Patents

Literature

65results about How to "Prominent effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

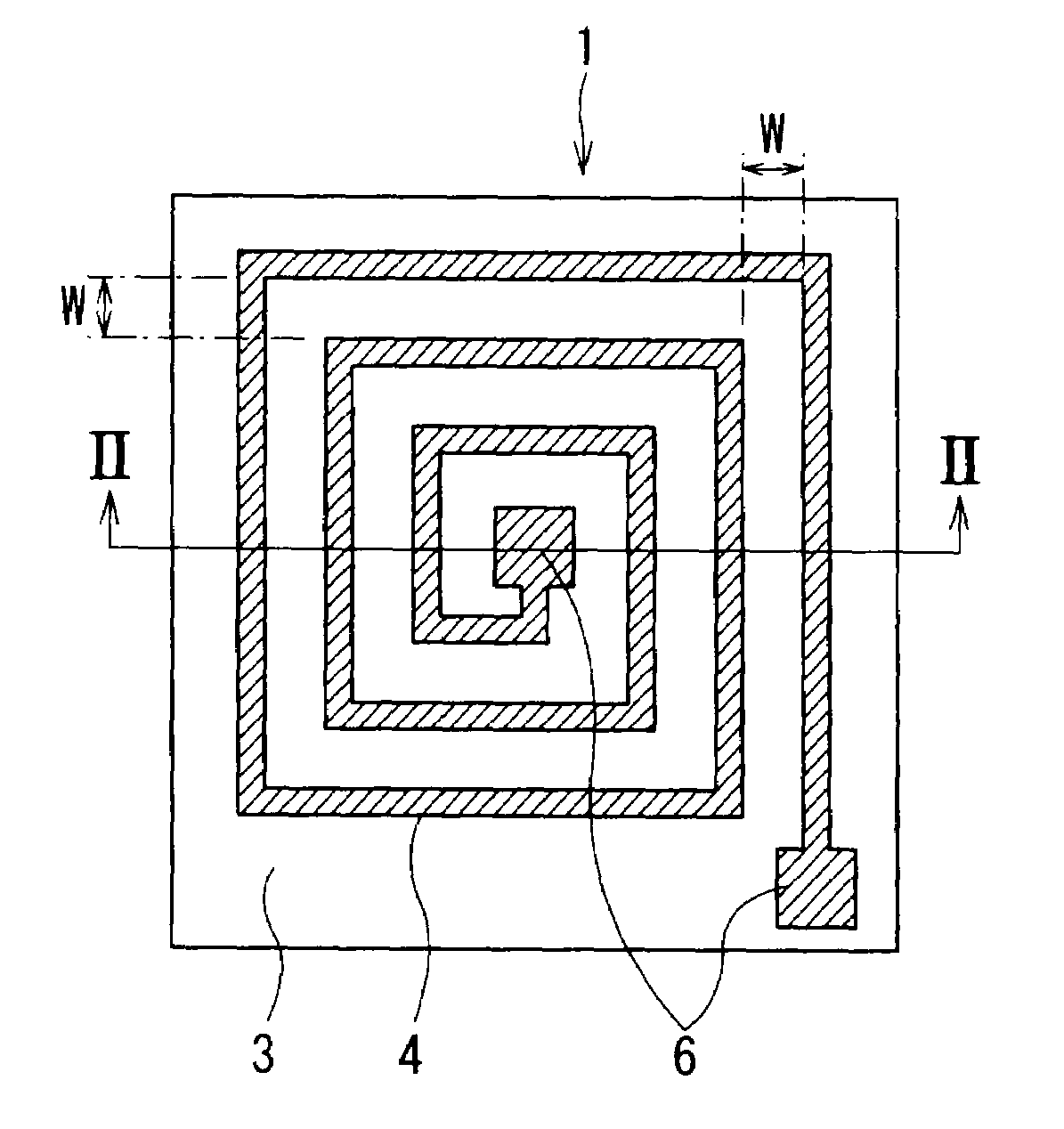

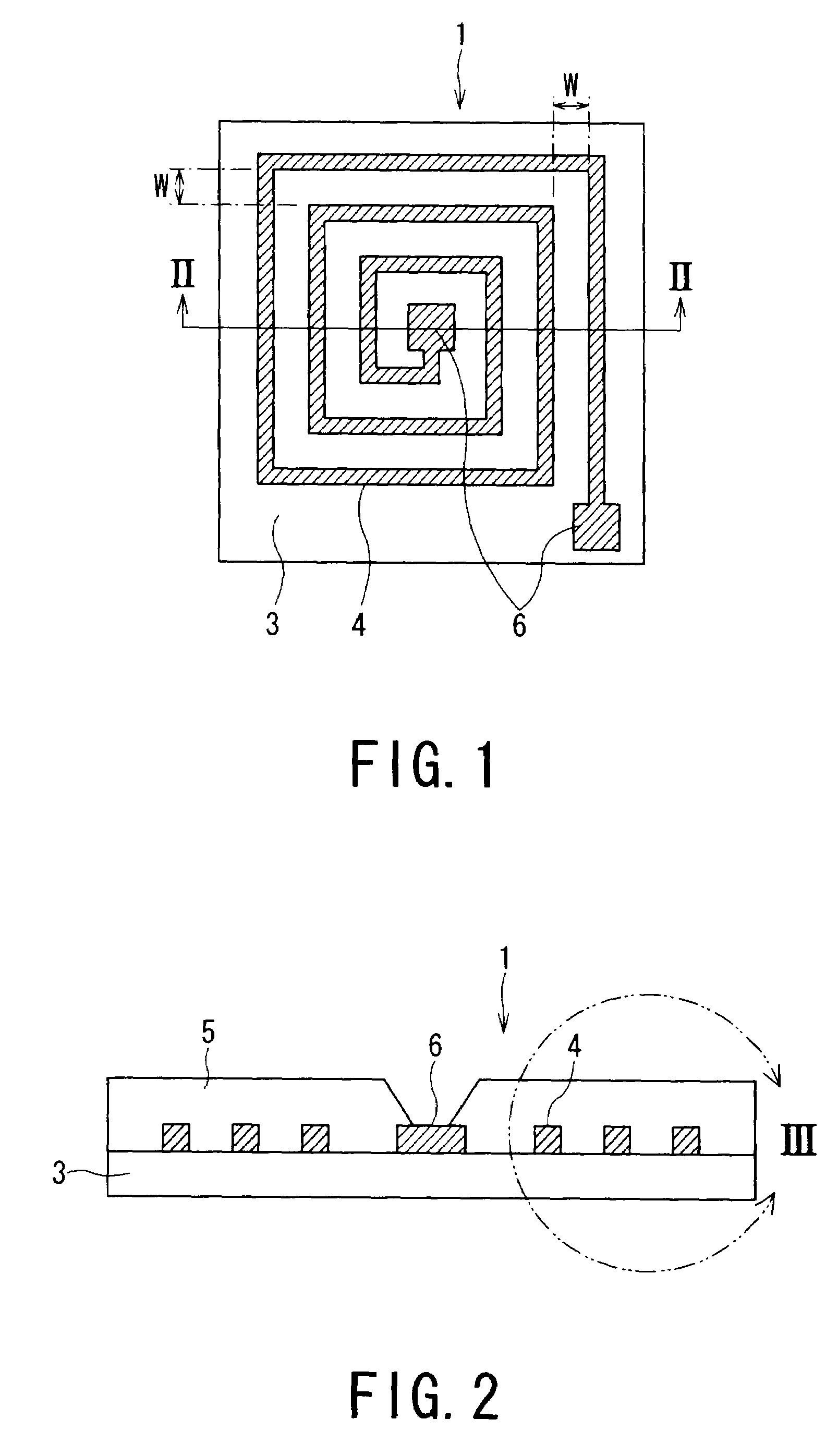

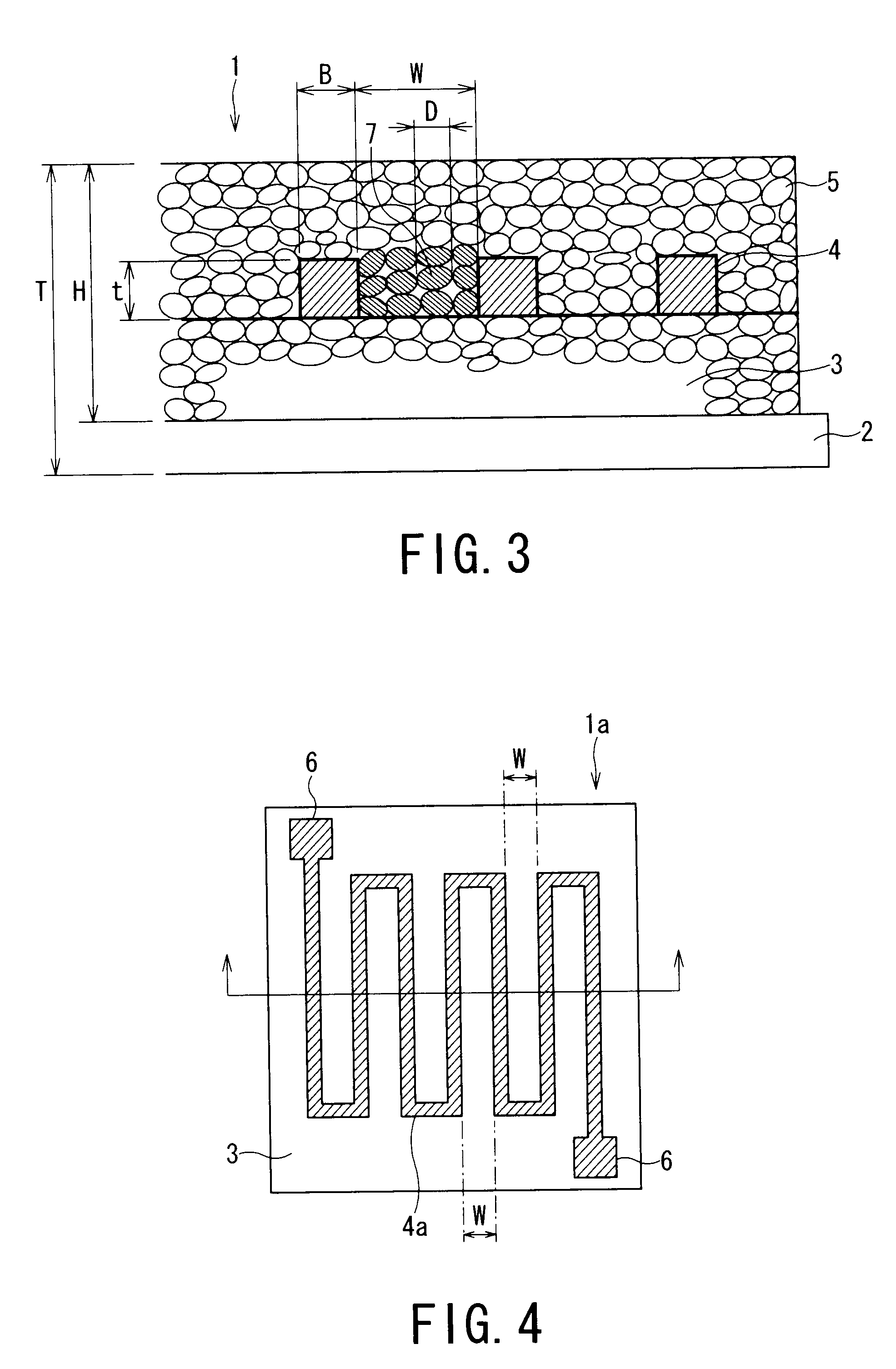

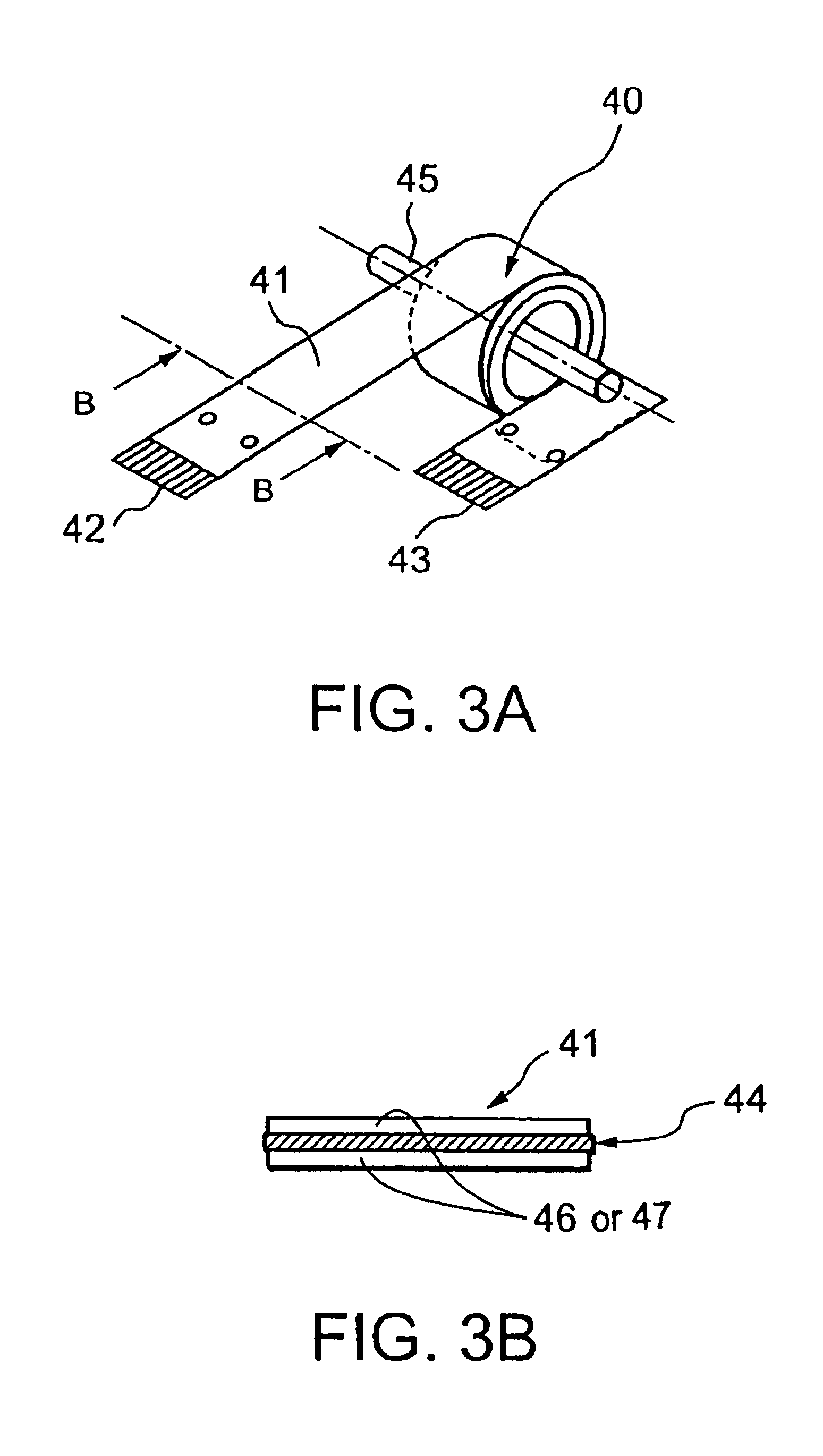

Flat magnetic element and power IC package using the same

ActiveUS20090243780A1Improve permeabilityIncrease inductanceSemiconductor/solid-state device detailsSolid-state devicesInductorInductance

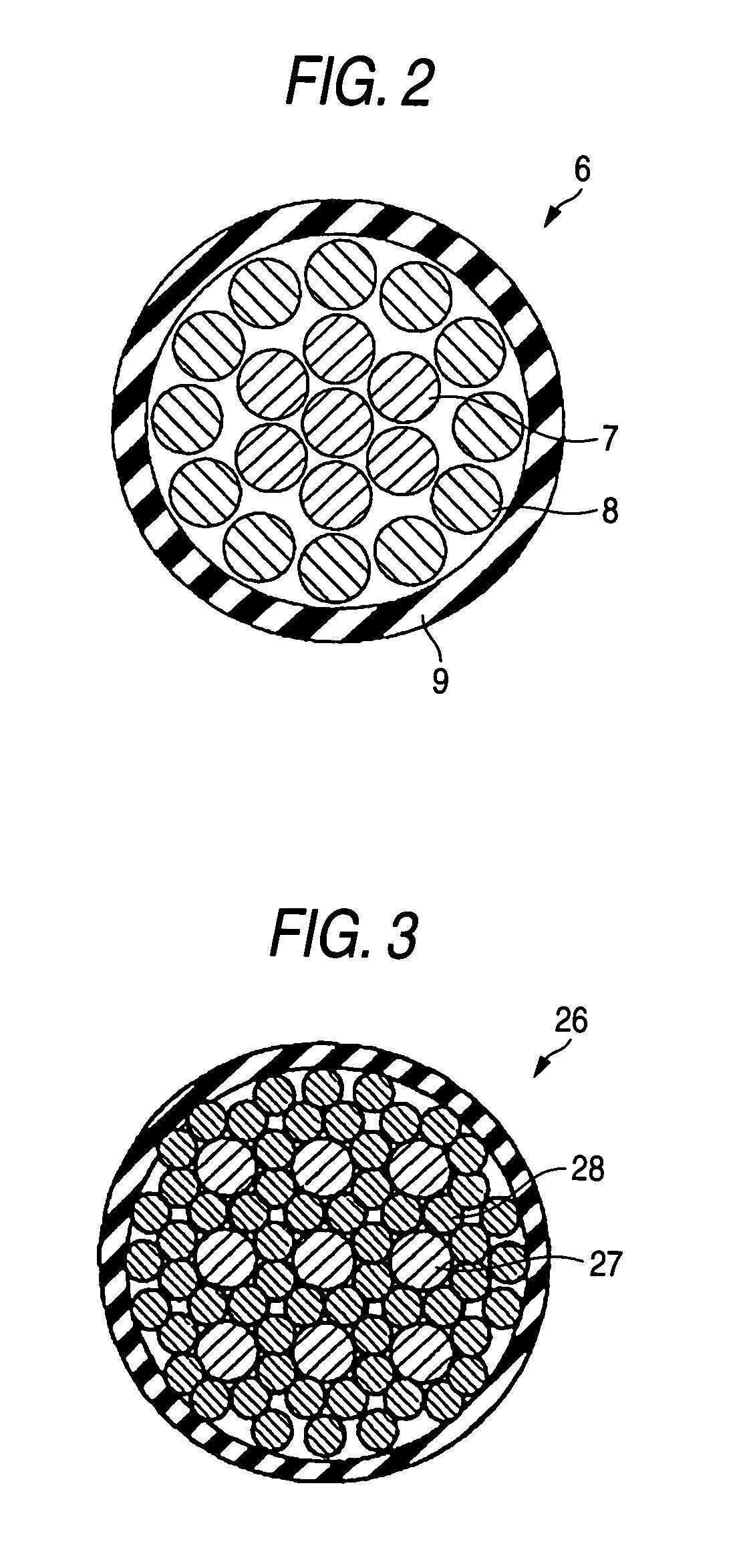

A planar magnetic device 1 including a first magnetic layer 3, a second magnetic layer 5, and a planar coil 4 disposed between the first magnetic layer 3 and the second magnetic layer 5, wherein magnetic particles 7 having a shape ratio S / L of 0.7 to 1 when a length of a long axis is L and a length of a short axis orthogonal to the long axis is L are filled in a gap W between coil wirings of the planar coil 4. According to the planar magnetic device 1, it is possible to realize a planar magnetic device such as an inductor reduced in height by using fine particles that enable to effectively obtain a large inductance value.

Owner:KK TOSHIBA +1

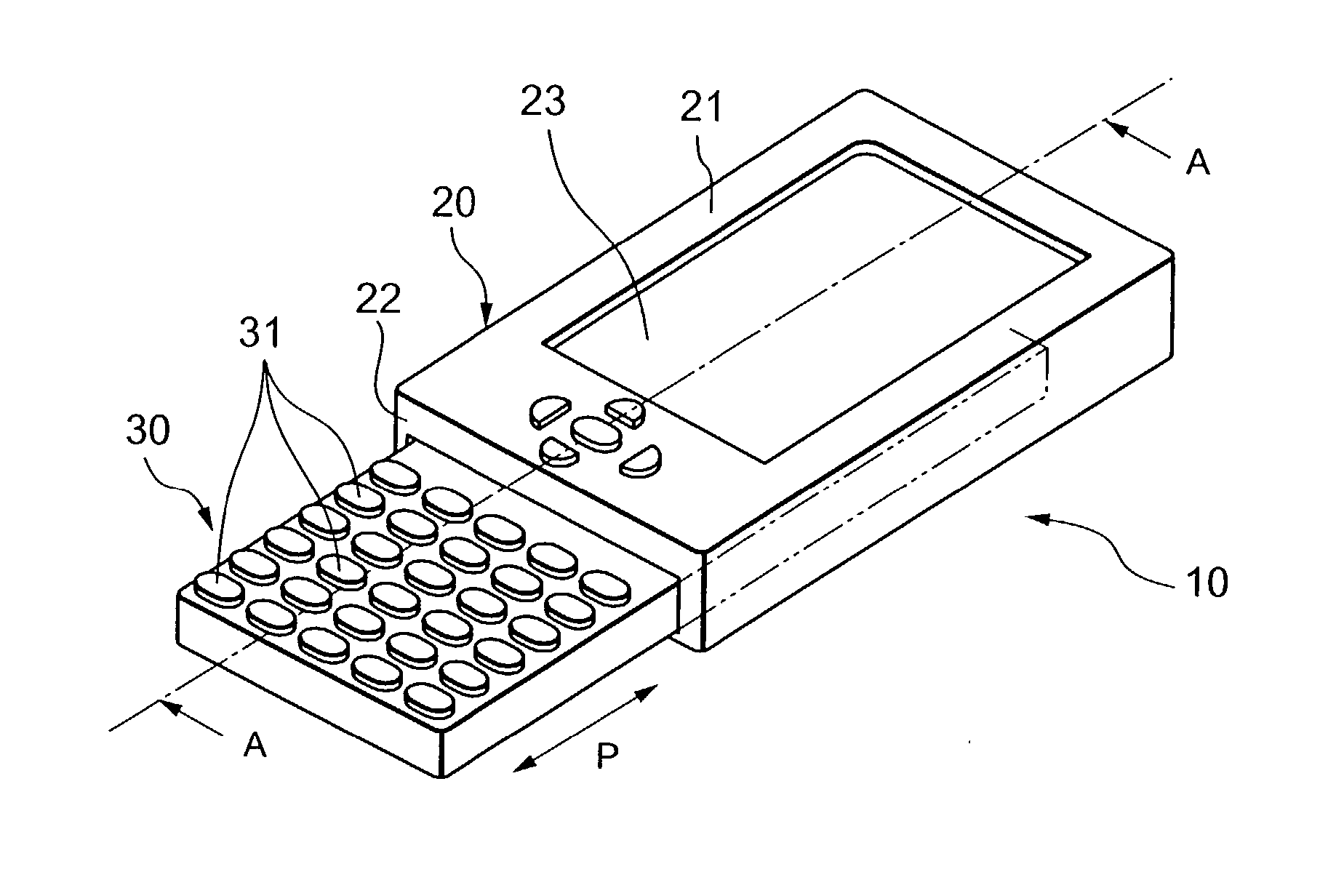

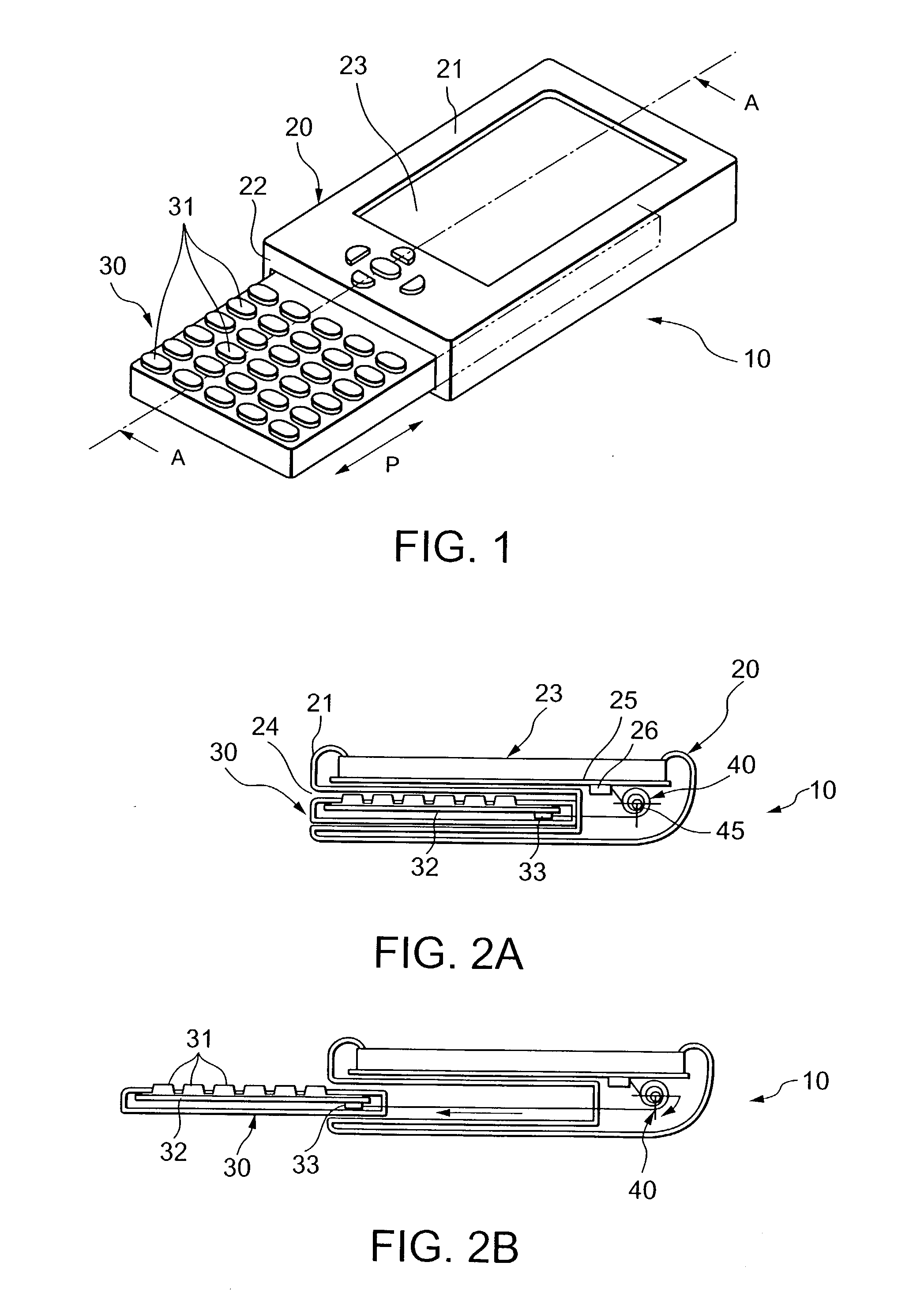

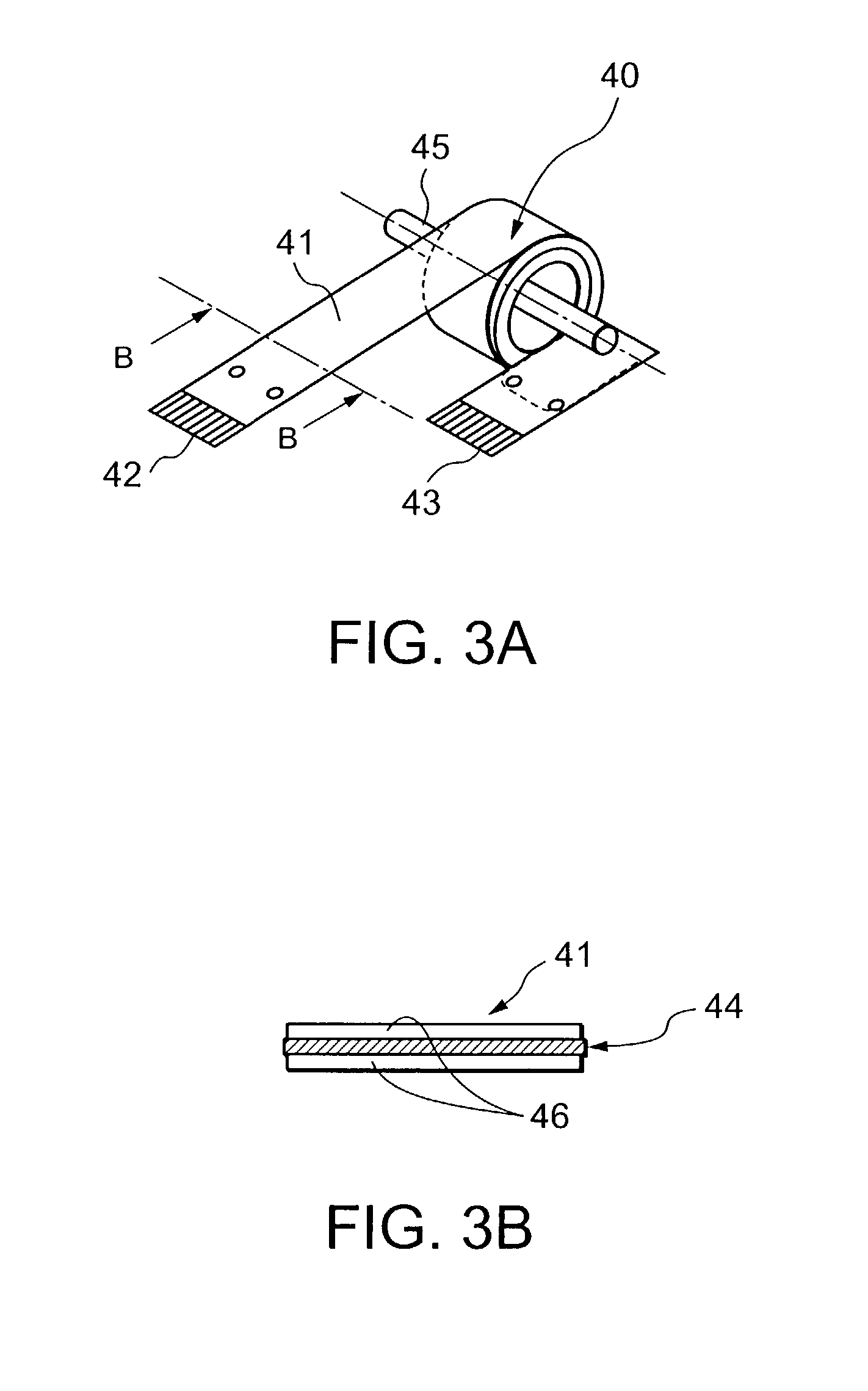

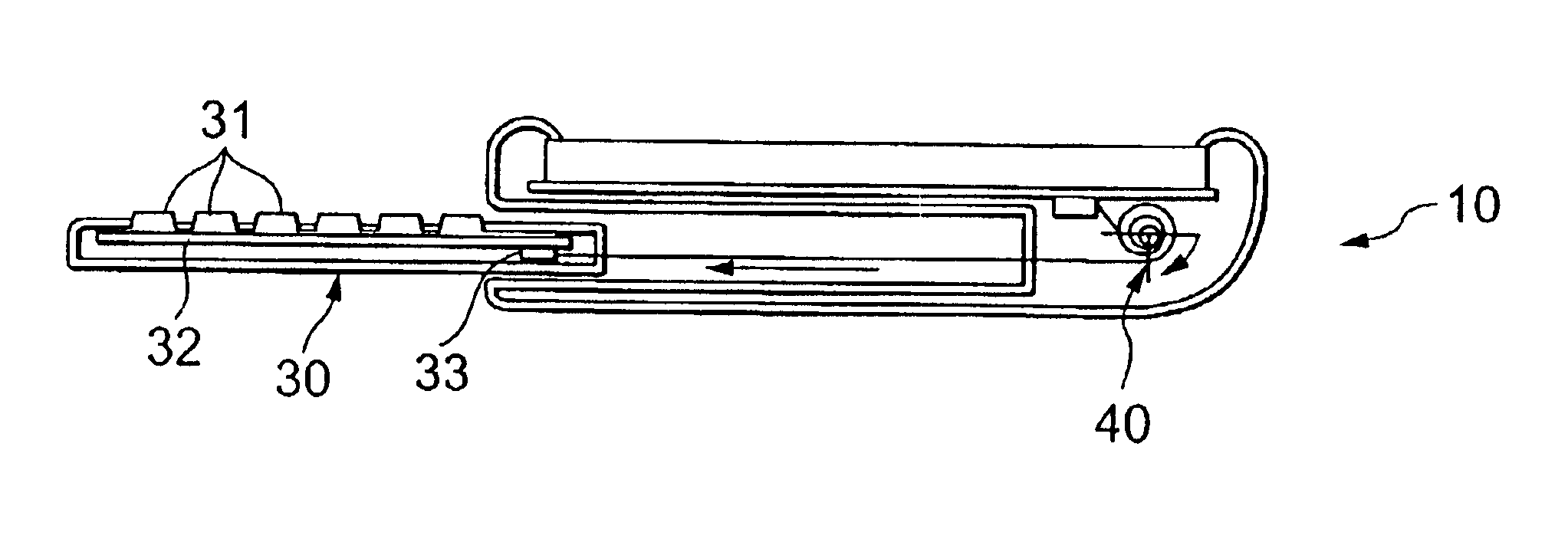

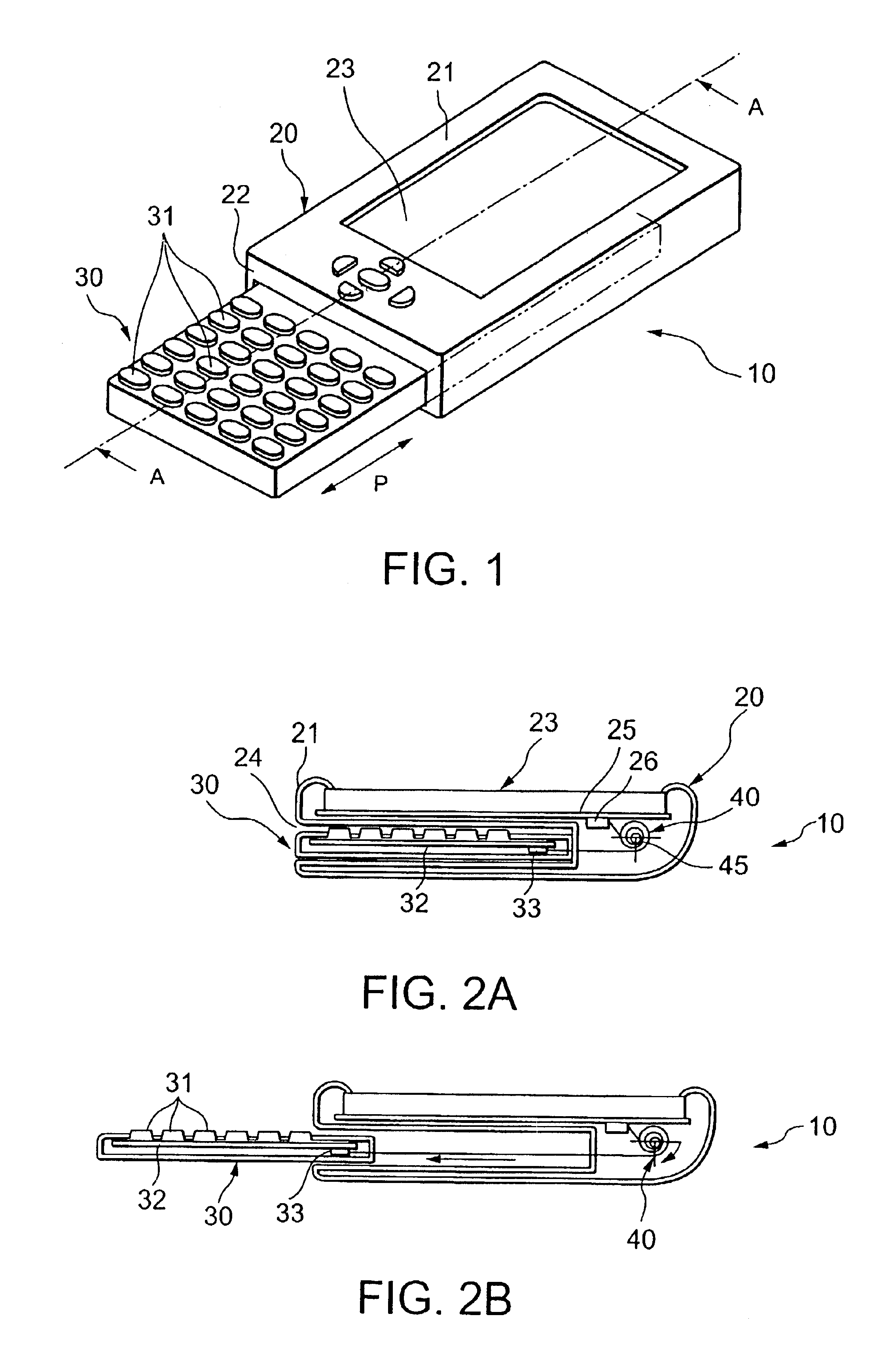

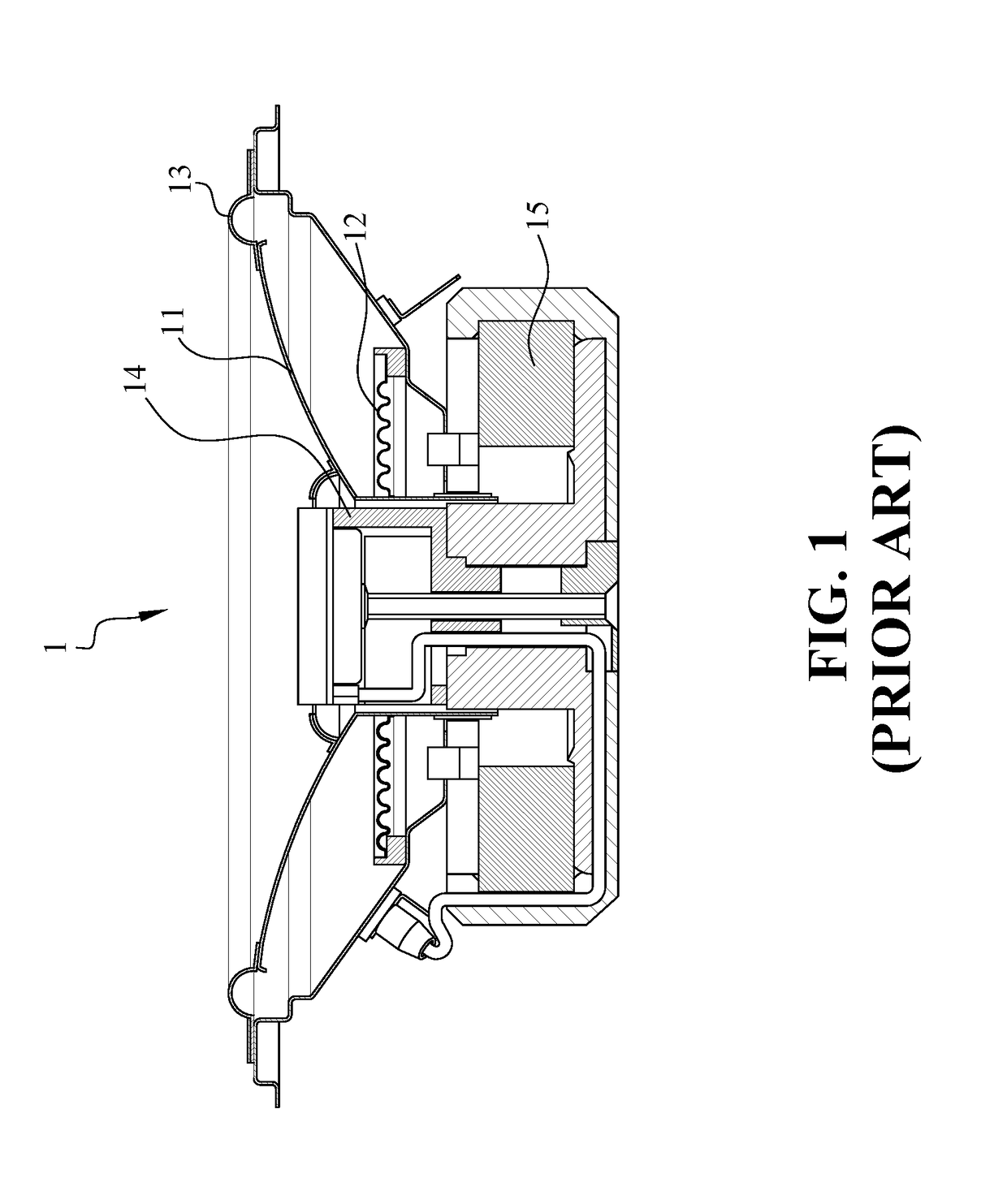

Portable information terminal capable of sliding one case unit against another case unit in the use state

InactiveUS20030081375A1Reduce in quantityLow costInput/output for user-computer interactionDigital processing power distributionEngineeringConductor Coil

Owner:NEC CORP

Portable information terminal capable of sliding one case unit against another case unit in the use state

InactiveUS6816363B2Reduce in quantityLow costInput/output for user-computer interactionDigital processing power distributionConductor CoilMechanical engineering

Owner:NEC CORP

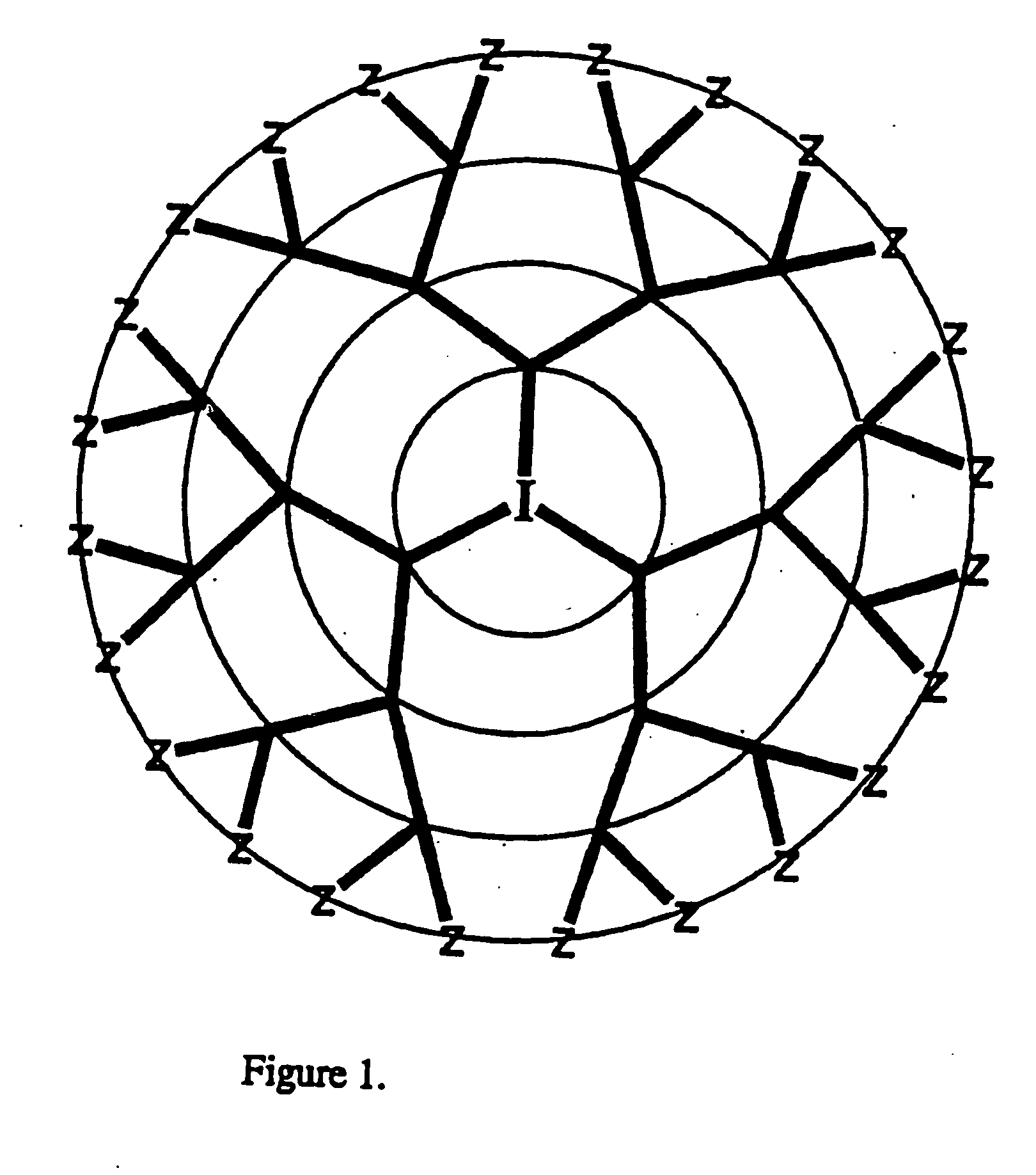

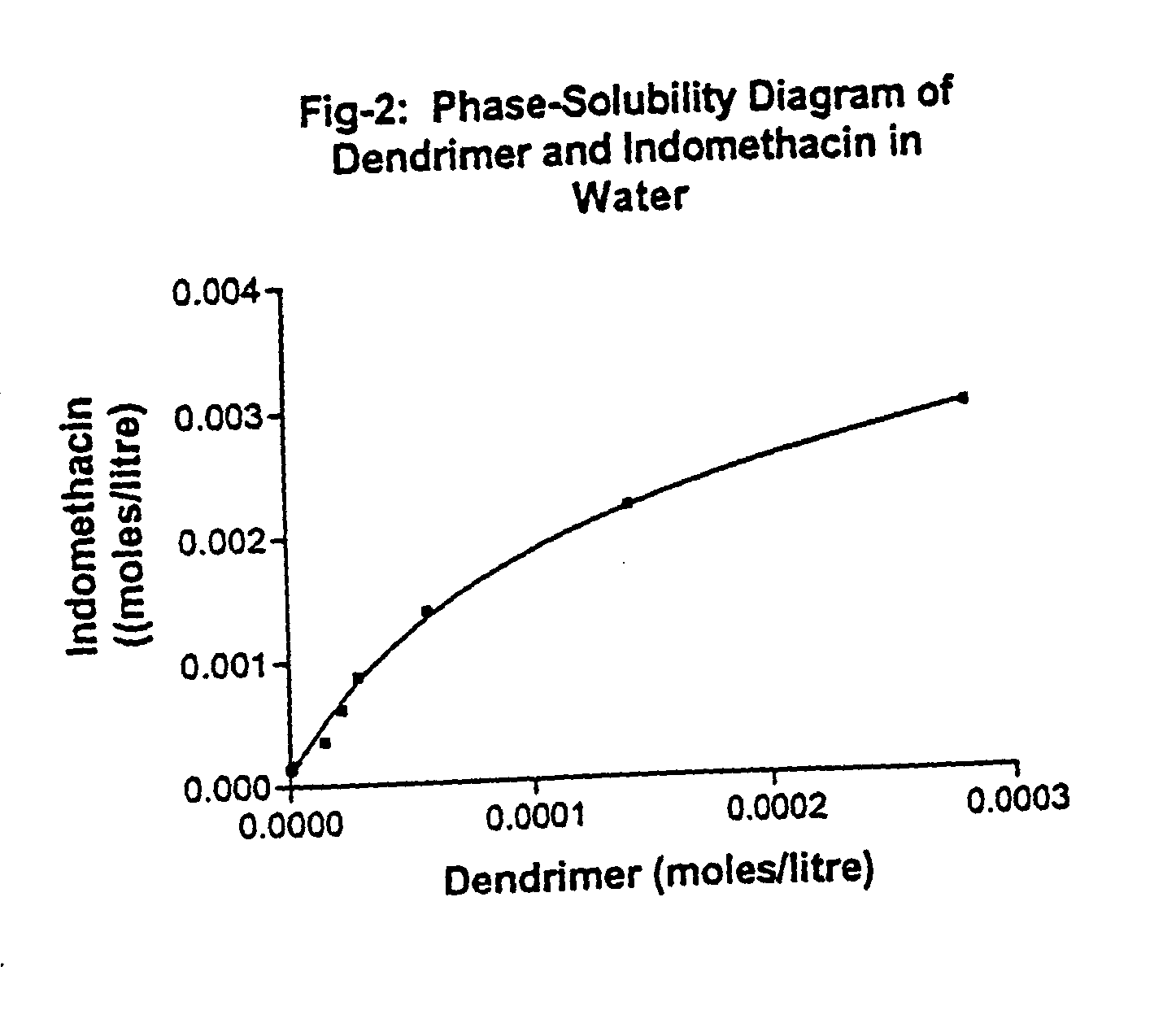

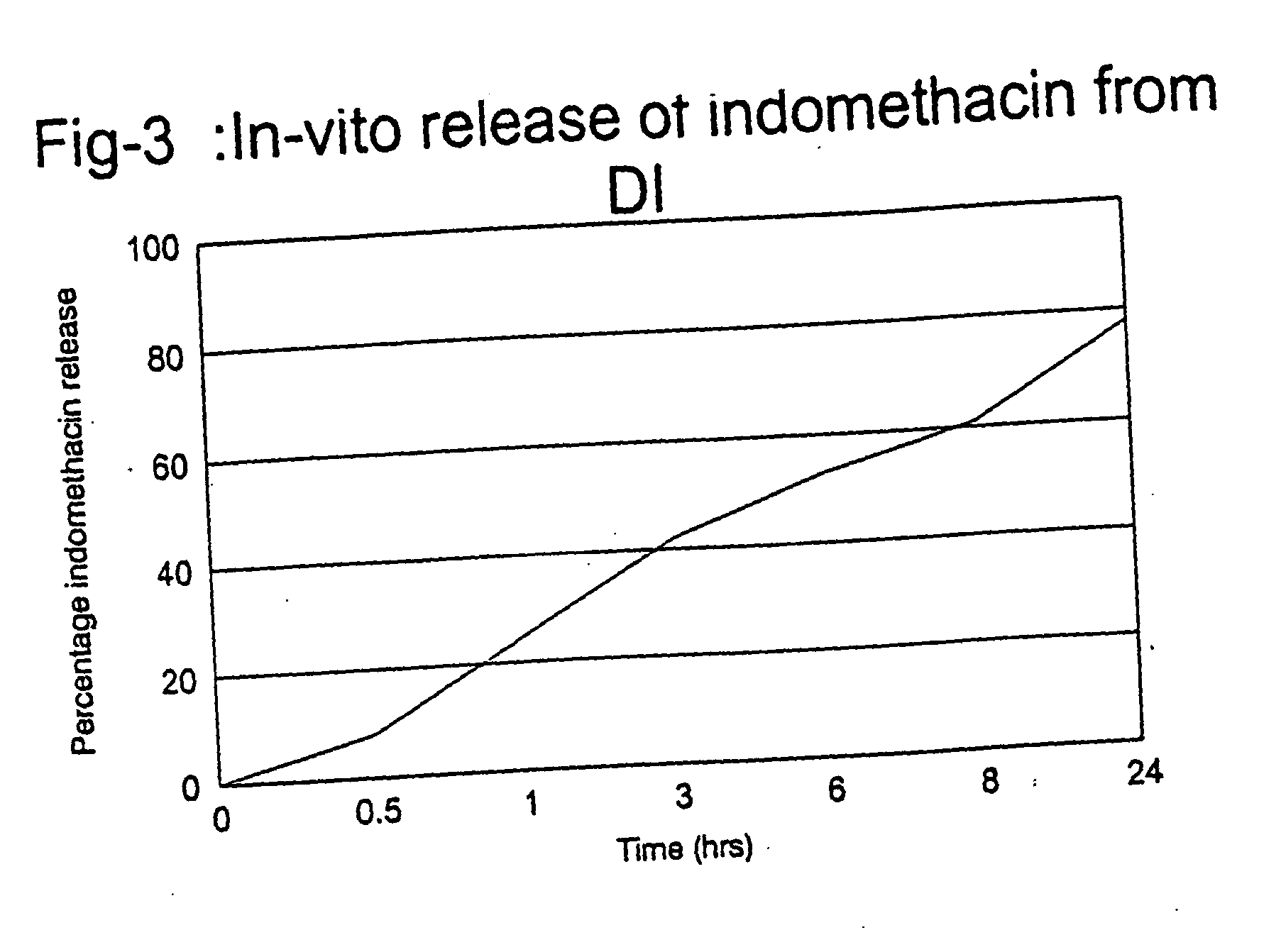

Compositions and complexes containing a macromolecular compound as potential anti-inflammatory agents

InactiveUS20070014757A1Improve solubilityProminent effectSynthetic polymeric active ingredientsDendrimerCompound (substance)

A composition exhibiting anti-inflammatory activity comprising of a momodisperse macromolecular polymers such as dendrimer having a plurality of terminal groups or such molecules bound / complexed to drug moieties having anti-inflammatory activity or which assist in anti-inflammatory activity and its use in the pharmaceutical formulation for treating disease or pathological conditions associated with inflammation.

Owner:COUNCIL OF SCI & IND RES

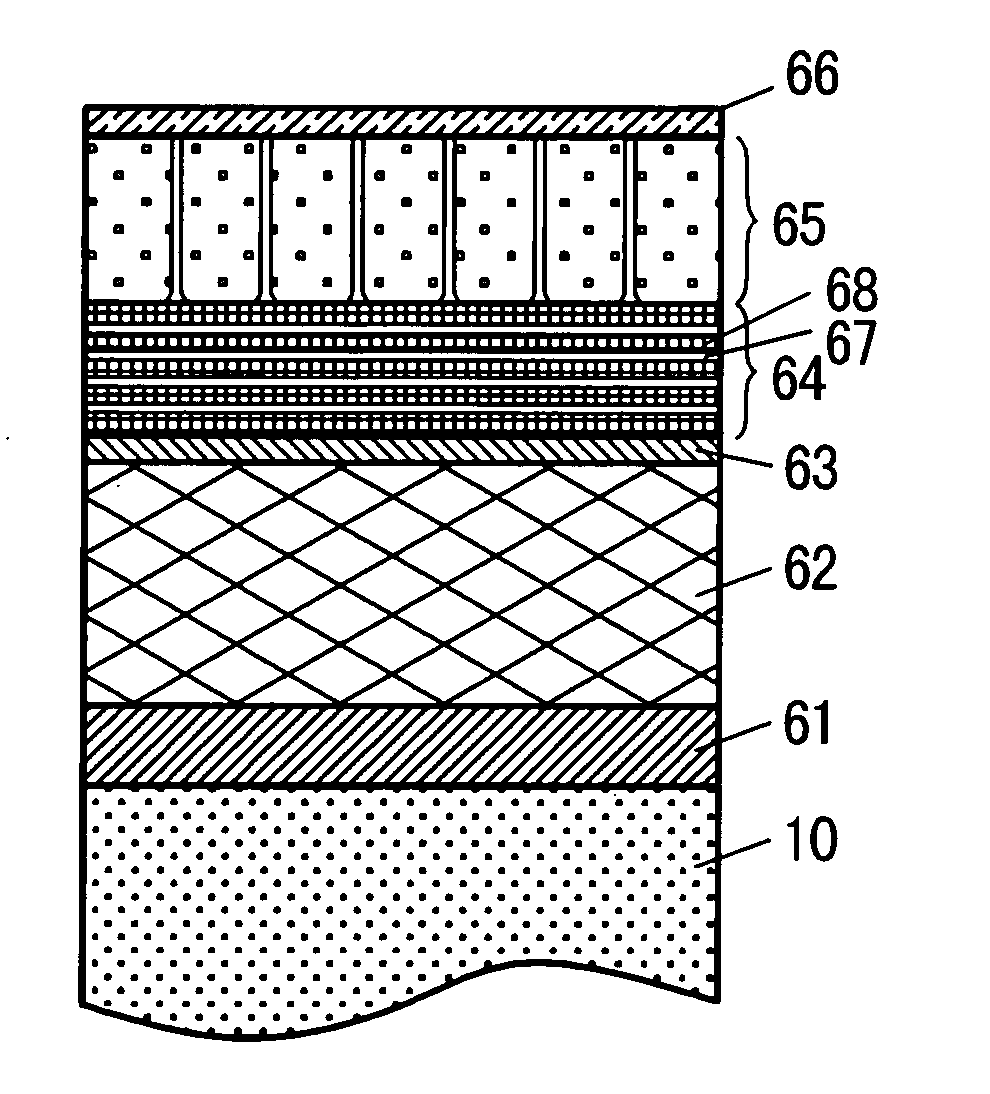

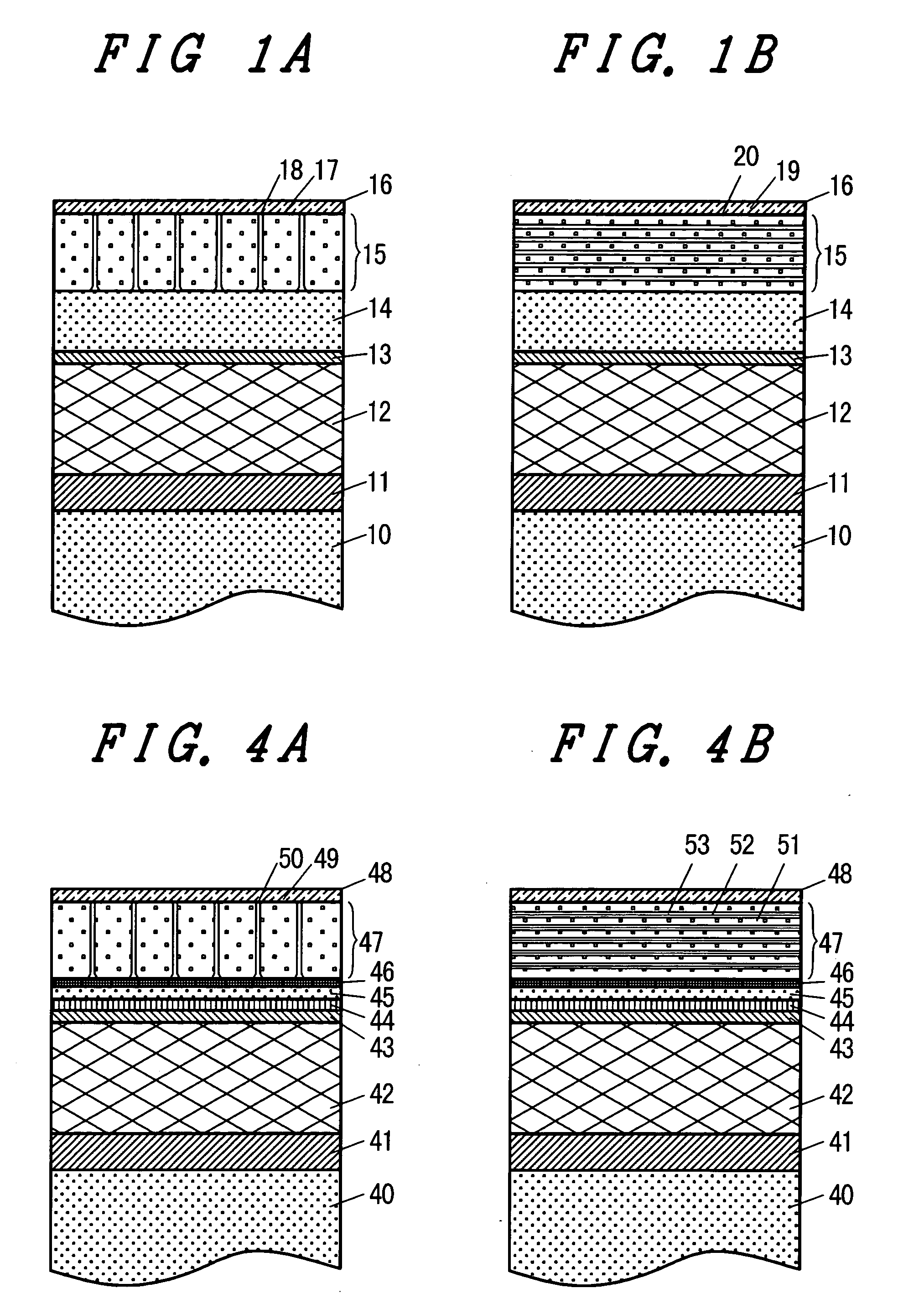

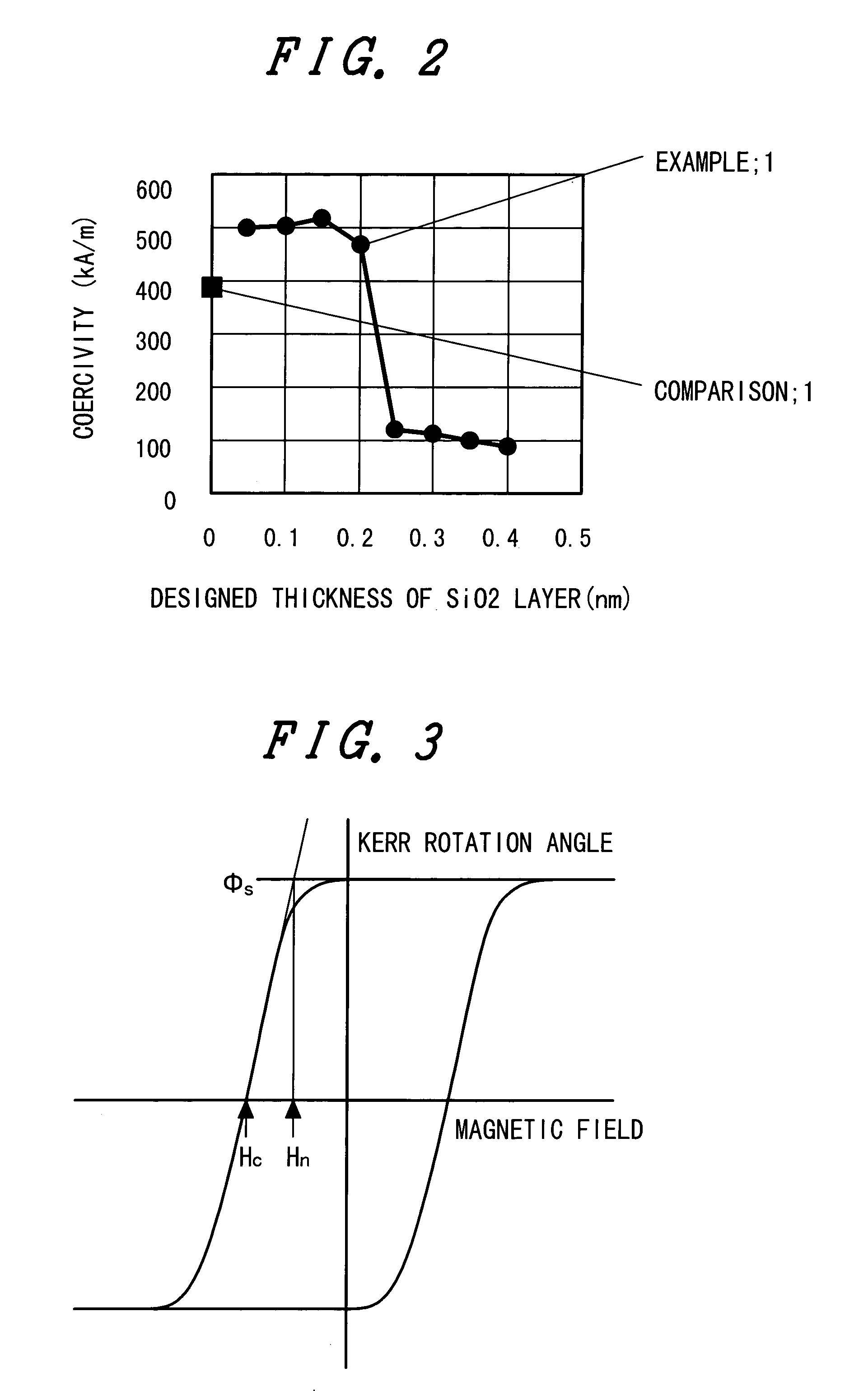

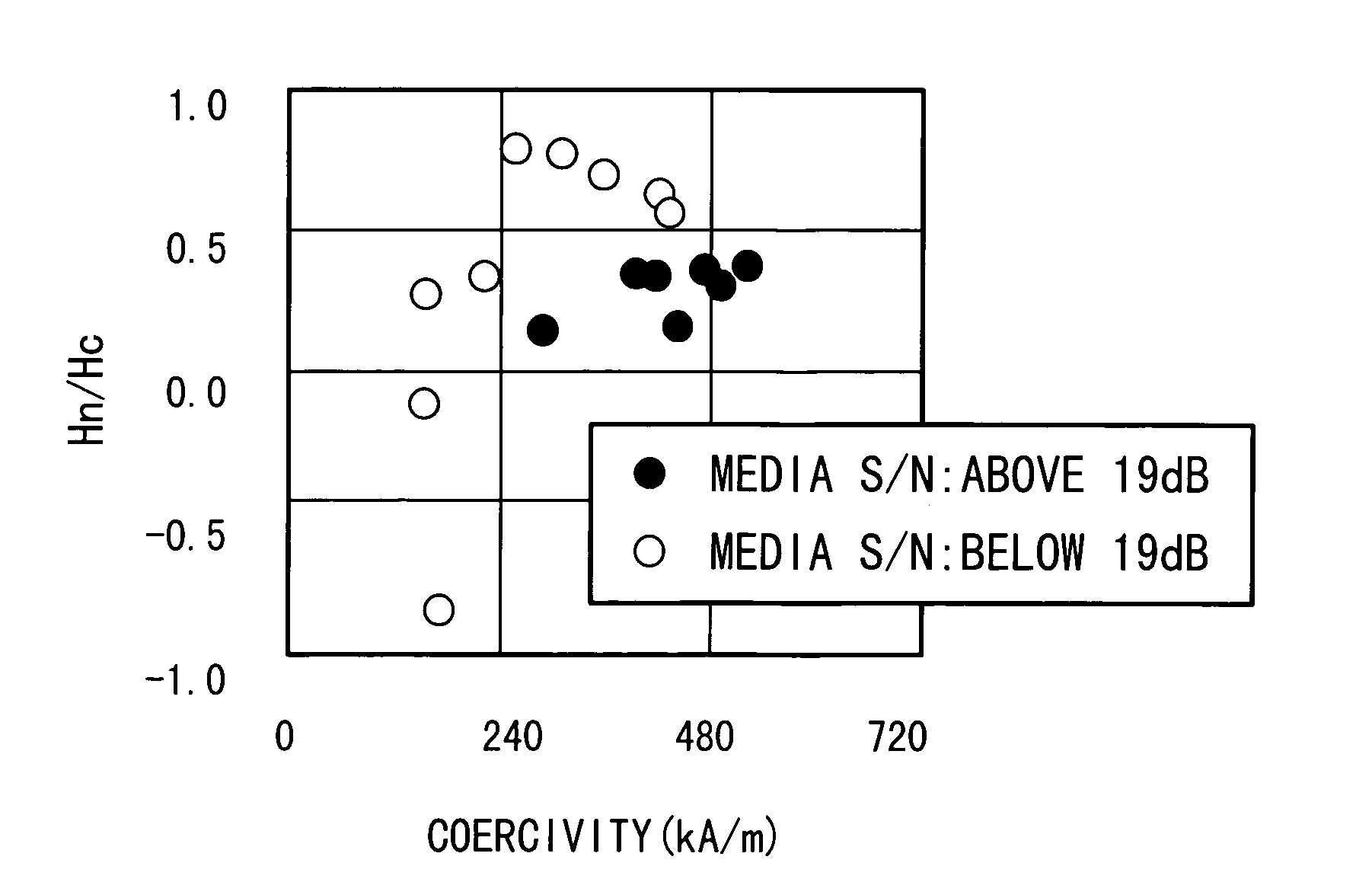

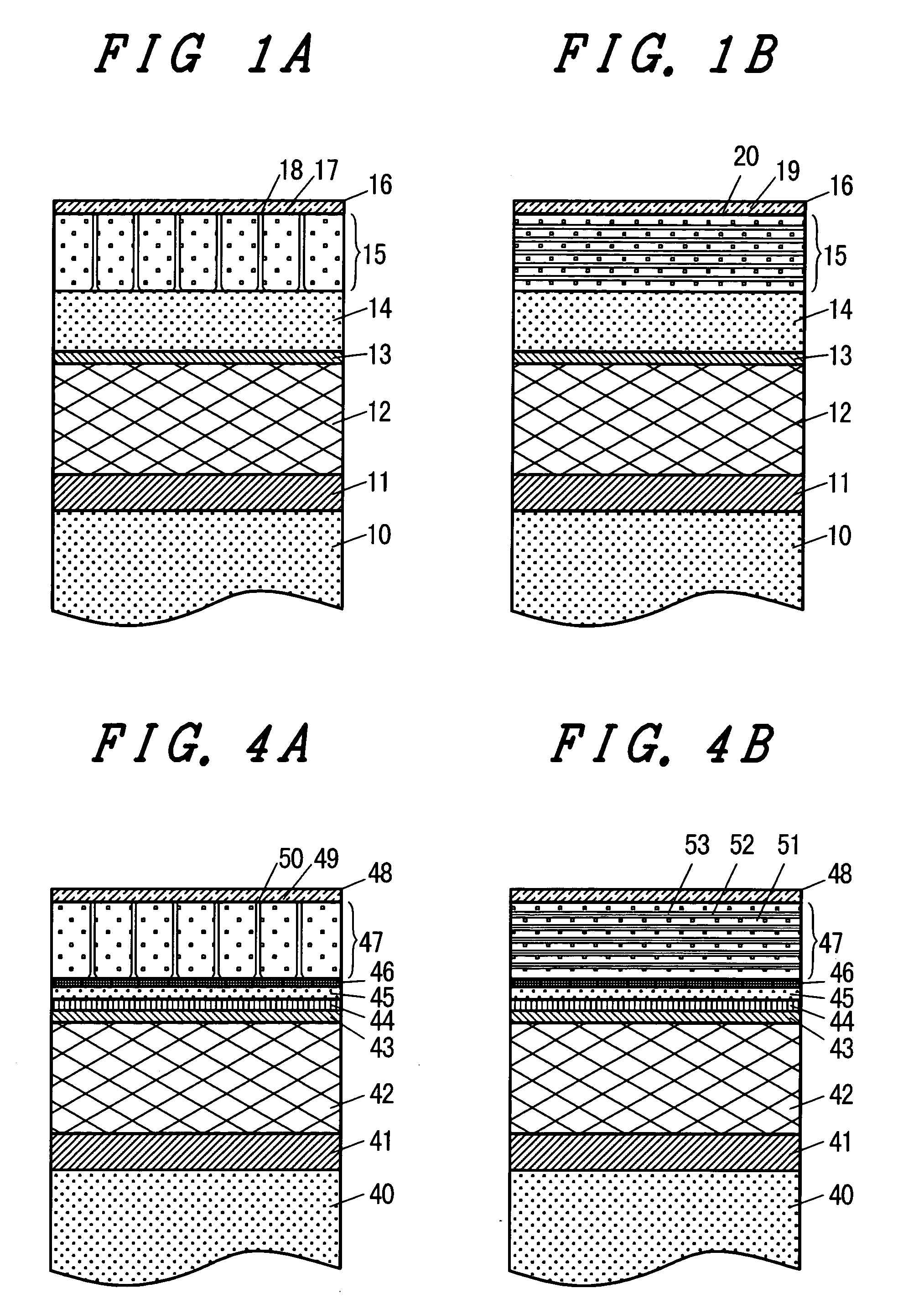

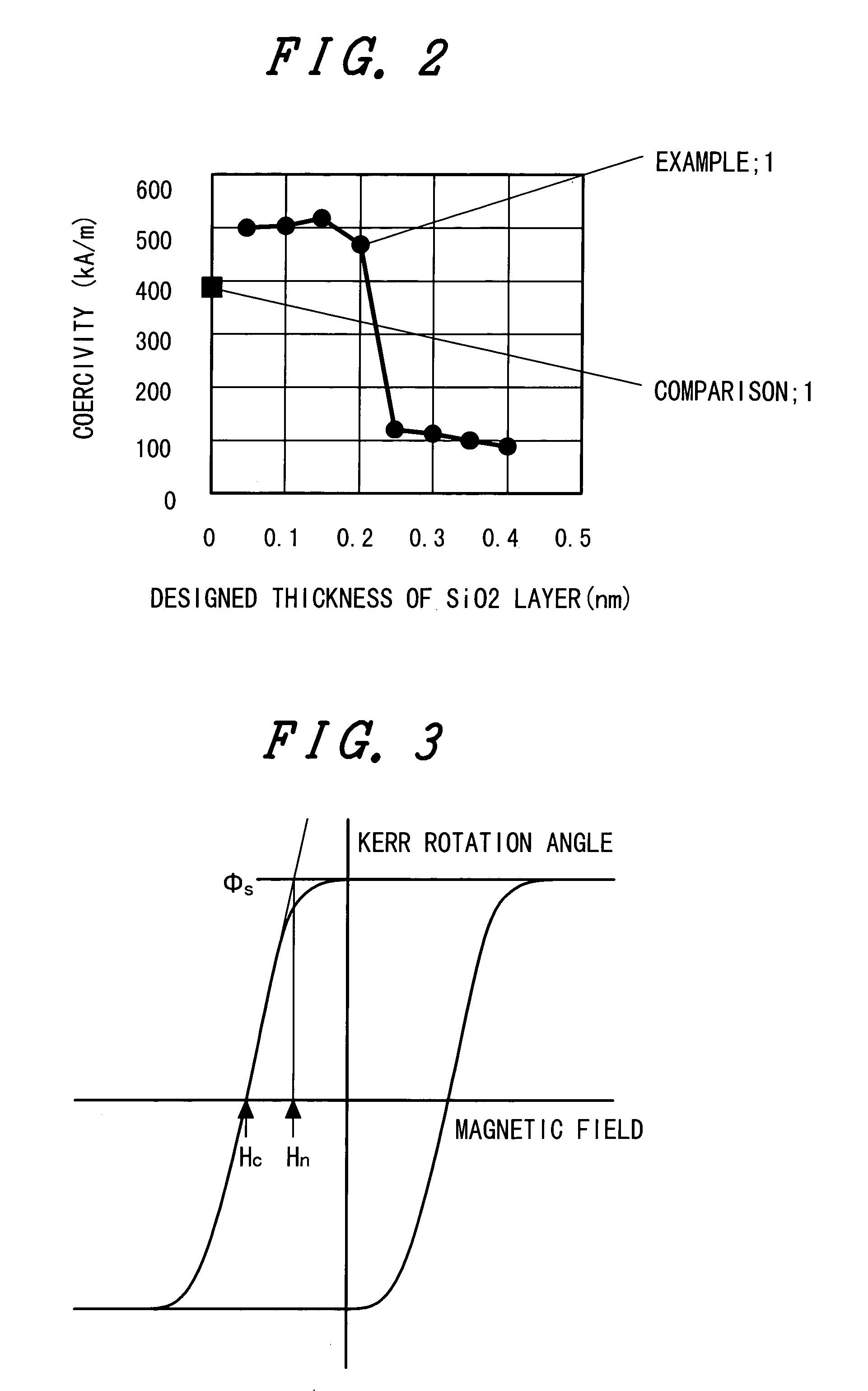

Perpendicular magnetic recording medium and method of manufacturing it

InactiveUS20040191571A1Good effectEfficiently formedLayered productsRecord information storageImage resolutionOptoelectronics

Disclosed are a perpendicular magnetic recording medium with lower medium noise, insusceptible to thermal fluctuation and high recording resolution and a method of manufacturing it. As the step of forming a metal layer at the time of forming a recording layer on a non-magnetic substrate via a plurality of underlayers and the step of forming an oxide layer with an average thickness of 0.2 nm or less are repeated, the crystal grains are magnetically isolated without disturbing the orientation of the crystal grain of the recording layer of the perpendicular magnetic recording medium or without degrading the magnetic characteristic of the crystal grain of the recording layer.

Owner:HITACHI GLOBAL STORAGE TECH JAPAN LTD

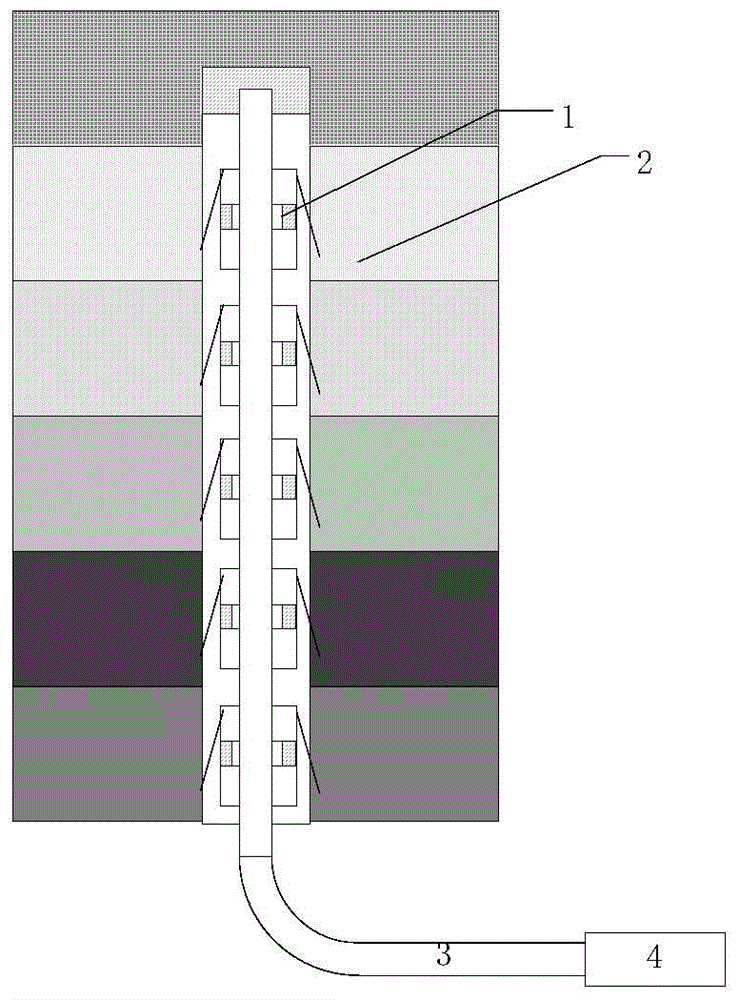

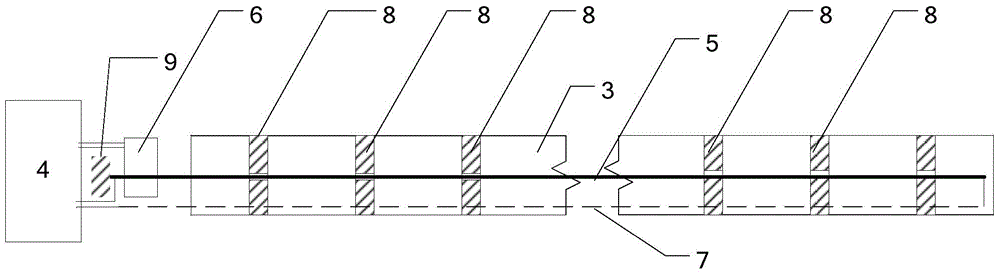

Mining intrinsically safe multi-point displacement meter

ActiveCN104533395AOutstanding FeaturesProminent effectConstructionsUsing electrical meansIntrinsic safetyLongitudinal wave

The invention discloses a mining intrinsically safe multi-point displacement meter with magnetic anchor heads and a magnetostrictive line as displacement sensors. The mining intrinsically safe multi-point displacement meter is structurally composed of the magnetic anchor heads, a flexible measuring bar, an instrument cabin, an echo energy change detection device, magnetostrictive line supporting blocks and an end fixing device, the magnetostrictive line is arranged in the flexible measuring bar, the magnetic anchor heads are fixed to a mine tunnel roof rock layer, a processor sends an electric pulse to the magnetostrictive line through a drive circuit, the electric pulse and the magnetic anchor heads interact to form torsional waves and longitudinal waves, the electric pulse spreads in the magnetostrictive line, the arrival time of an echo wave is detected through the echo energy change detection device, and the roof displacement of the positions of the magnetic anchor heads can be calculated. Compared with a multi-point displacement meter with four to six measuring ropes, the number of multi-point displacement ropes in the same drilled hole of the mine tunnel roof rock layer can be reduced, and the problem that the multi-point displacement ropes in the same drilled hole are complex in mounting and prone to being wound is effectively solved.

Owner:晋能控股电力集团有限公司 +1

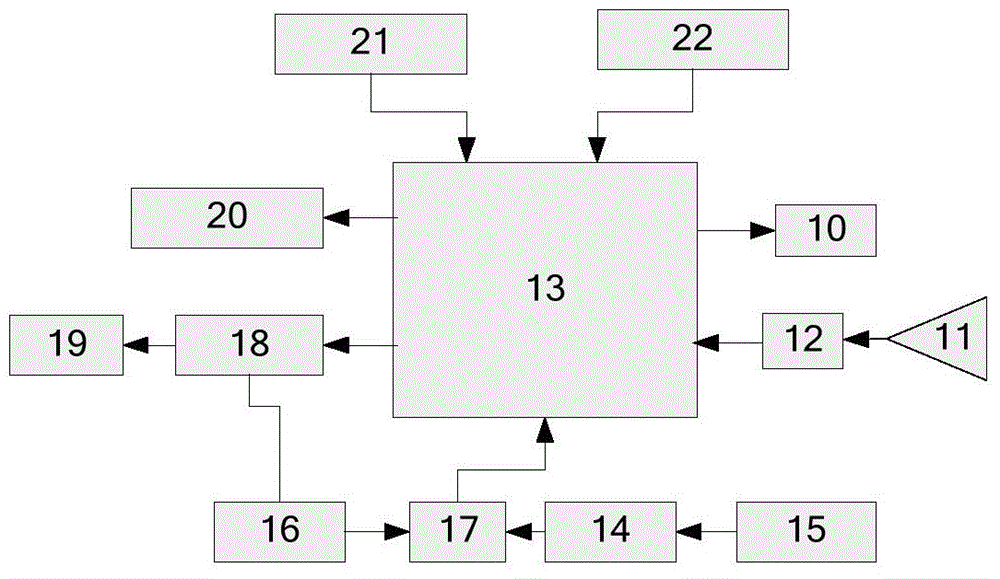

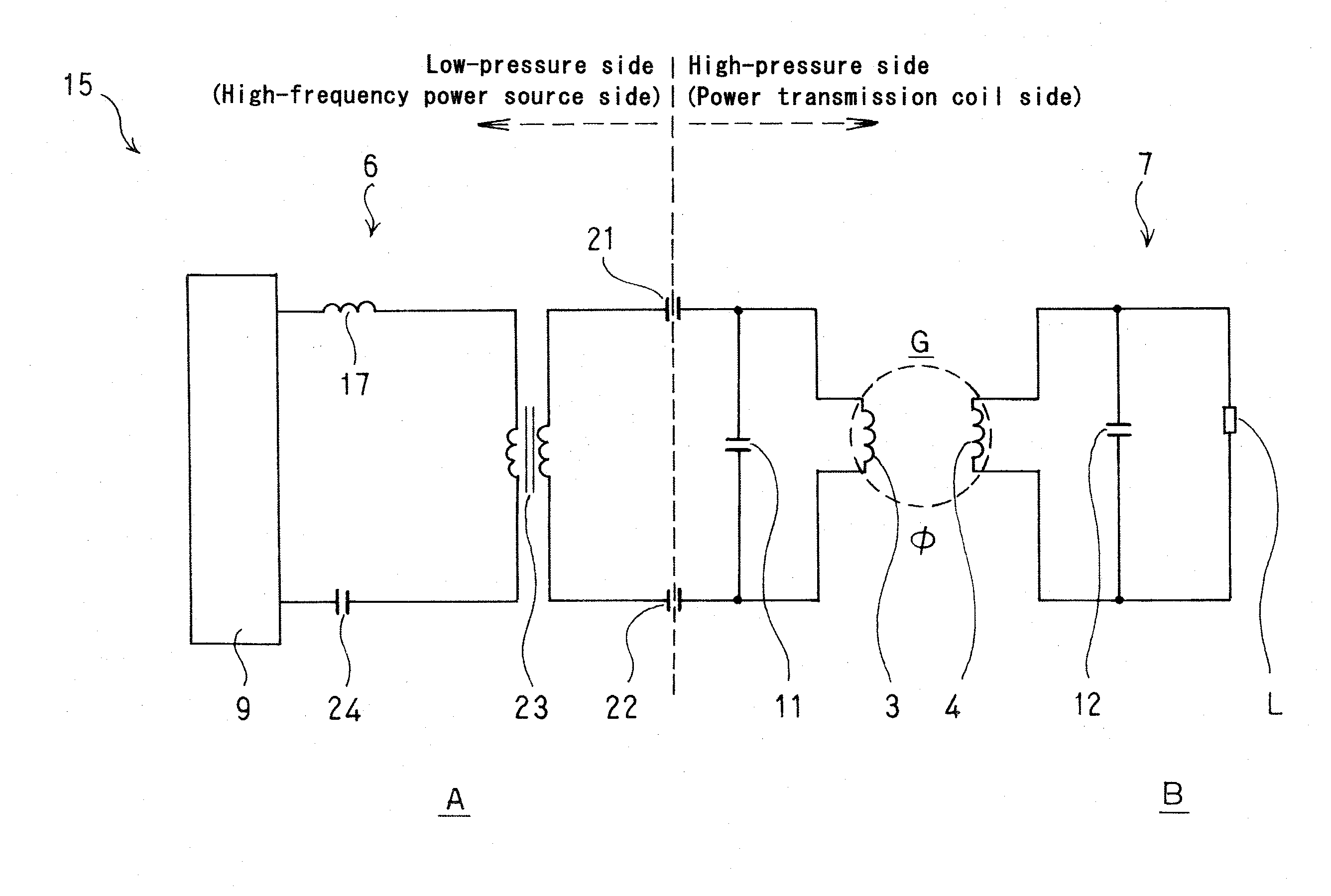

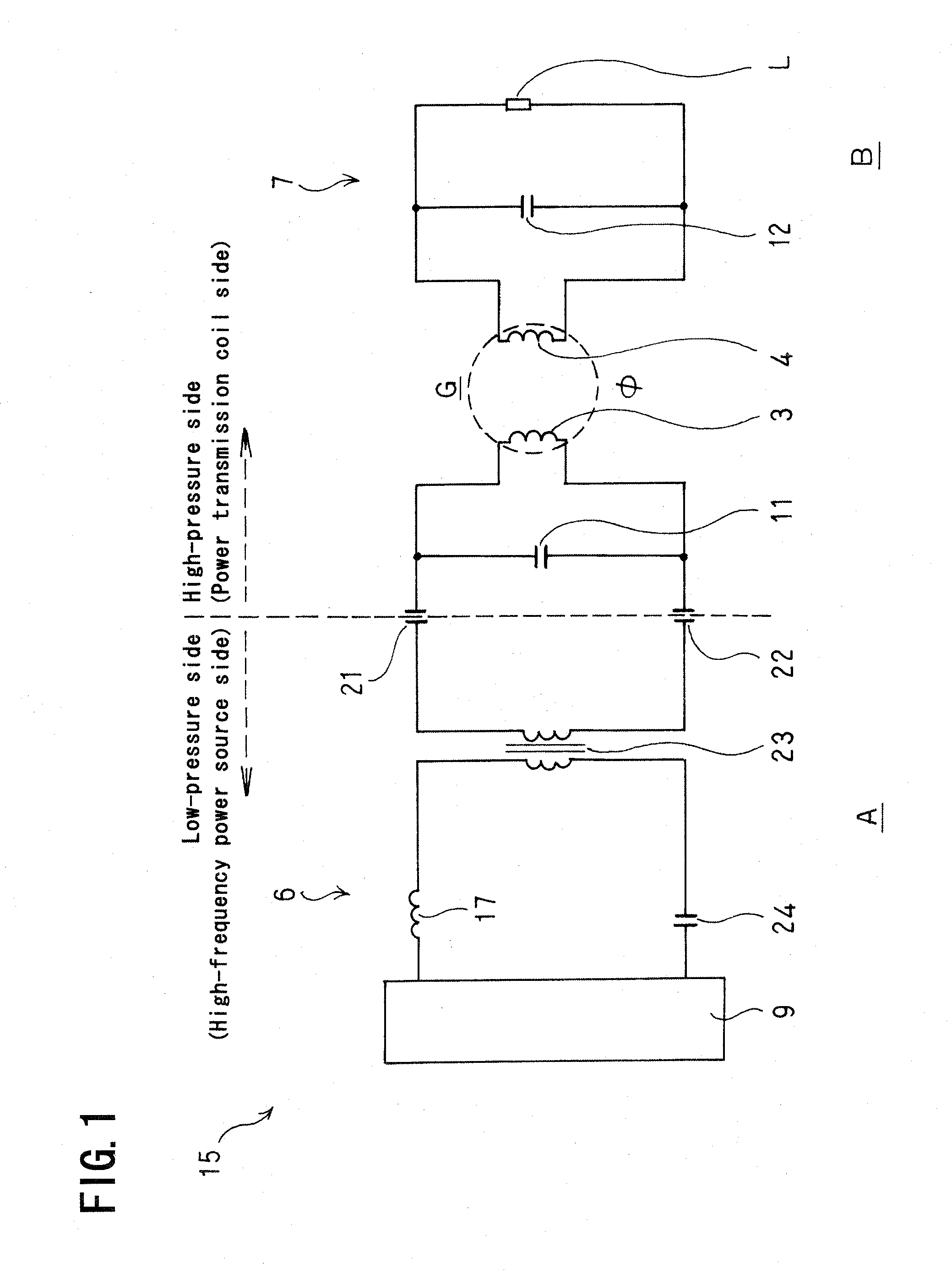

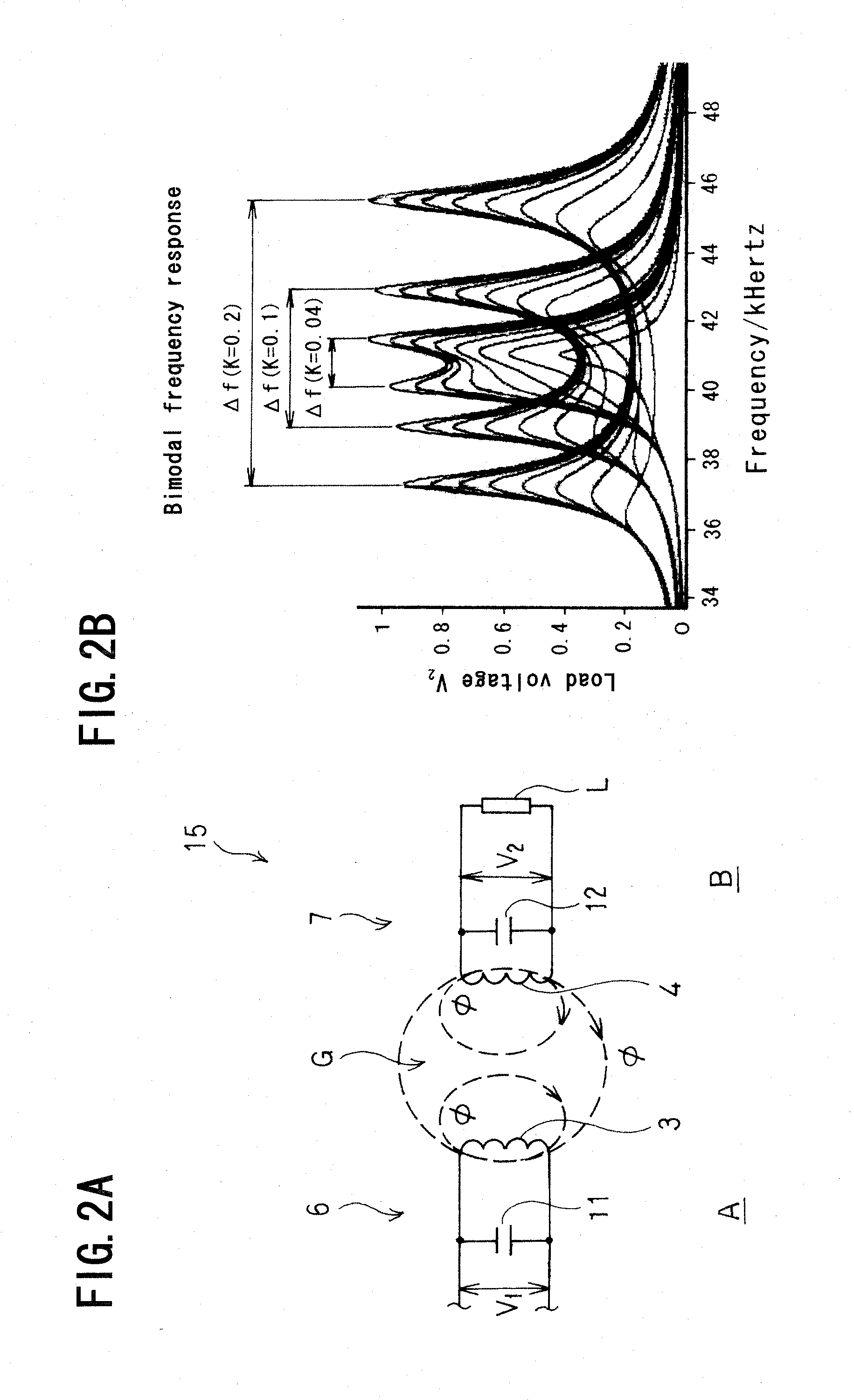

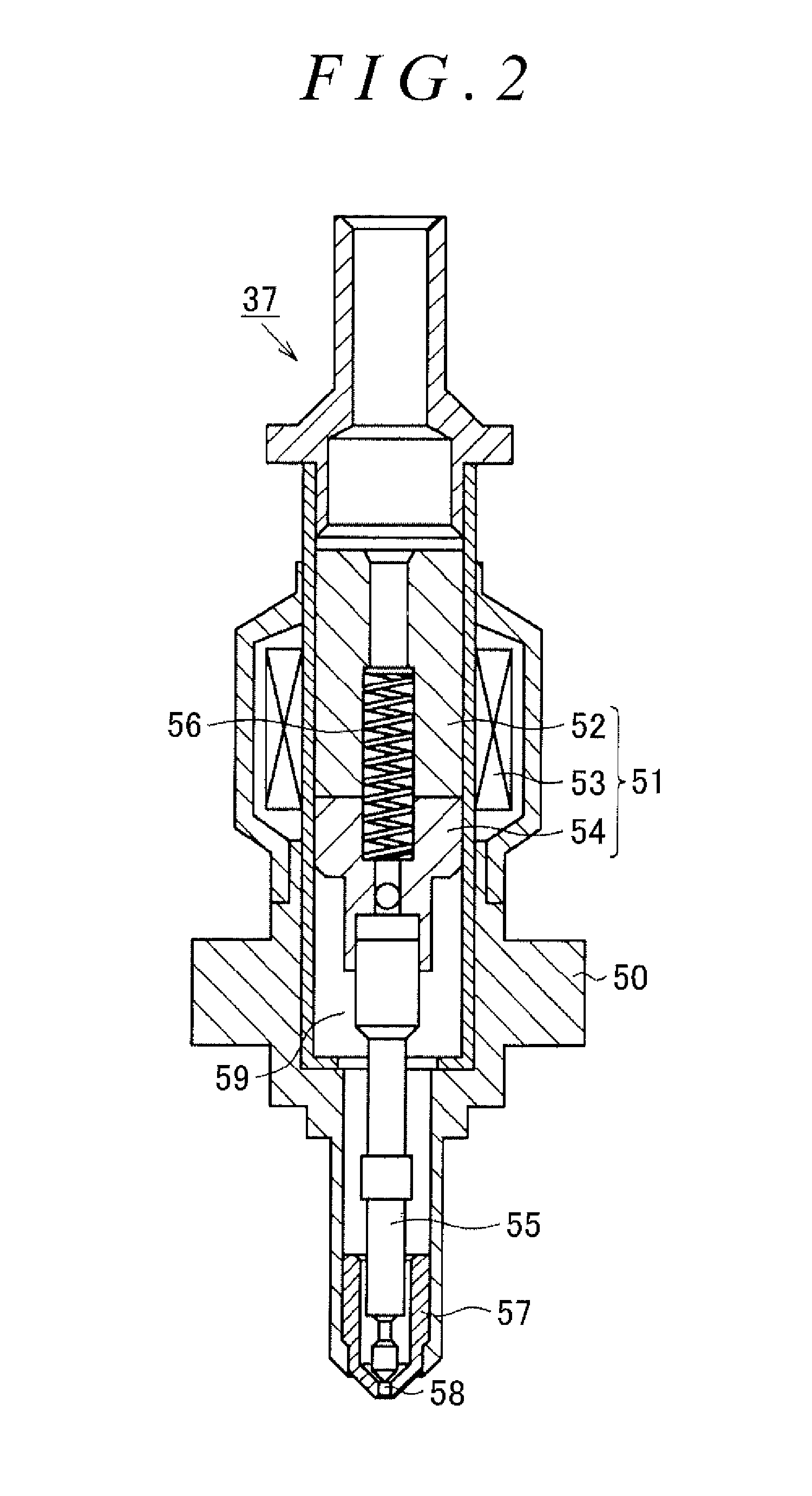

Non-contact power feeding apparatus of magnetic resonance method

InactiveUS20120169135A1Unnecessary electromagnetic radiation can be reducedReduce riskRail devicesElectromagnetic wave systemElectric power transmissionHigh frequency power

In this non-contact power feeding apparatus, a power feeding circuit is provided with a power transmission coil and a first parallel capacitor to provide a first parallel resonance circuit, while a power receiving circuit is provided with a power receiving coil and a second parallel capacitor to provide a second parallel resonance circuit. Both parallel resonant circuits are set to have the same resonance frequency and a power frequency of a high-frequency power source in the power feeding side circuit is set to be the same as this resonance frequency. A circuit section including the high-frequency power source and a circuit section including the first parallel capacitor and the power transmission coil are connected by the electric field coupling of electric field coupling capacitors.

Owner:SHOWA AIRCRAFT INDUSTRY

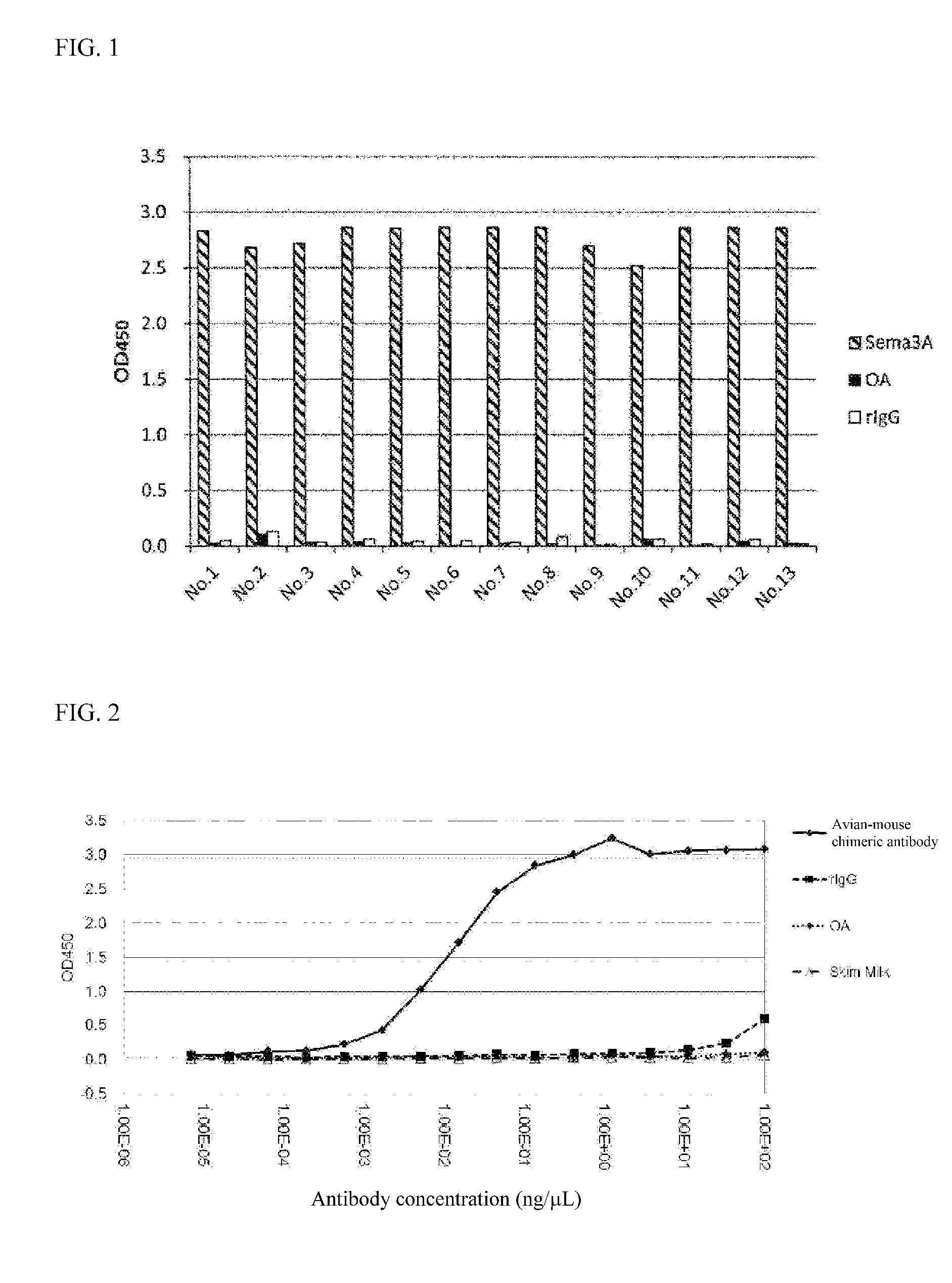

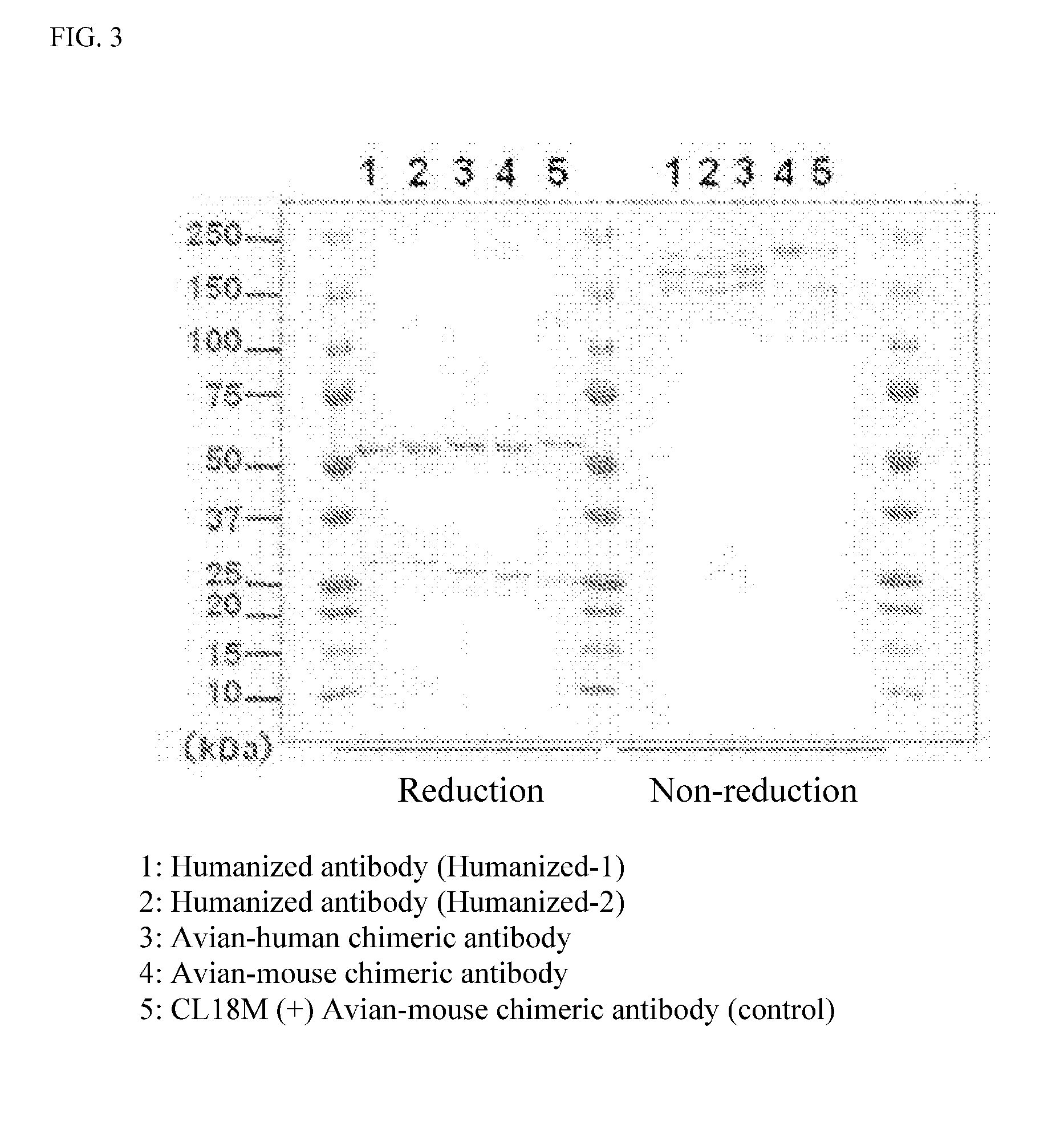

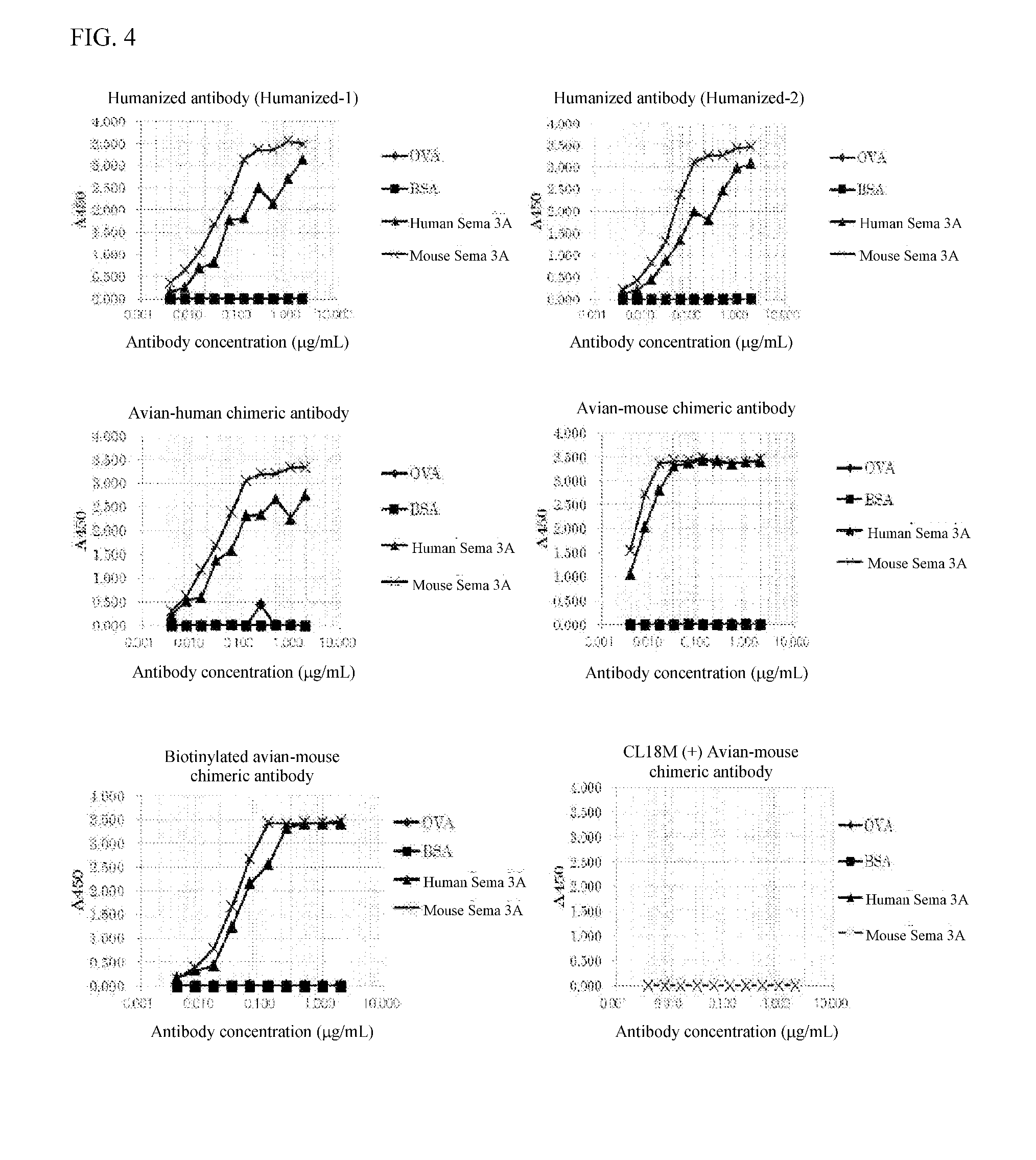

Anti-semaphorin 3a antibody and treatment of alzheimer's disease and inflammatory immune diseases using same

ActiveUS20150368327A1Effectively prevent and treatSymptoms improvedAntibacterial agentsSenses disorderDisseminated coagulopathyAutoimmune disease

The present invention mainly addresses the problem of providing an antibody against semaphorin 3A protein, said antibody enabling effective prevention and / or treatment of a disease, in which Sema 3A protein participates, such as a neurodegenerative disease, autoimmune disease, inflammatory disease, cancer, infectious disease, etc. or disseminated intravascular coagulation syndrome. An anti-Sema 3A antibody comprising CDRs having specific amino acid sequences (SEQ ID NOS: 1-6, 60-62, 64-66, 68-70, 72-74, 76-78, 80-82, 84-86 and 88-90) enables effective prevention and / or treatment of a disease, in which Sema 3A protein participates, such as a neurodegenerative disease, autoimmune disease, inflammatory disease, cancer, infectious disease, etc. or disseminated intravascular coagulation syndrome and, therefore, remarkably ameliorates symptoms associated with such a disease.

Owner:CHIOME BIOSCIENCE INC +1

Perpendicular magnetic recording medium and method of manufacturing it

InactiveUS7033686B2Magnetic reversal units are reduced drasticallyLow coercivityRecord information storageCoating by sputteringImage resolutionOptoelectronics

Disclosed are a perpendicular magnetic recording medium with lower medium noise, insusceptible to thermal fluctuation and high recording resolution and a method of manufacturing it. As the step of forming a metal layer at the time of forming a recording layer on a non-magnetic substrate via a plurality of underlayers and the step of forming an oxide layer with an average thickness of 0.2 nm or less are repeated, the crystal grains are magnetically isolated without disturbing the orientation of the crystal grain of the recording layer of the perpendicular magnetic recording medium or without degrading the magnetic characteristic of the crystal grain of the recording layer.

Owner:HITACHI GLOBAL STORAGE TECH JAPAN LTD

Polyethylene Powder, Microporous Membrane, and Fiber

ActiveUS20150249242A1Excellent in resistance to end breakage and dimensional stability and acid resistanceIncrease resistanceLead-acid accumulatorsCell component detailsMagnesiumFiber

It is intended to provide a polyethylene powder which can offer a fiber excellent in resistance to end breakage, dimensional stability, and acid resistance and / or a microporous membrane excellent in dimensional stability and acid resistance, and a microporous membrane and a fiber which are obtained by forming the polyethylene powder. The present invention provides a polyethylene powder comprising: 0.5 ppm or higher and 3,000 ppm or lower of aluminum hydroxide having an average particle size smaller than 50 μm; and 0.5 ppm or higher and 12 ppm or lower of a magnesium element, wherein the polyethylene has a viscosity-average molecular weight of 100,000 or larger.

Owner:ASAHI KASEI CHEM CORP

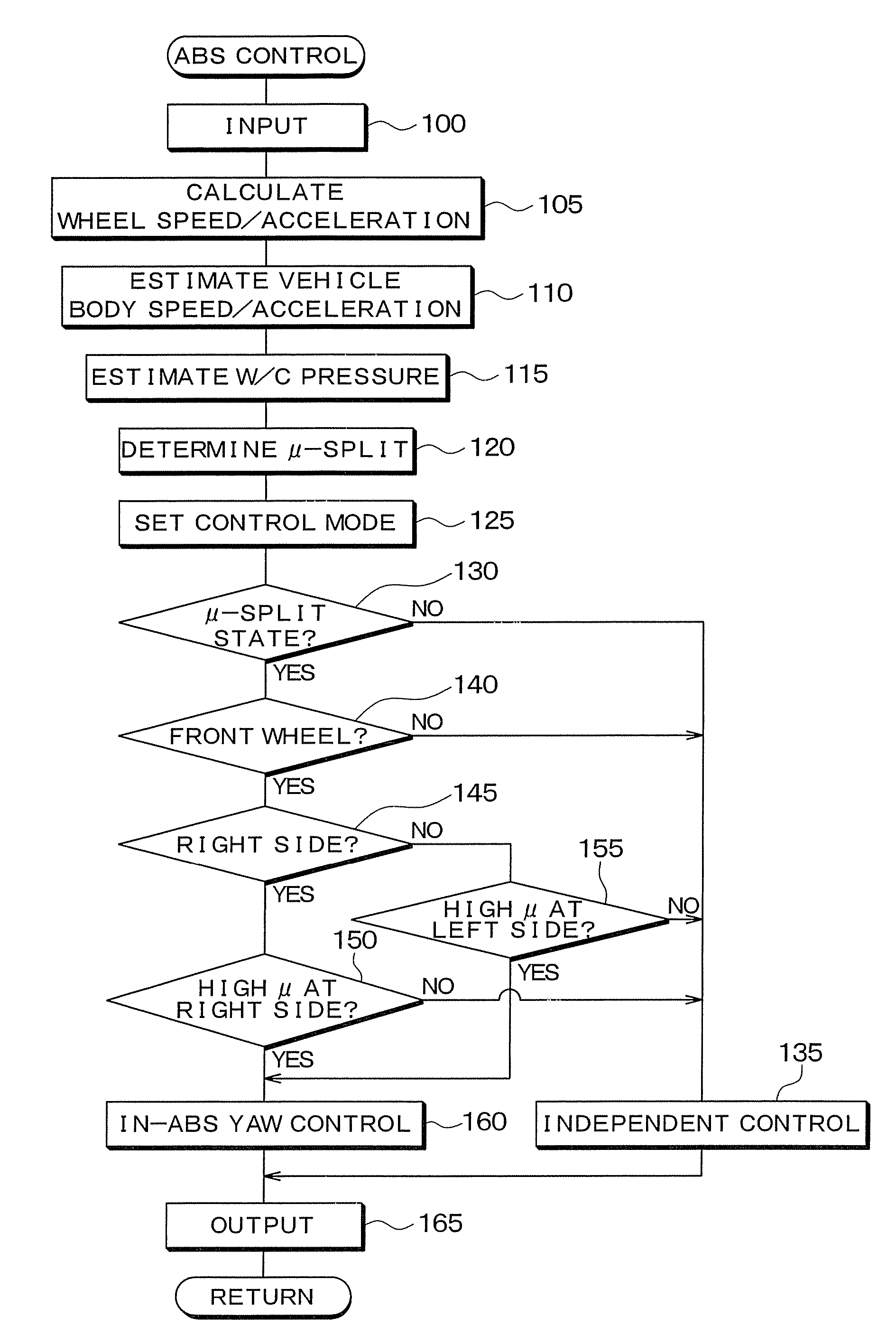

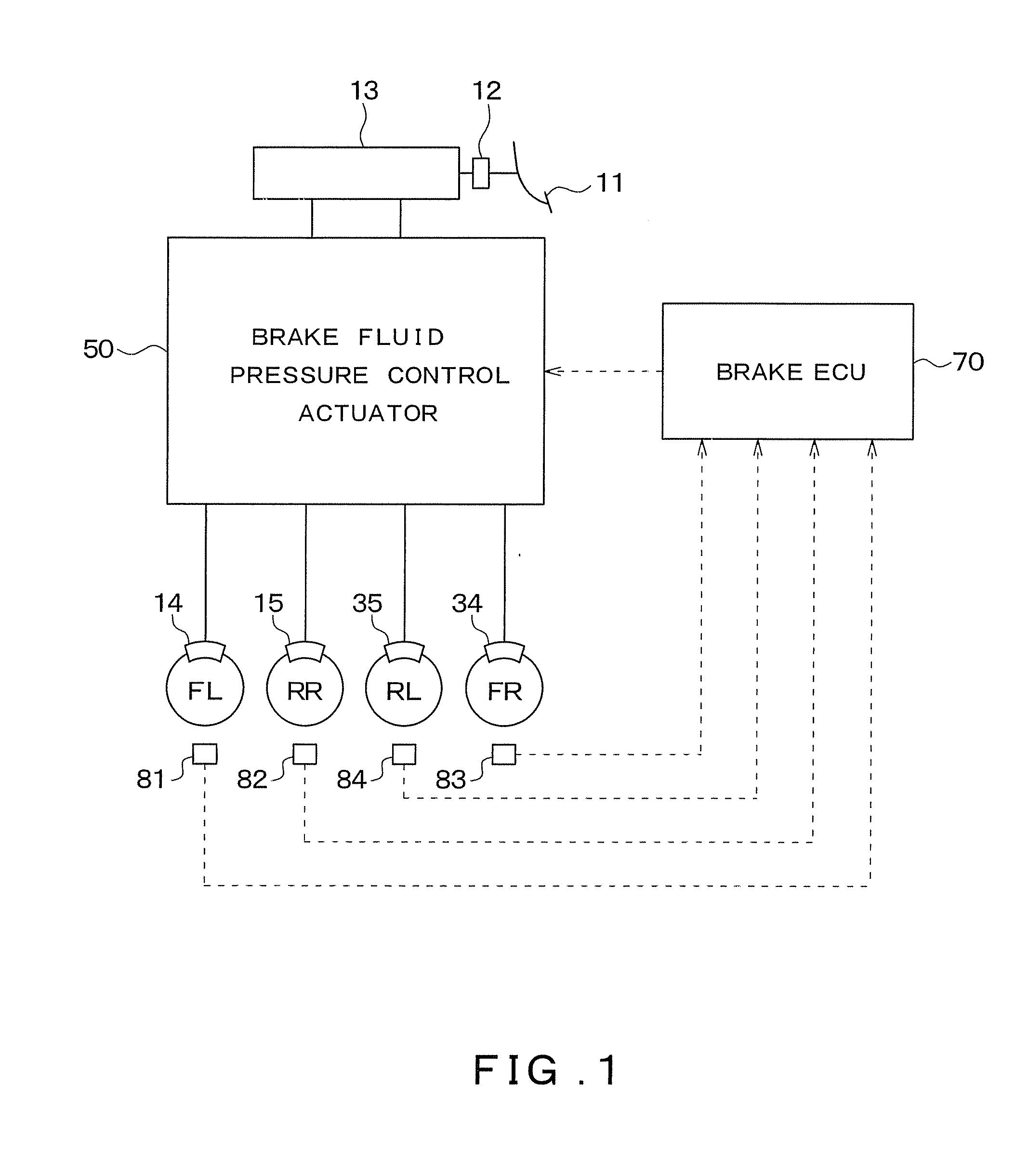

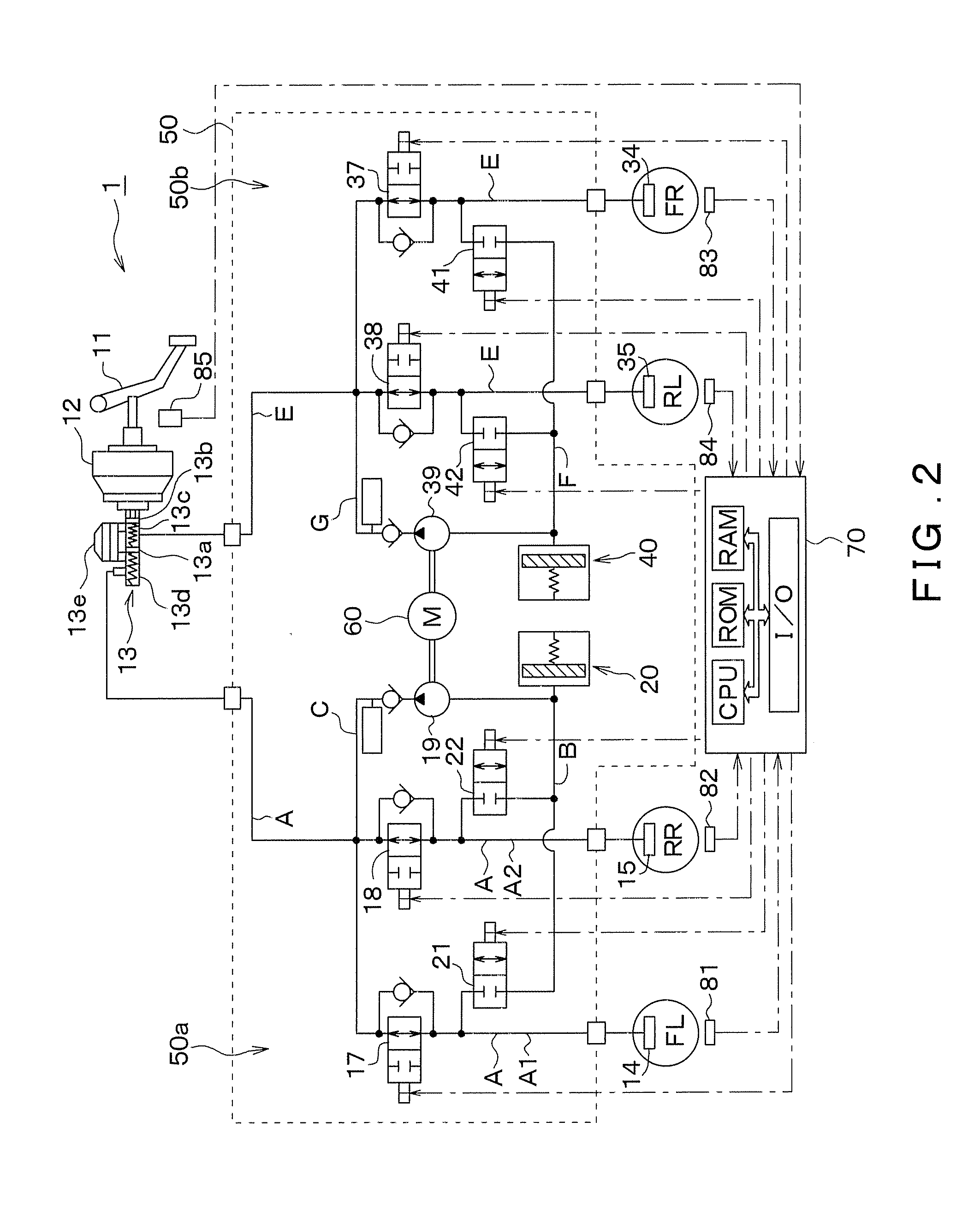

Anti-skid control device and automatic brake control device

ActiveUS20090095551A1Prominent effectAvoid differencesDigital data processing detailsAutomatic initiationsAutomatic brakingEngineering

An anti-skid control device or an automatic brake control device gradually increases a W / C pressure for a boost control valve for a front wheel FR or FL on a high-μ surface, by repeating a cycle in which the differential pressure for the boost control valve at the high-μ surface side is kept at the first differential pressure for a first period, and after that kept at the second differential pressure for a second period. Therefore, it is possible to suppress the individual variation in the capability for W / C pressure boosting, and accordingly to suppress the difference of the W / C pressures between the right front wheel and the left front wheel. Thus, it is possible to suppress the yaw torque applied to the vehicle and therefore to suppress the spin of the vehicle.

Owner:ADVICS CO LTD

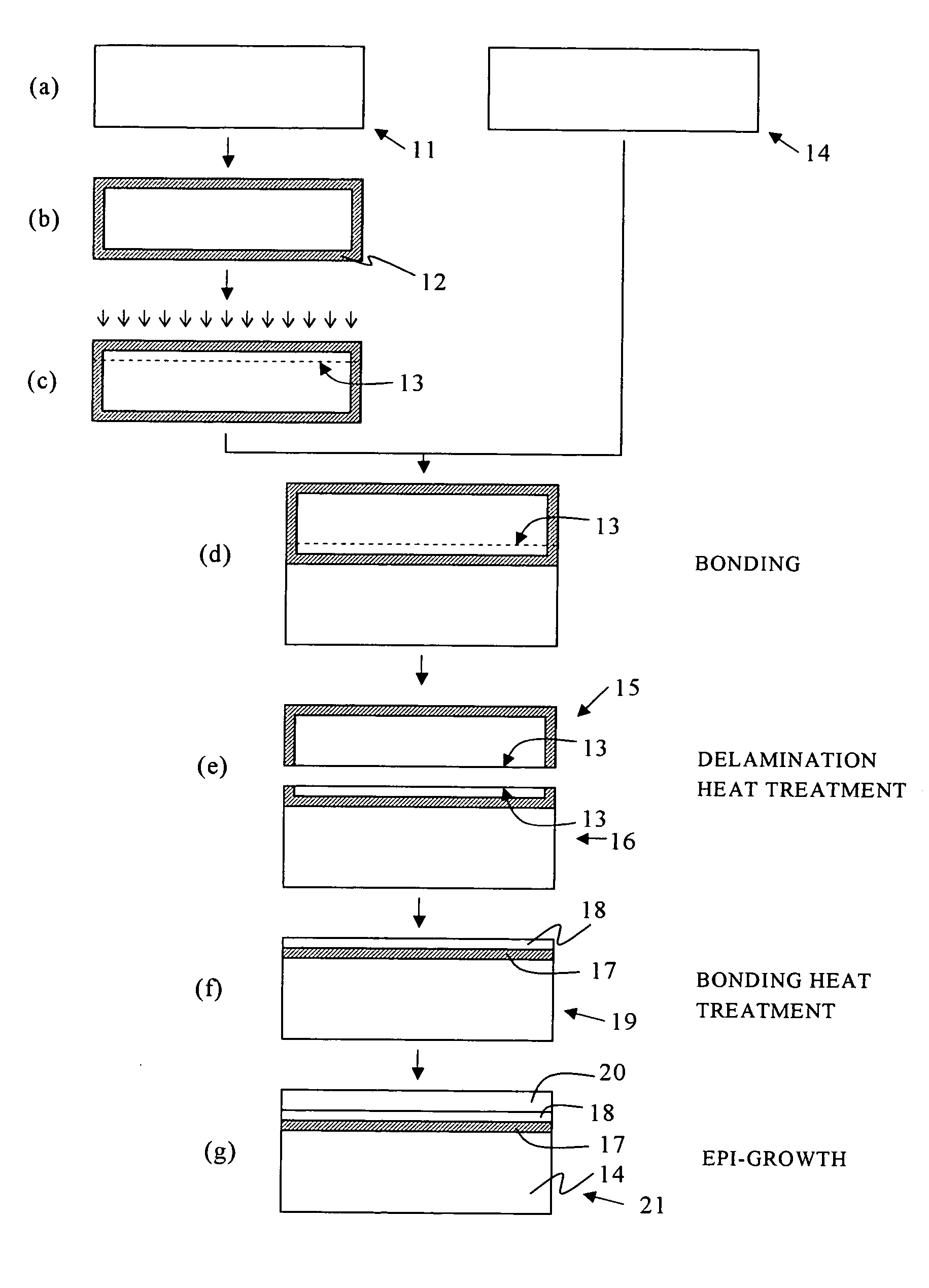

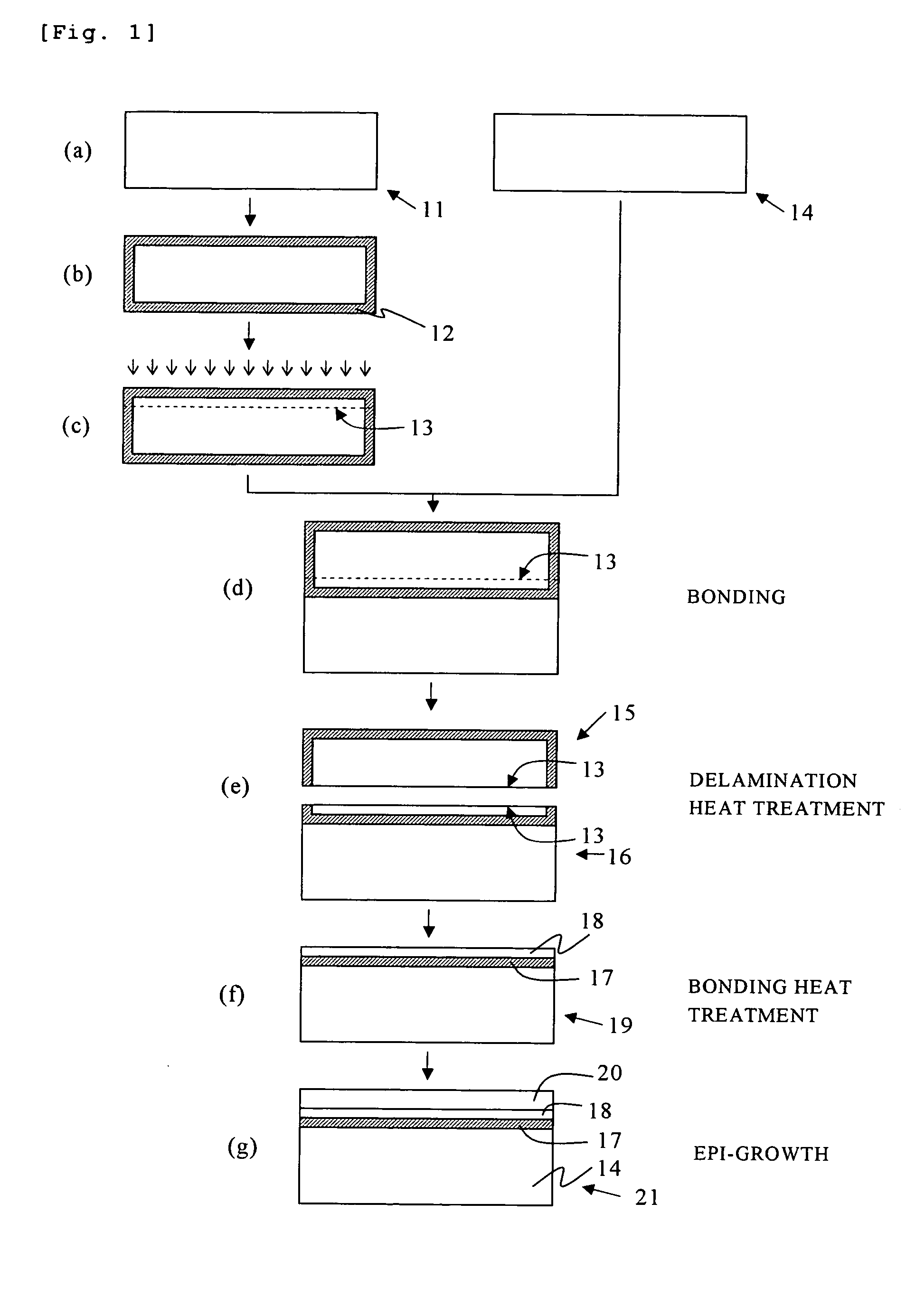

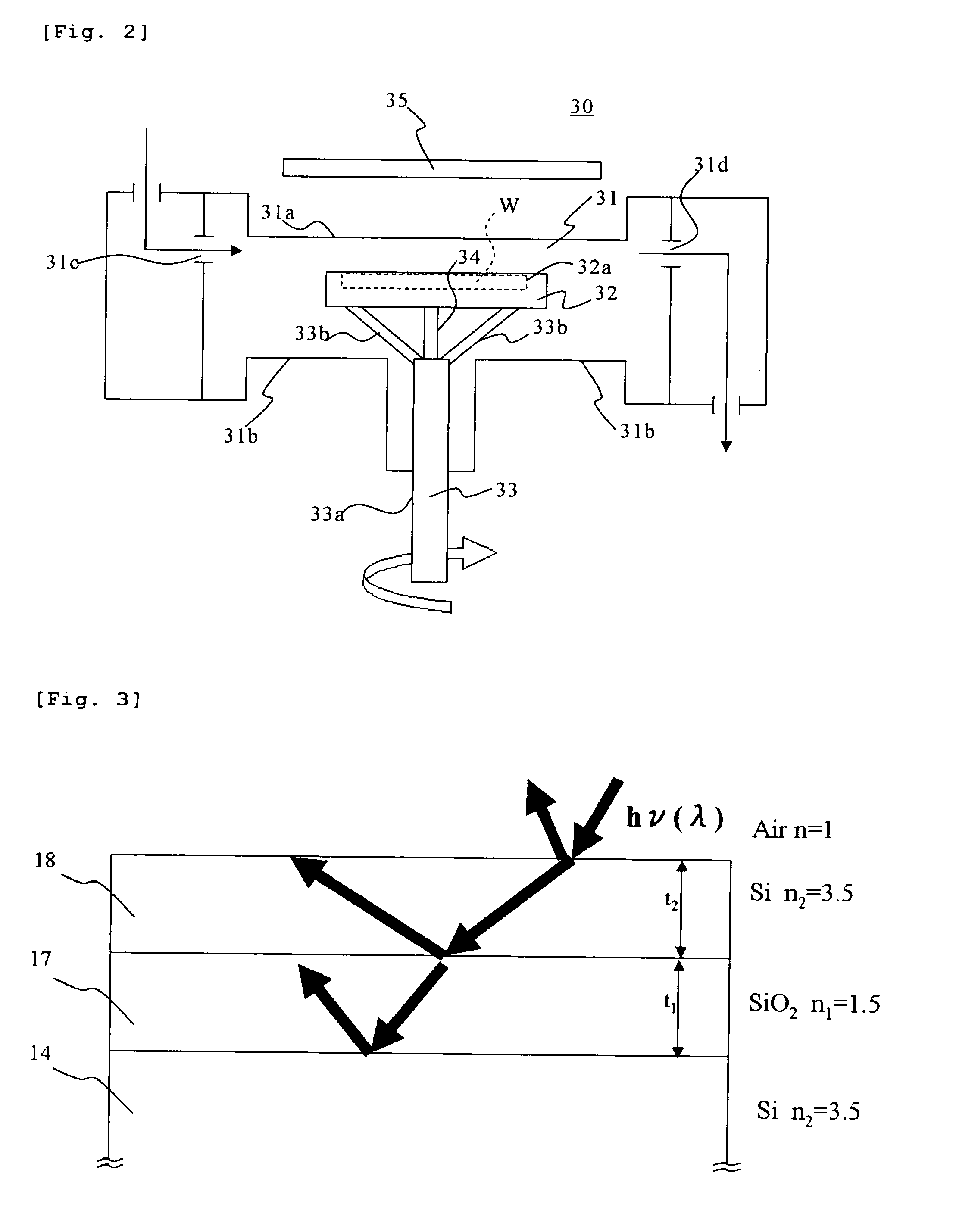

Method For Manufacturing Soi Wafer and Soi Wafer

ActiveUS20090042364A1Less slip dislocationIncreasing the thicknessSemiconductor/solid-state device manufacturingWaferingLength wave

The present invention provides a method for manufacturing an SOI wafer in which a thickness of an SOI layer is increased by growing an epitaxial layer on the SOI layer of the SOI wafer having an oxide film and the SOI layer formed on a base wafer, wherein the epitaxial growth is performed in such a manner that a reflectivity of a surface of the SOI wafer on which the epitaxial layer is grown in a wavelength region of a heating light at the start of the epitaxial growth falls within the range of 30% to 80%. As a result, in the method for manufacturing the SOI wafer in which a thickness of the SOI layer is increased by growing the epitaxial layer on the SOI layer of the SOI wafer having the oxide film and the SOI layer formed on the base wafer, a method for manufacturing a high-quality SOI wafer with less slip dislocation and others is provided.

Owner:SHIN-ETSU HANDOTAI CO LTD

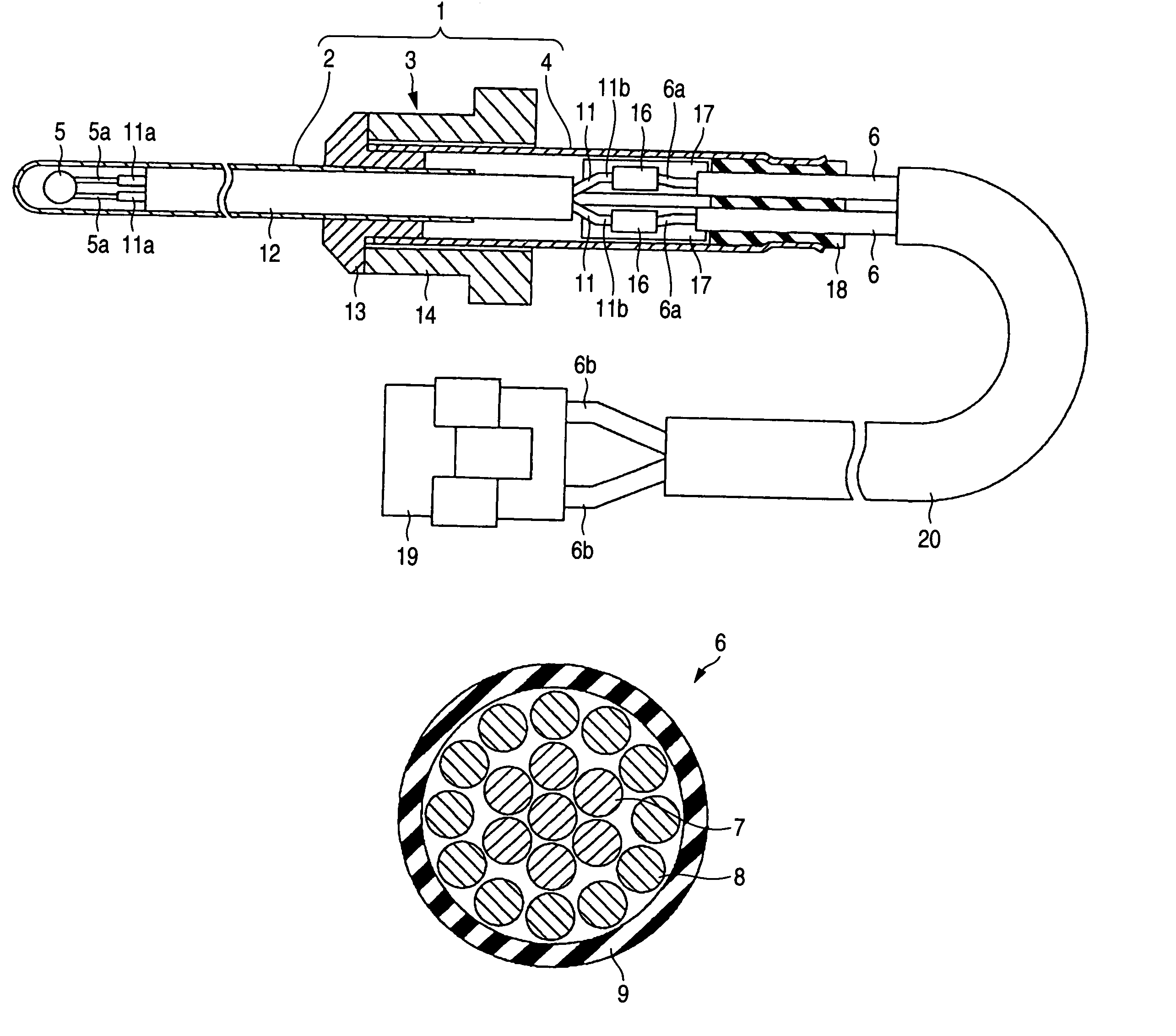

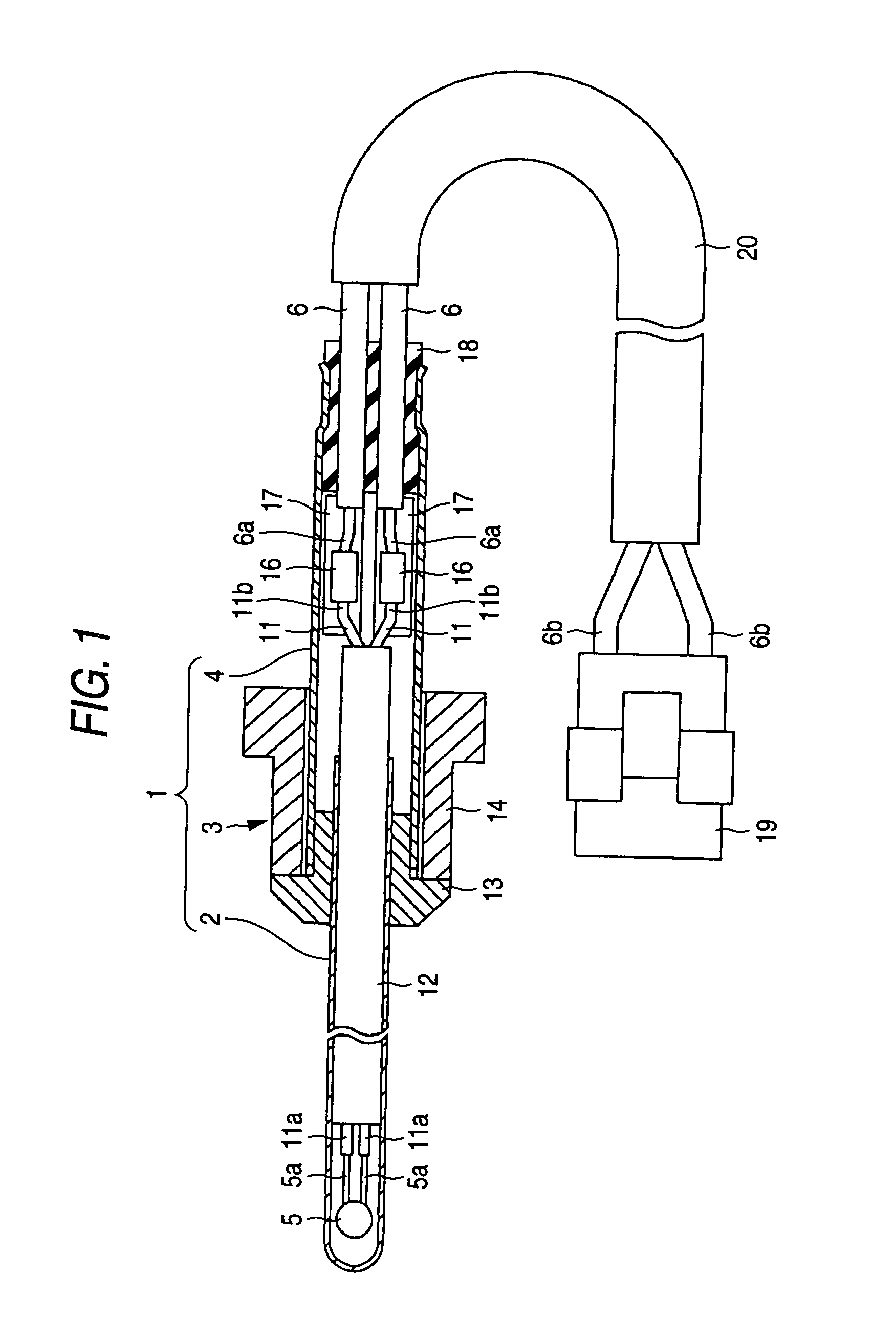

Temperature sensor

InactiveUS6997604B2Good precisionIncreased durabilityThermometer detailsTemperature measurement in motorsElectricityElectrical conductor

A temperature sensor comprising: a housing; a thermo-sensitive element housed in the housing for outputting electric characteristics varying with a temperature, as an electric signal; and a pair of lead wires connected at their one-side ends with the thermo-sensitive element for extracting the electric signal from the thermo-sensitive element to an outside of the housing, wherein at least one of the lead wires is made of a mixed twisted wire including: first electric wires made of a first conductor containing copper; and second electric wires made of a second conductor having a higher bending resistance and a tensile strength than those of the first conductor.

Owner:NGK SPARK PLUG CO LTD

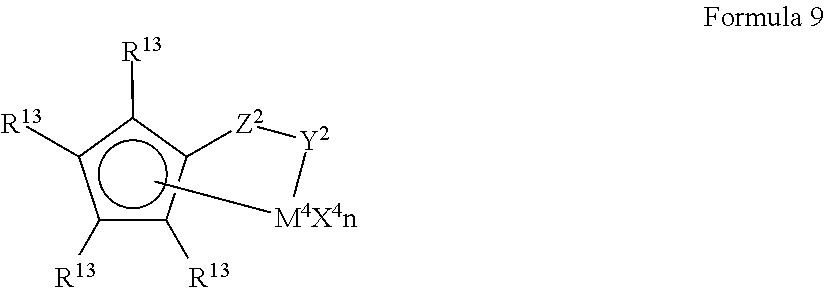

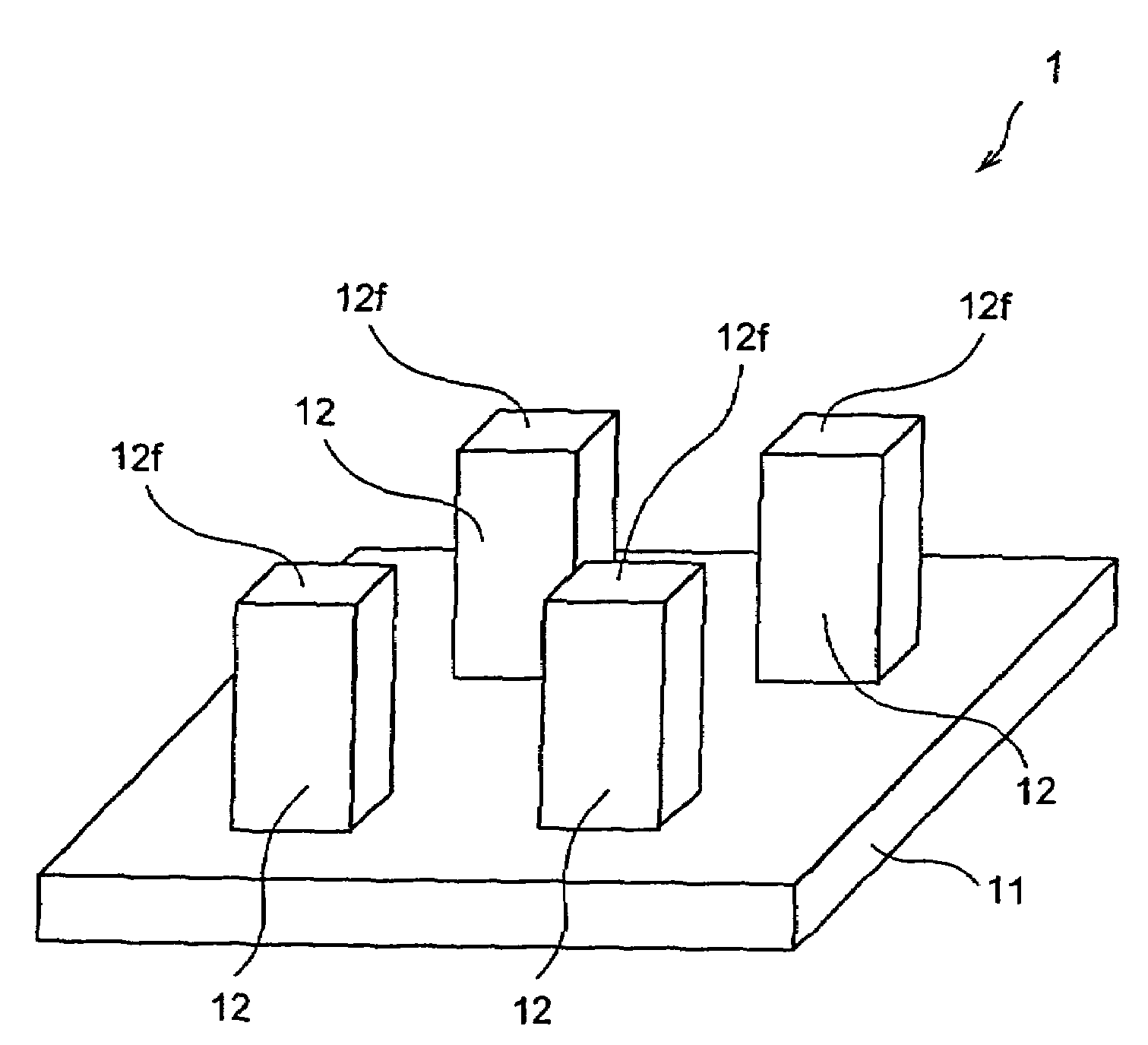

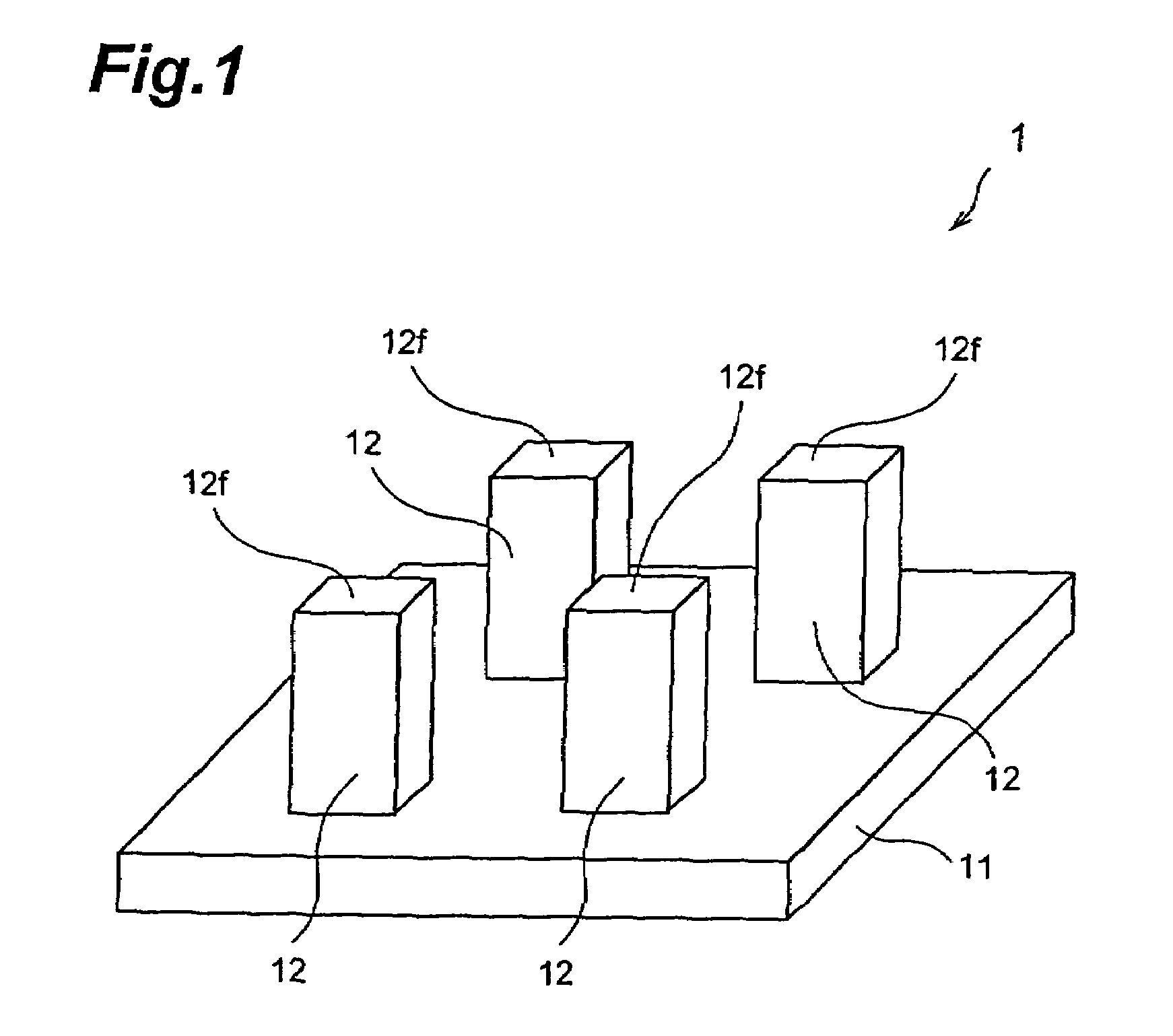

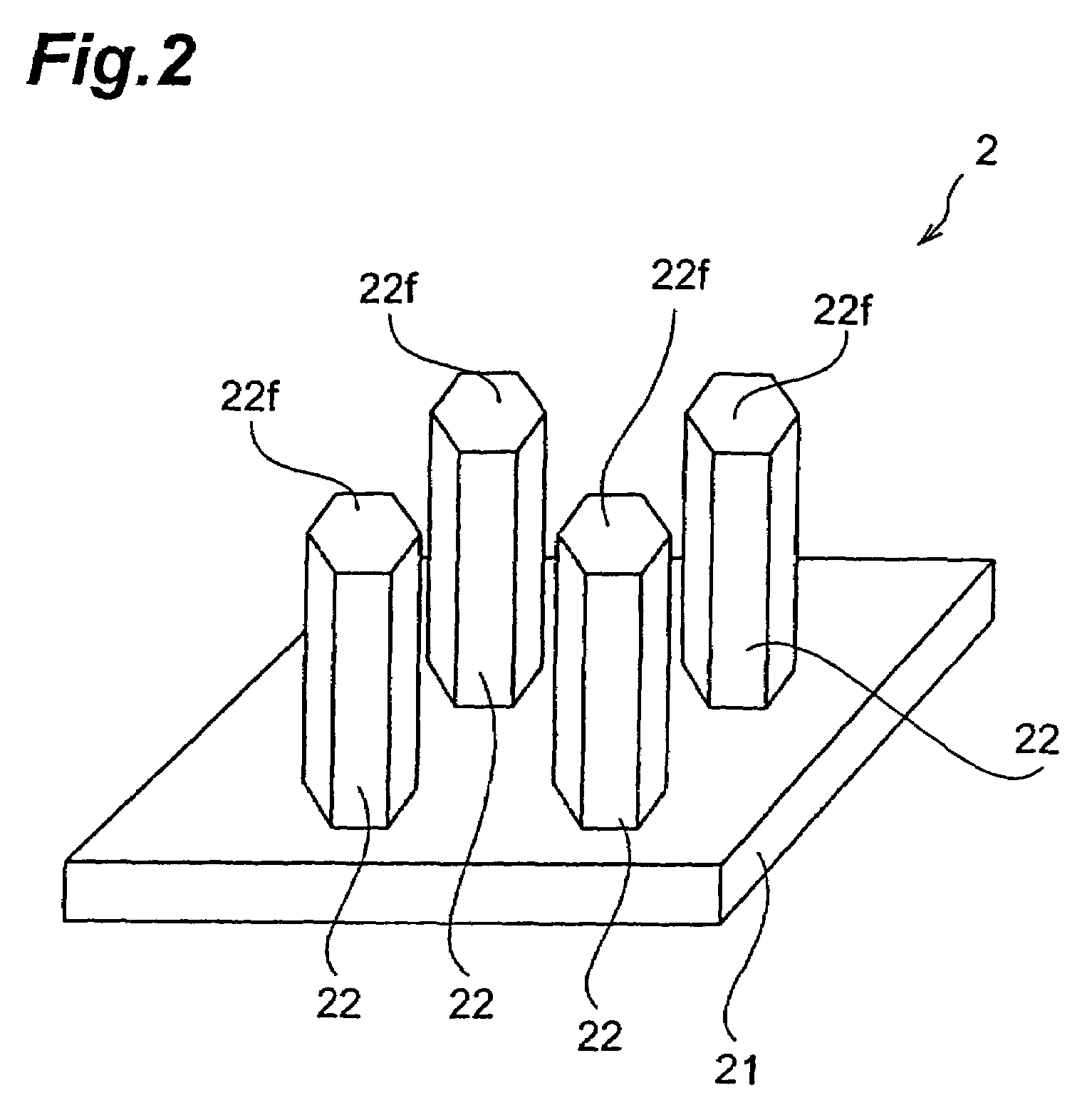

Microfabricated diamond element and method of fabricating microfabricated diamond element

InactiveUS7147918B2Improve luminous efficiencyProminent effectLayered productsIndividual molecule manipulationMaterials scienceLength wave

A diamond electron emission element is provided with a substrate, and a plurality of quadrangular columns (microscopic projections) composed of diamond and with side faces of flat faces, which are arranged at equal intervals on the substrate. A top end face (horizontal section) is of a quadrangular shape having a length of long sides being a [nm] and a length of short sides being ka [nm], and a thin film of SiO2 is formed on a side face on the short-edge side. The length a [nm] of long sides and the length ka [nm] of short sides satisfy relational expressions of Formulae (1) and (2) below.C1=2a√{square root over (1+k2)} (1)nλ=C1 (2)C1: a distance [nm] of a lap in a situation where light generated inside each quadrangular column goes around on a specific circuit while being reflected on the side faces of the quadrangular column,n: an arbitrary positive integer, andλ: an emission peak wavelength λ [nm] of the diamond making the quadrangular columns.

Owner:SUMITOMO ELECTRIC IND LTD +1

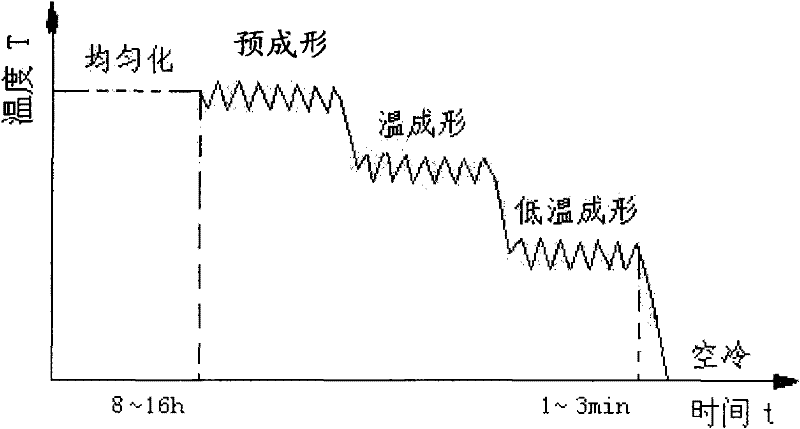

Magnesium alloy construction member step temperature forming method

InactiveCN102172750ARealize comprehensive utilizationImprove performanceMetal-working apparatusThermal energyHeating furnace

The invention provides a magnesium alloy construction member step temperature forming method. The method comprises the process route, namely homogenizing, preforming, warm forming and low temperature forming and is characterized in that: 1, in the stage of homogenizing and preforming, homogenizing is carried out in a heating furnace, and upsetting and preforming are directly carried out by utilizing a blank homogenizing temperature, wherein the thermal temperature of preforming is 380 minus or plus 10 DEG C; 2, in the stage of warm forming, warm extrusion forming is carried out on the preformed upsetting blank in a mould, wherein the warm forming temperature is 340 minus or plus 10 DEG C; and 3, in the stage of low temperature reshaping, low temperature reshaping is carried out on a semi-formed blank obtained after the warm forming is finished in the mould again, wherein the low temperature reshaping temperature is 300 minus or plus 10 DEG C. By adopting the method provided by the invention, the problems that high temperature forming performance of a magnesium alloy is low and the magnesium alloy can not be formed at a low temperature are solved, coordination and uniform of forming and toughening on the magnesium are realized, and product performance is improved; and energy sources are saved, the process is simplified, and waste heat of homogenizing is utilized to directly carry out subsequent plastic deformation, thus the process is simplified, the thermal energy is effectively utilized, and the production cost is reduced.

Owner:ZHONGBEI UNIV

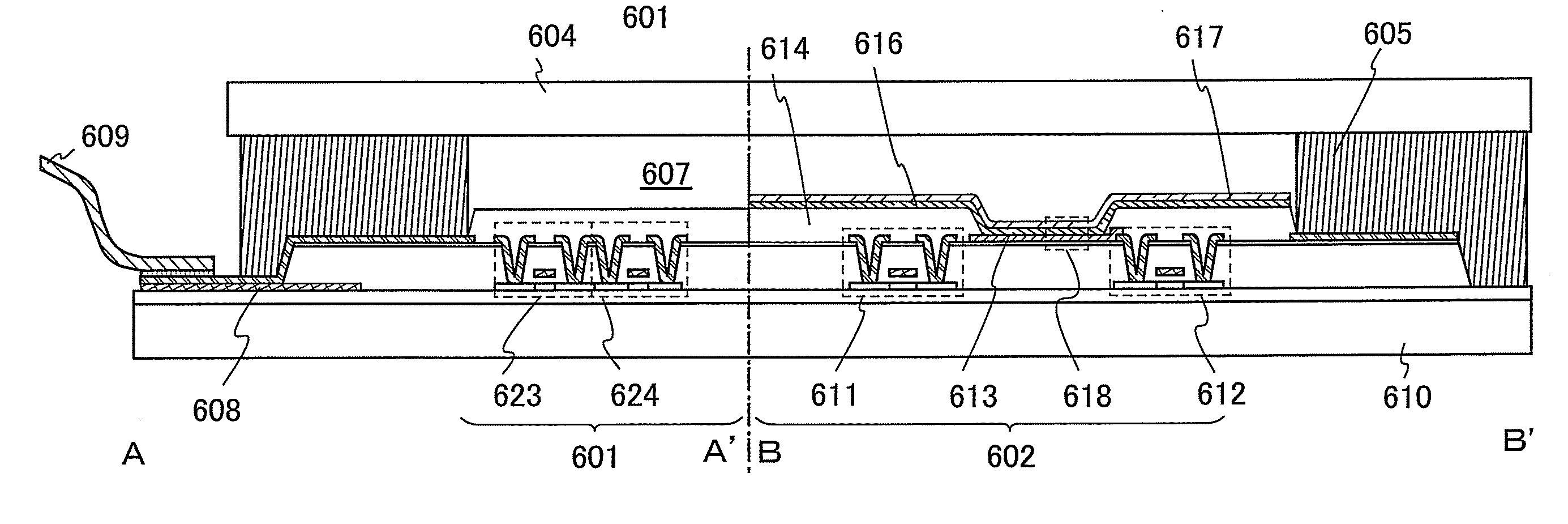

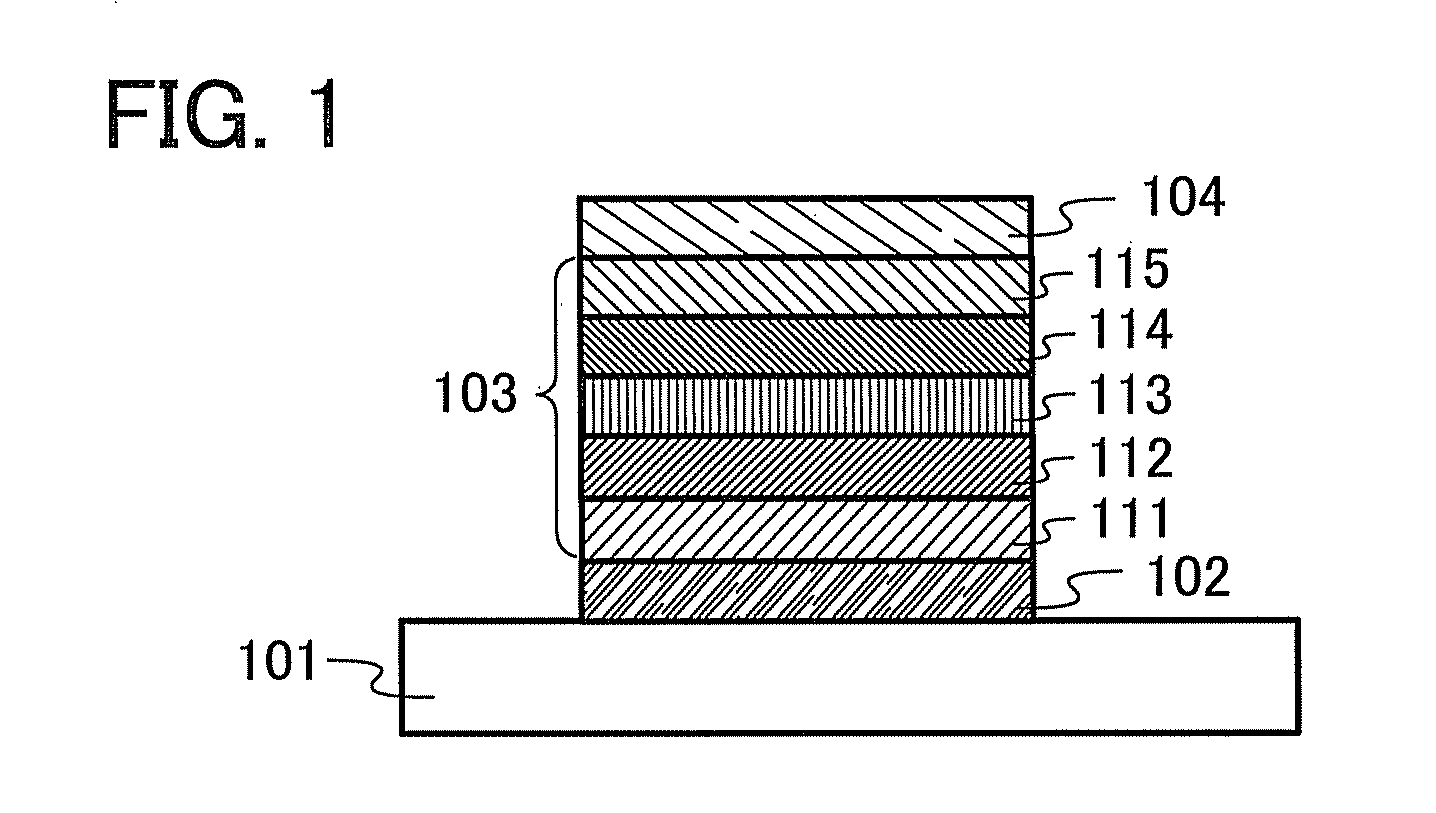

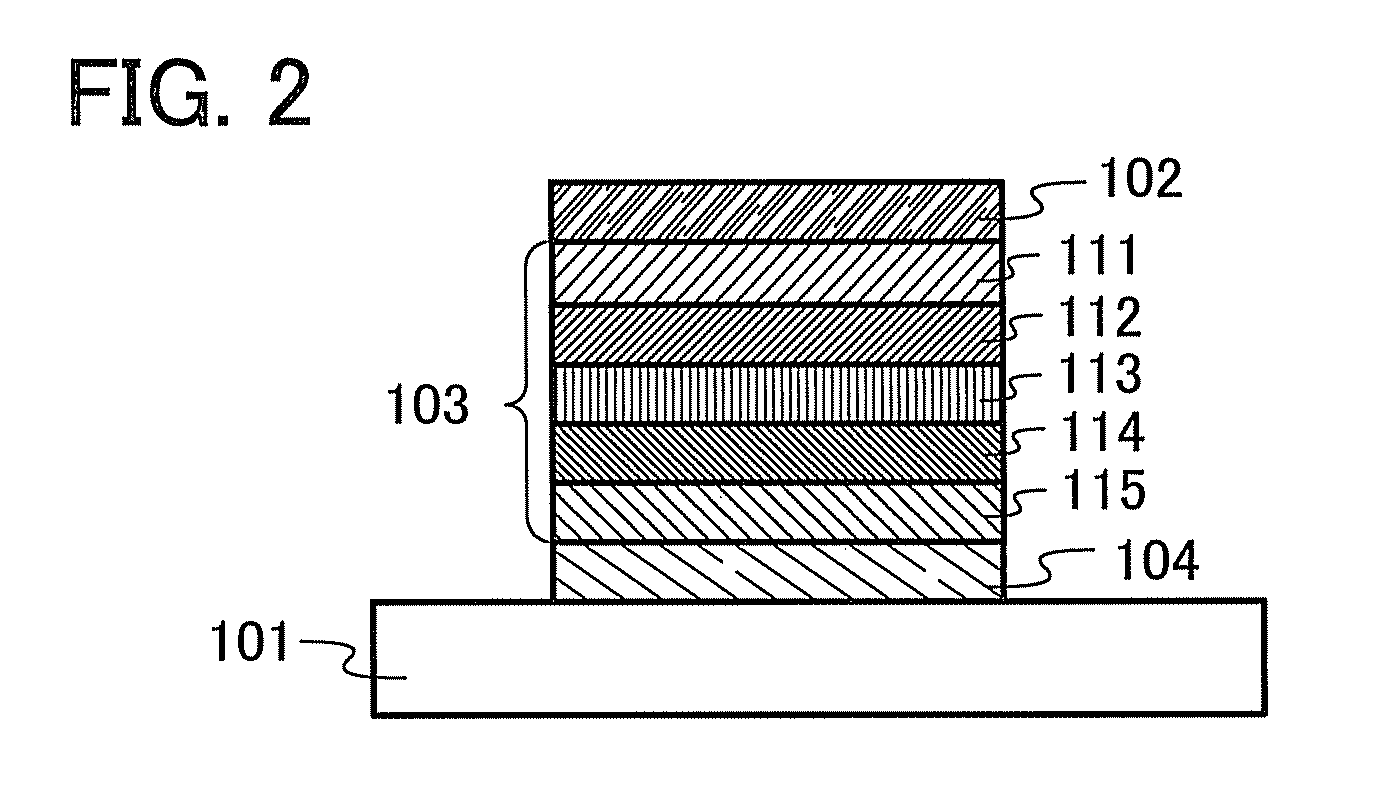

Fluorene Derivative, Organic Compound, and Light-Emitting Element, Light-Emitting Device, and Electronic Device Using the Compound

InactiveUS20120049768A1Reduce the driving voltageImprove emission efficiencyOrganic chemistrySolid-state devicesOrganic compoundLight emitting device

To provide a novel organic compound having a bipolar property. To reduce power consumption of a light-emitting element, a light-emitting device, and an electronic device. The organic compound has a fluorene skeleton and a structure in which an electron-accepting unit and a hole-accepting unit are bonded through carbon at the 9-position of the fluorene skeleton. The organic compound has a bipolar property and a large band gap. The use of the organic compound makes it possible to reduce power consumption of a light-emitting element, a light-emitting device, and an electronic device.

Owner:SEMICON ENERGY LAB CO LTD

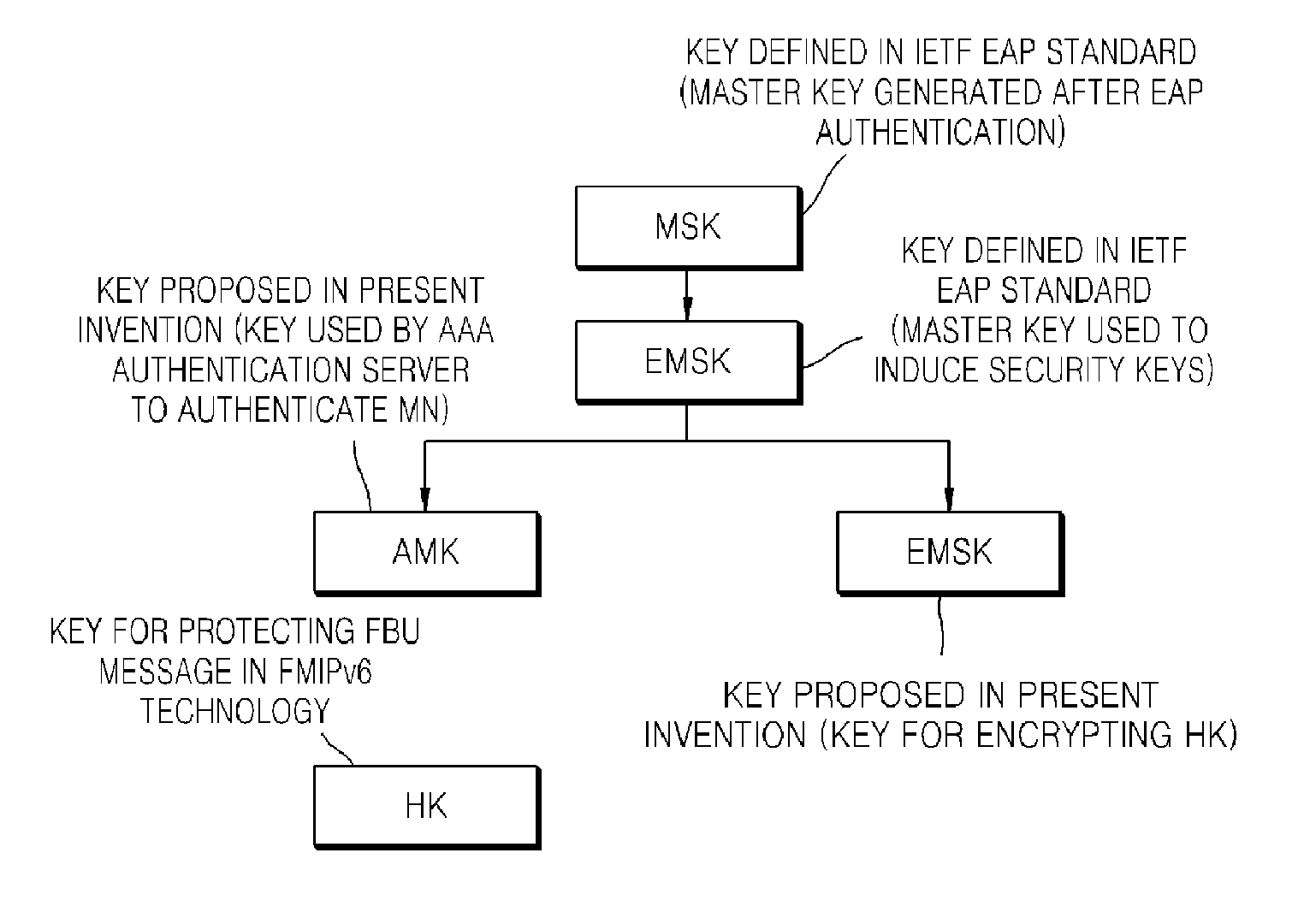

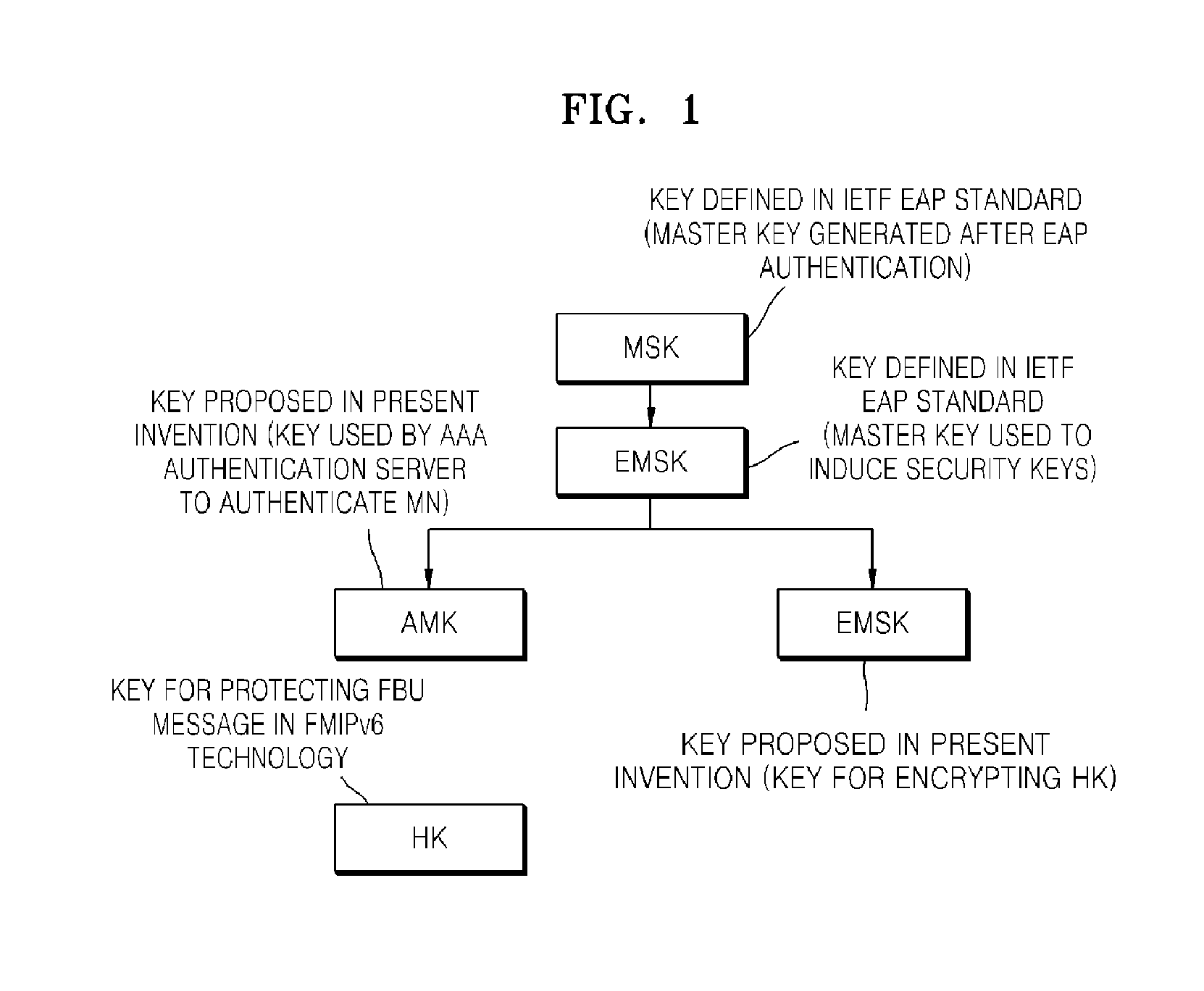

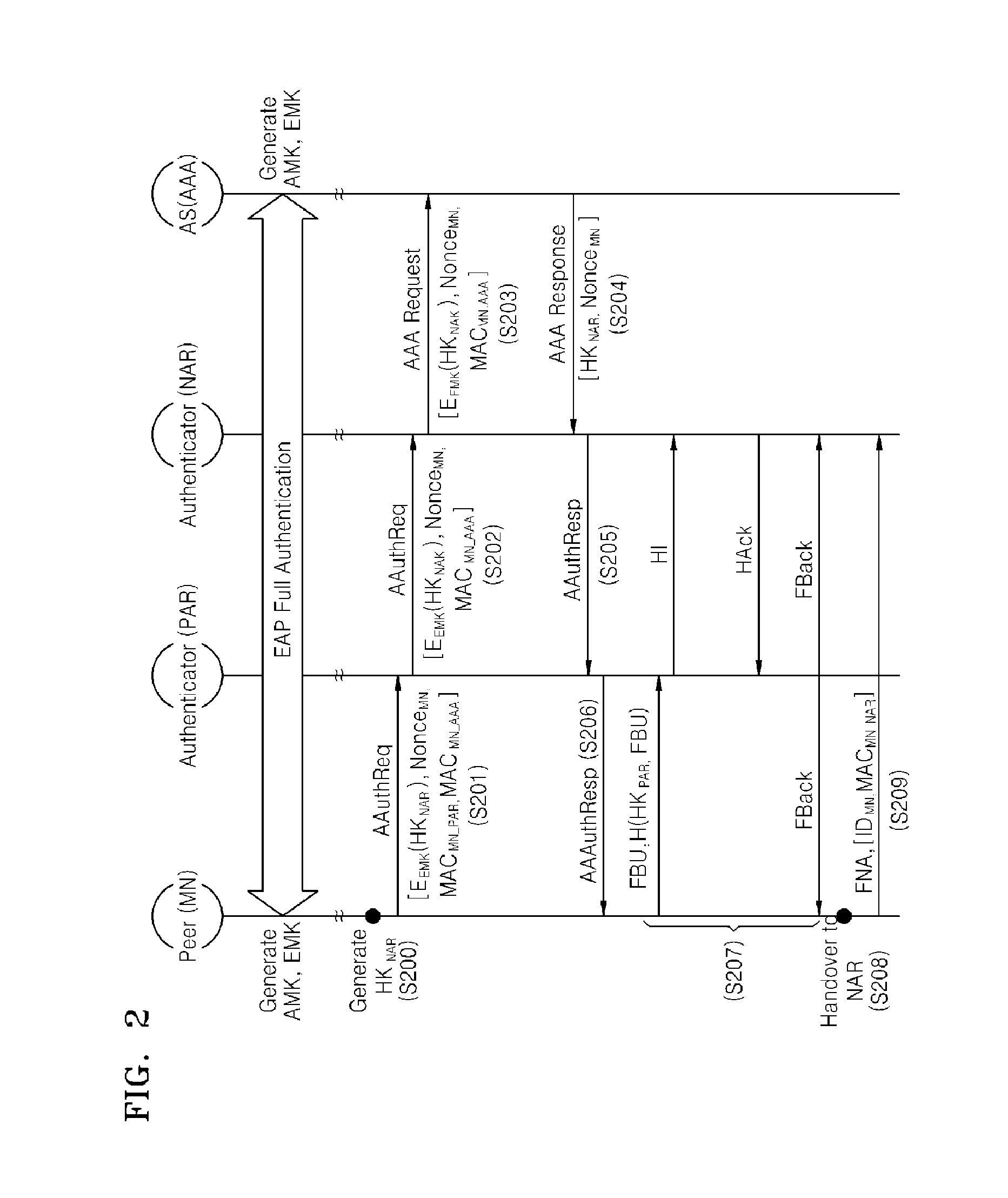

Integrated handover authenticating method for next generation network (NGN) with wireless access technologies and mobile IP based mobility control

InactiveUS20110002465A1Minimize overheadMinimizes numberWireless network protocolsSecret communicationMobility controlAccess technology

Integrated handover authentication technology for a next generation network (NGN) environment to which wire-less access technology and mobile IP based mobility control technology are applied is provided. In a method of operating a mobile terminal MN in order to perform the integrated handover authentication in the NGN environment including an access router PAR, a target router NAR, and an authentication(AAA) server. First, a handover authentication key HKNAR which is shared by the mobile terminal and the target router and protects a fast binding update (FBU) message between the mobile terminal and the target router is generated. Then, an authentication request message AAuthReq generated using the handover authentication key HKNAR is transmitted. Thereafter, an authentication success message AAuthResp is received in response to the authentication request message AAuthReq. Accordingly, hierarchical handover can be performed according to the localization of the mobility of the mobile terminal, thereby minimizing the overhead of the authentication (AAA) server.

Owner:ELECTRONICS & TELECOMM RES INST

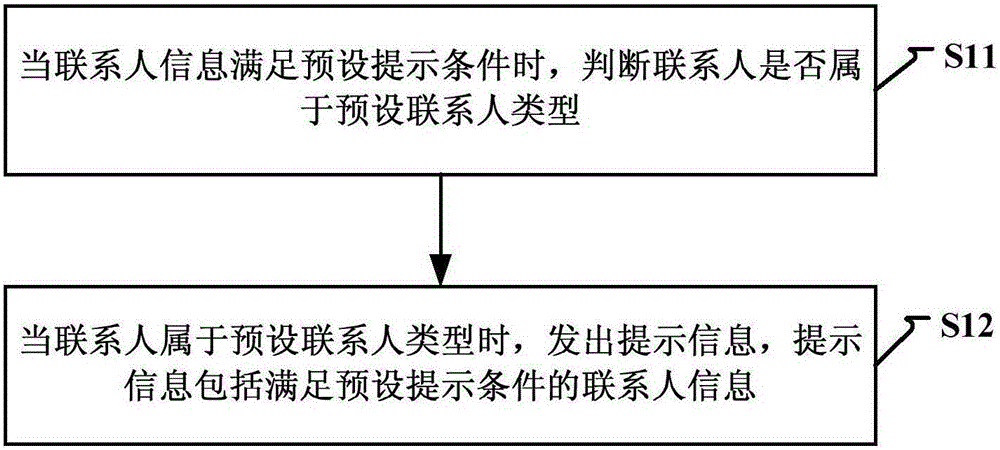

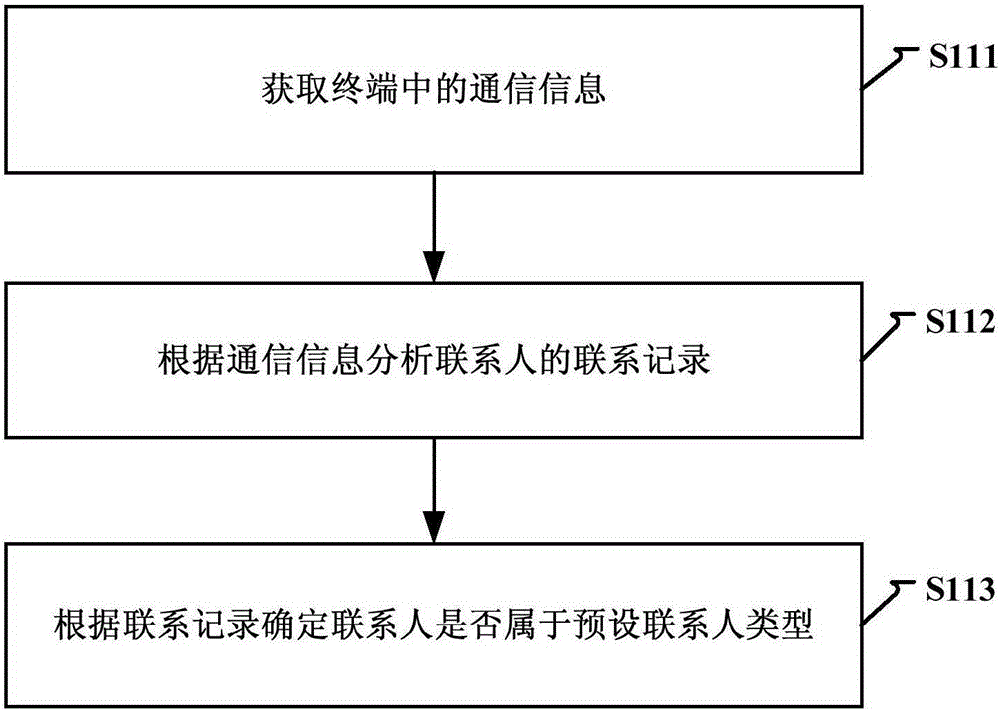

Information prompt method and information prompt device

The invention relates to an information prompt method and an information prompt device which are used for accurately and efficiently reminding users of contact information. The method comprises the following steps: judging whether a contact belongs to a default contact type when the contact information meets a default prompt condition; and sending out prompt information when the contact belongs to the default contact type, wherein the prompt information contains the contact information meeting the default prompt condition. According to the technical scheme, whether the contact belongs to the default contact type is judged first when the information of the contact meets the default prompt condition, and prompt information is sent to a user only when the contact belongs to the default contact type. Therefore, contact information prompt that users do not need to know is avoided, users are prevented from being disturbed to a great extent, and the effect of information prompt is more evident.

Owner:XIAOMI INC

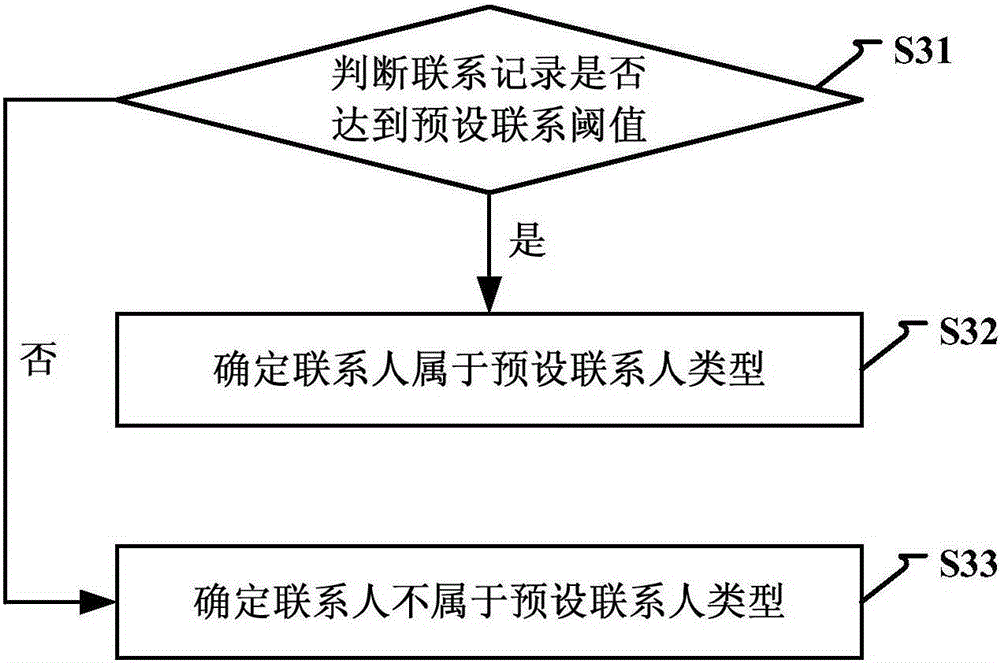

Water-in-oil emulsified sunscreen cosmetic

InactiveUS20160220457A1Improve protectionLess irritatingCosmetic preparationsMake-upWater in oilIron oxide

The present invention provides a water-in-oil emulsified sunscreen cosmetic comprising the following ingredients (a), (b), (c), and (d) in the outer phase and not comprising octylmethoxy cinnamate, octocrylene, or avobenzone.(a) 5-15 wt % of hydrophobized rutile type crystallized titanium dioxide having an average particle size of 30-80 nm,(b) 0.1-10 wt % of iron oxide,(c) 5-15 wt % of hydrophobized zinc oxide having an average particle size of 20-80 nm,(d) 0-1.0 wt % of titanium dioxide for white pigment having an average particle size of 180 nm or more.The object of the present invention is to provide a water-in-oil emulsified sunscreen cosmetic that is applied on the face including the areas surrounding the eyes, wherein irritation to the eyes is minor, the UVB and UVA protection effect is high, and a superior makeup effect is also manifested.

Owner:SHISEIDO CO LTD

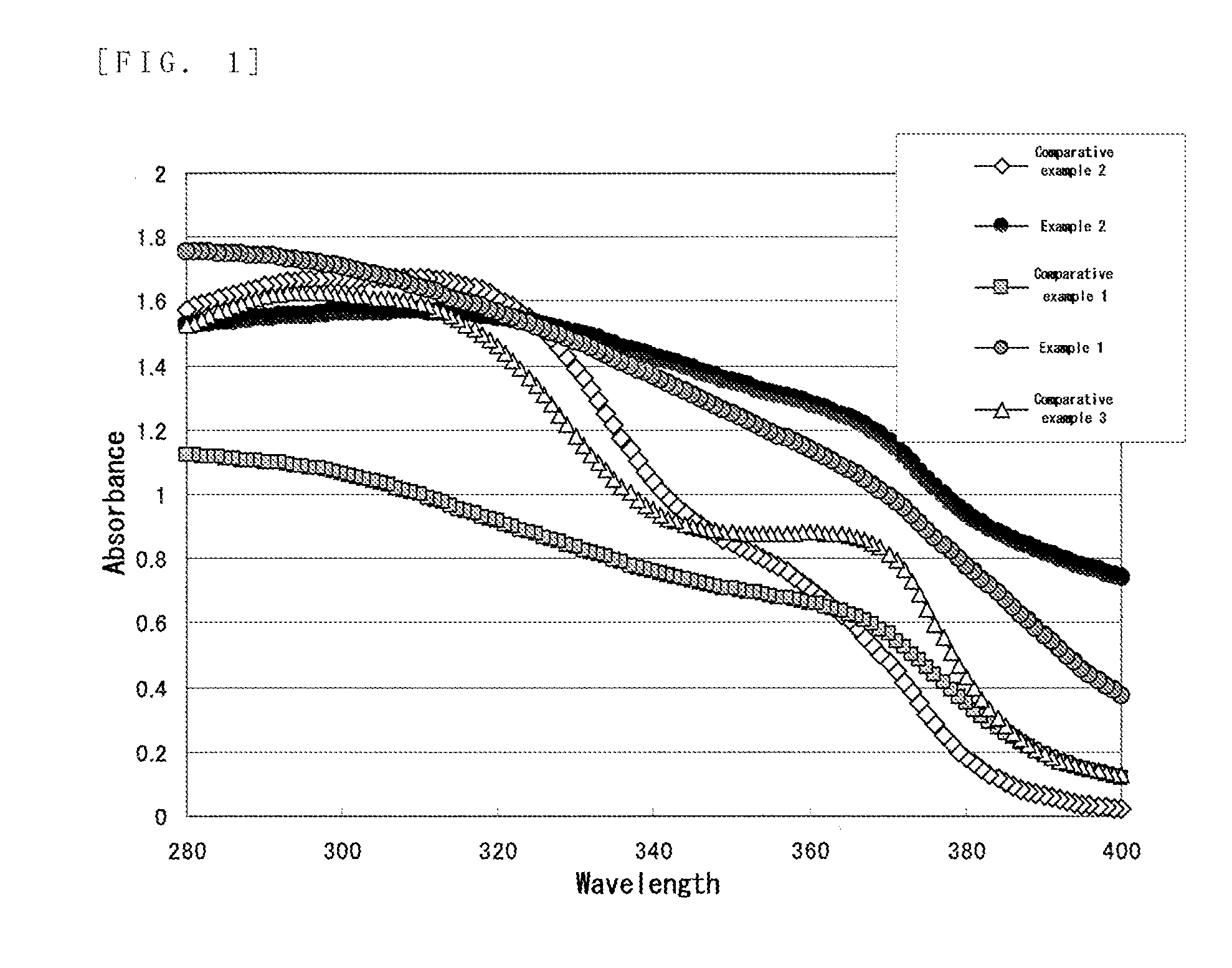

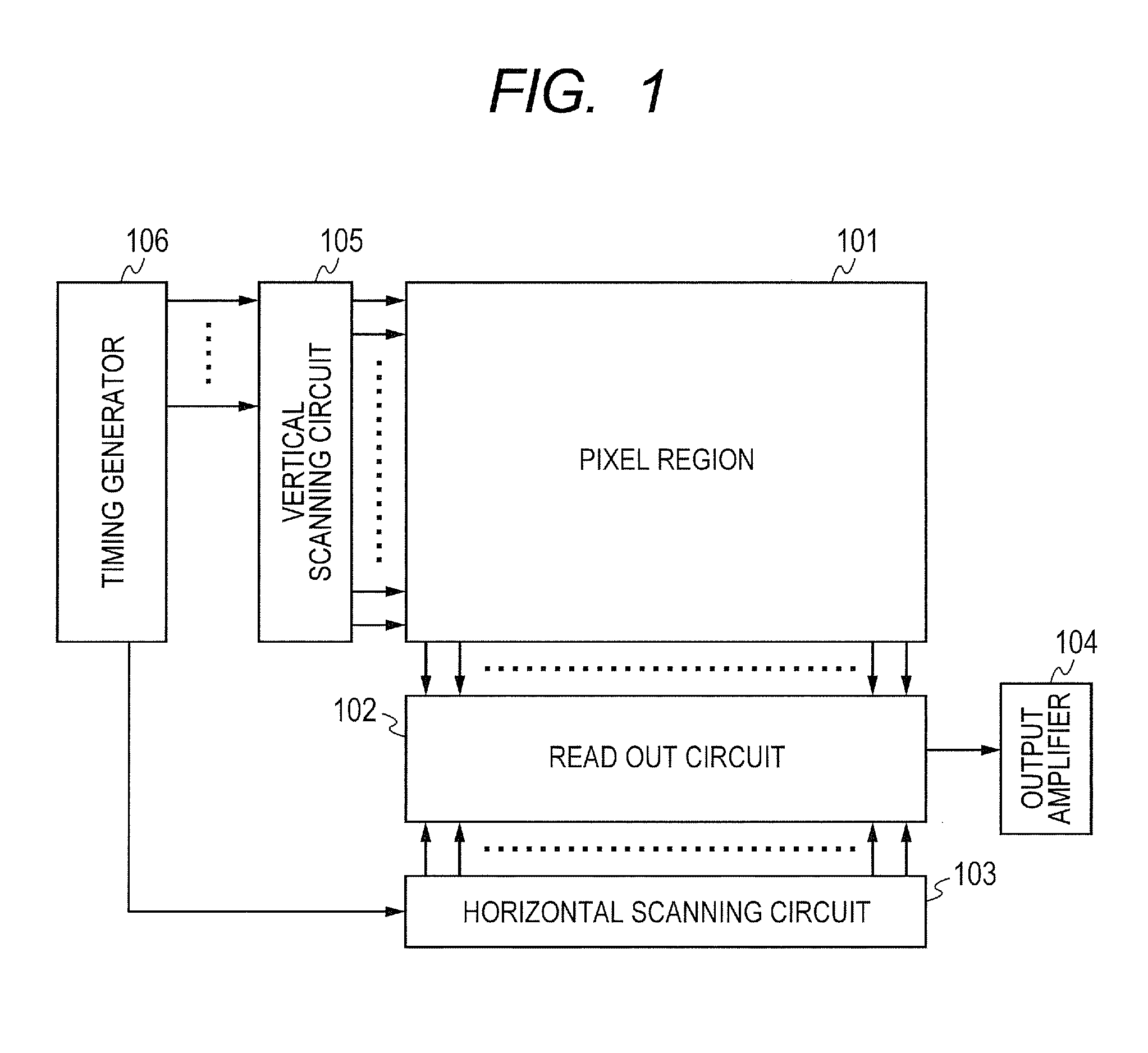

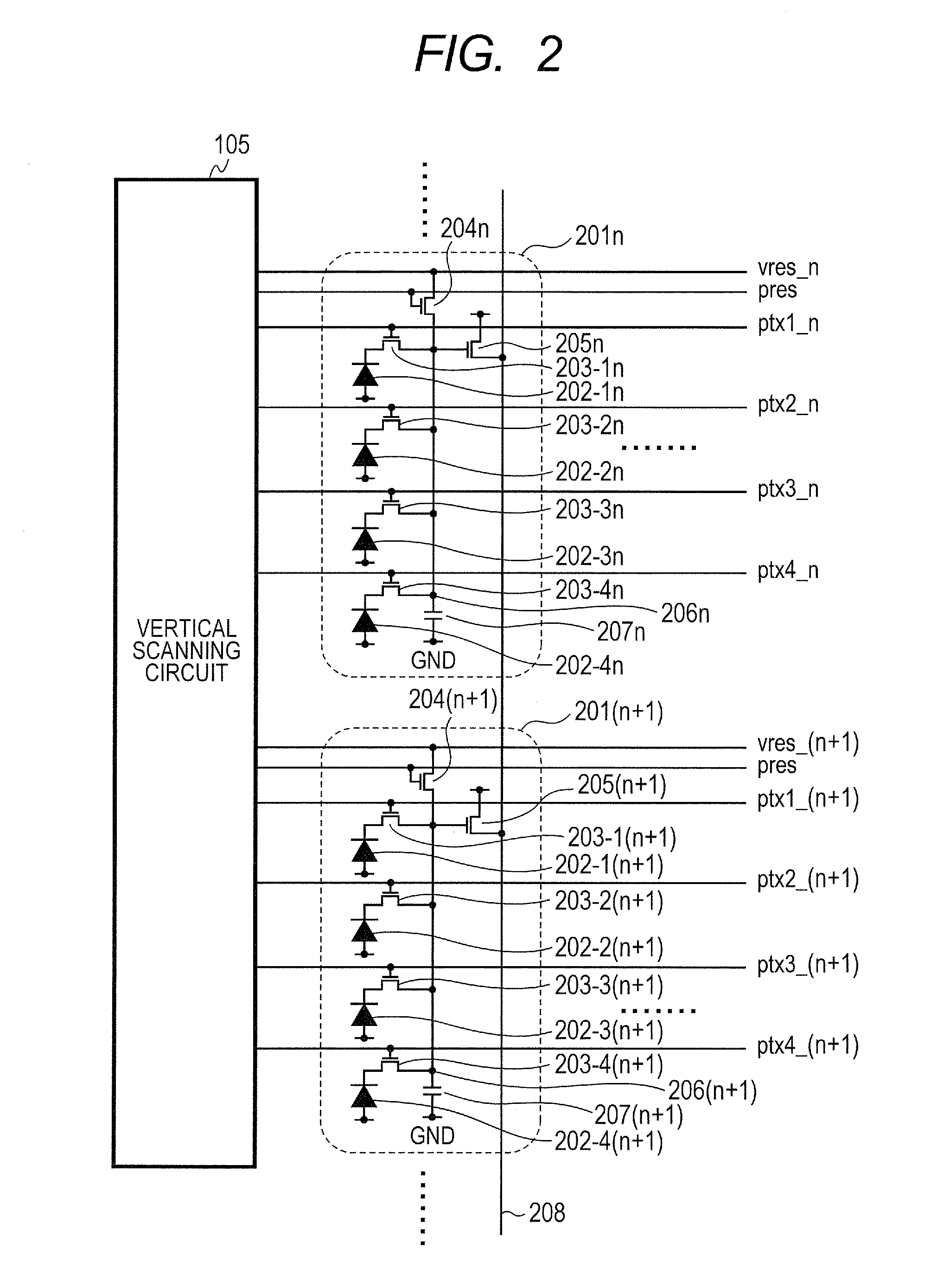

Imaging apparatus and driving method of the imaging apparatus

InactiveUS20130037696A1Prominent effectReducing effect of voltage variationTelevision system detailsSolid-state devicesComputer hardwareHemt circuits

A driving method of an imaging apparatus comproses: horizontally transferring, by a horizontal scanning circuit, a signal based on a photoelectric conversion portion of a first pixel unit held in a signal holding capacitor to a common line; before ending of the horizontal transfer; applying, by a reset switch of a second pixel unit, a selection reset voltage to a floating diffusion region of the second pixel unit; and after the horizontal transfer, transferring, by a transfer switch of the second pixel unit, a signal of a photoelectric conversion portion of the second pixel unit to the floating diffusion region of the second pixel unit and amplifying, by an amplification transistor of the second pixel unit, a signal of the floating diffusion region of the second pixel unit to output the signal to an output line.

Owner:CANON KK

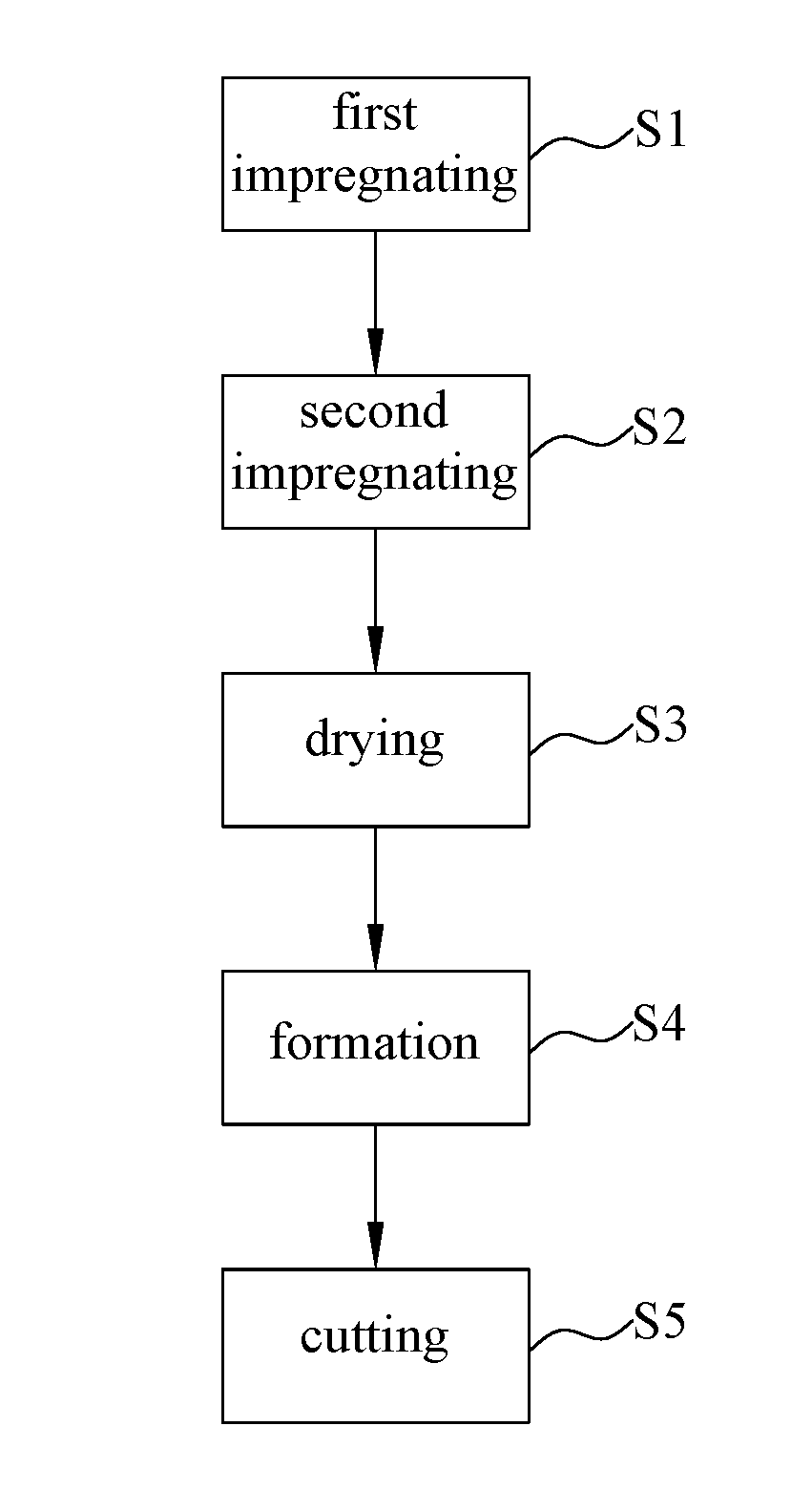

Speaker vibrating member and method of making the same

ActiveUS20170251307A1Good flexibilityImprove fatigue resistanceFibre diaphragmsPolymeric diaphragmsFiberWater based

The present invention provides a method for making a speaker vibrating member, including: impregnating a fiber cloth with a resin solution for at least one time; removing the fiber cloth from the resin solution, and impregnating the fiber cloth with a water-based rubber solution for at least one time; drying the fiber cloth; forming at least one speaker vibrating member shaped portion on a dried fiber cloth; and cutting the at least one speaker vibrating member shaped portion off from the dried fiber cloth to acquire the speaker vibrating member. In such a way, the fiber cloth may be prevented from sticking with the mold during the formation step due to the protection provided by the release layer. In addition, the speaker vibrating member manufactured by the method has a higher flexibility and a remarkable fatigue resistance; consequently, the sound quality of the speaker may be enhanced.

Owner:OHARA HIROSHI

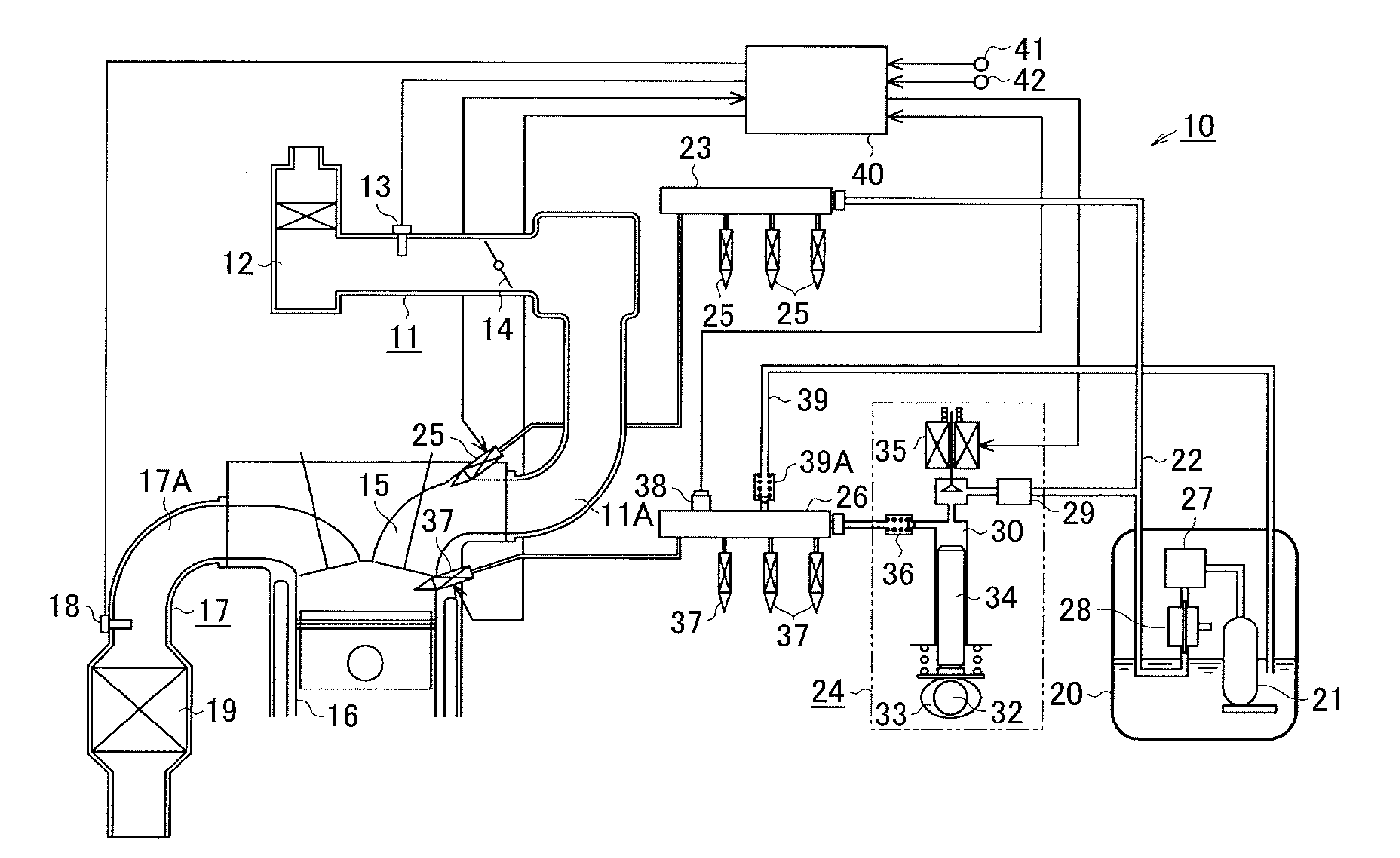

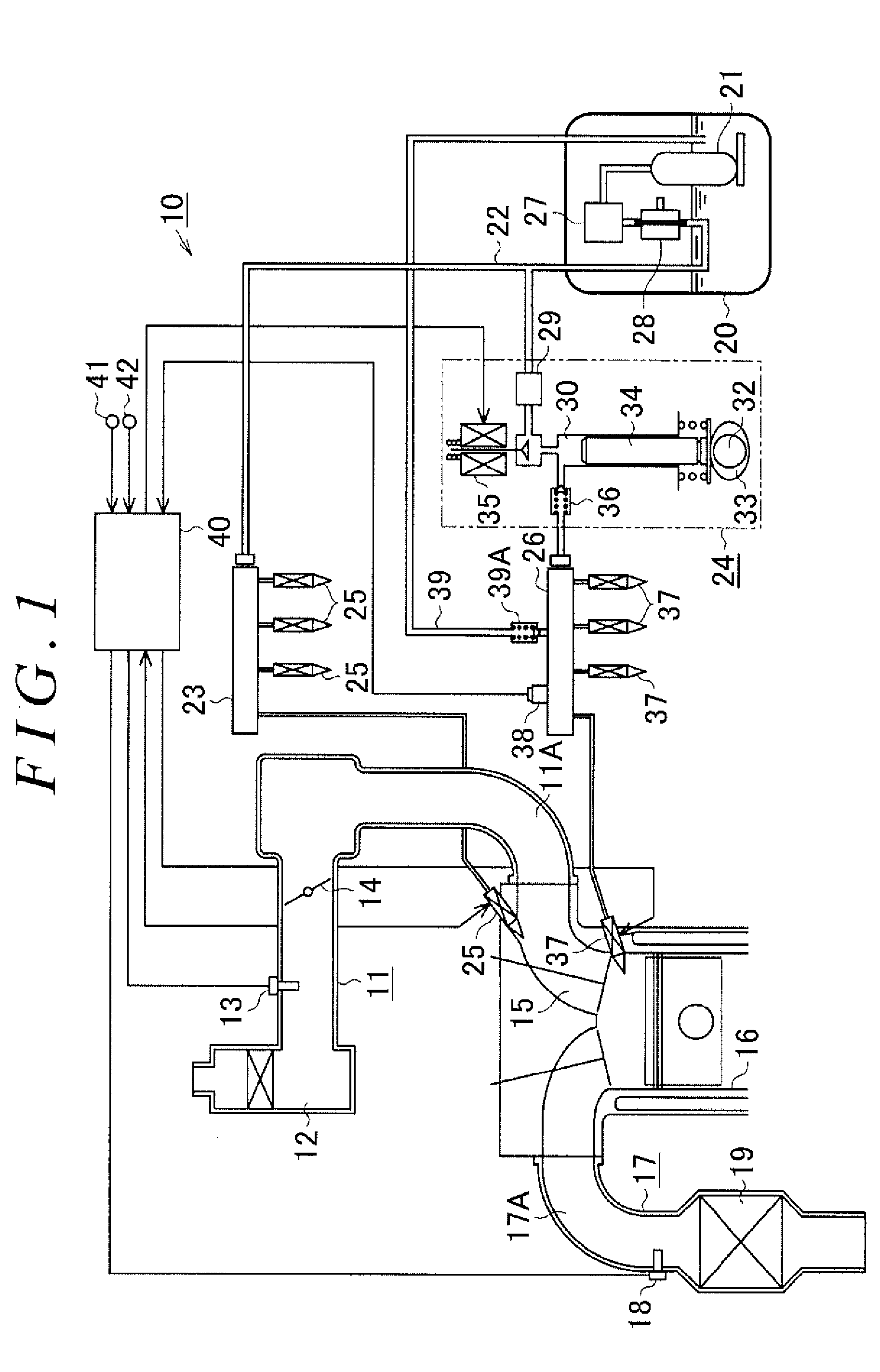

Control system

ActiveUS20160363078A1Deterioration in combustion state is restrainedRestrain in combustion of engineElectrical controlInternal combustion piston enginesControl systemFuel injection

An abnormality flag is set when a first abnormality determination condition is established in an abnormality diagnosis of a fuel pressure sensor and it is determined that an abnormality occurs. In a case where the abnormality flag is kept cleared, when a fuel pressure detection value of the fuel pressure sensor is kept fixed for a prescribed time T2 or more and a second abnormality determination condition is established, a partial lift injection is prohibited, such that an injection control of a fuel injection valve is performed so as to perform a fuel injection without performing the partial lift injection.

Owner:TOYOTA JIDOSHA KK

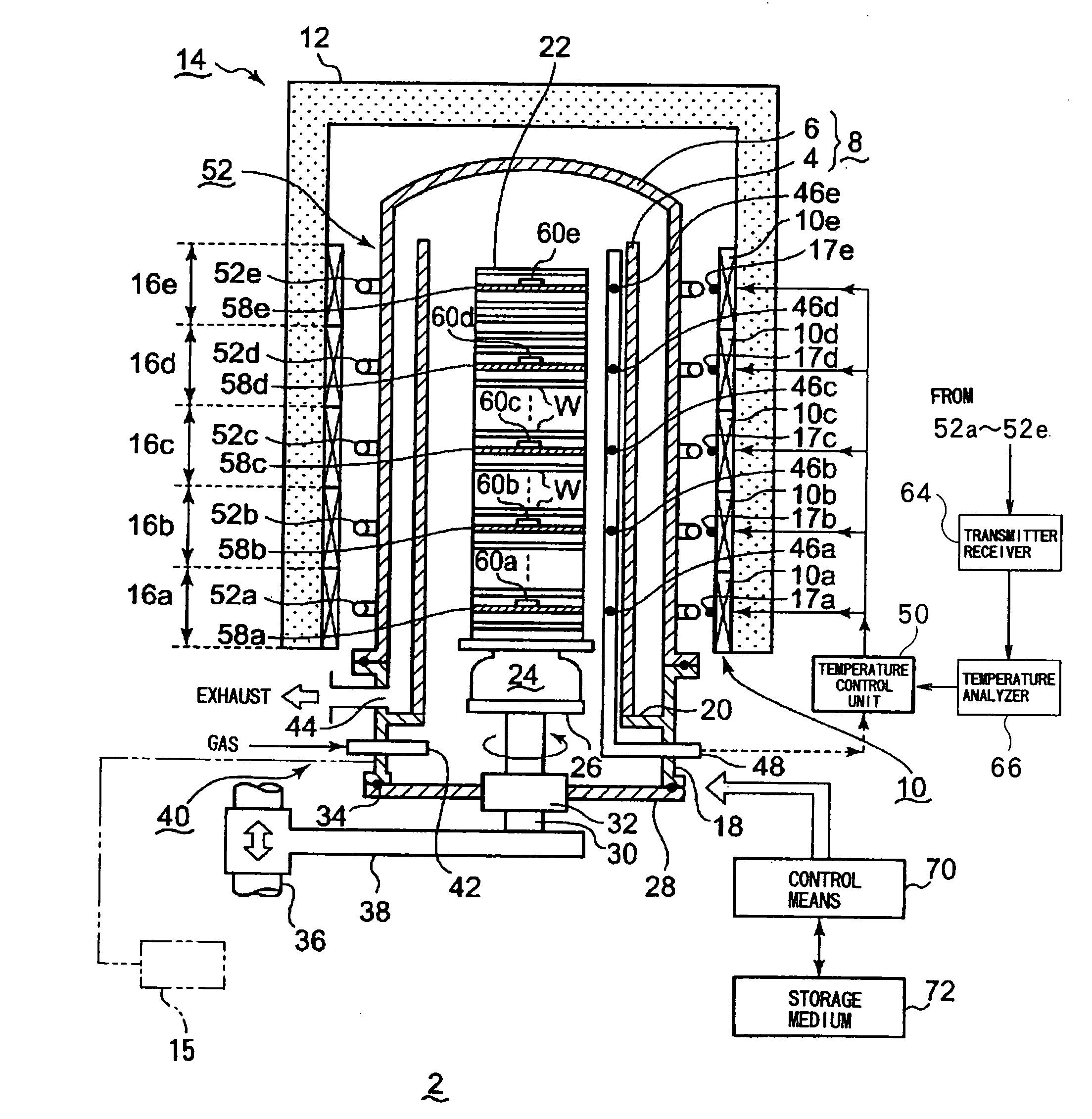

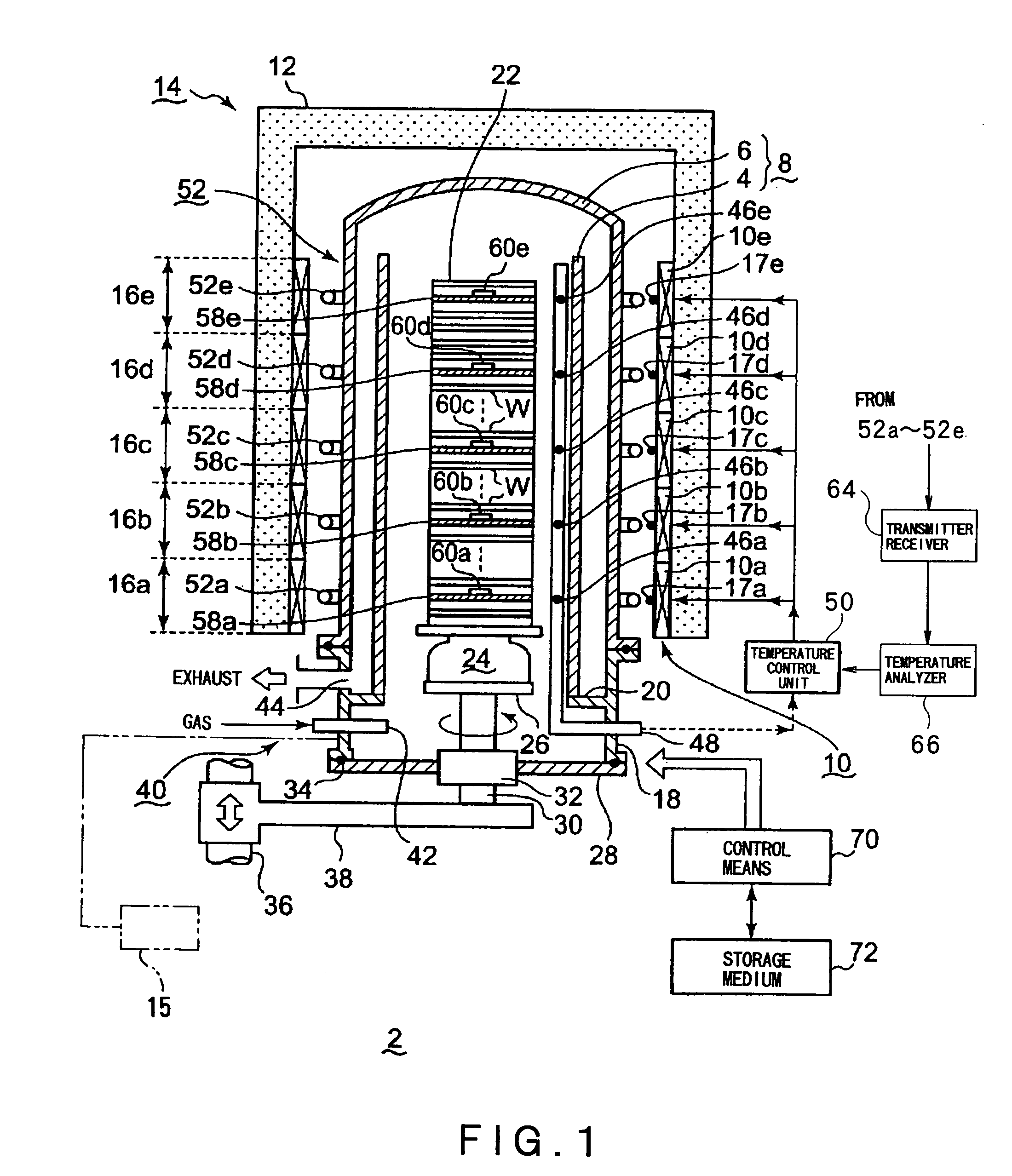

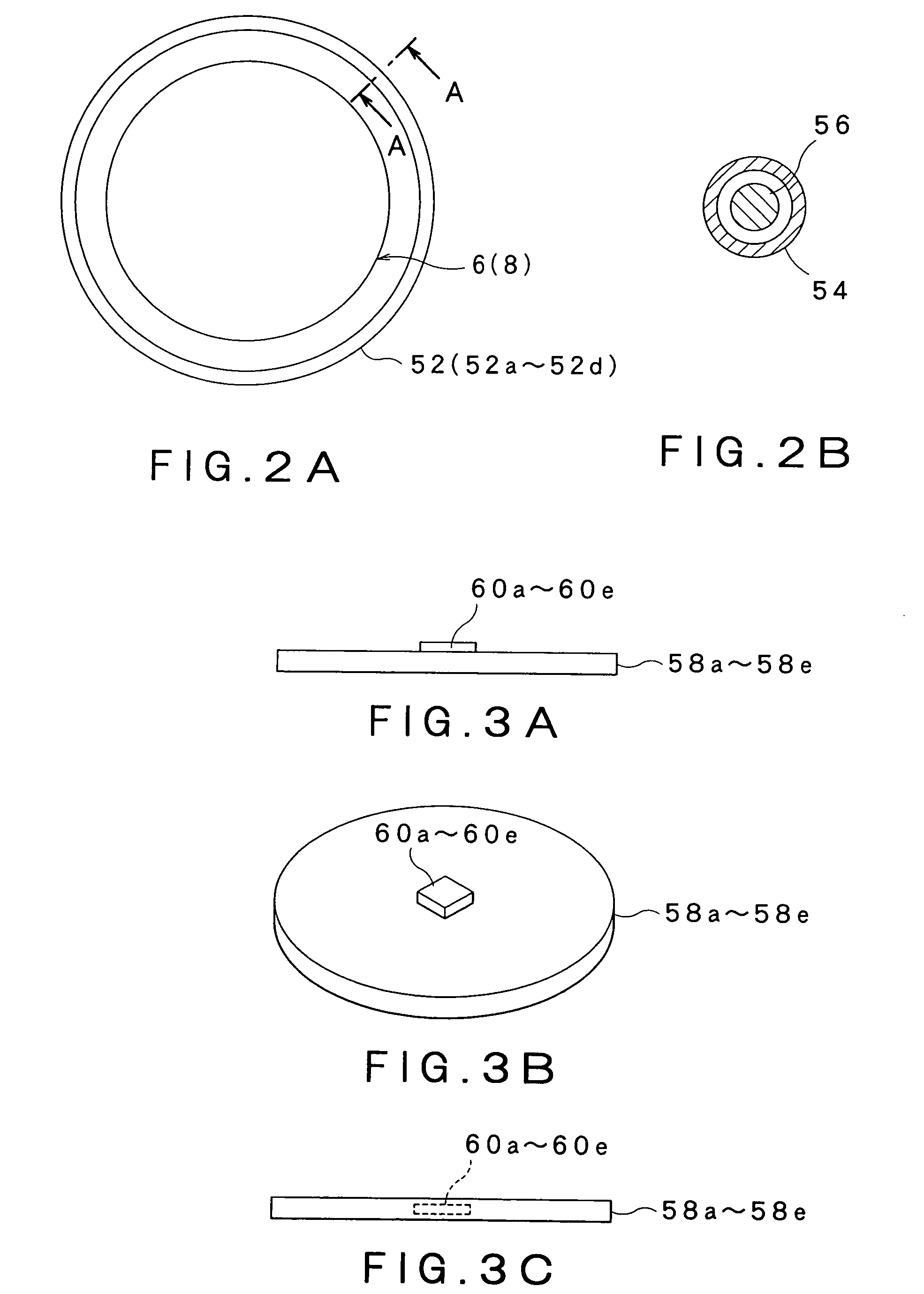

Heating apparatus for heating objects to be heated, heating method for heating the objects to be heated, and storage medium in which computer-readable program is stored

ActiveUS20080203084A1High precision temperature controlEasy to controlThermometer detailsVacuum evaporation coatingTemperature controlEngineering

The present invention provides a heating apparatus for heating objects to be processed, which can detect a temperature of the objects to be processed with higher precision and accuracy, thereby to achieve higher precision temperature control. A heating apparatus 2 includes a processing vessel 8 configured to contain therein a plurality of objects W to be processed, the objects W including objects 58a to 58e to be processed for temperature measurement, each object 58a to 58e having each corresponding elastic wave element 60a to 60e, a heating means 10 adapted for heating the objects W to be processed, and a holding means 22 adapted to hold the objects W to be processed. To the processing vessel 8, a transmitter antenna 52 adapted to transmit an electric wave for measurement toward each elastic wave element 60a to 60e, and a receiver antenna 52 adapted to receive an electric wave having a frequency corresponding to the temperature and generated from each elastic wave element 60a to 60e are provided. A temperature analyzer 66 adapted to obtain the temperature of the wafers W to be processed for temperature measurement is connected with the receiver antenna 52, and a temperature control unit 64 adapted to control the heating means 10 is in turn connected with the temperature analyzer 66.

Owner:TOKYO ELECTRON LTD

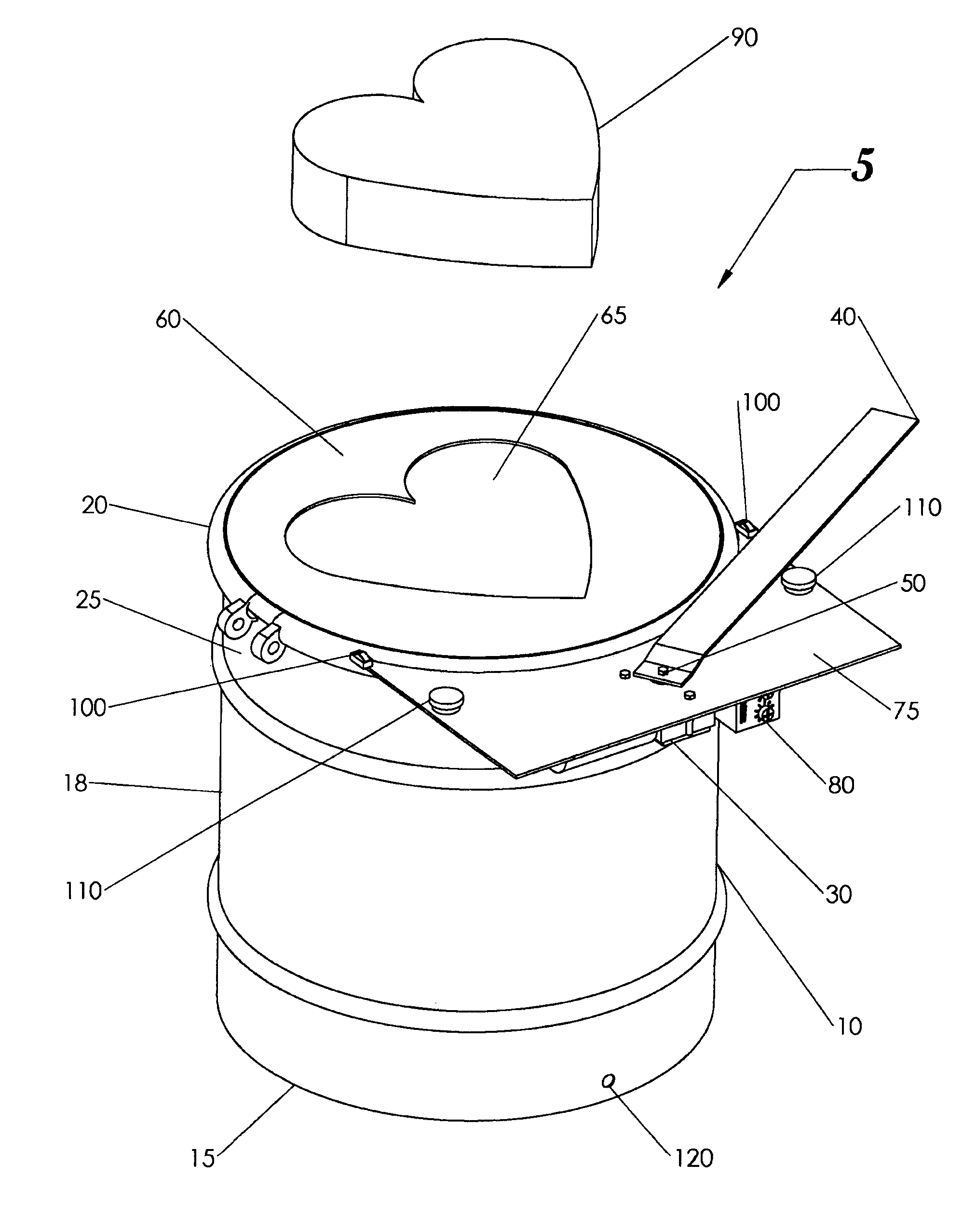

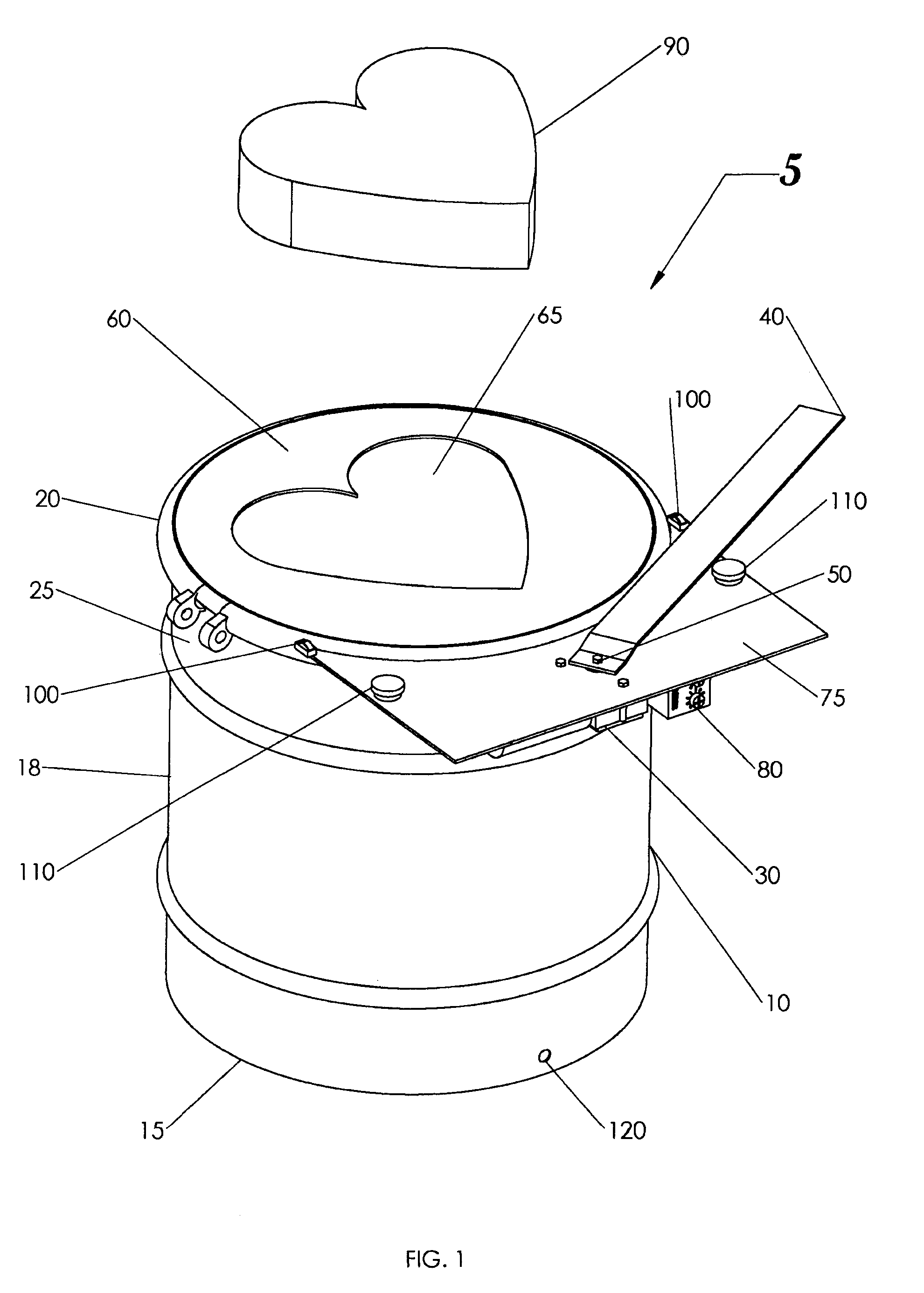

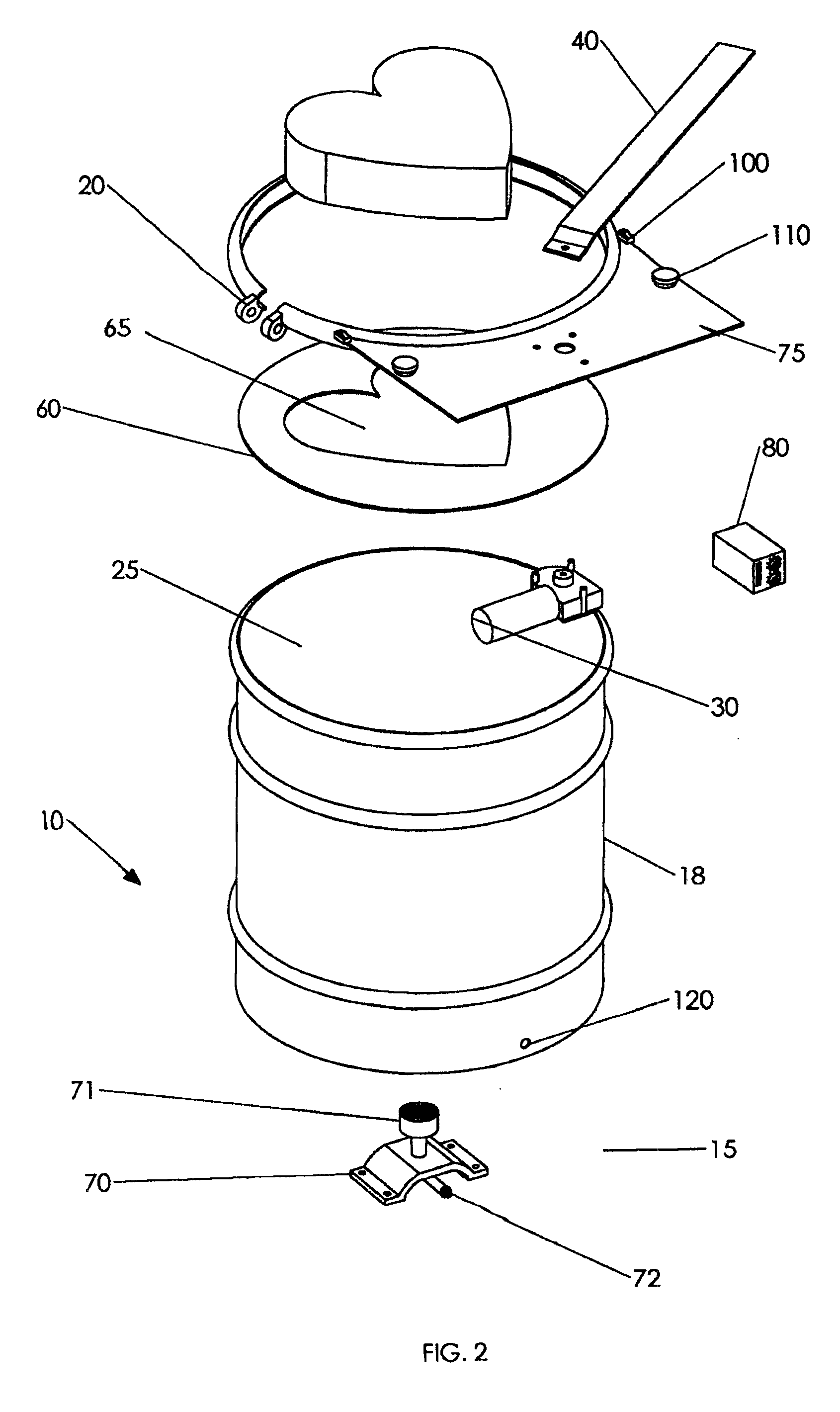

Flying Foam Apparatus and Method of Making Flying Foam

InactiveUS20090193695A1Prominent effectLow densityData processing applicationsMouldsProcess engineeringFoam fractionation

Owner:GUERRA FRANCISCO +1

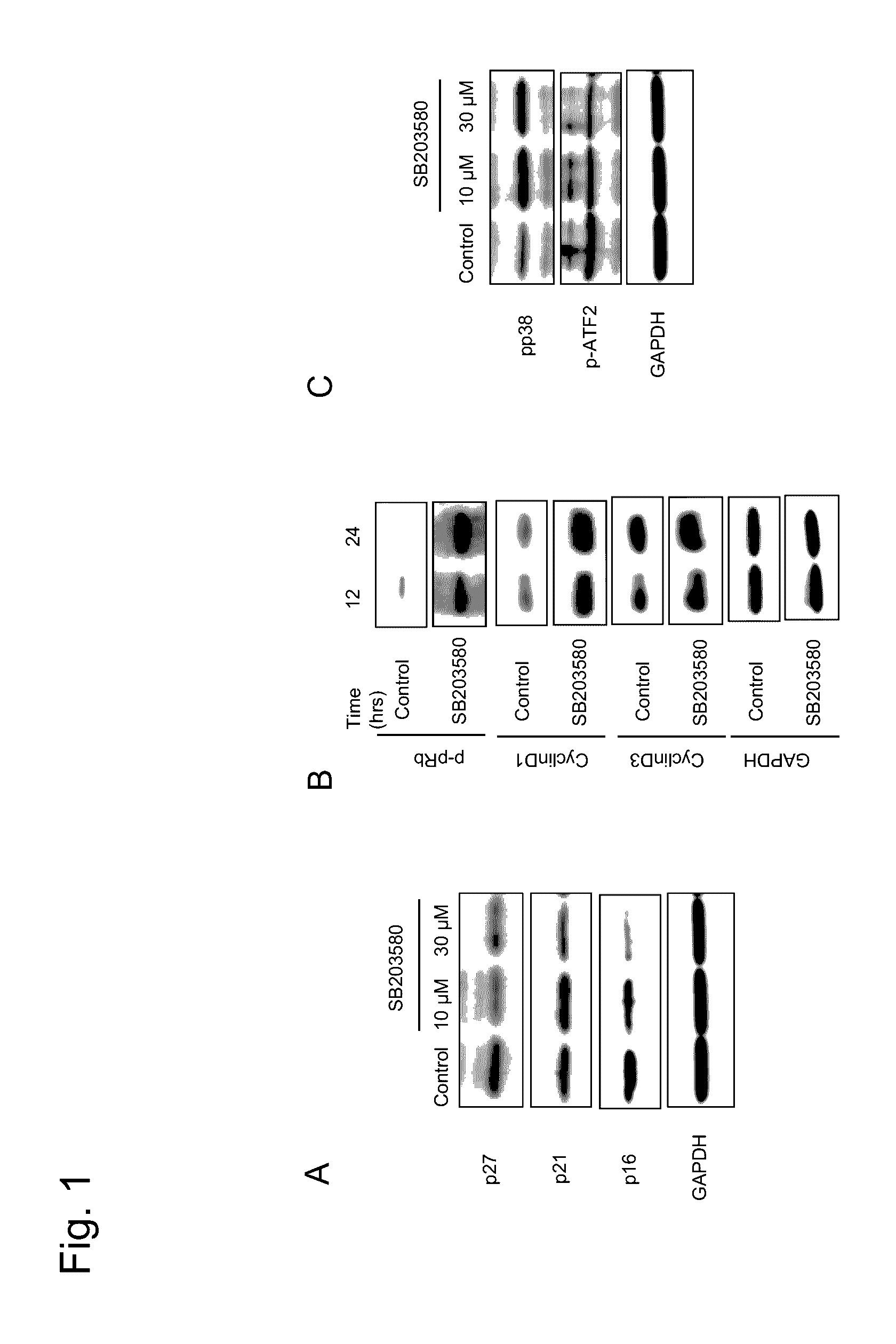

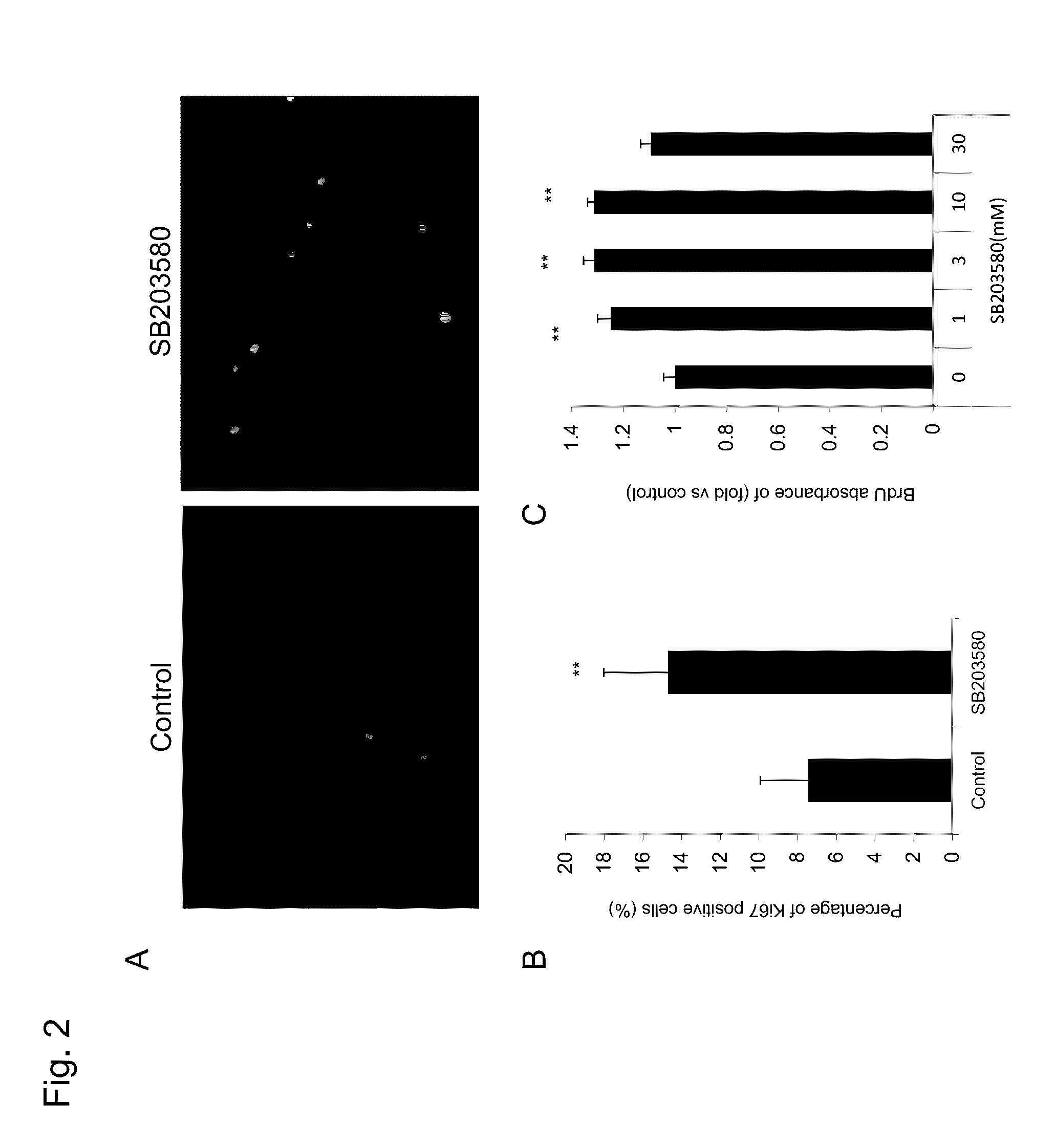

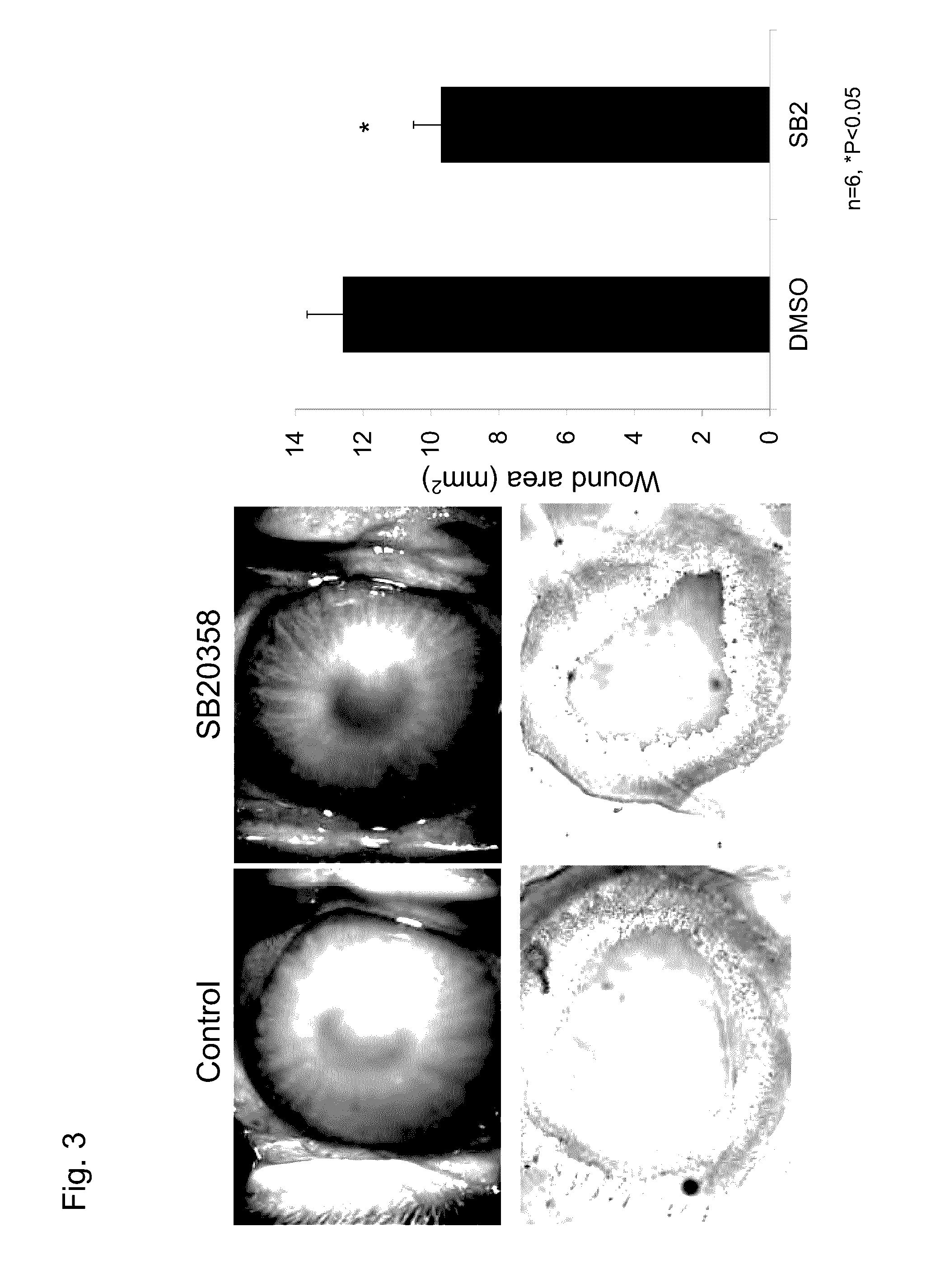

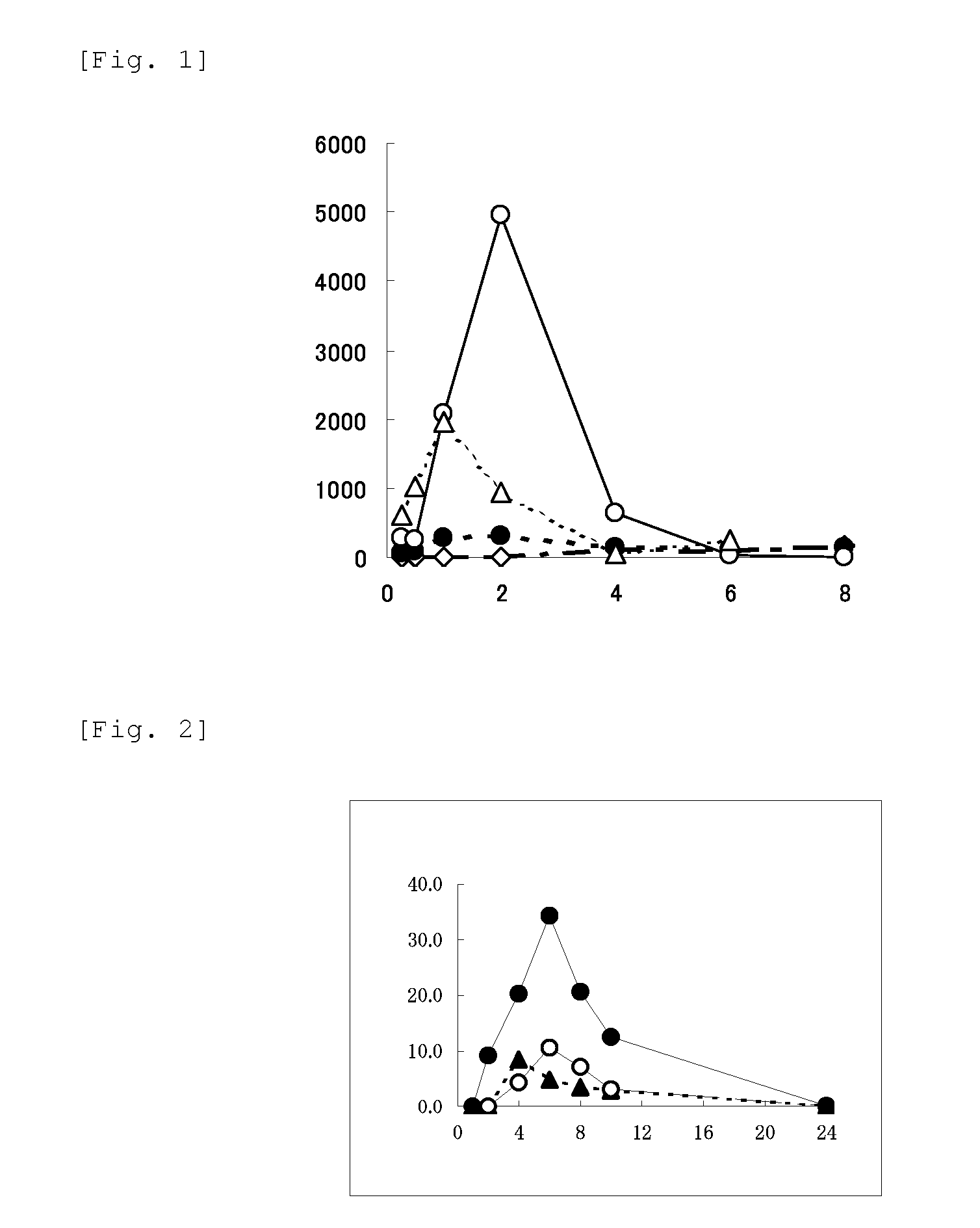

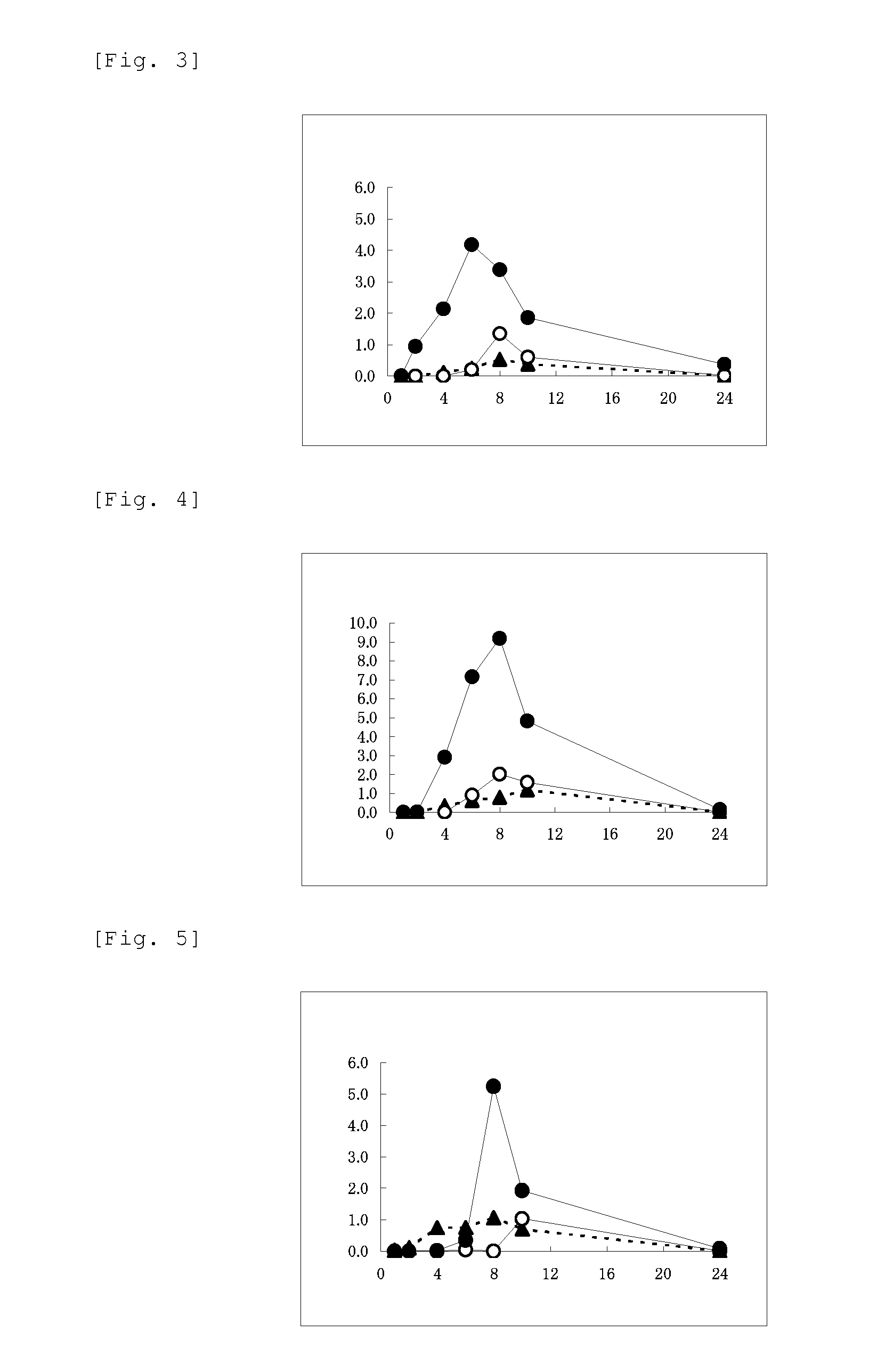

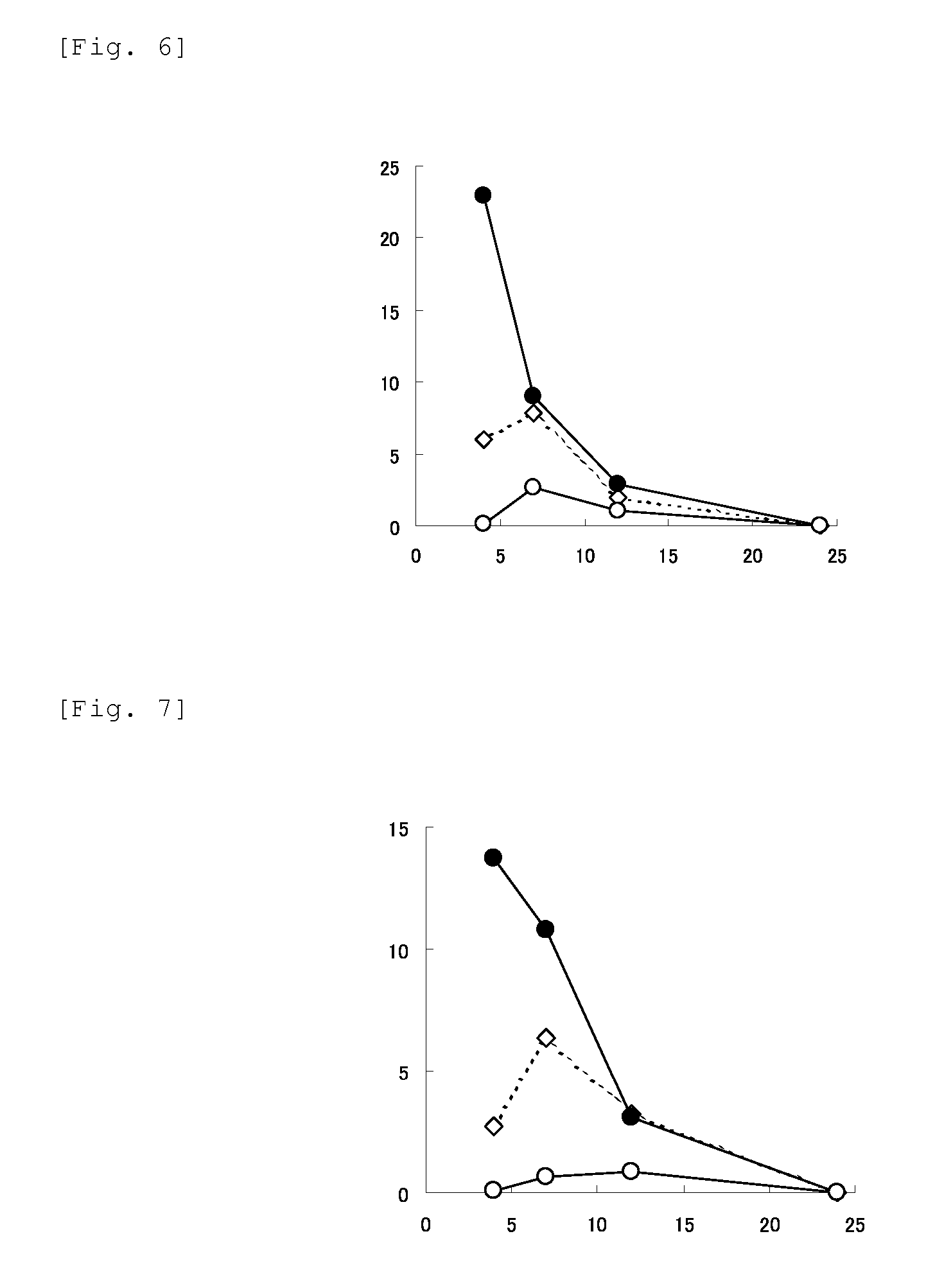

Drug for treating corneal endothelium by promoting cell proliferation or inhibiting cell damage

ActiveUS20160331736A1Prevent and healProminent effectSenses disorderHeterocyclic compound active ingredientsDrugDisease

Provided is an agent for treating or preventing a corneal endothelial disorder wherein cell proliferation is required. More specifically, provided is an agent for treating or preventing a corneal endothelial disorder, wherein cell proliferation is required, said agent comprising a p38MAP kinase inhibitor. In a preferred embodiment, the corneal endothelial disorder is a wound. In a preferred embodiment, the p38MAP kinase inhibitor is soluble in water. The p38MAP kinase inhibitor may comprise 4-[4-(4-fluorophenyl)-2-(4-methylsulfinylphenyl)-1H-imidazole-5-yl]pyridine (SB203580) or a salt thereof.

Owner:DOSHISHA CO LTD

Glycoside prodrug of 5- aminosalicylic acid

InactiveUS20070173461A1Reduce systemic side effectsIncrease doseBiocideSugar derivativesManagement of ulcerative colitisLarge intestine

An object of the present invention is to provide a therapeutic agent for ulcerative colitis which allows 5-aminosalicylic acid (5-ASA) useful as a therapeutic agent for ulcerative colitis to be efficiently delivered to the large intestine of the affected site almost without being absorbed or metabolized in the stomach or the upper part of the small intestine and is safe and can be administered over a long term. The present invention relates to 5-ASA into which D-galactose represented by the following general formula [1] has been introduced. The compound of the present invention can be efficiently delivered to the large intestine of the site of action, and is degraded by the intestinal bacterial flora, whereby 5-ASA as the active ingredient can be produced in the large intestine.

Owner:NIPPON SHINYAKU CO LTD

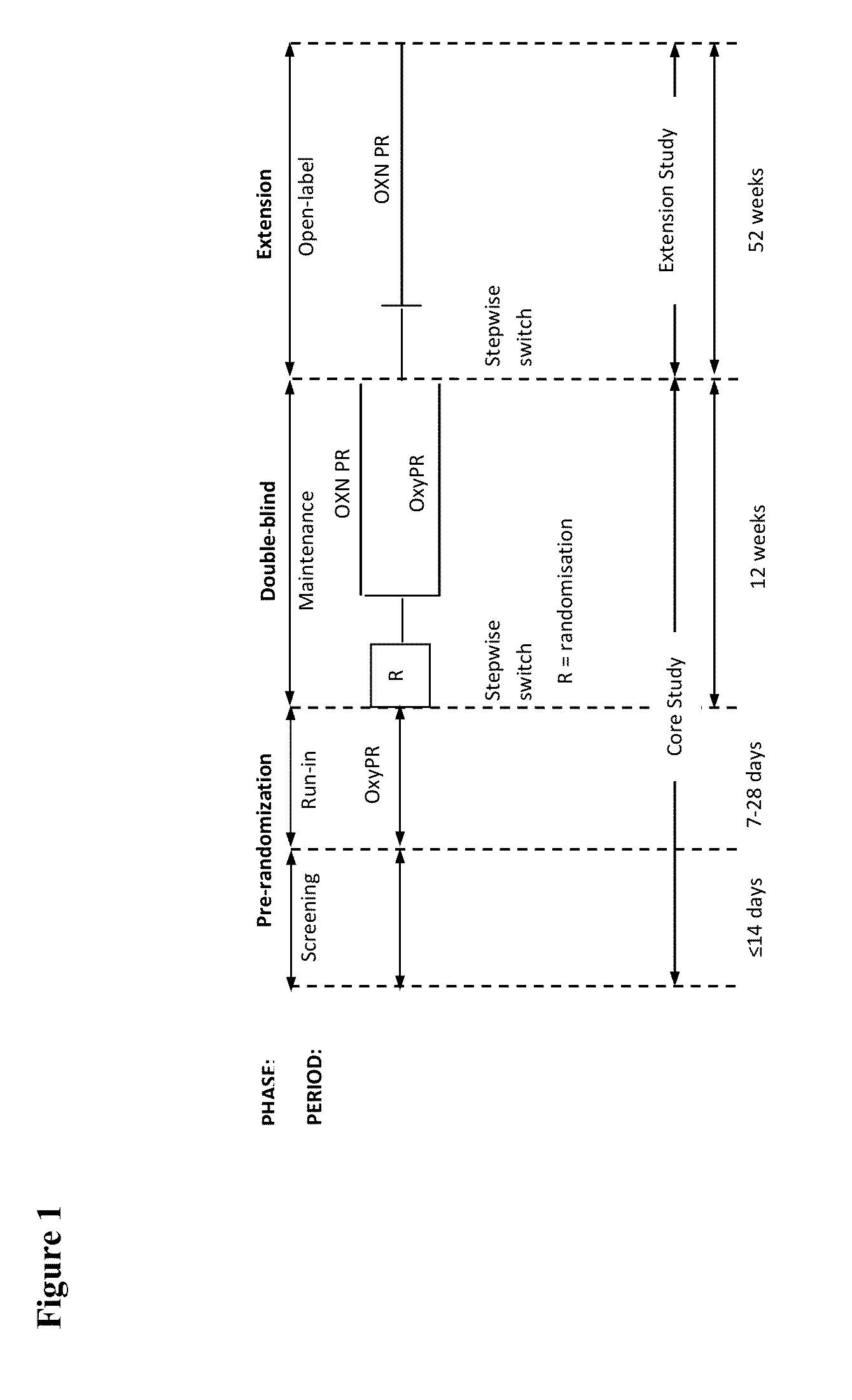

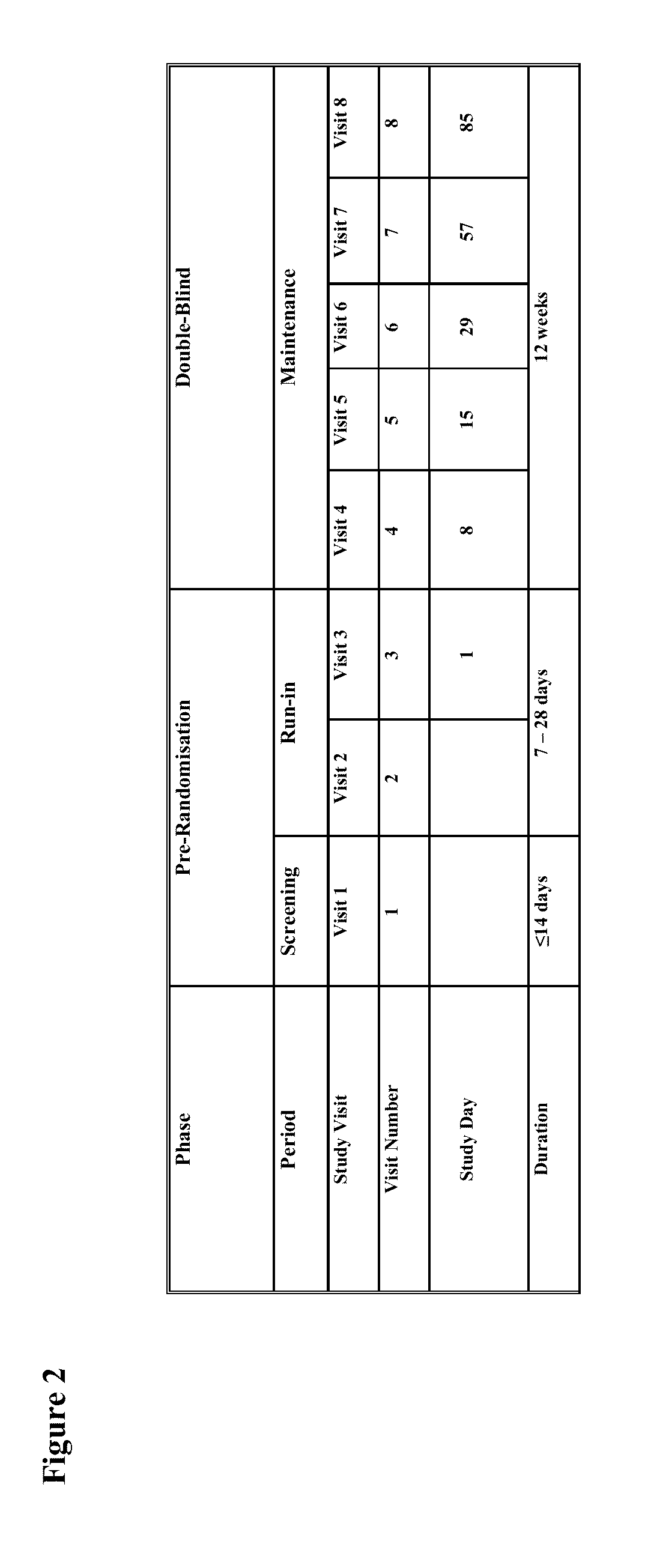

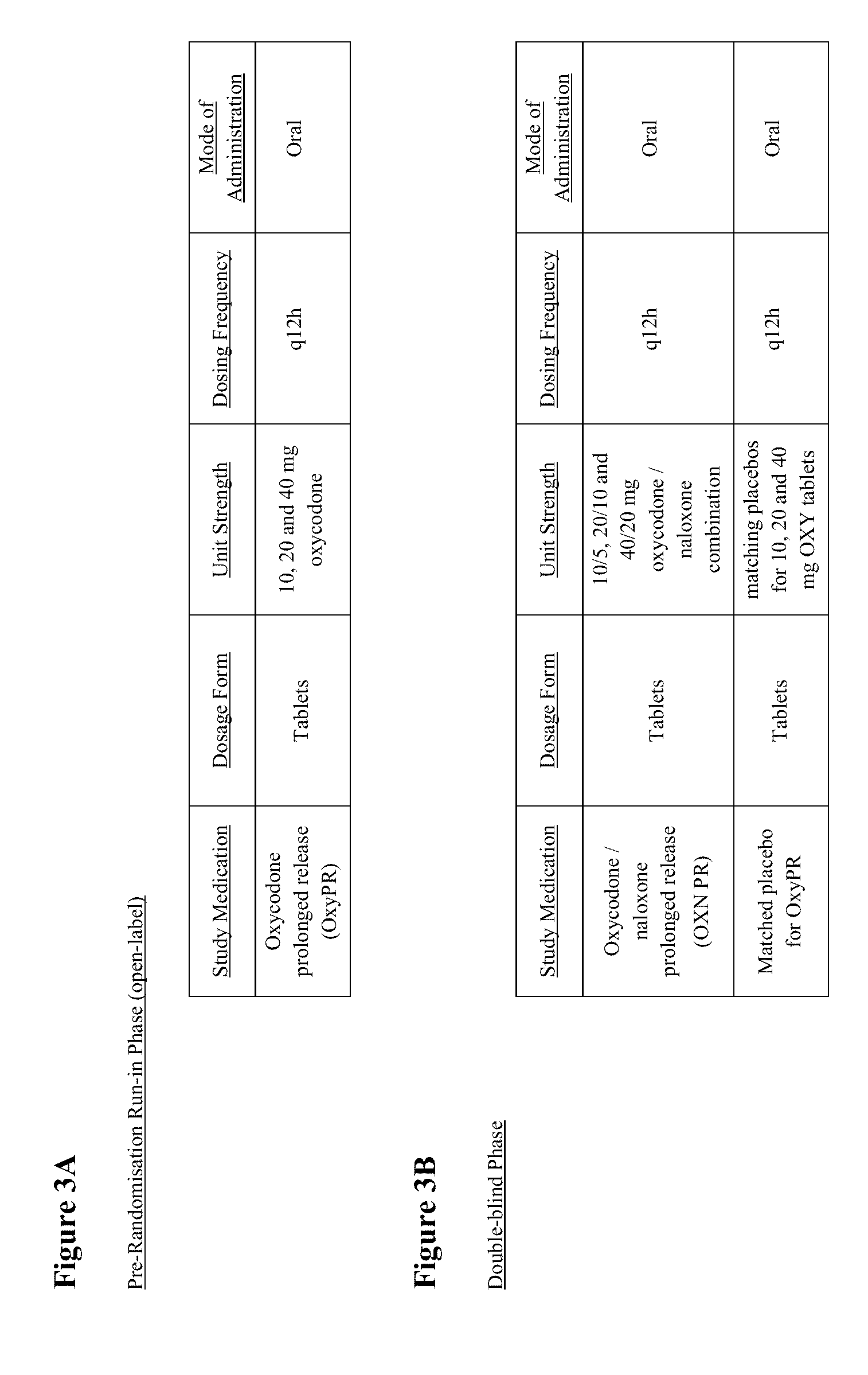

Combination of an opioid agonist and an opioid antagonist in the treatment of parkinson's disease

InactiveUS20140037729A1Prominent effectImprove the first effectBiocidePowder deliveryDrugOpioid antagonist

The present invention provides a pharmaceutical dosage form comprising an opioid agonist and an opioid antagonist for use in the treatment of Parkinson's disease. The present invention also refers to the use of an opioid agonist and an opioid antagonist in such a dosage form.

Owner:PURDUE PHARMA LP

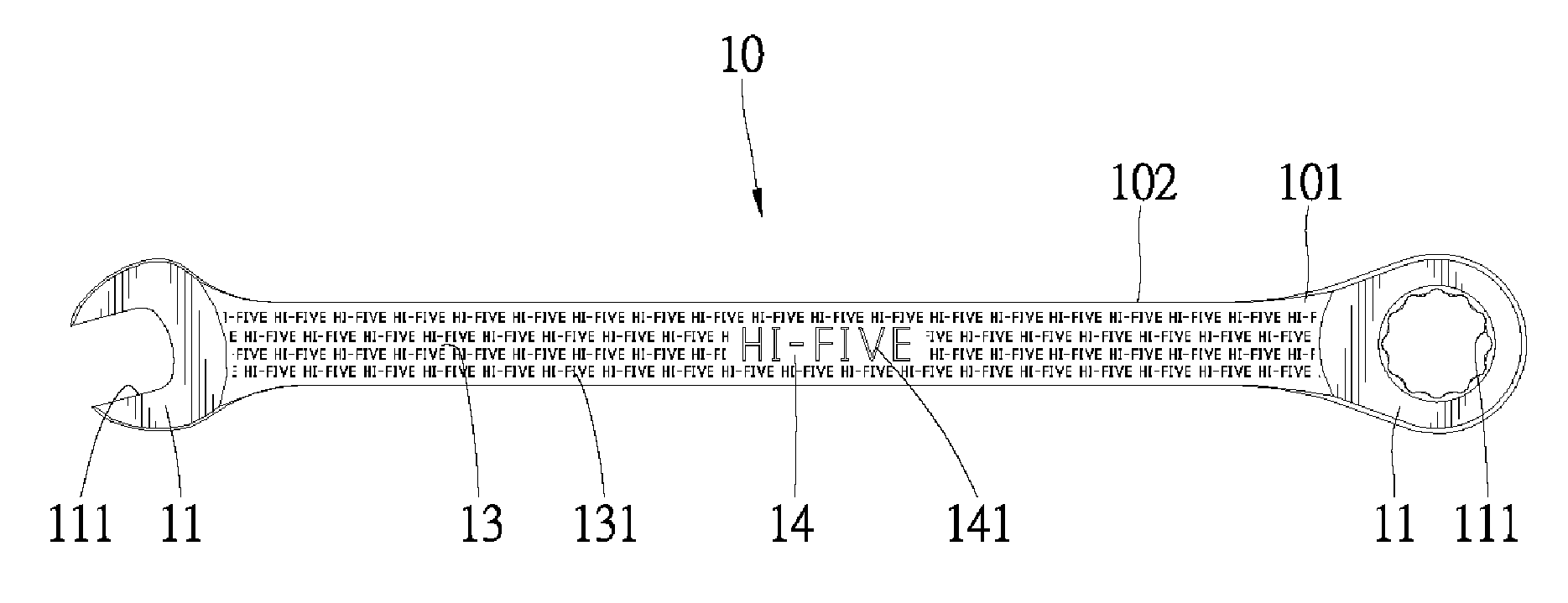

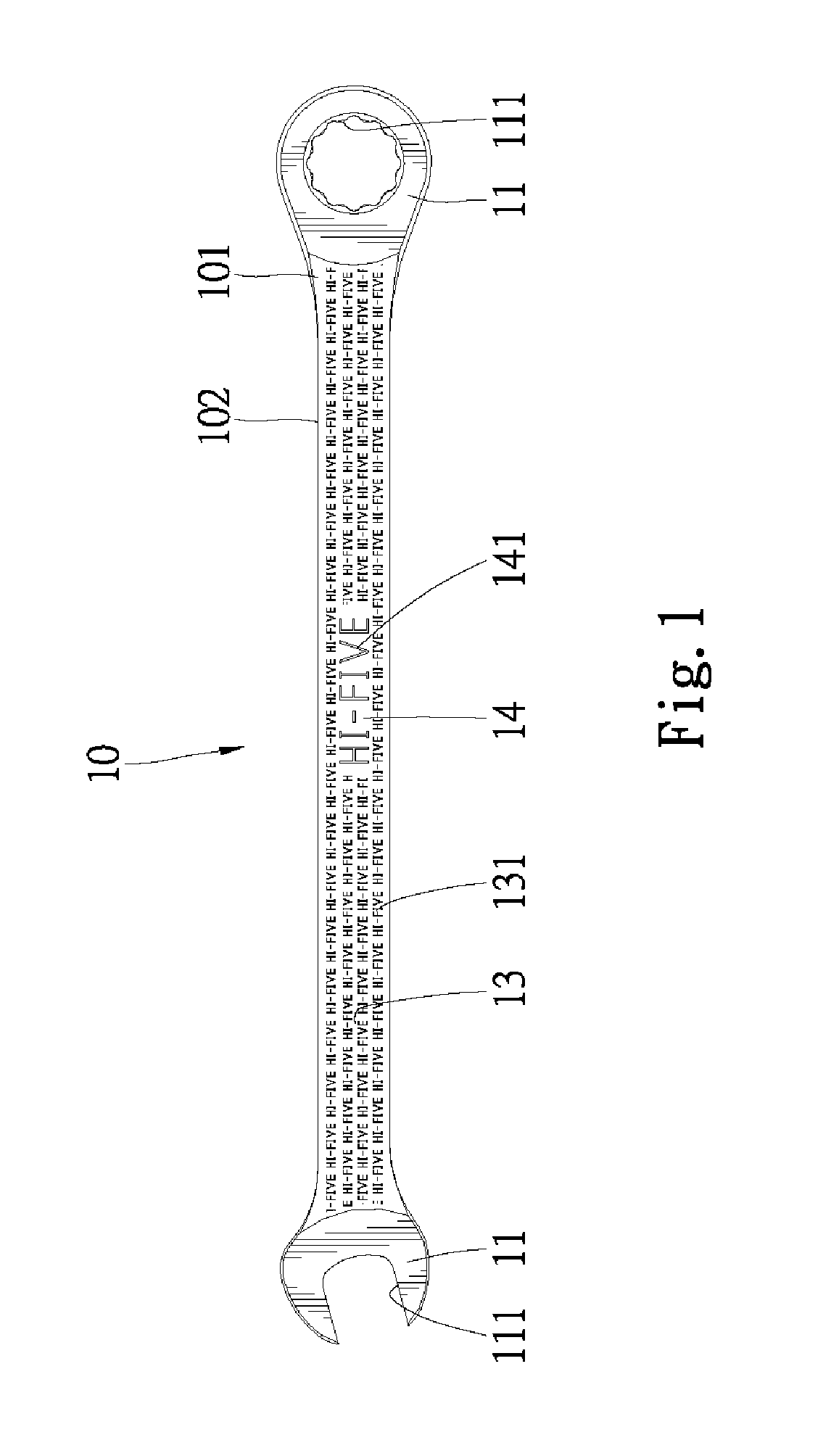

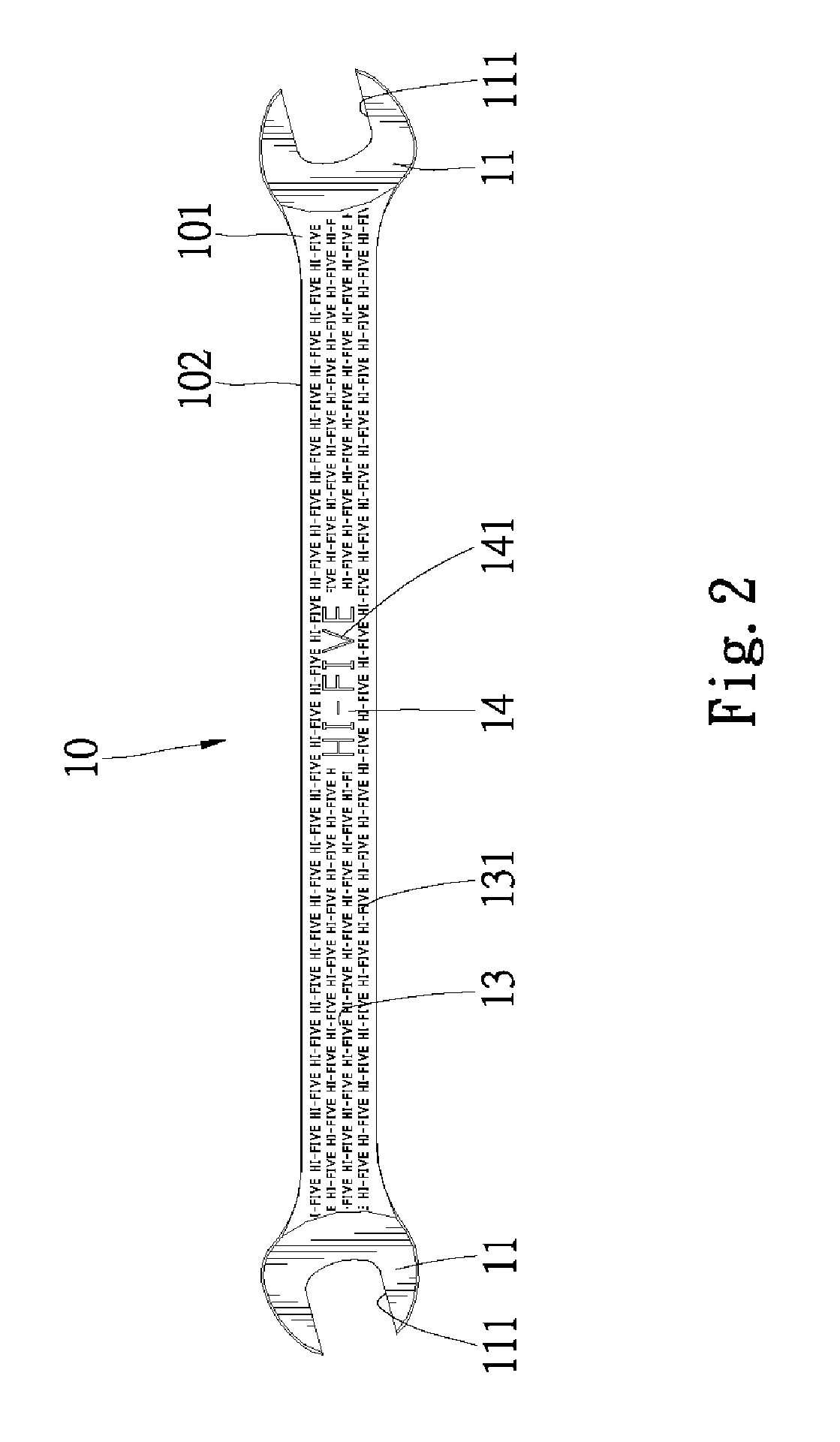

Wrench with pressed character units

A wrench includes a body having two ends and a handle between the ends of the body. At least one of the ends of the body can be used for driving an object. A plurality of character units are provided on each holding face and form an anti-slipping section. At least one of the holding faces includes at least one indication area located in the anti-slipping section. The indication area includes an indication marking.

Owner:HU BOBBY

Polyethylene powder, microporous membrane, and fiber

ActiveUS9362539B2Excellent in resistance to end breakage and dimensional stability and acid resistanceIncrease resistanceLead-acid accumulatorsCell component detailsFiberPolymer science

It is intended to provide a polyethylene powder which can offer a fiber excellent in resistance to end breakage, dimensional stability, and acid resistance and / or a microporous membrane excellent in dimensional stability and acid resistance, and a microporous membrane and a fiber which are obtained by forming the polyethylene powder. The present invention provides a polyethylene powder comprising: 0.5 ppm or higher and 3,000 ppm or lower of aluminum hydroxide having an average particle size smaller than 50 μm; and 0.5 ppm or higher and 12 ppm or lower of a magnesium element, wherein the polyethylene has a viscosity-average molecular weight of 100,000 or larger.

Owner:ASAHI KASEI CHEM CORP

Polyketone Fiber Paper, Polyketone Fiber Paper Core Material For Printed Wiring Board, And Printed Wiring Board

InactiveUS20080105395A1High modulusHigh strengthNon-fibrous pulp additionNatural cellulose pulp/paperEpoxyVoid ratio

An aliphatic polyketone fiber paper comprising aliphatic polyketone fibers and a polyketone fiber paper core material for a printed wiring board are provided. The polyketone fiber paper and the core material have high strength and modulus of elasticity; excellent dimensional stability, chemical resistance, heat resistance, adhesiveness and electrical insulation; and low dielectricity and water absorbance, and are thin, porous, and uniform. A printed wiring board prepared from the core material having a low dielectric constant, dimensional stability, electrical insulation, and properties of being uniformly bored by laser punching is also provided. The aliphatic polyketone fiber paper and the core material for a printed wiring board comprises 1 to 100% by mass of aliphatic polyketone fibers which comprise the repeating unit of the below-mentioned formula (1), the fibers having an average fiber length of 0.5 to 10 mm, an average fiber diameter of 0.1 to 20 μm, a thickness of 5 to 200 μm, a void ratio of 30 to 90%, and a strength per unit mass of 100 MN / kg or more. Also provided is a single layer or multilayer printed wiring board which comprises a core material impregnated or coated with a polymer resin, a low dielectric polymer resin, or a polyphenylene ether-based epoxy resin.—CH2—CH2—CO— (1)

Owner:ASAHI KASEI CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com