering, and an outer metal layer 1 is set on the front tip.

[0035] In the above technical scheme, the production method uses a high-temperature co-sintering technology similar to Metal Ceramics Heater cermets. The material of the resistor 2 is a slurry containing metal tungsten, molybdenum, manganese...

Embodiment

[0042] see figure 1 , Figure 4 , single-conductive pin tip-hot soldering iron head, only one conductive metal pin 8 is provided at the rear end of the heating element 3 to connect with the resistor 2, and it is inserted into the supporting socket 10 of the main body of the electric soldering iron during installation, and the electrode at the other end of the resistor is led out of the heating body 3 is connected with the outer metal layer 1, and the outer metal layer 1 is connected with the shell of the soldering iron body through the metal protective sheath 9, and the circuit is connected. The circuit principle is the same as that of most existing flashlights. Pointed thermal tip with single conductive pin is only suitable for rechargeable soldering iron with safe power supply.

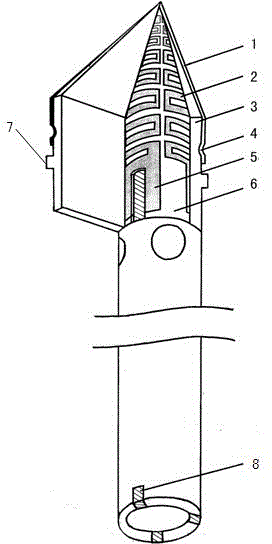

[0043] see figure 2 , image 3 , Figure 4 , the pointed hot-type soldering iron tip with three conductive pins, the pointed hot-type soldering iron tip with three conductive pins, in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com