Patents

Literature

204 results about "Foam fractionation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

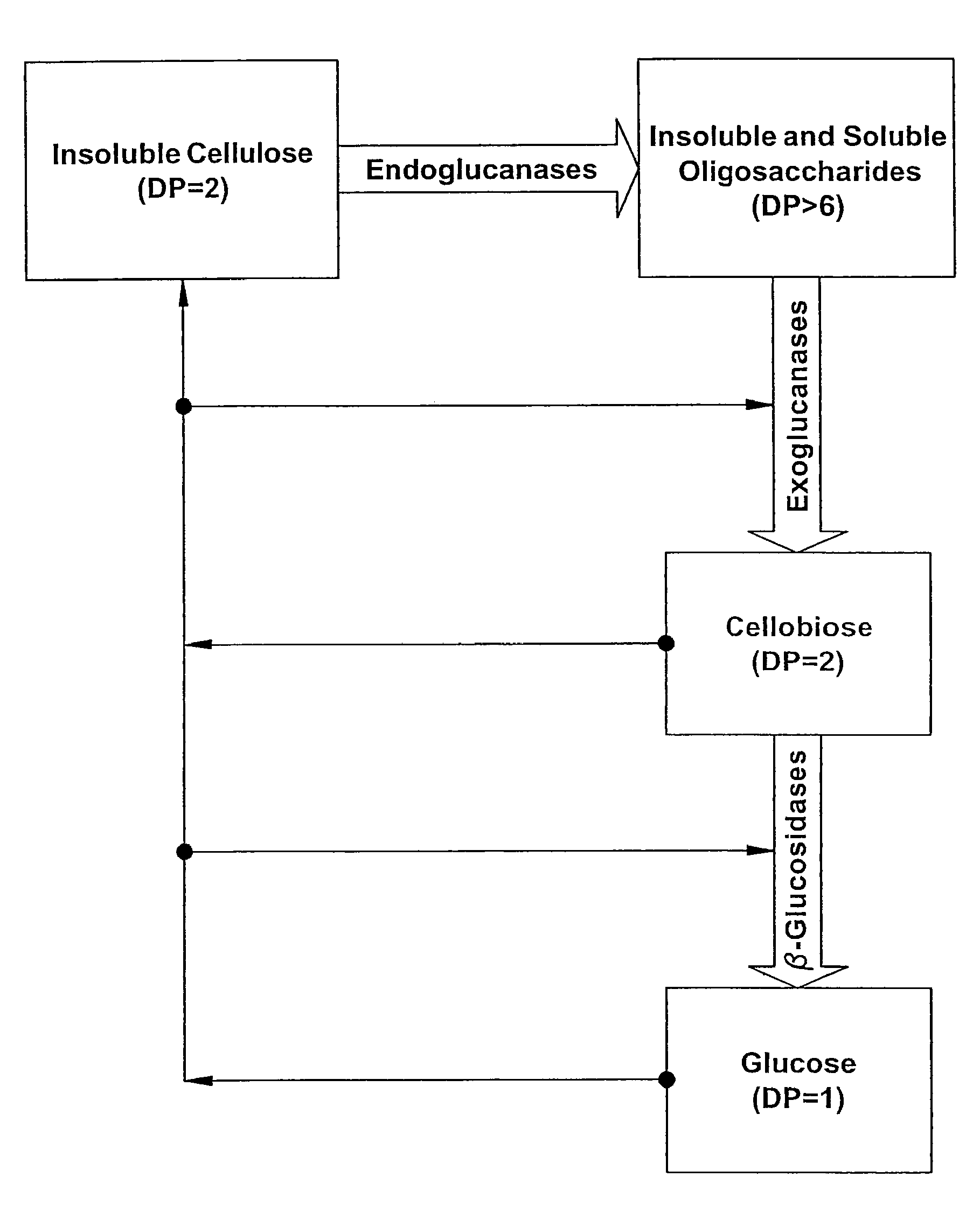

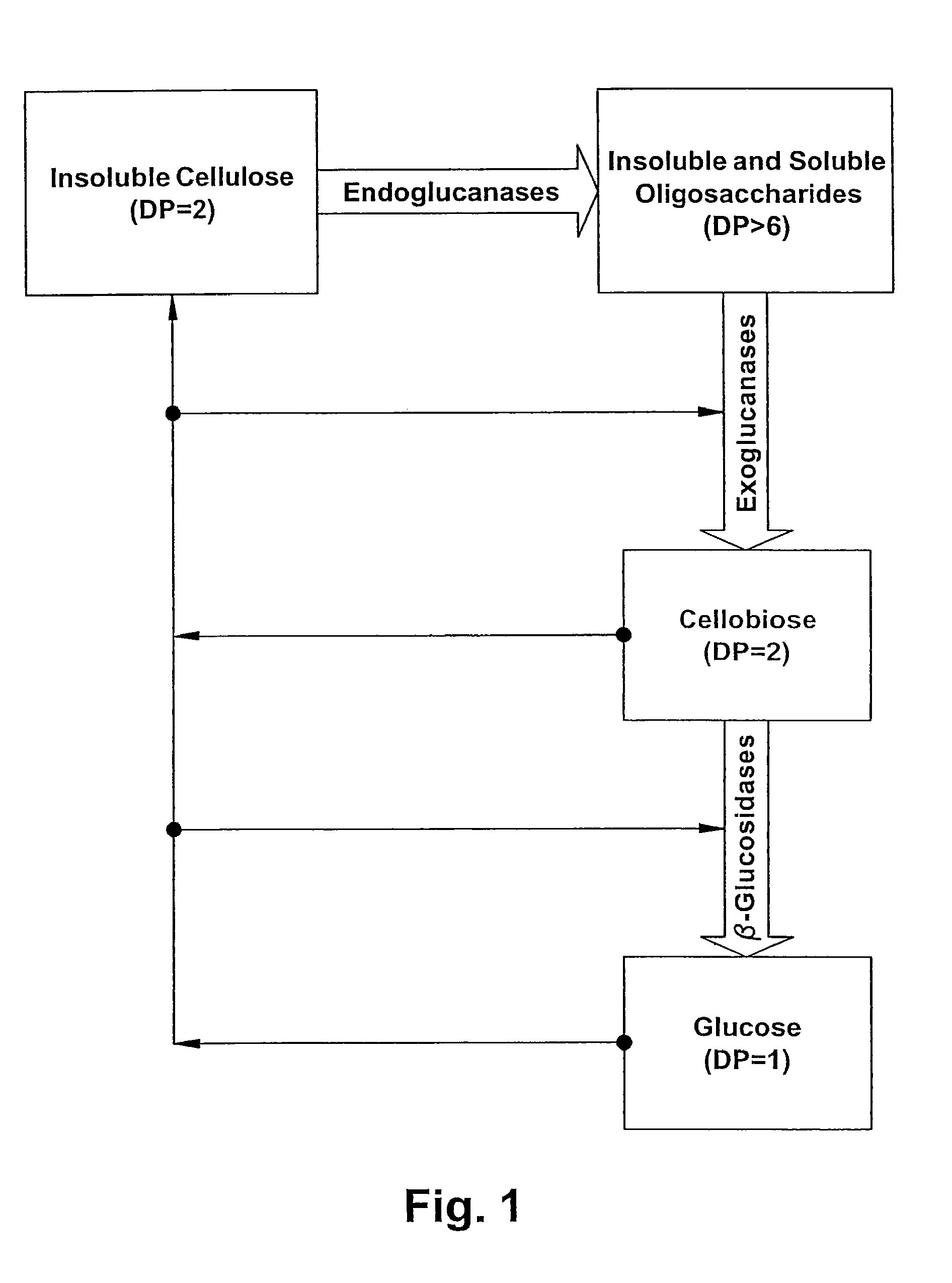

Foam fractionation is a chemical process in which hydrophobic molecules are preferentially separated from a liquid solution using rising columns of foam. It is commonly used, albeit on a small scale, for the removal of organic waste from aquariums; these units are known as "protein skimmers". However it has much broader application in the chemical process industry and can be used for the removal of surface active contaminants from waste water streams in addition to the enrichment of bio-products.

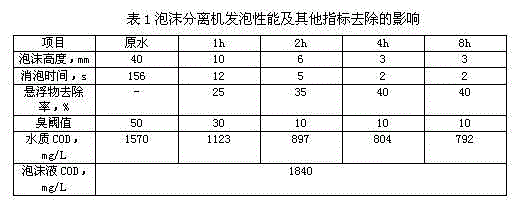

Water treatment method of circulating water fish culture in factory style

InactiveCN1545865AReduce BODReduce CODClimate change adaptationPisciculture and aquariaHuman wasteWater quality

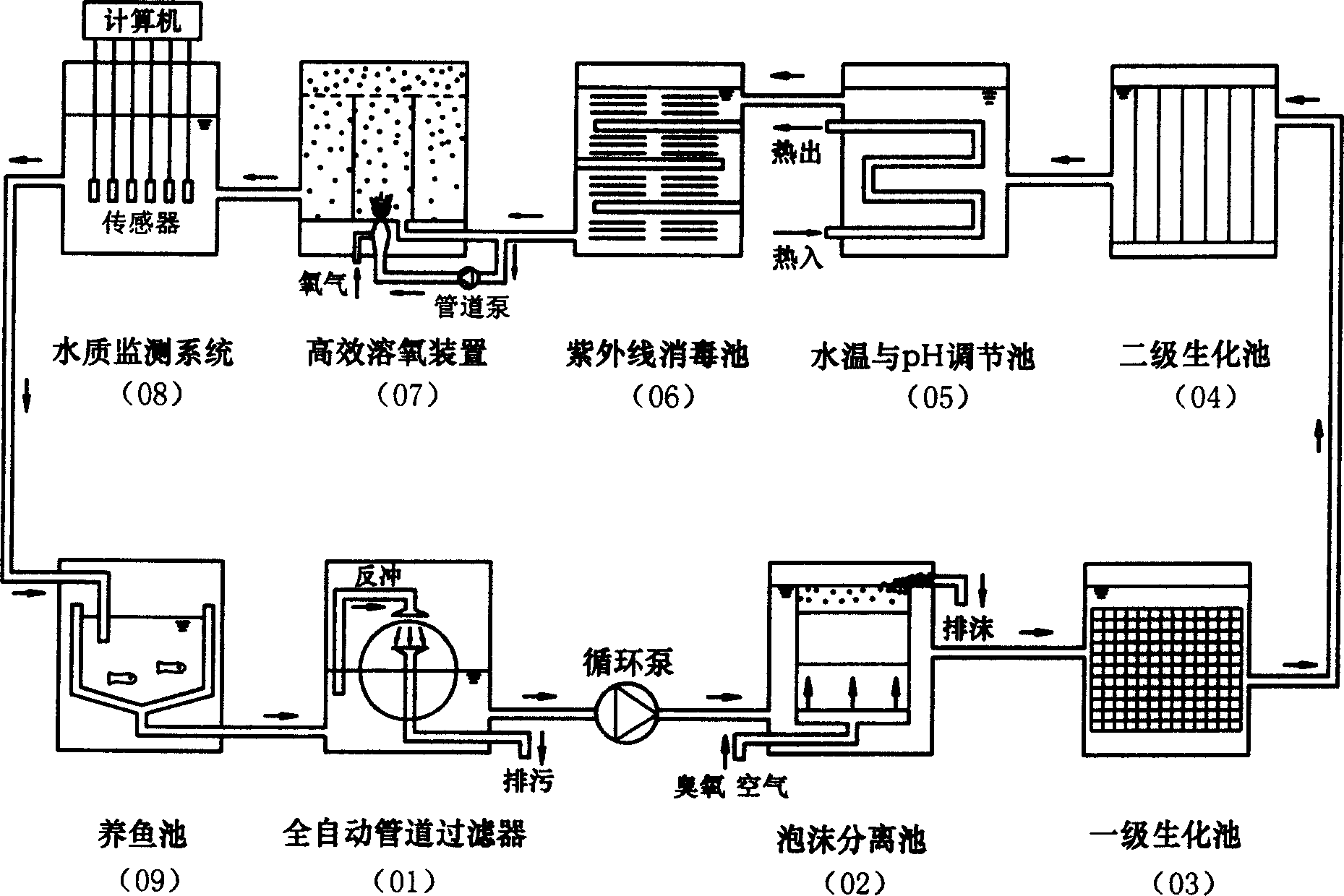

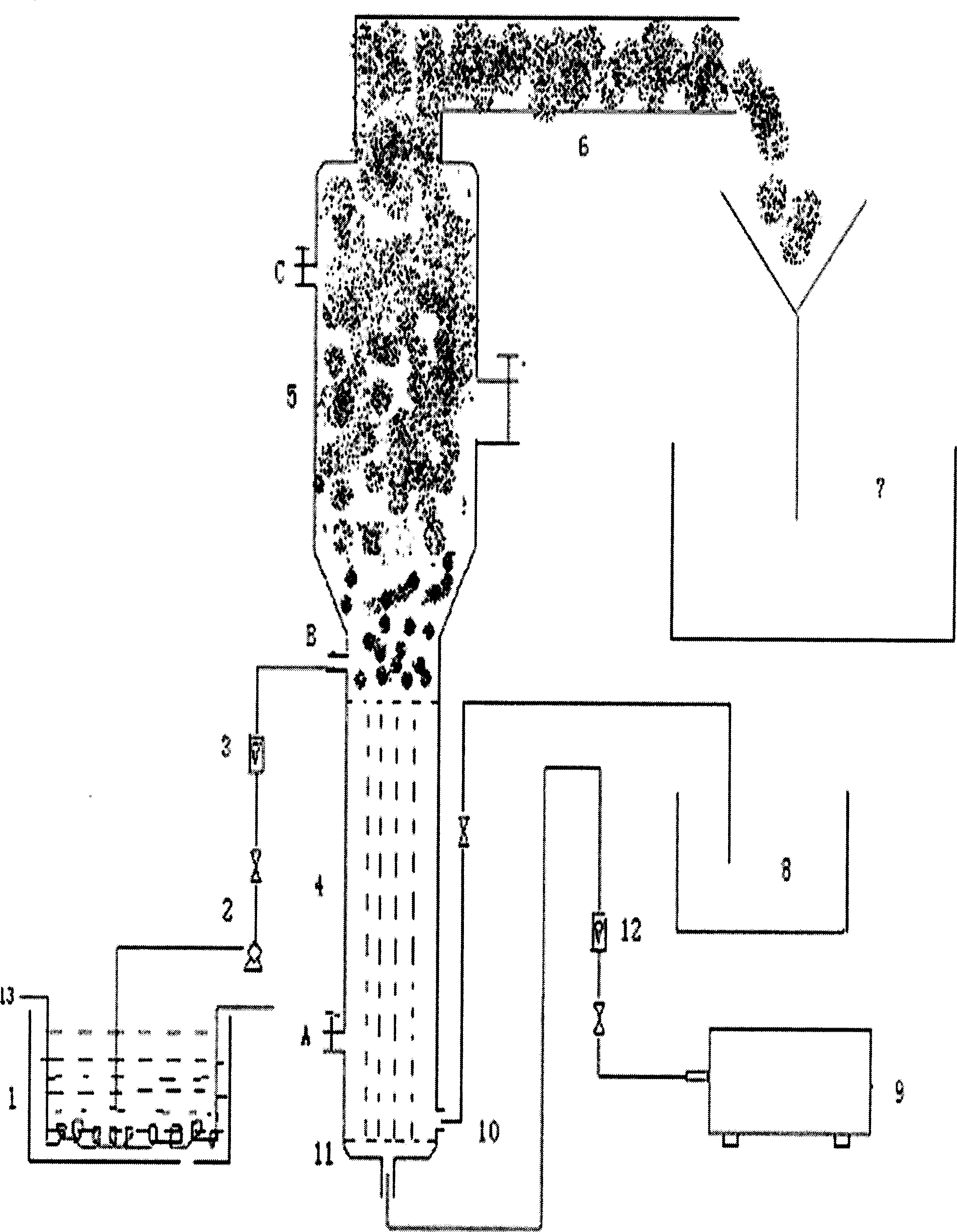

The invention discloses a seawater factory-style circulating water fish farming treatment method which comprises, removing the residual bait and excrement from the seawater flowing out of the fish pond through full-automatic conduit pipe filter apparatus, entering foam separate tank from the circulating pump to remove part of the suspended matter and protein, then removing ammonia nitrogen through biological cleaning tank, adjusting water temperature and pH, disinfecting through ultraviolet rays, oxygenation, charging the detected water into the fish pond again, thus completing a circulation.

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI

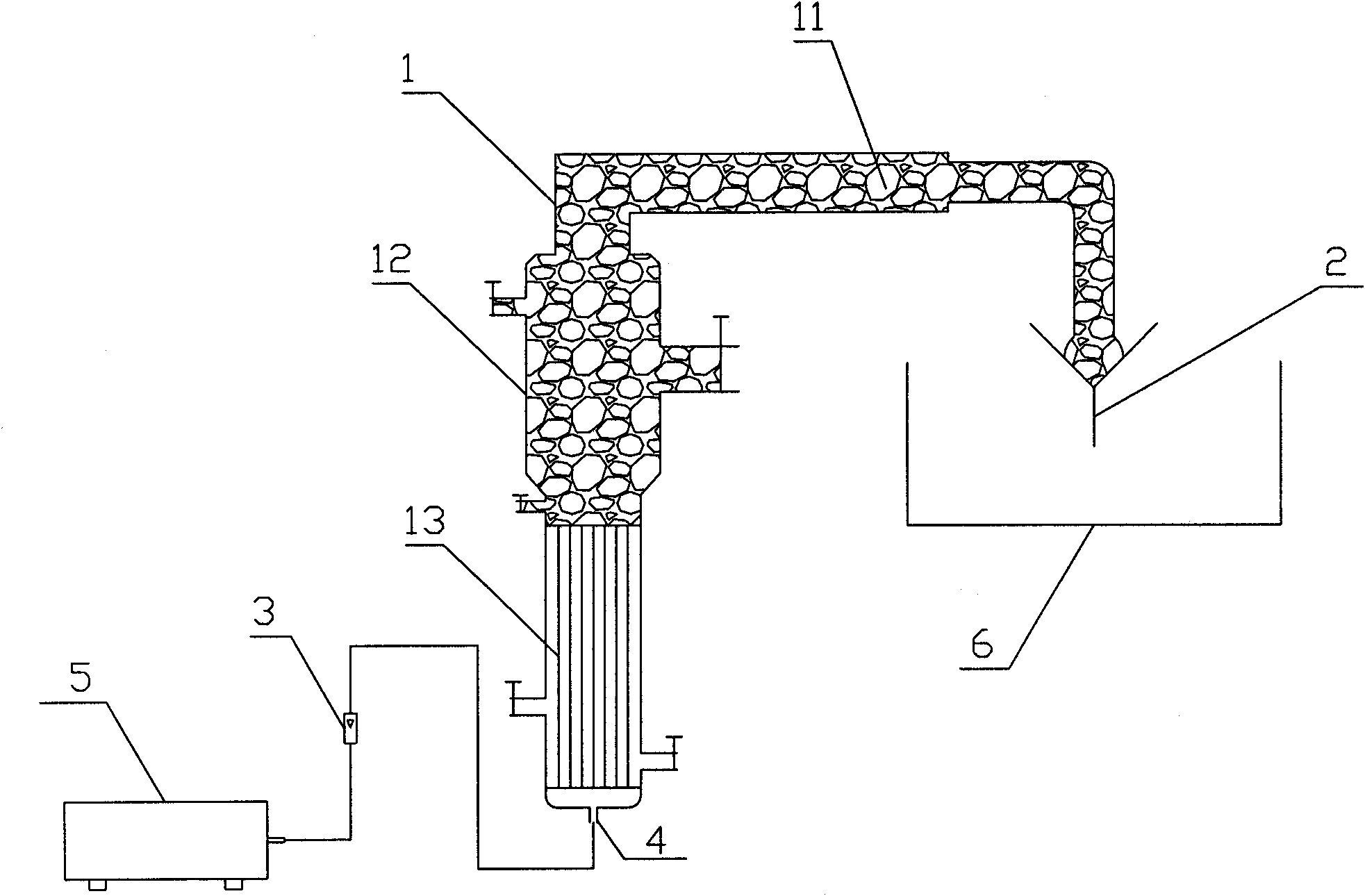

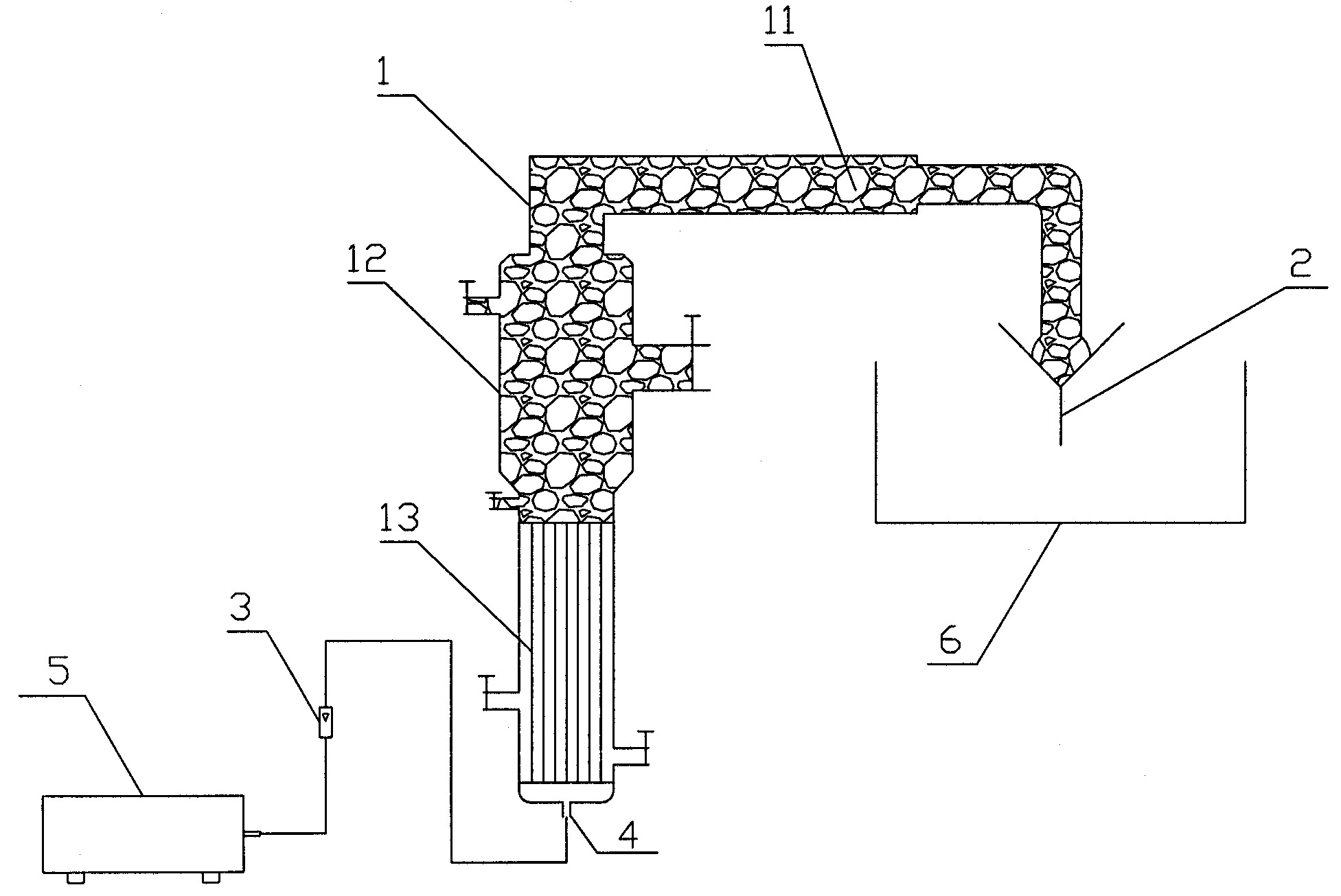

Industrialization ecological treatment circulation utilization system for fish culture waste water

InactiveCN101215069AImprove processing efficiencyReduce energy consumptionMultistage water/sewage treatmentSustainable biological treatmentAxial-flow pumpConstructed wetland

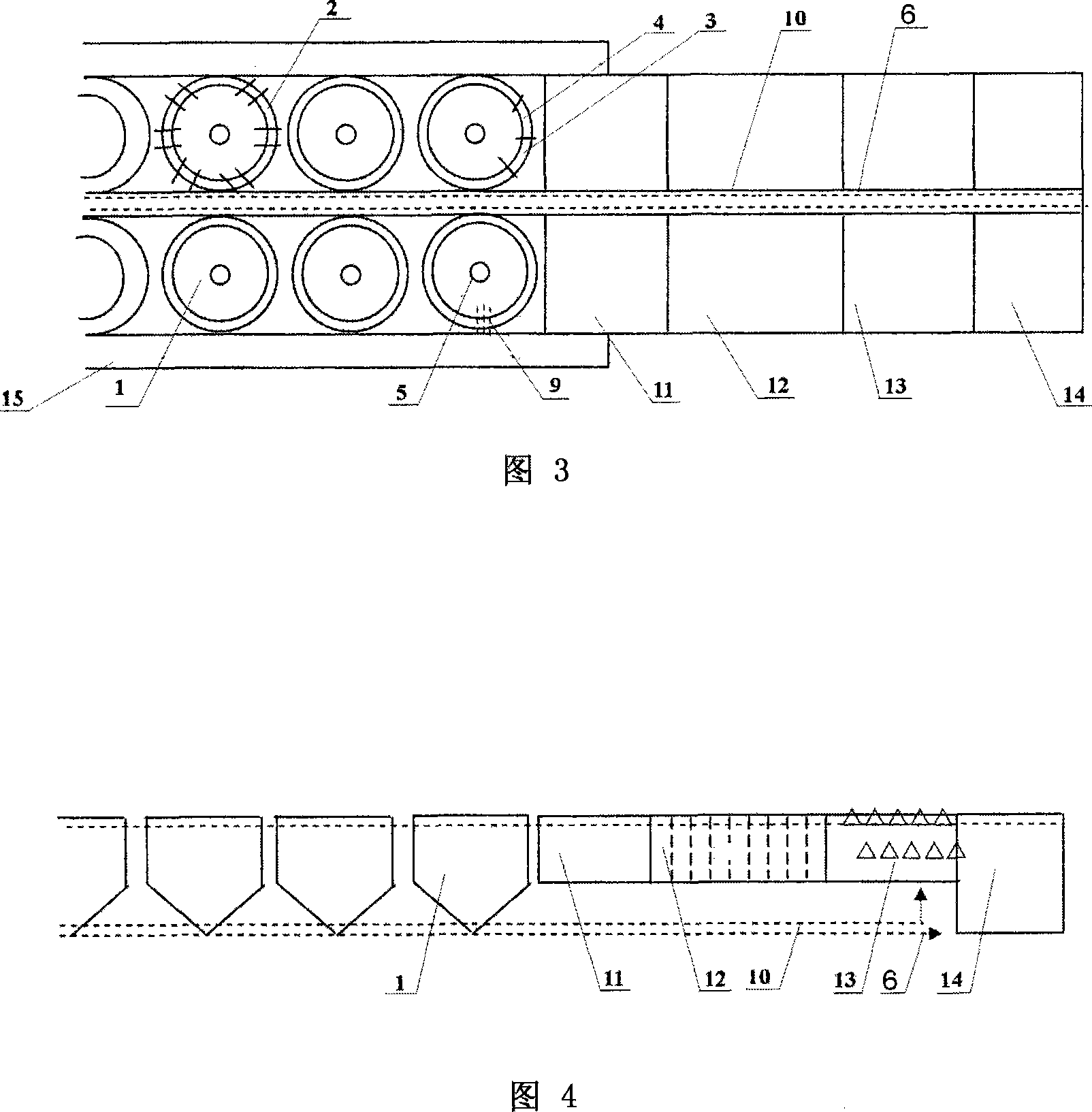

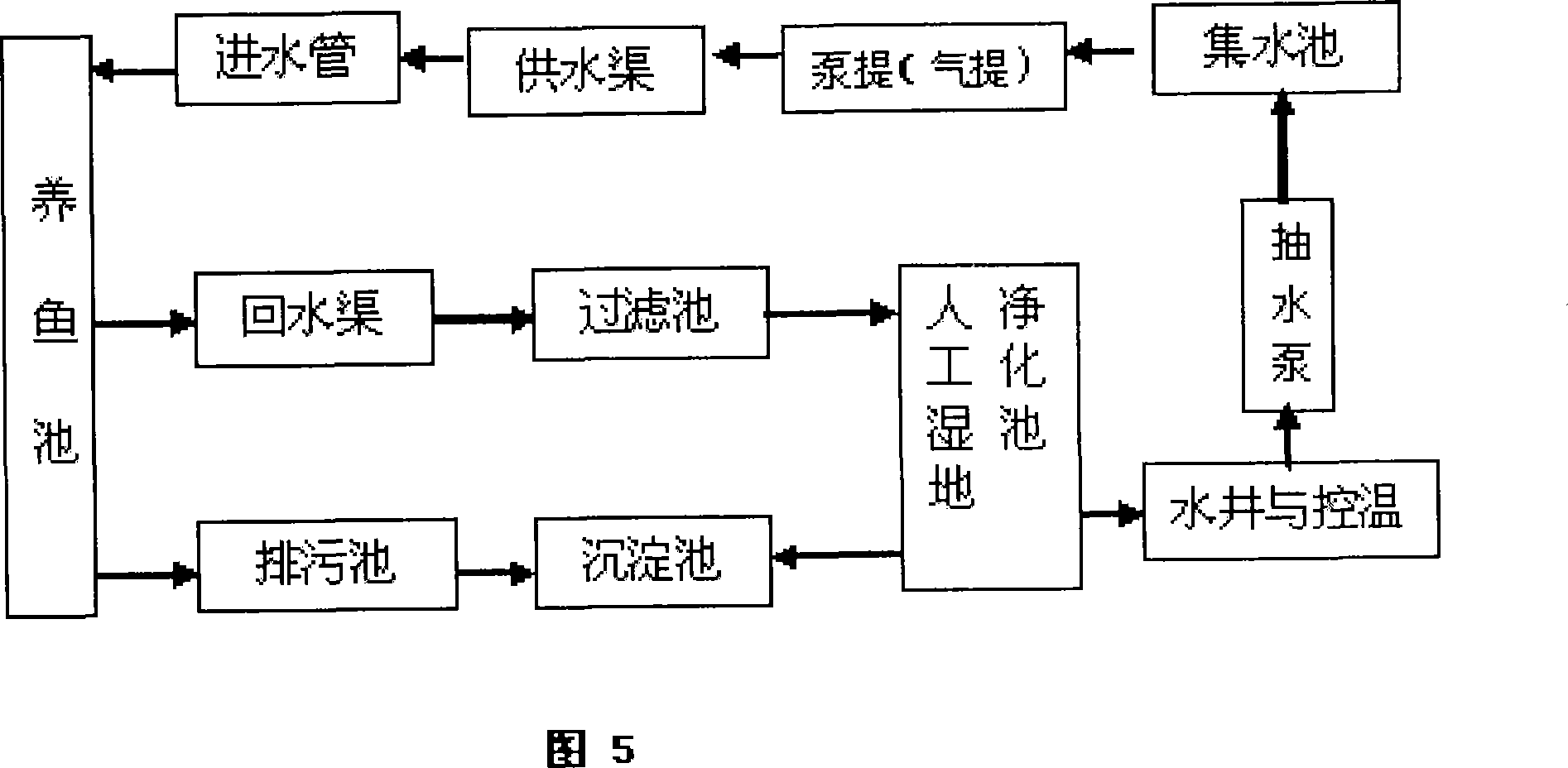

Disclosed is an ecological treatment and recycling system for factory fish-farming wastewater, which belongs to the field of fishery cultivation. The system comprises facilities and devices for treating recycle water like a fish pond, an ultra-low axial flow pump, a jet aeration oxygenation facility, a foam separating facility, a pure oxygen supplying device, a temperature control device, artificial wetland and the like, using an open type high-volume feed canal and a backwater canal to replace sealed pipes, using the foam separating facility to replace a protein separator, using the temperature control device of deep well to replace a heating-up and cool-down device, using the jet aeration oxygenation facility to replace an automatic aerator, a gas relay rock and an air pipe, using water plants of the artificial wetland and economic filtering materials to replace purifying filtration devices like a solid-liquid separation device and the like. The invention achieves functions like water lift, aeration, oxygenation, defoaming, temperature control and the like. The invention optimizes and combines a facility engineering technique and a biologic technology to replace expensive and complex water-treating equipment, and has the advantages of safety and dependability, simple management, energy-saving and environment protection, high yield and high grade and the like.

Owner:宜都天峡特种渔业有限公司

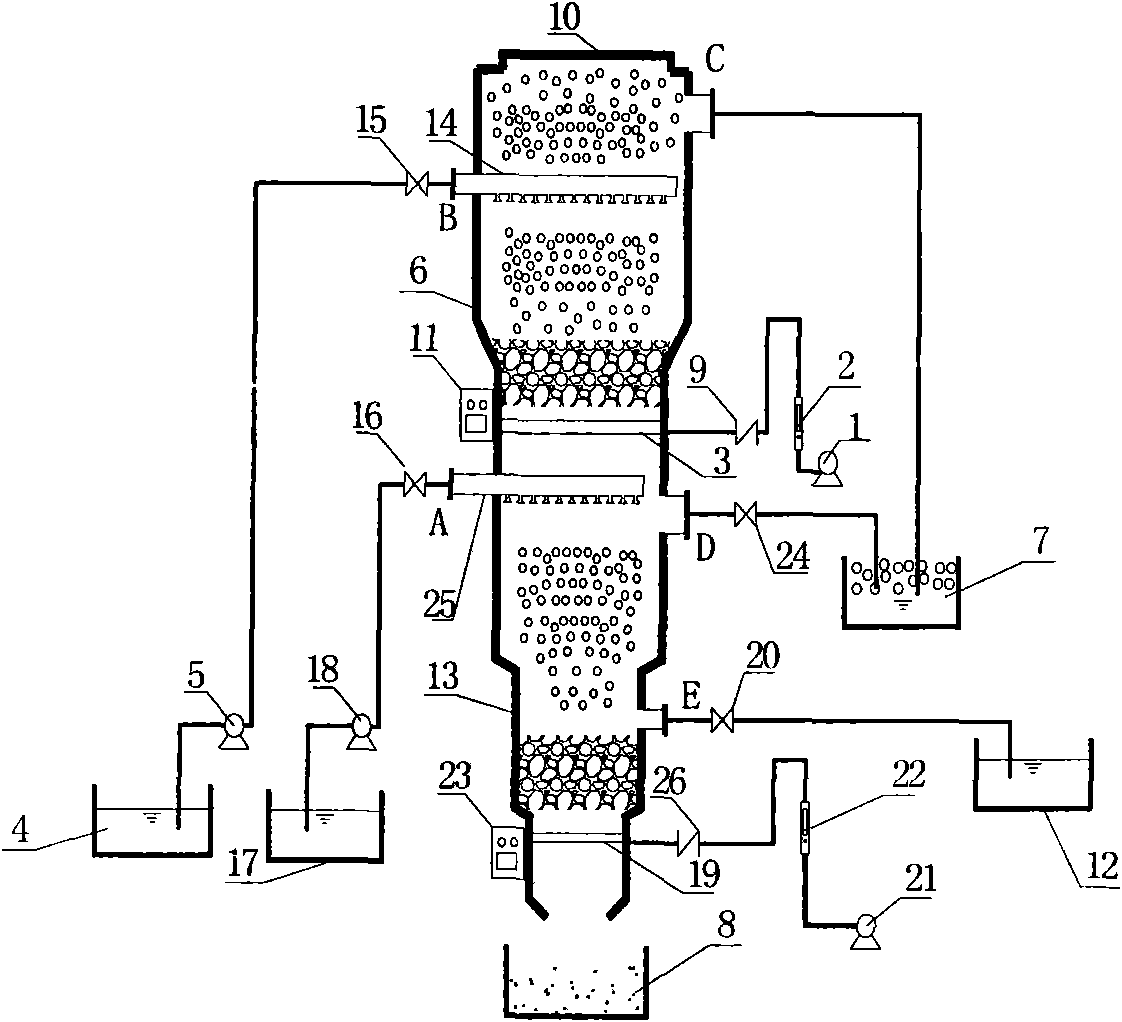

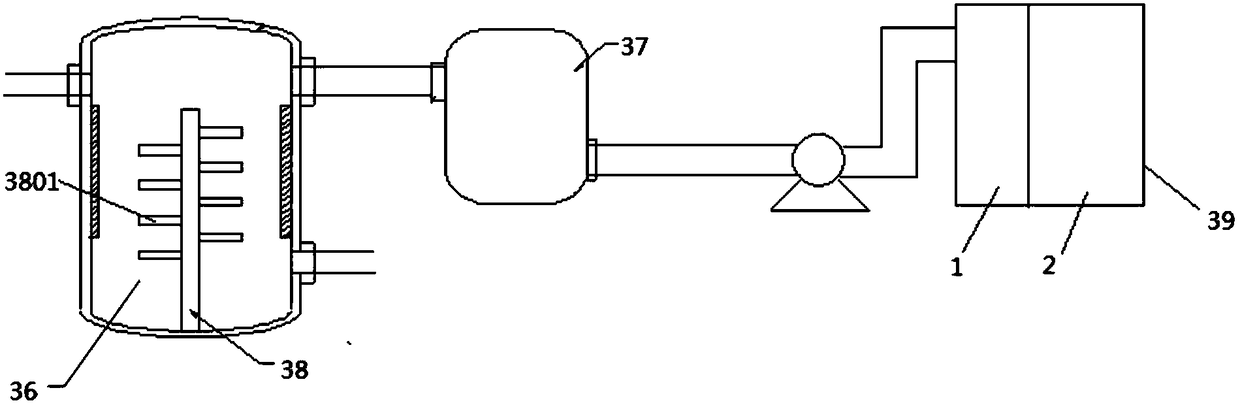

Integrated circulating water culture system

ActiveCN102754613AQuick removalEfficient removalMultistage water/sewage treatmentPisciculture and aquariaSuspended particlesParticulates

The invention discloses an integrated circulating water culture system which comprises a culture water tank, a foam separation and degassing chamber, a biological active carbon nitration reaction chamber and a low-pressure gas dissolution chamber, and is characterized in that: one part of water from a water drainage structure of the culture water tank is discharged and led into a biological flocculating constituent culture pool from the bottom of the culture water tank, and the other part flows into the foam separation and degassing chamber through an overflow hole at the upper part of the culture water tank; the suspended particles in the culture water are adsorbed by the micro bubbles of the foam separation and degassing chamber and rise to the top of the foam separation and degassing chamber to be discharged out; the culture water flows into the biological active carbon nitration reaction chamber through the foam separation and degassing chamber and is purified by a nitration biomembrane of the biological active carbon nitration reaction chamber and drawn out from the bottom of the biological active carbon nitration reaction chamber; 90% of the culture water drawn out is directly fed into the low-pressure gas dissolution chamber, and 10% of the culture water is fed into a pipeline mixer to mix pure oxygen and ozone and then fed into the low-pressure gas dissolution chamber; and the processed culture water flows back to the culture water tank from a drainage hole at the bottom of the low-pressure gas dissolution chamber.

Owner:SHANGHAI OCEAN UNIV

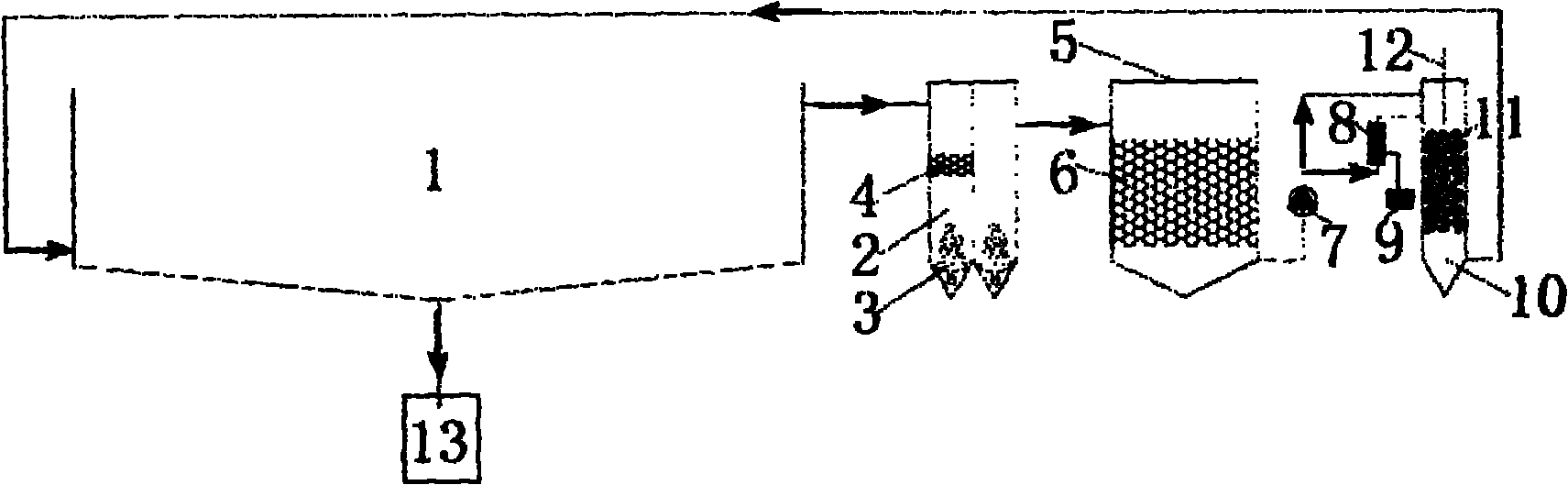

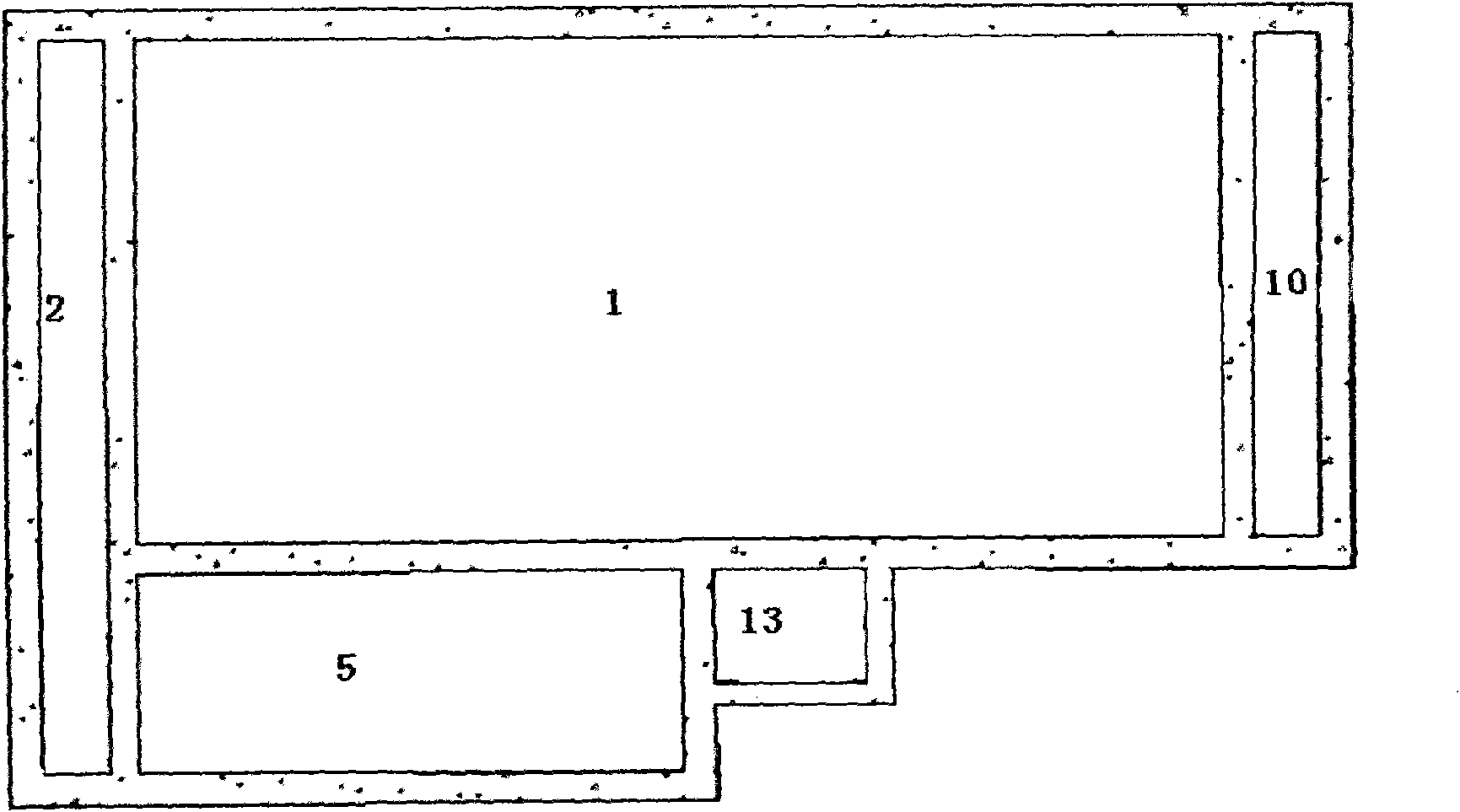

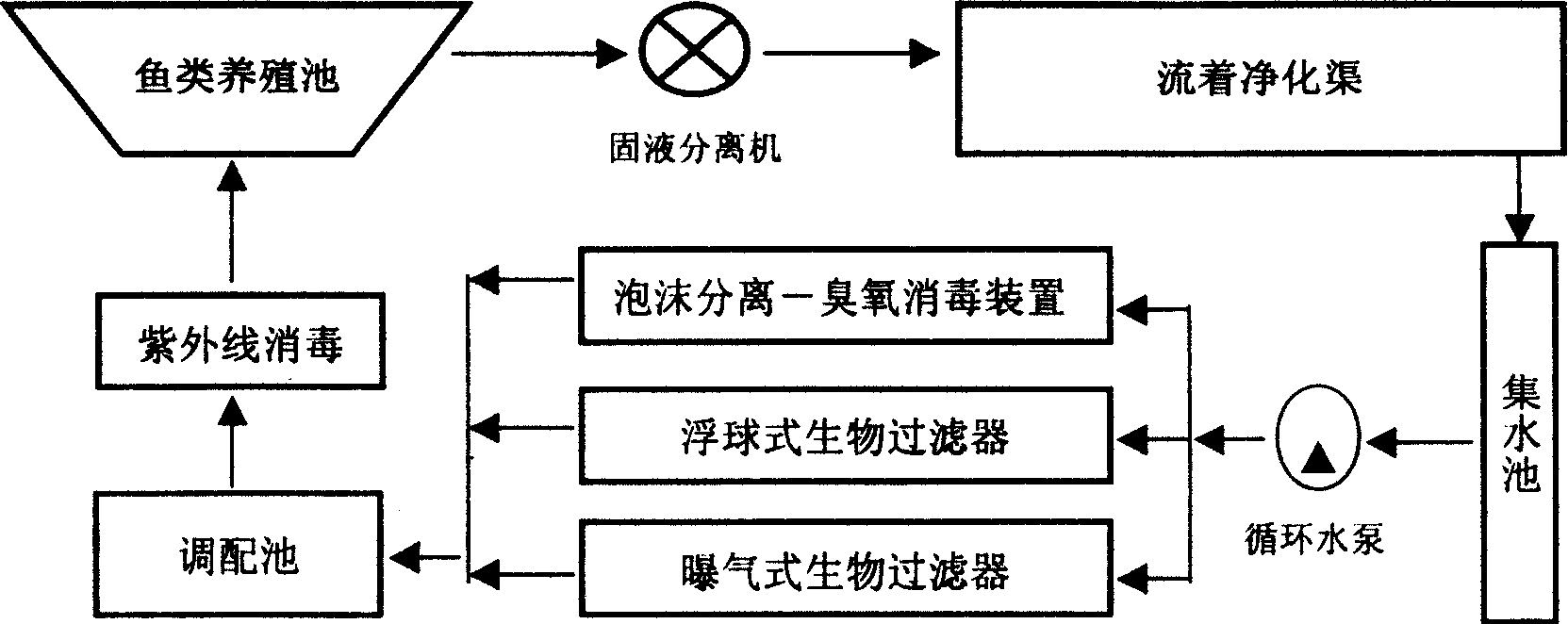

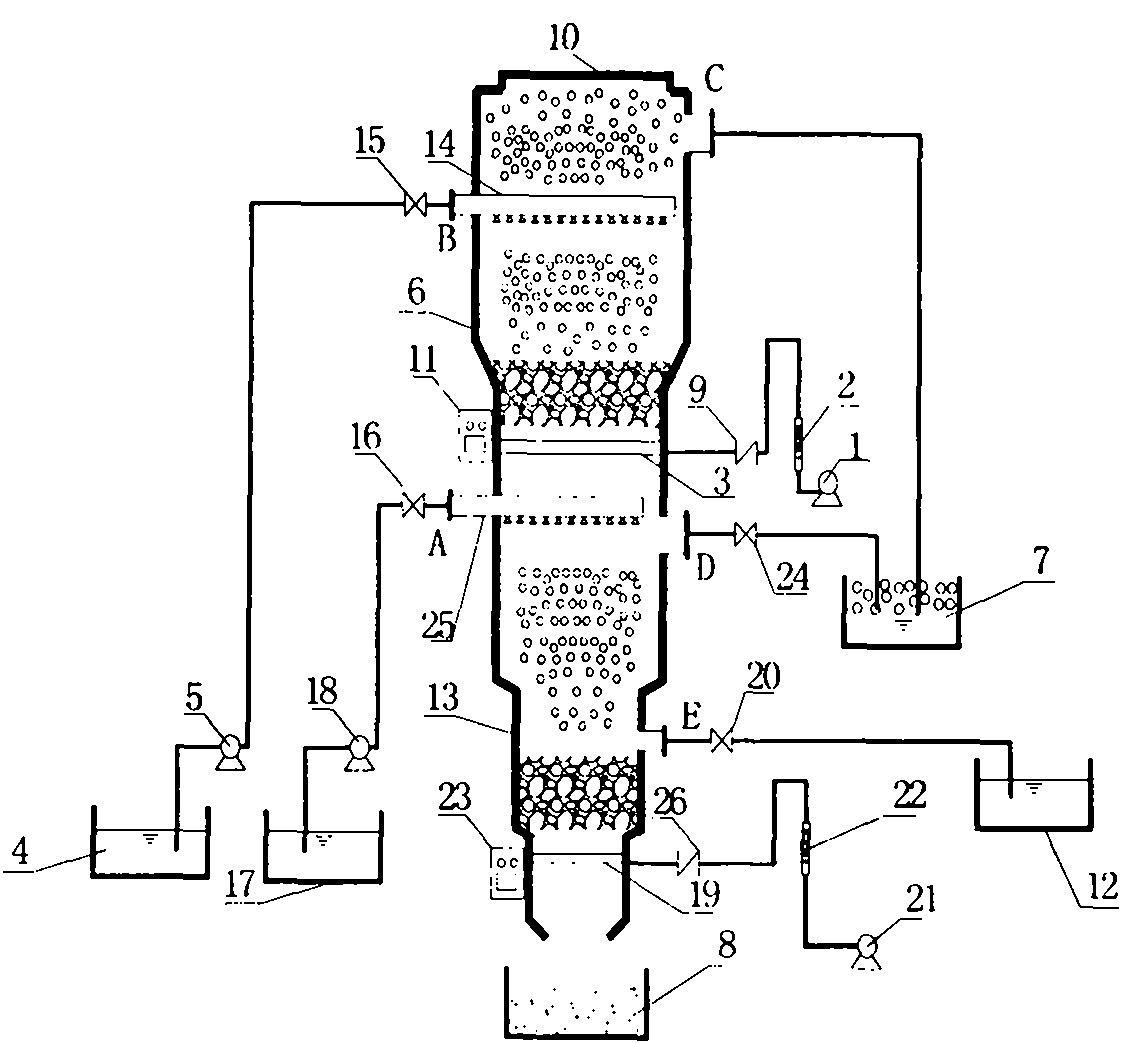

Aquiculturing system process for works with circulating water

InactiveCN1981574AReduce in quantityReduce operating energy consumptionClimate change adaptationWater aerationBiological filterClosed loop

An industrinized aquatic product culturing technology with closed-loop circulated water system includes such steps as pumping the culture water from culture pool into drum-type solid-liquid separator, removing suspended big particles, making the water flow through a purifying channel to remove suspended small particles and part of NH4-N and NO2-N, collecting the water in a pool, pumping the water into an aerating bio-filter and floating ball type bio-filter, removing the most of NH4-N, NO2-N and COD, by-passing through foam separating-ozone disinfecting unit for removing COD and suspended fine particles while disinfecting and aerating, regulating pH value and water temp, ultraviolet disinfecting, and returning the water back into culture pool.

Owner:SHANGHAI OCEAN UNIV

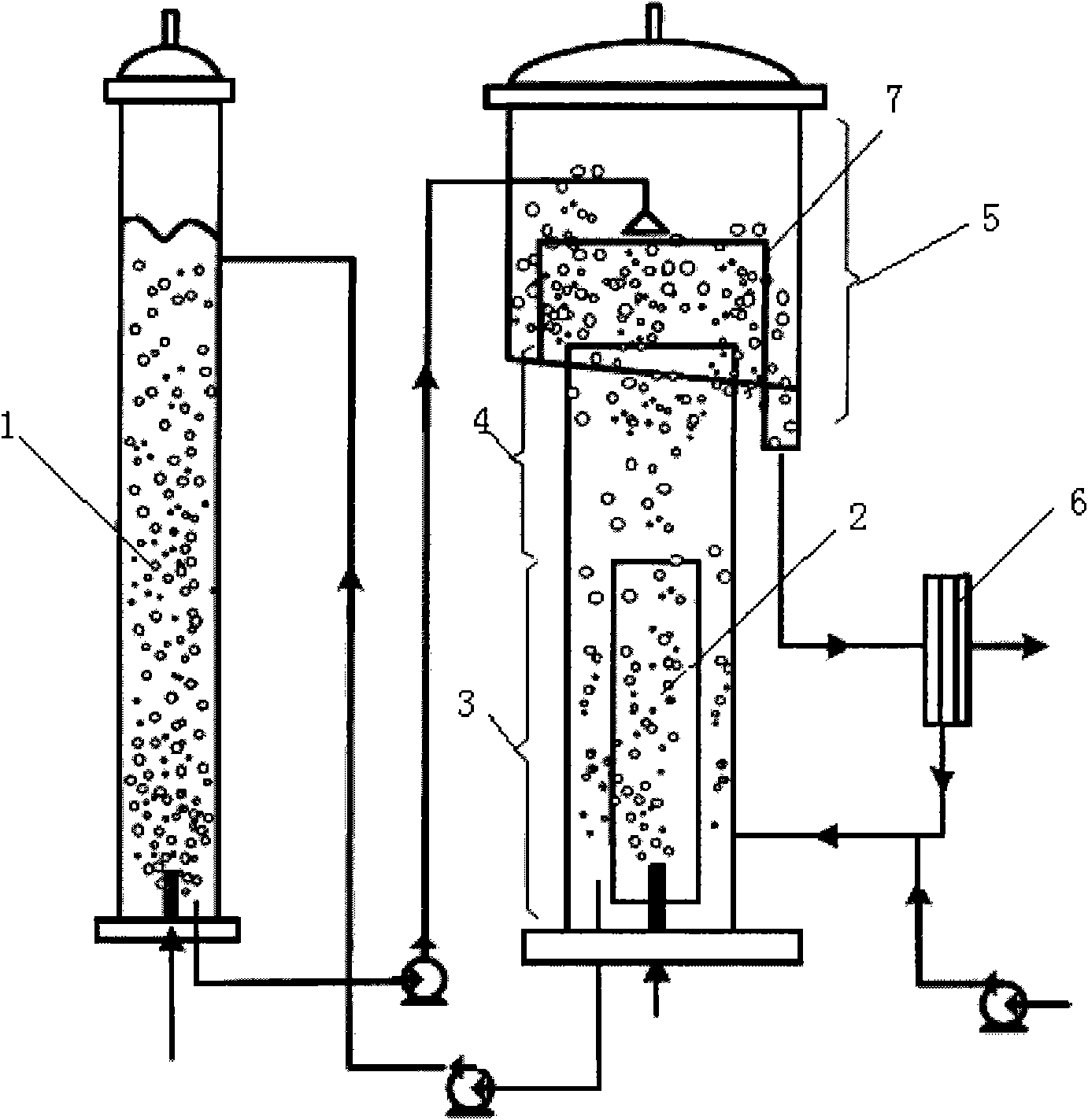

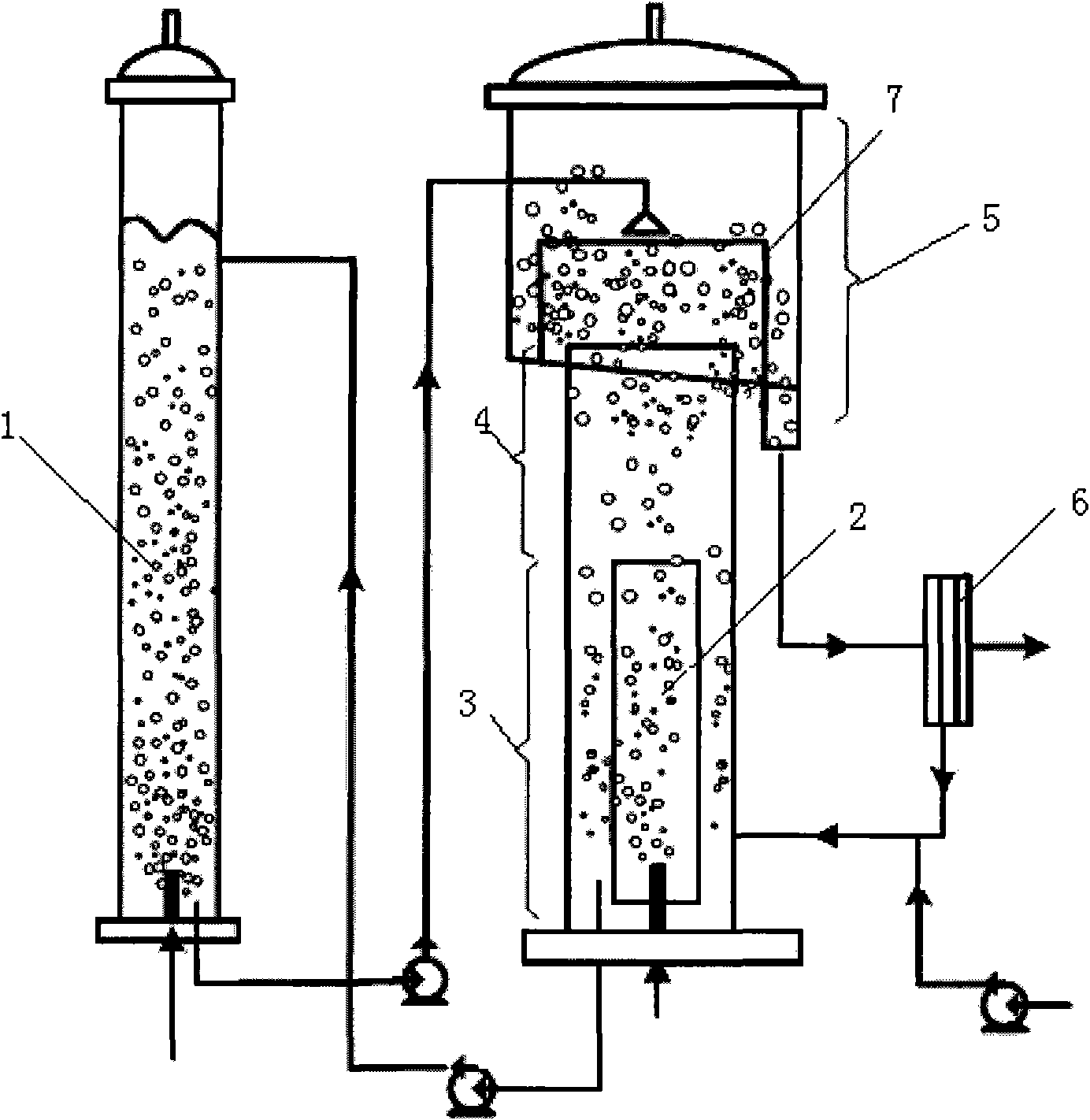

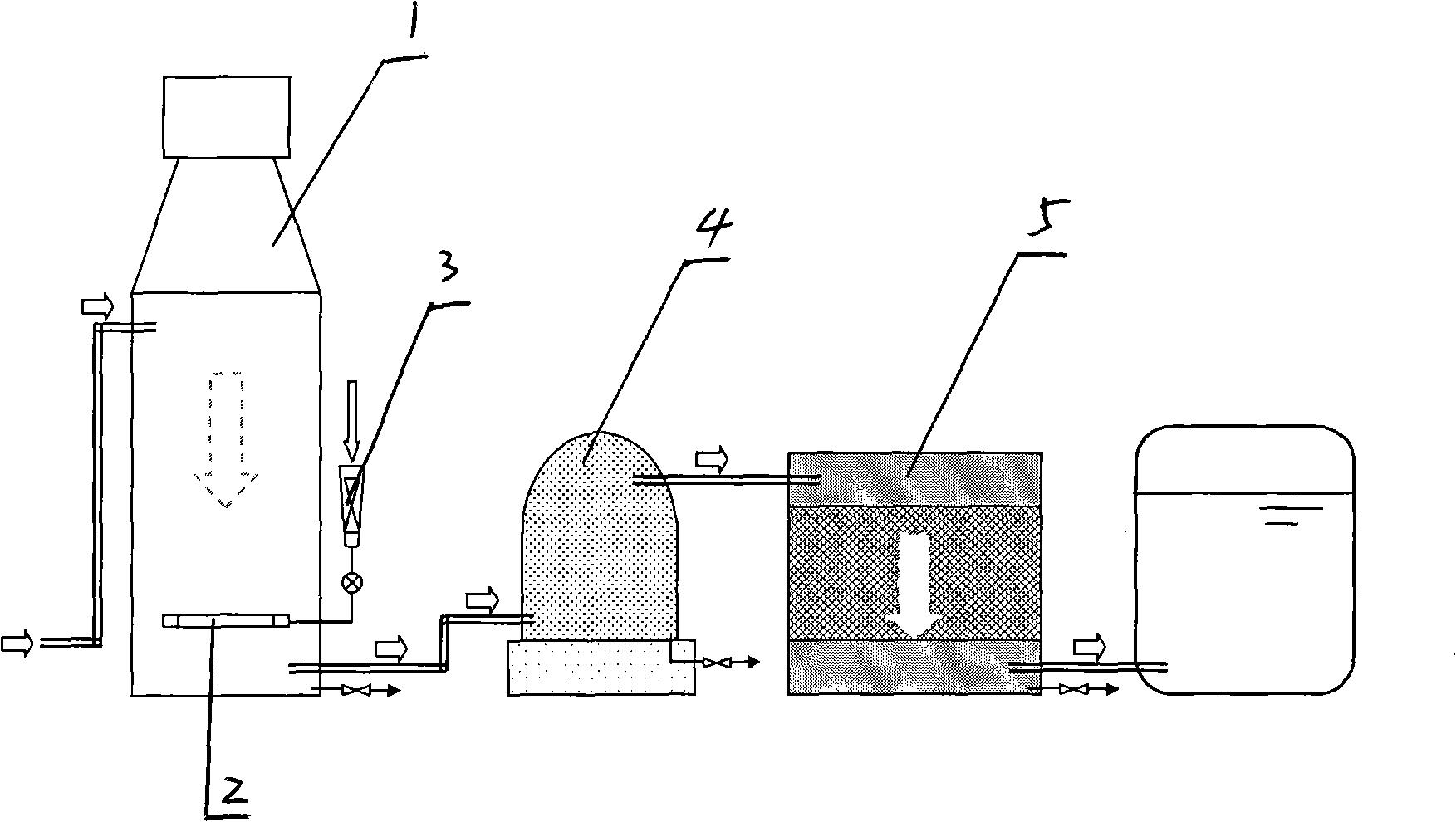

Process for concentrating protein in soy protein wastewater by two-stage foam separation method

InactiveCN101870722AReduce processing loadHigh recovery ratePeptide preparation methodsSolubilitySeparation technology

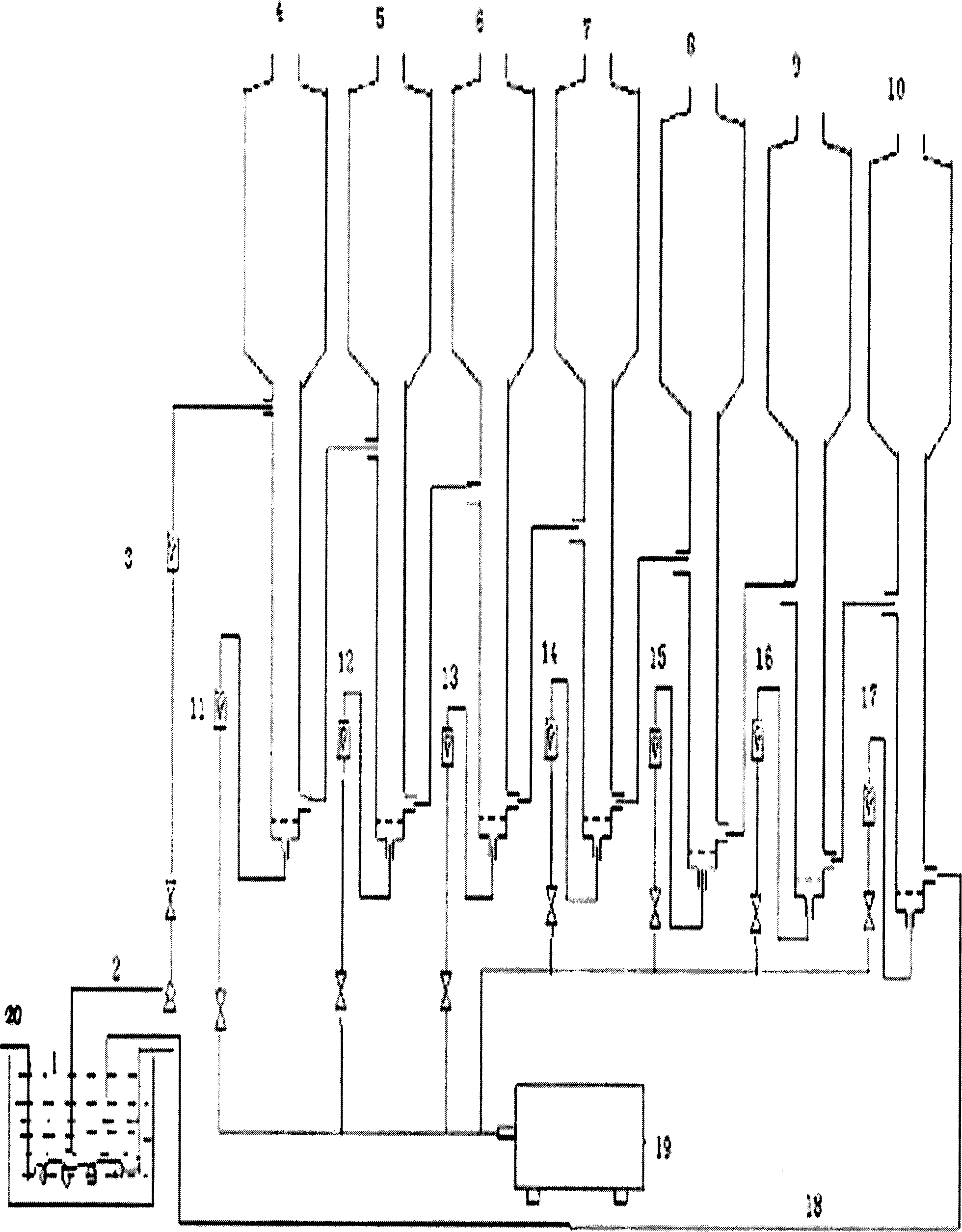

The technical scheme of the invention belongs to the wastewater processing field, in particular to a process for concentrating protein in soy protein wastewater by a two-stage foam separation method, comprising the following steps: 1) collecting and detecting soy protein production wastewater; 2) preheating the soy protein production wastewater; and 3) performing two-stage foam separation processby utilizing a foam separation tower. In the process, the two-stage foam separation technology is applicable to concentrating the protein in the soy protein wastewater, the concentration ratio of theprotein in primary foam separation can reach 6.0-8.0, the protein in defoaming solution is dissolved out after the concentration thereof exceeds solubility, and the dissolved protein can be directly used as a production raw material of soy protein; and the protein recovery rate in secondary foam separation is as high as possible, and the defoaming solution and the initial wastewater are mixed andadded into feed of the primary foam separation. The two-stage foam separation process can greatly improve the protein concentration ratio and enhance the recovery rate.

Owner:HEBEI UNIV OF TECH

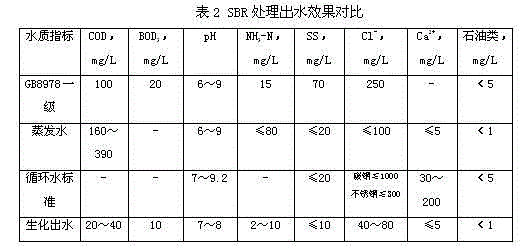

Advanced treatment process for gas field produced water

ActiveCN103601348AEasy to separateReduce odorMultistage water/sewage treatmentSequencing batch reactorEvaporation

The invention discloses an advanced treatment process for gas field produced water, which solves the problem that in existing wastewater treatment processes, foam cannot be well controlled, calcium and magnesium ions cannot be well removed, and resources cannot be utilized. The process comprises the following treatment processes: a foam separating process; an absorption-coagulation integrated process; a two-effect evaporation process; a catalytic oxidation treatment process; and an SBR (Sequencing Batch Reactor) biochemical treatment. Through the treatment process, existing produced water with high content of slat and organic matters reaches the standards, and the treatment process disclosed by the invention is reasonable in flow, compact in equipment installation, small in occupied area and can be conveniently used together with other processes. In addition, the treatment process is low in investment expense, low in operating cost and low in comprehensive energy consumption, and the environment-friendly and social benefits are remarkably superior to those of other technical schemes.

Owner:四川光隆环保科技有限公司

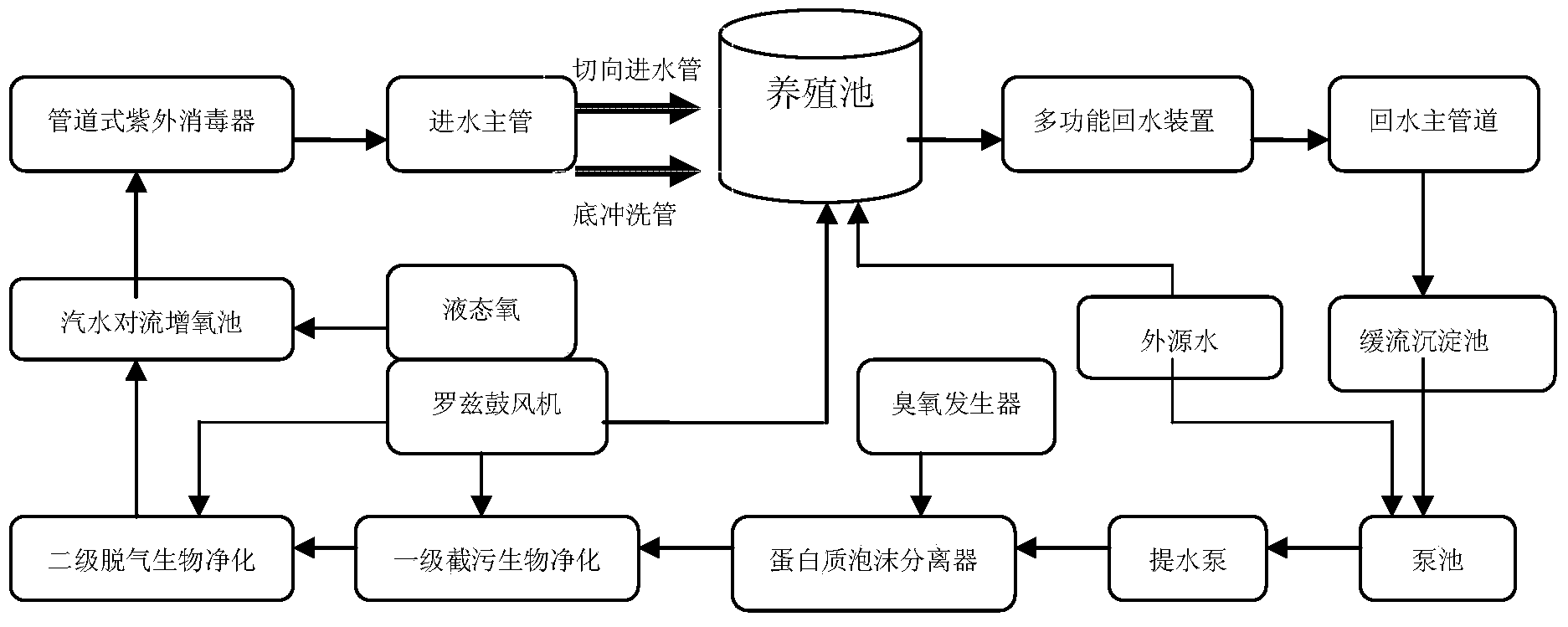

Factorized totally-closed circulating aquaculture system of sea cucumbers

InactiveCN104322419AReduce temperature control energy consumptionEasy dischargeClimate change adaptationPisciculture and aquariaTemperature controlWater saving

The invention relates to a factorized totally-closed circulating aquaculture system of sea cucumbers, belonging to the technical field of aquaculture. The factorized totally-closed circulating aquaculture system comprises a special culture pond and a water treatment system; the special culture pond is a circular bead pond of which the bottom is shaped as a pan bottom, a water outlet is formed in the lowest position of the center of the special culture pond, and three to five circles of porous bottom flushing pipes are horizontally paved at the bottom of the pond; the water treatment system comprises a slow flow settling pond, a pump pond, a water lifting pump, a protein foam separator, a first-stage pollution cut biopurification pond, a second-stage degassing biopurification pond, a steam water convection oxygenation pond and a pipeline type ultraviolet sterilizer. The culture system suitable for factorized totally-closed circulating aquaculture is designed according to the biological characteristics of sea cucumbers and an aquaculture water circulation utilization technology; the daily supplement of new water is less than 5 percent during culture by using the system disclosed by the invention. Compared with a traditional water change or running water culture method, the system disclosed by the invention has the advantages that the water saving amount reaches over 95 percent; more importantly, the temperature control energy consumption in the culture process is greatly reduced and the energy is saved by over 70 percent.

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI

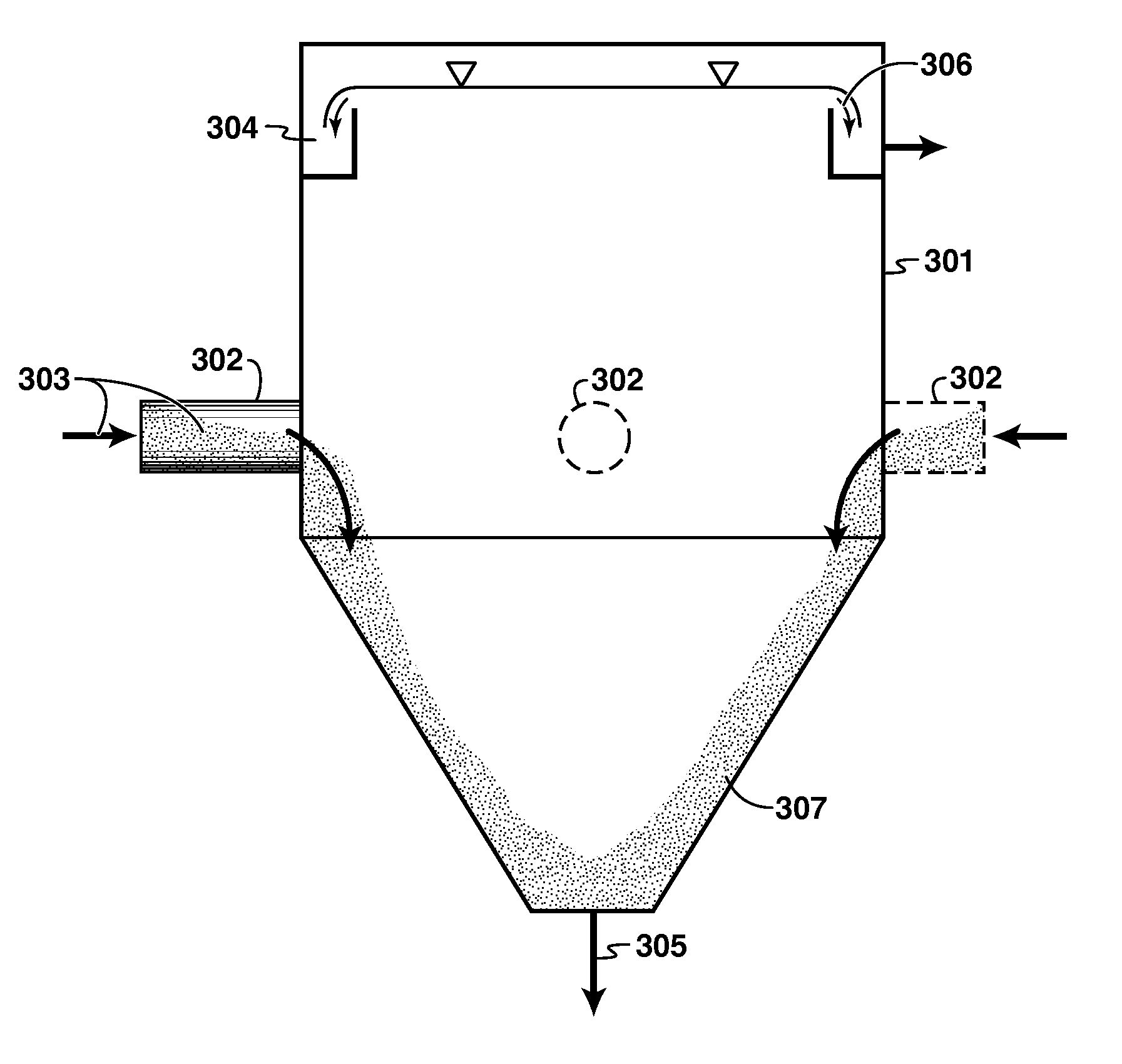

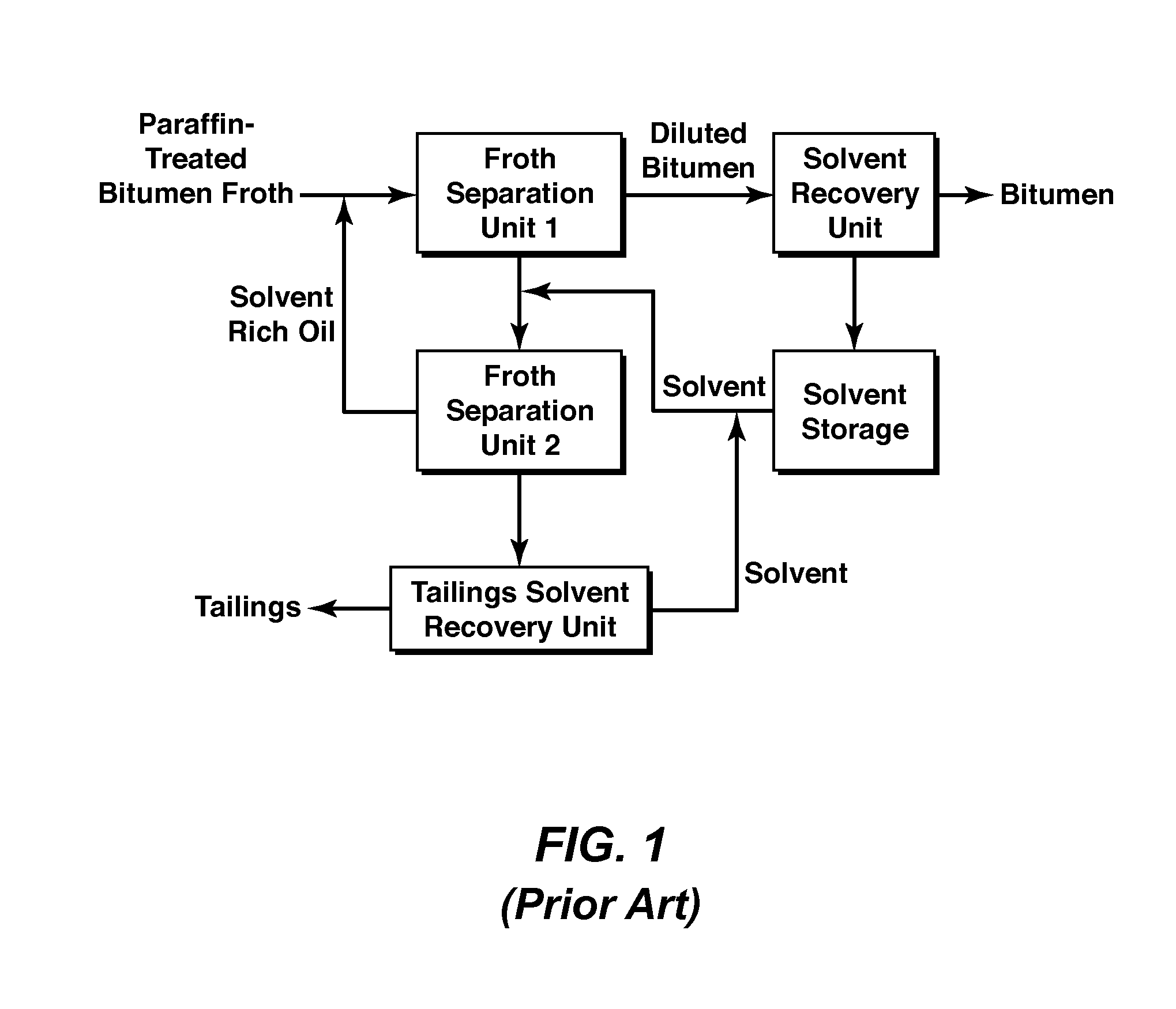

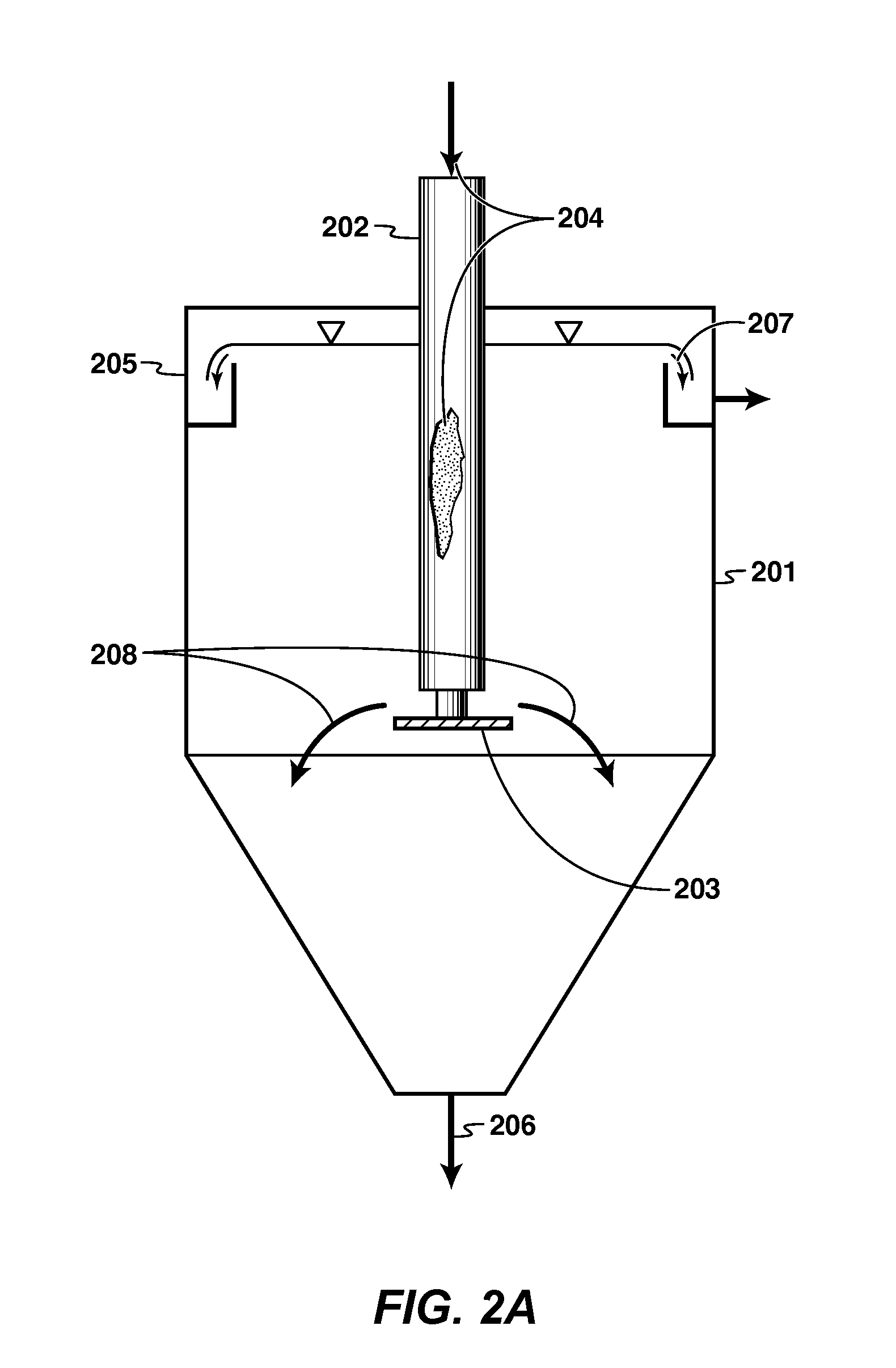

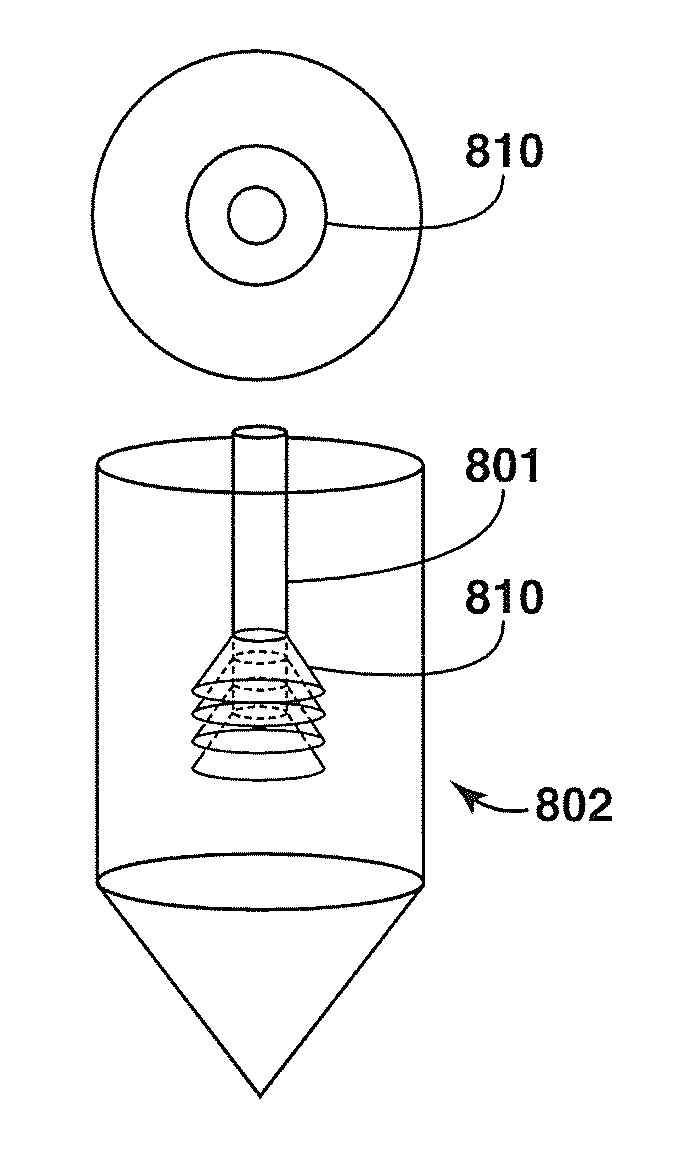

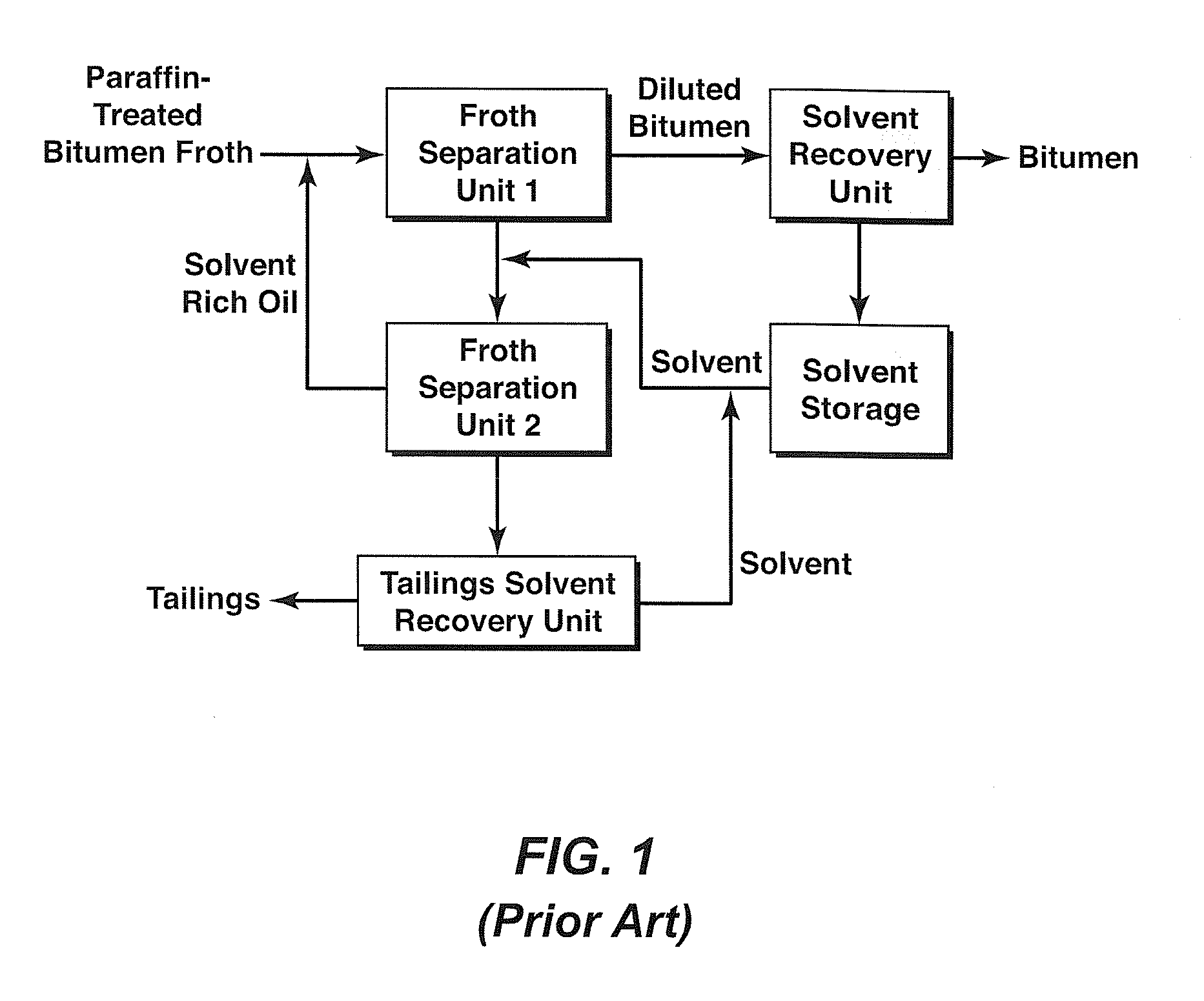

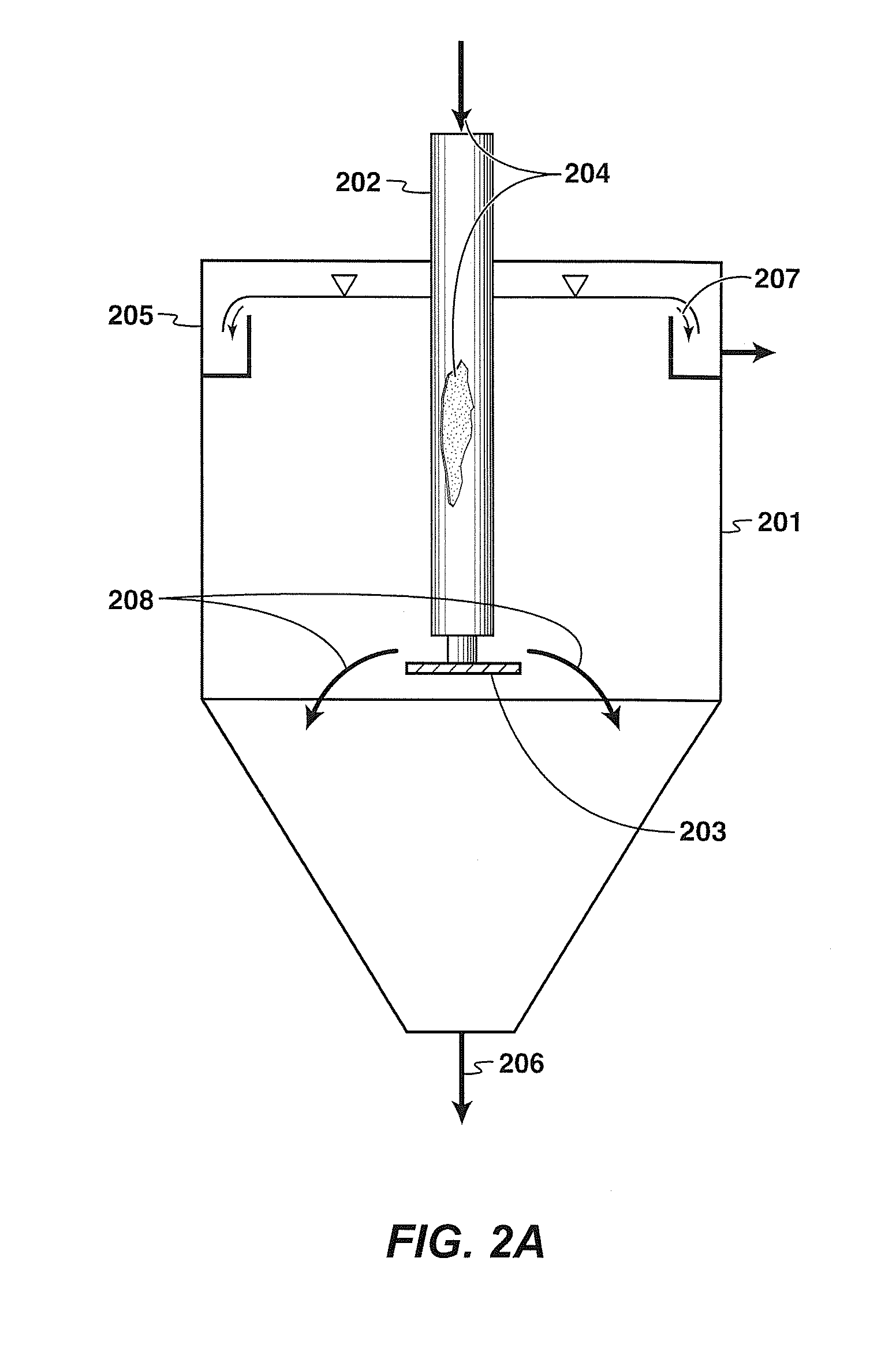

Feed Delivery System For A Solid-Liquid Separation Vessel

InactiveUS20110011769A1Easy to separateMinimize dispersionDewatering/demulsification with mechanical meansLiquid displacementBi modalEngineering

A method of delivering feed, for example a paraffinic solvent treated bitumen froth, to a separation vessel, for example a froth separation unit (FSU). The feed is delivered from one or more side inlets that may be substantially normal to, and flush with, the wall of the vessel. In contrast to certain conventional feed systems used in gravity separators which use a distributor plate to widely distribute the feed with a vessel, the feed is delivered such that it flows down the inside wall of the vessel. This feed delivery is characterized by a Richardson number of greater than 1.0. Such feed delivery is particularly useful where the feed has particles with a bi-modal size distribution to be separated from an overflow stream. The gentle flow serves to mitigate the upward flux of the smaller particles, for example mineral solids, by being trapped below the larger particles, for example precipitated asphaltene aggregates.

Owner:EXXONMOBIL UPSTREAM RES CO

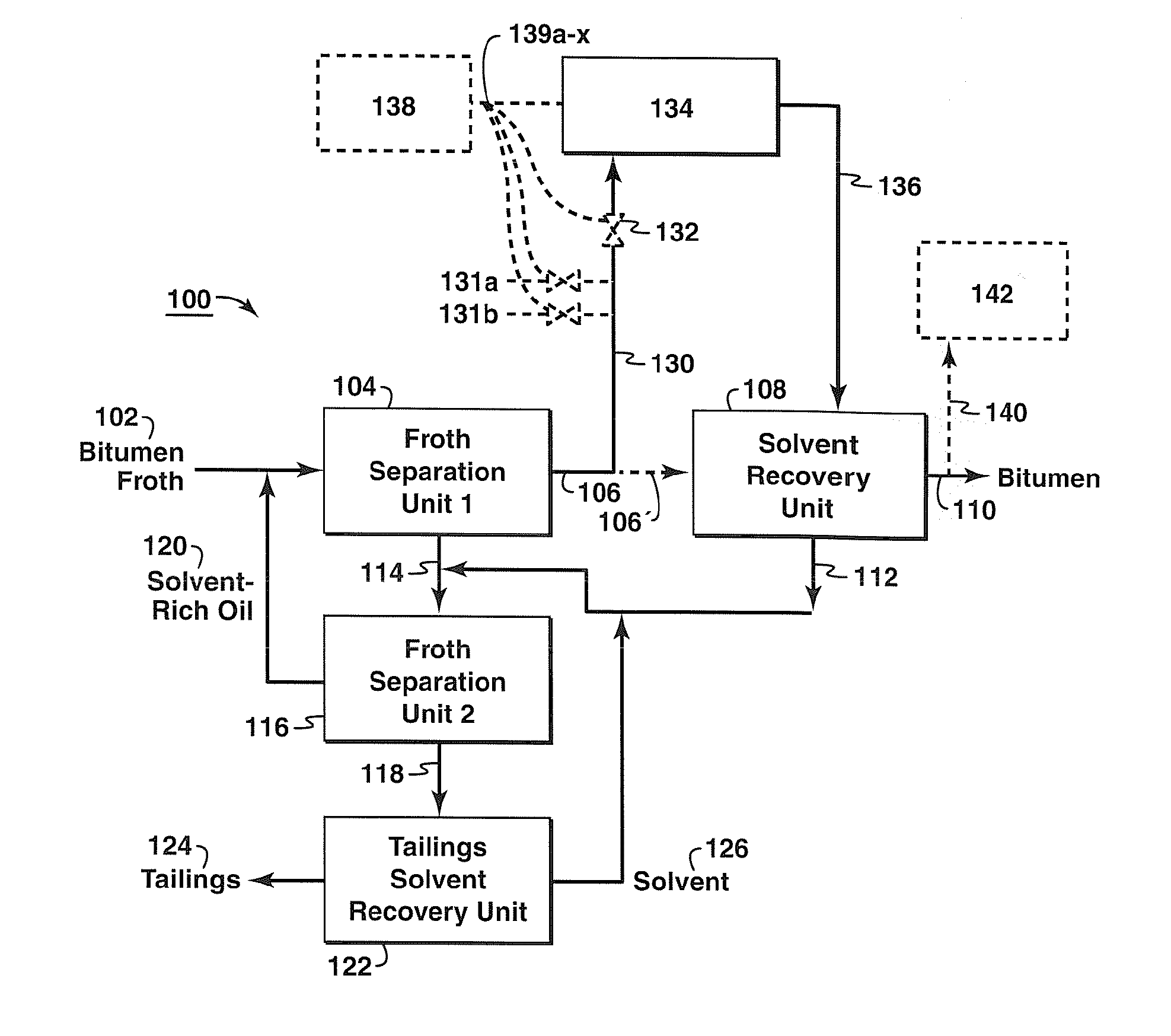

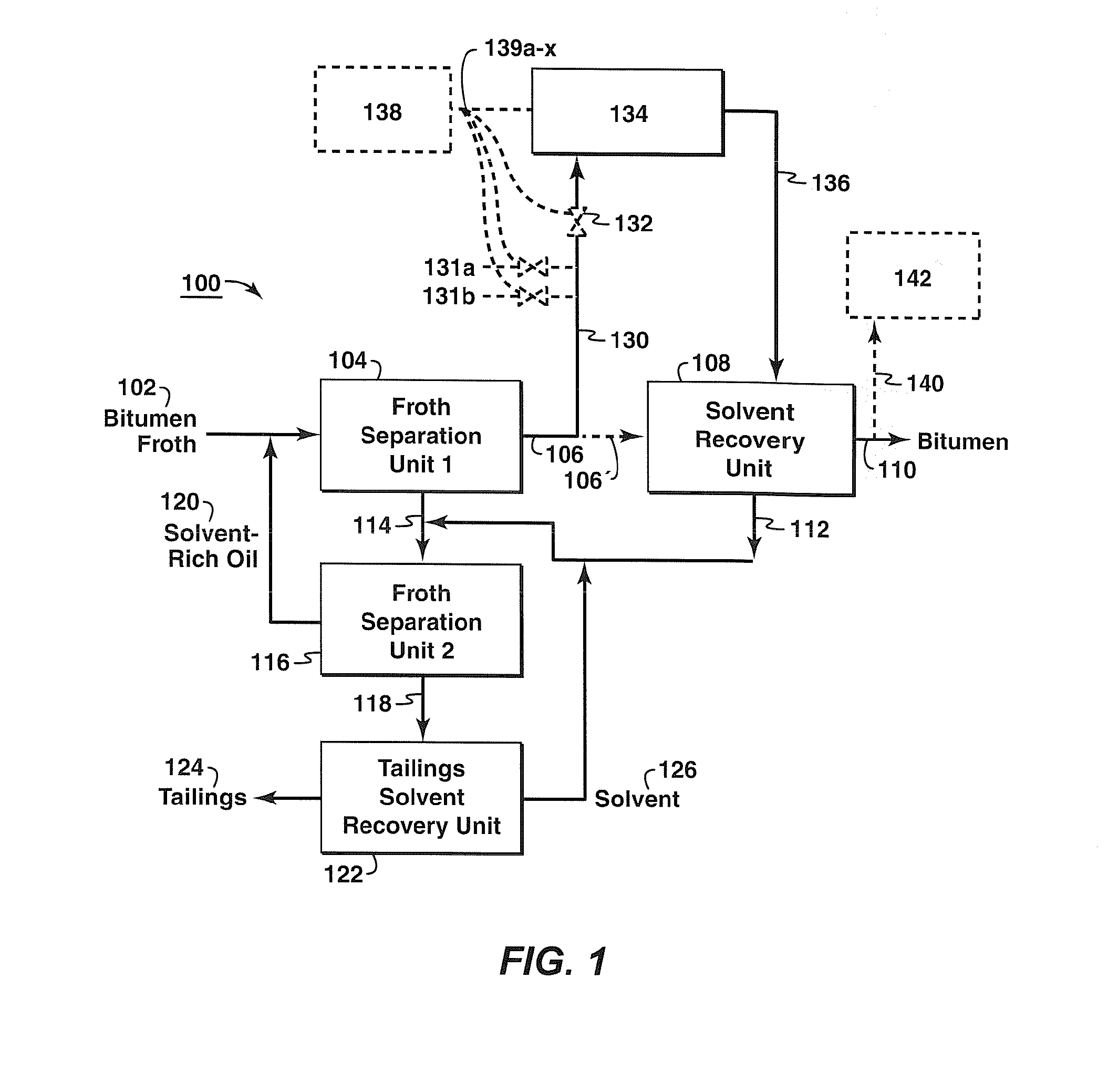

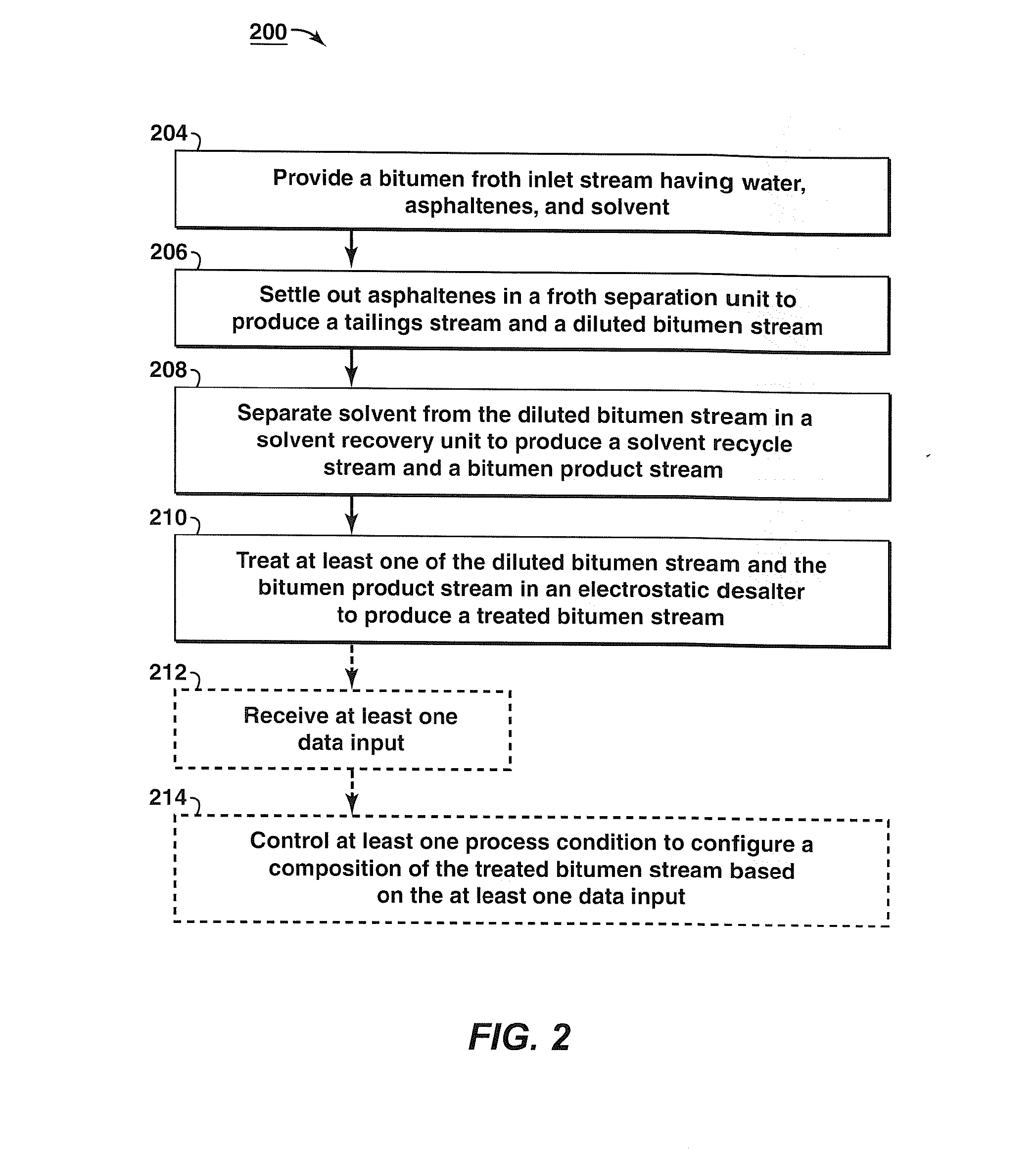

Optimizing Heavy Oil Recovery Processes Using Electrostatic Desalters

InactiveUS20120217187A1Working-up pitch/asphalt/bitumen by selective extractionDewatering/demulsification with electric/magnetic meansFuel oilDesalter

Owner:SHARMA ARUN K +1

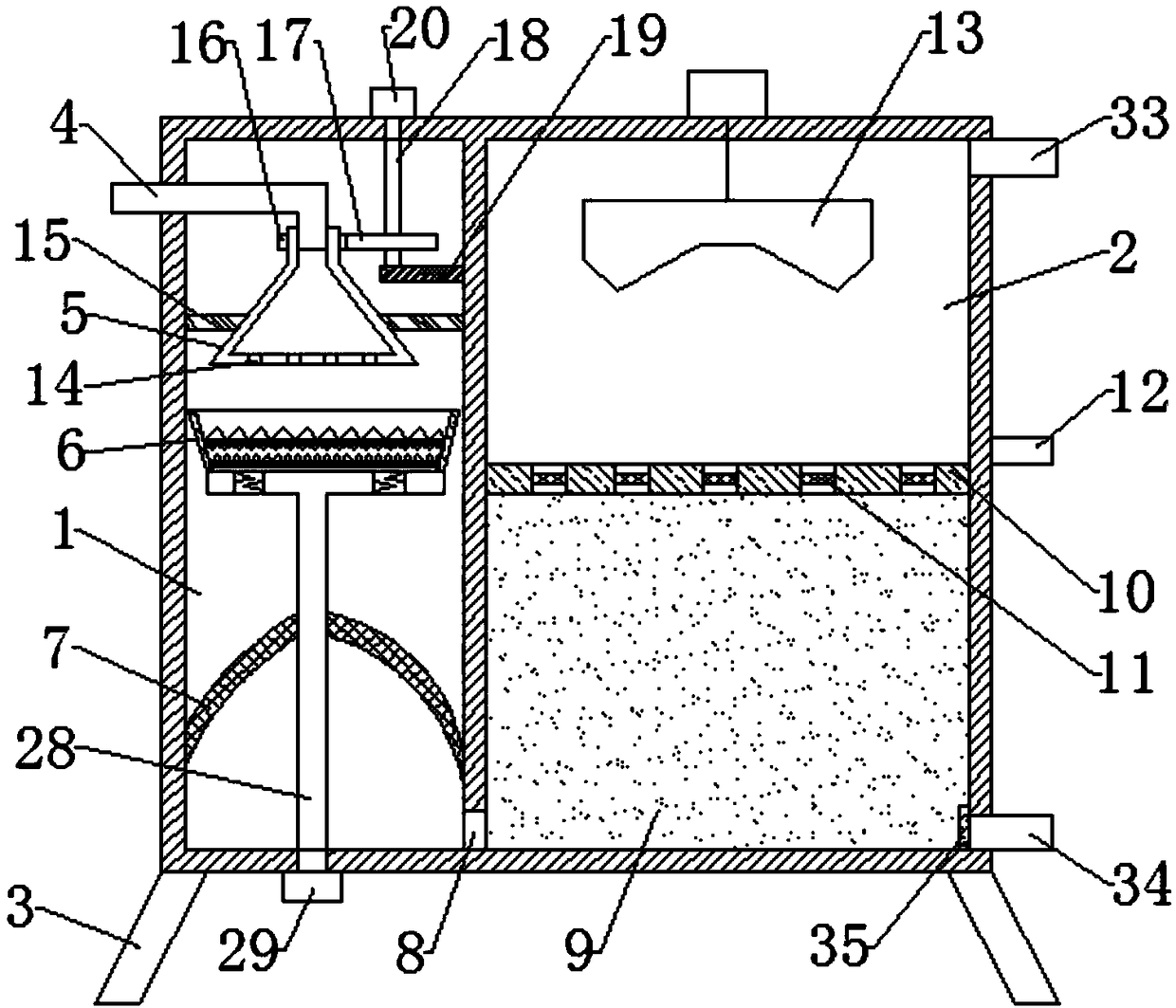

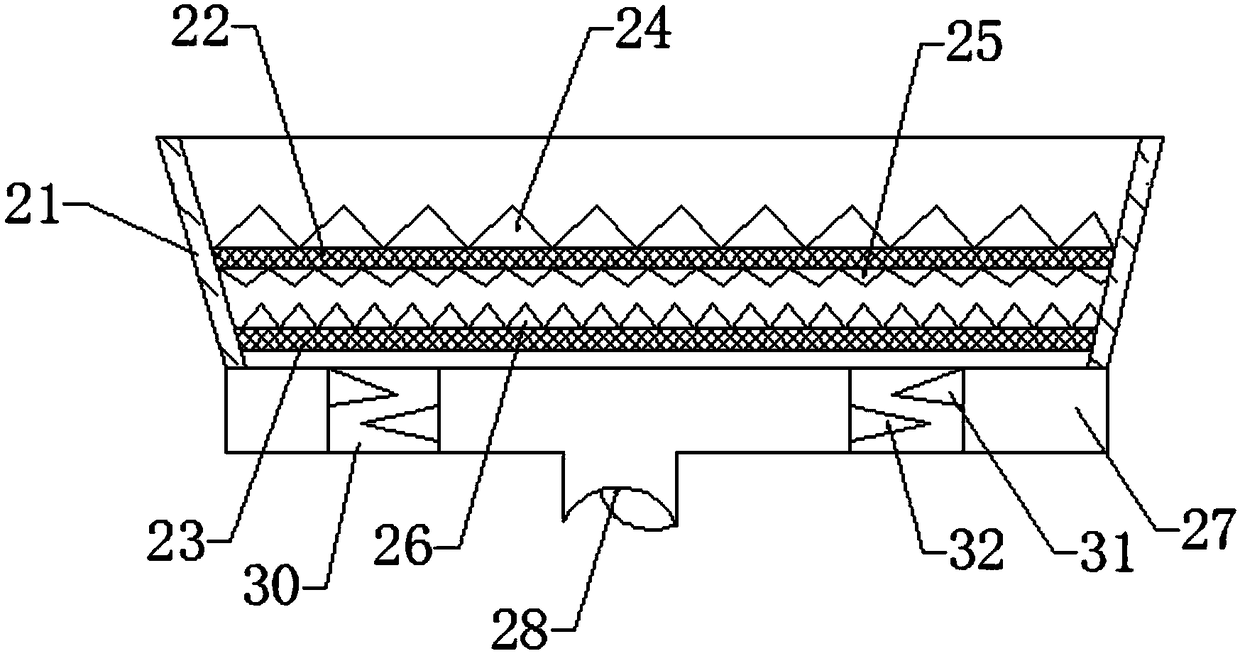

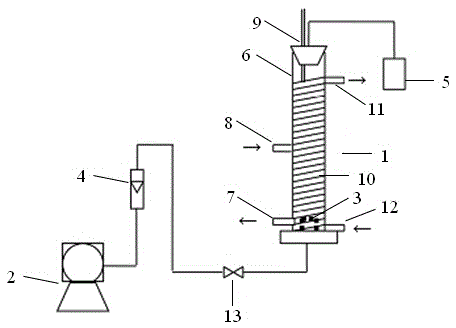

Novel foam separation equipment for restoring heavy metal polluted soil

InactiveCN101879520AEasy to separateHigh removal rateContaminated soil reclamationSurface-active agentsTower

In order to restore heavy metal polluted soil, the invention provides novel foam separation equipment for restoring the heavy metal polluted soil. The whole foam separation equipment is provided with two stages of foam separation towers, firstly, soil to be treated is placed into the primary foam separation tower, a surface active agent mixed solution is uniformly sprayed through an annular water distribution device for soaking the soil, at the same time, the aeration is carried out through a water distribution plate, heavy metals in the soil carry out complexation with the surface active agent through sufficient contact via the stripping effect, complex compounds are attached on air bubbles to be separated from the soil, the air distribution plate is opened after the primary reaction is completed, and soil particles enter the secondary foam separation tower to carry out further separation treatment and to be cleaned. The invention has the advantages of little secondary pollution and high removal rate of heavy metal.

Owner:长春联创水质工程有限公司

Regenerative and integrative hydrogen sulfide liquid phase oxidation absorption method of sulphur separation/desulfuration solution

ActiveCN101870884AImprove separation efficiencyImprove gas-liquid mass transfer coefficientRefining with oxygen compoundsReaction rateSelf-absorption

The invention relates to a regenerative and integrative hydrogen sulfide liquid phase oxidation absorption method of sulphur separation / desulfuration solution, comprising a regeneration-separation tower composed of a bubbling reaction section, an air liquid separation section and a foam collection section. Desulfuration solution used for absorbing H2S flows out of a self-absorption tower and enters into the regeneration-separation tower, and then is oxidized and regenerated by a catalyst at the bubbling reaction section so as to enrich sulphur granules on a bubble interface; at the air liquidseparation section, the regeneration / desulfuration solution is separated from foams and is returned to an absorption tower for recycling, and sulphur is carried to the foam collection section by foams and is recovered by collecting foams; 0.008-0.012g of surfactant is added when per desulfuration solution containing 1g of sulphur enters into the tower; air dose introduced in the desulfuration solution containing 1g of sulphur is no less than 34L, and empty tower gas velocity is 0.8-2.5cm / s; and the sulphur granule separation rate and regenerative reaction rate are high, the energy consumptionand catalyst consumption are low, and the method can be applicable to the process of absorbing H2S gas in medium-size sulphur throughputs.

Owner:PETROCHINA CO LTD +1

Affinity foam fractionation for collection and purification of materials

Owner:THE UNIVERSITY OF AKRON

Method for separating Chinese medicinal active substances

ActiveCN1789220AIncreased purity of glycyrrhizic acidHigh purityOrganic compounds purification/separation/stabilisationGlycosidesActive matterOperation mode

The invention relates to a method for separating active matter from traditional Chinese medicine, which in detail is to separate saponin and other surface active substance from traditional Chinese medicine coarse extraction solution; basing the difference of physicochemical property of the component in the traditional Chinese medicine water extraction solution, applying basal principle of foam phase separation, employing four different operation mode to separate and enrich the component from the liquorice coarse extraction, the technology is characterized by the no usage of chemical agent, low cost, simple device, simple device, small investment and no pollution to environment, the method is not only suited for liquorice coarse extraction, but also for other traditional Chinese medicine extracting solution containing saponin and other surface active substance, and is a feasible and effective new technology in the traditional Chinese medicine separating engineering.

Owner:JIANGXI HUIREN PHARMA CO LTD

Affinity Foam Fractionation for Collection and Purification of Materials

InactiveUS20090008325A1Easy to splitEvaporationDifferential sedimentationBiological materialsFoam fractionation

Owner:AKRON THE UNIV OF

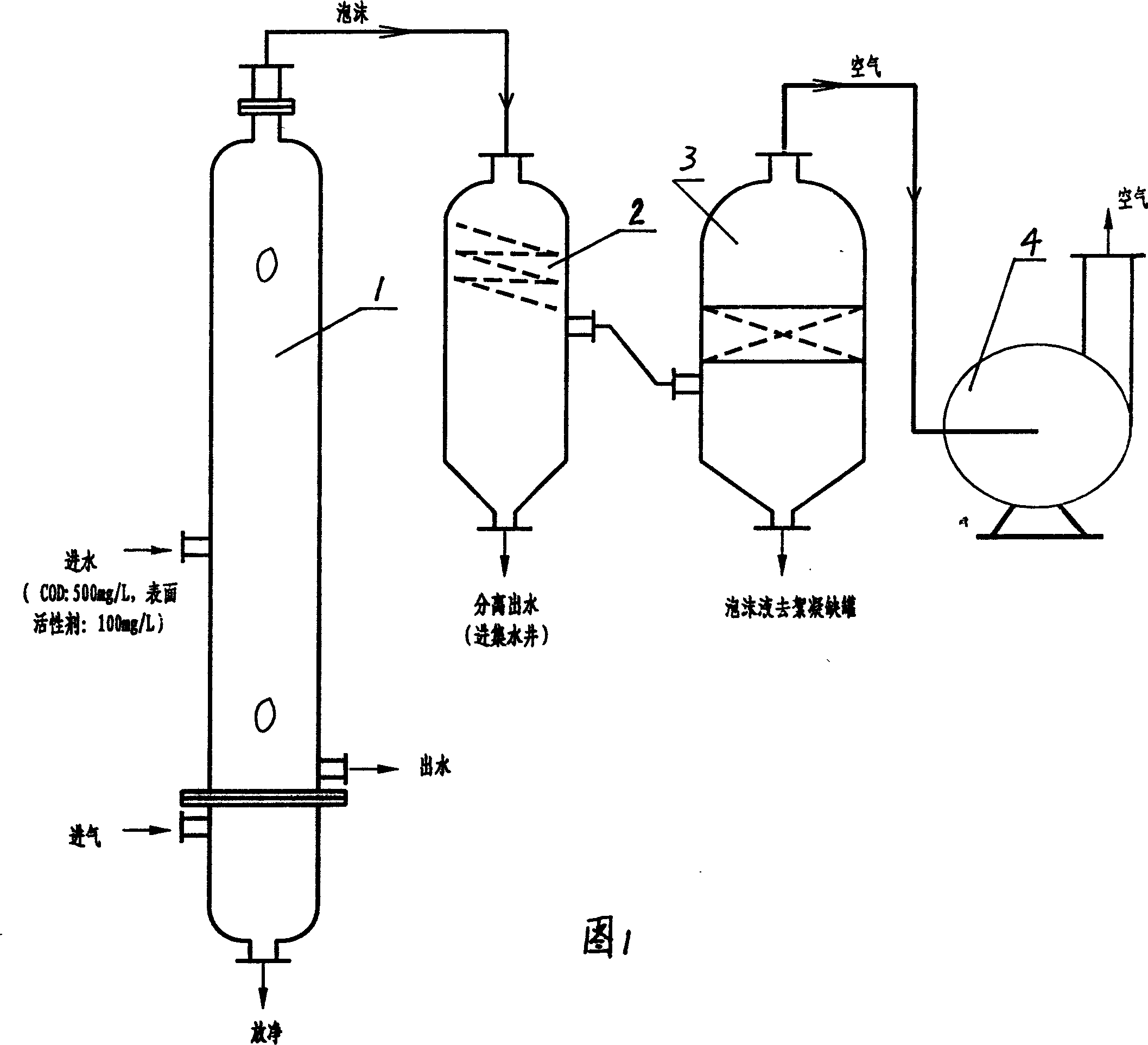

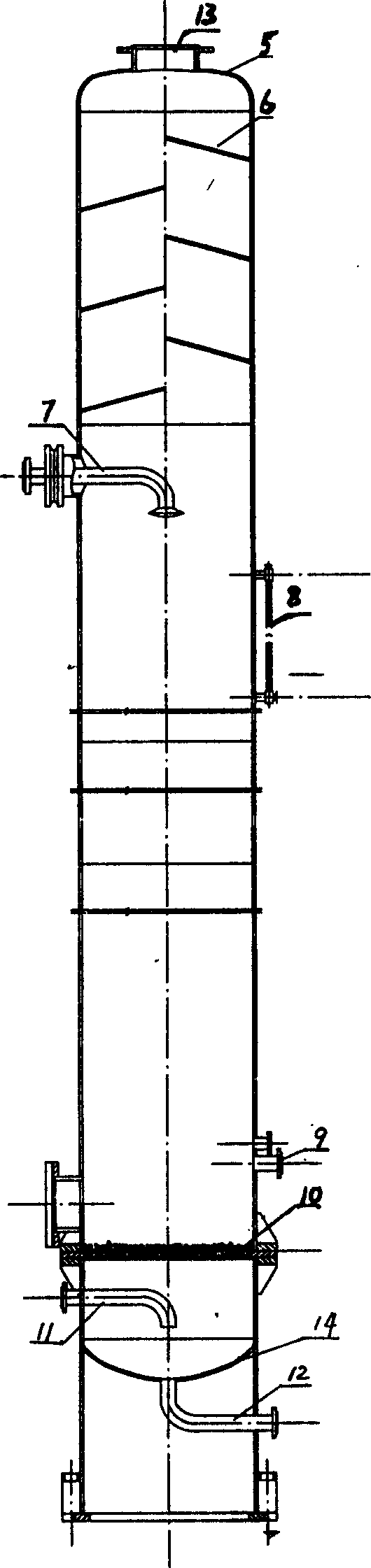

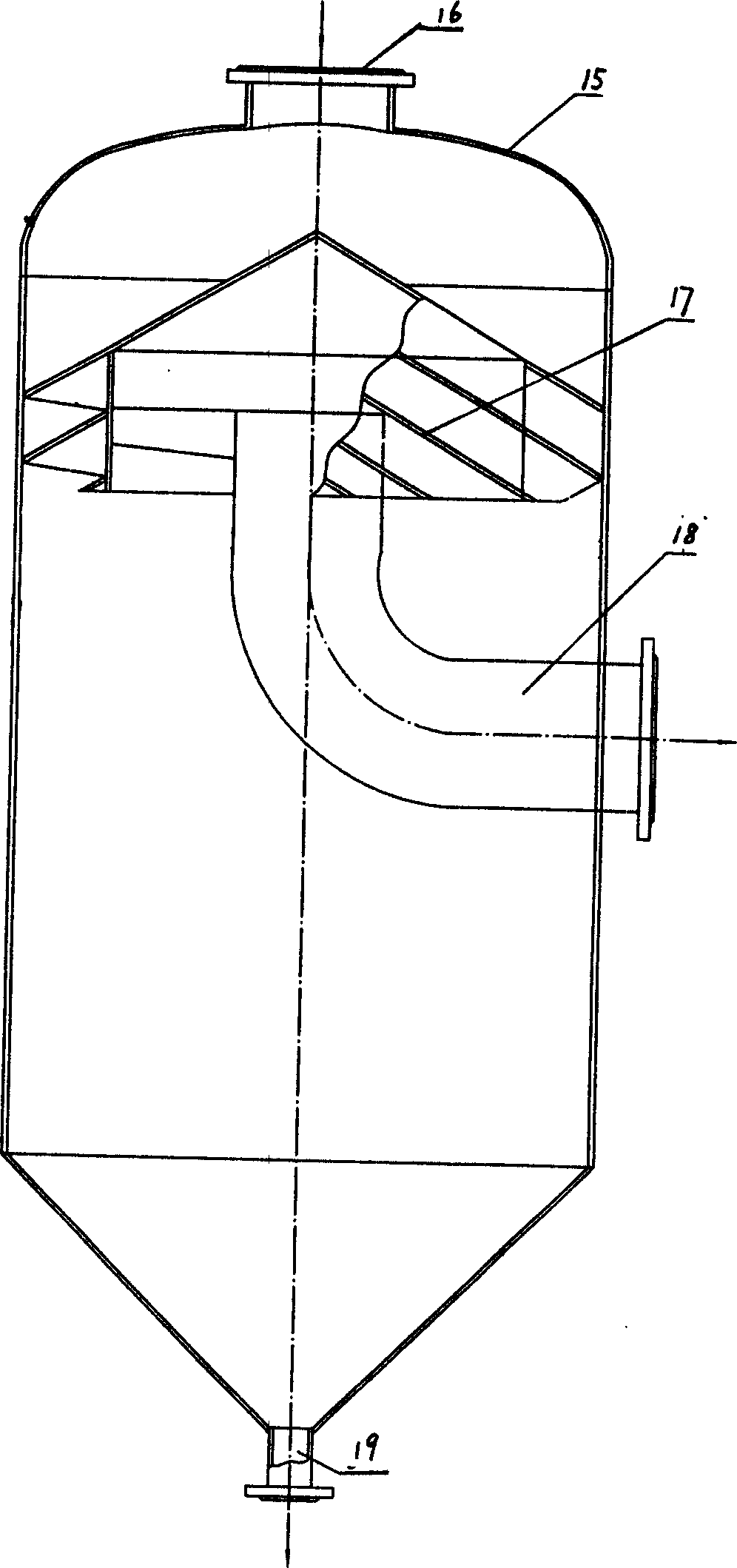

Foam separating and eliminating technology and production line of surface activator

InactiveCN1544118ASimple processLess investmentFoam dispersion/preventionProduction lineVapor–liquid separator

The invention discloses a technique and production line to separate and eliminate surface active agent foams in waste water treatment, separating foams by separating column, removing the water carried in the foams by gas-liquid separator, breaking the foams by negative pressure foam breaker, and realizing the separation and elimination by induced draft fan exhausting the foam-broken gas. It is a new method and producing device for the industries as wash, dyeing and printing and leather to treat waste water and improve environmental pollution.

Owner:徐州市市政设计院有限公司

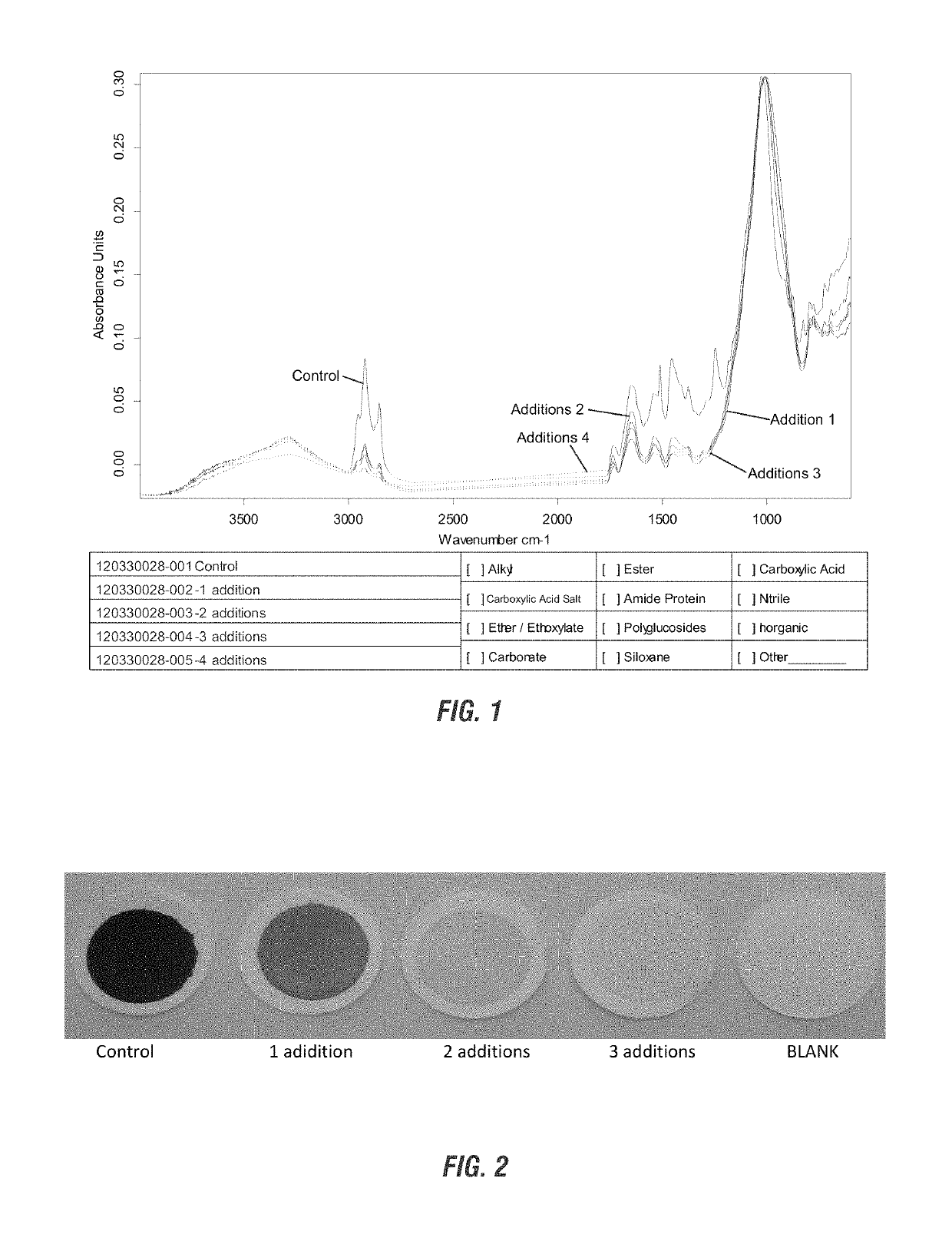

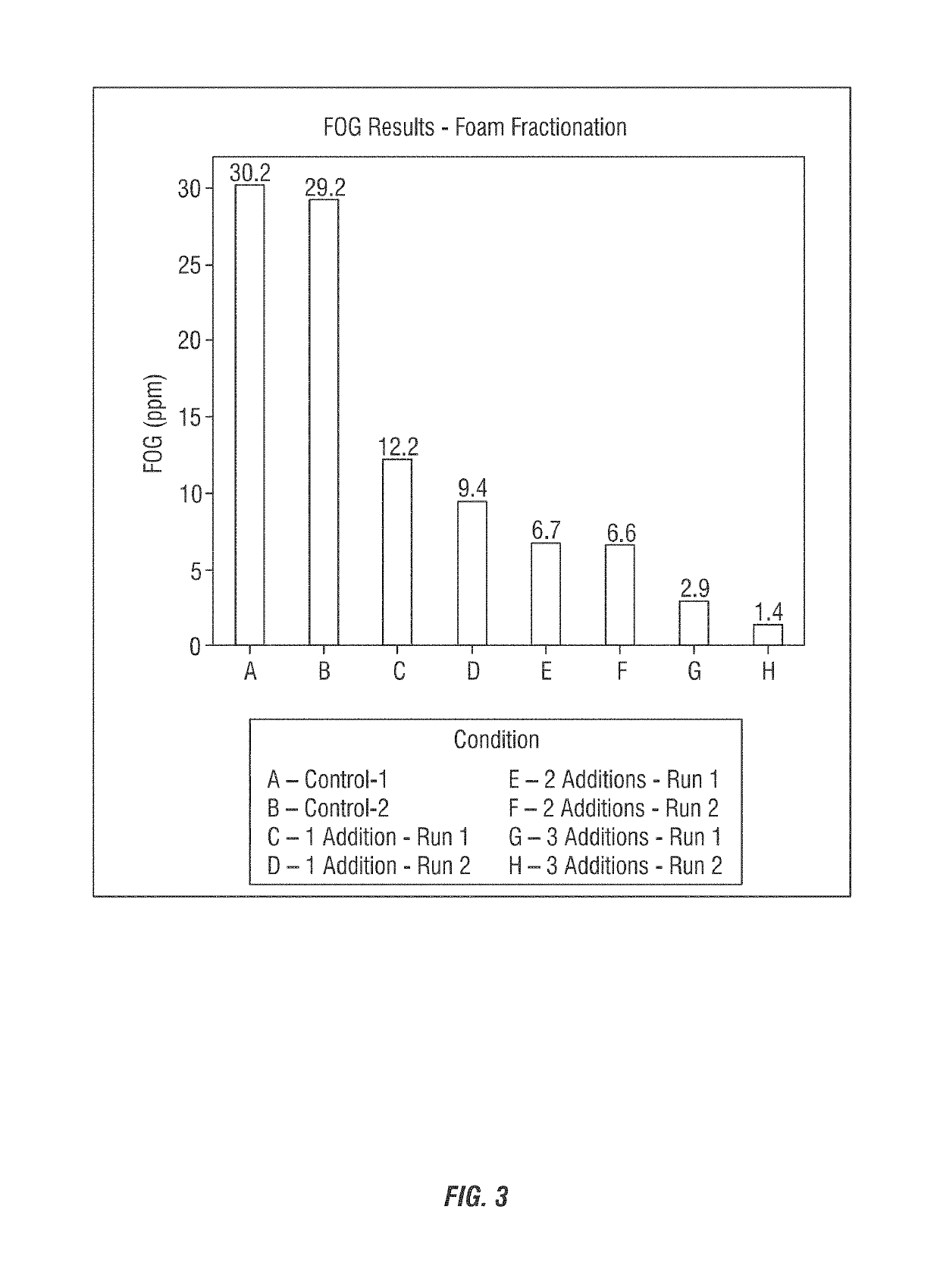

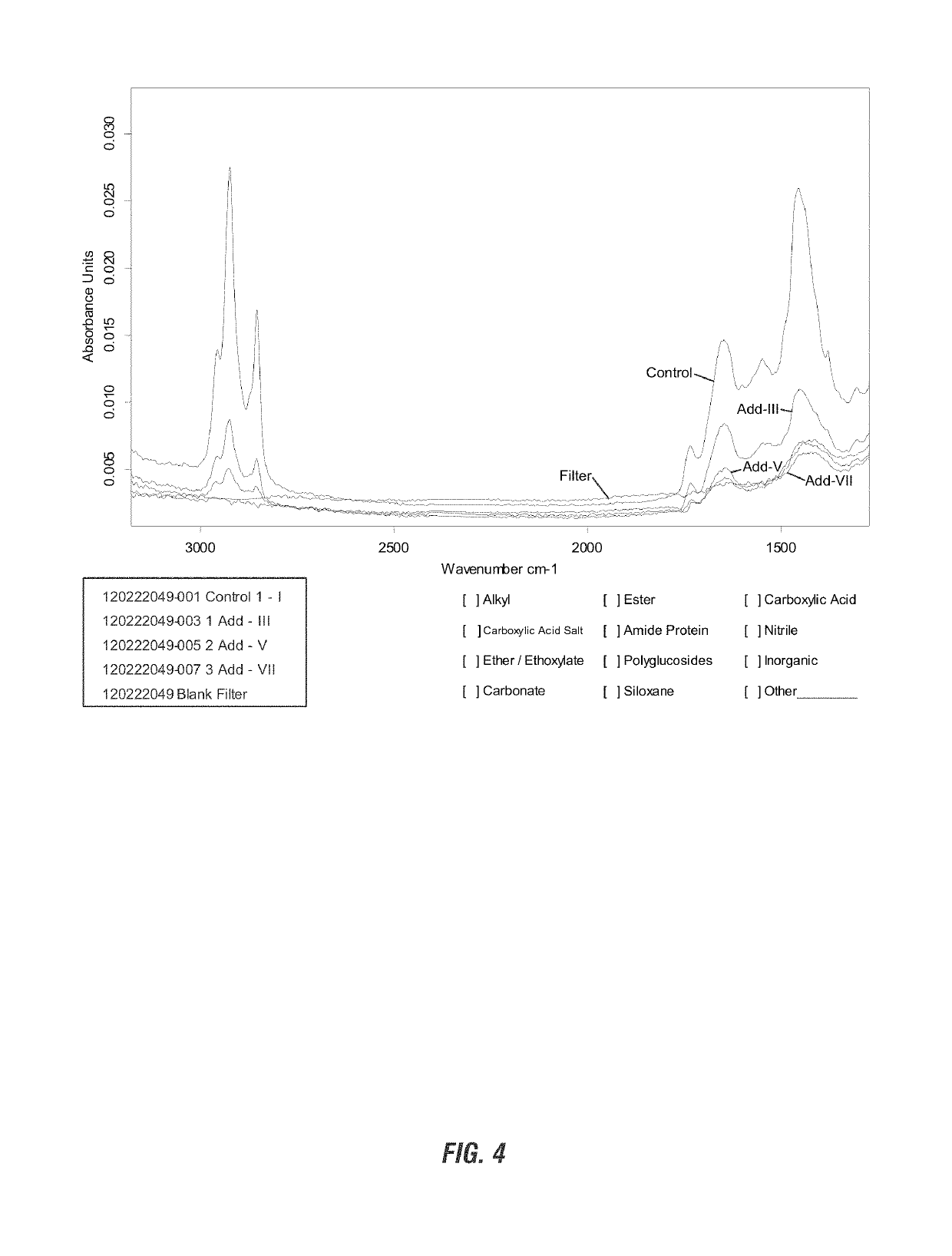

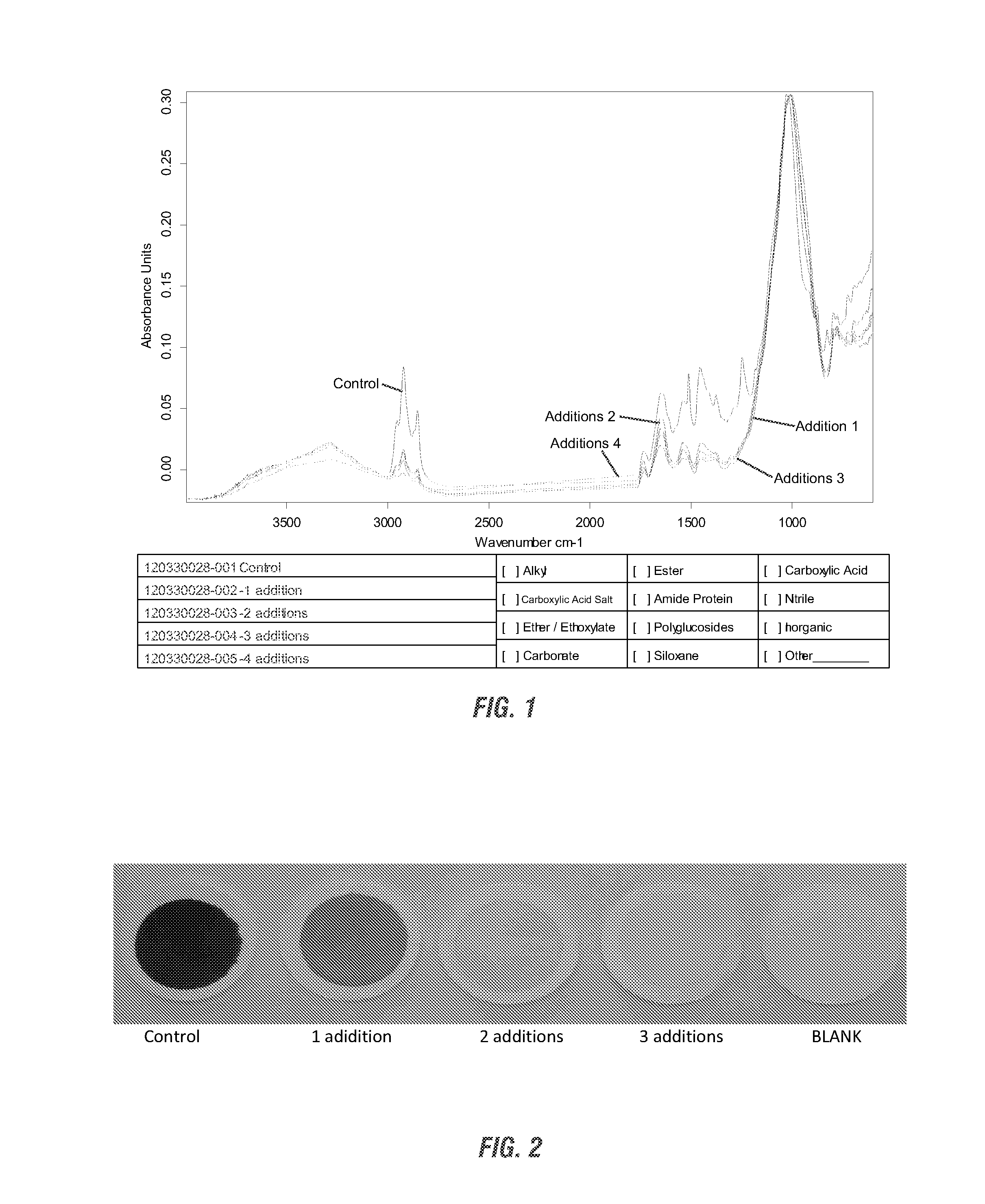

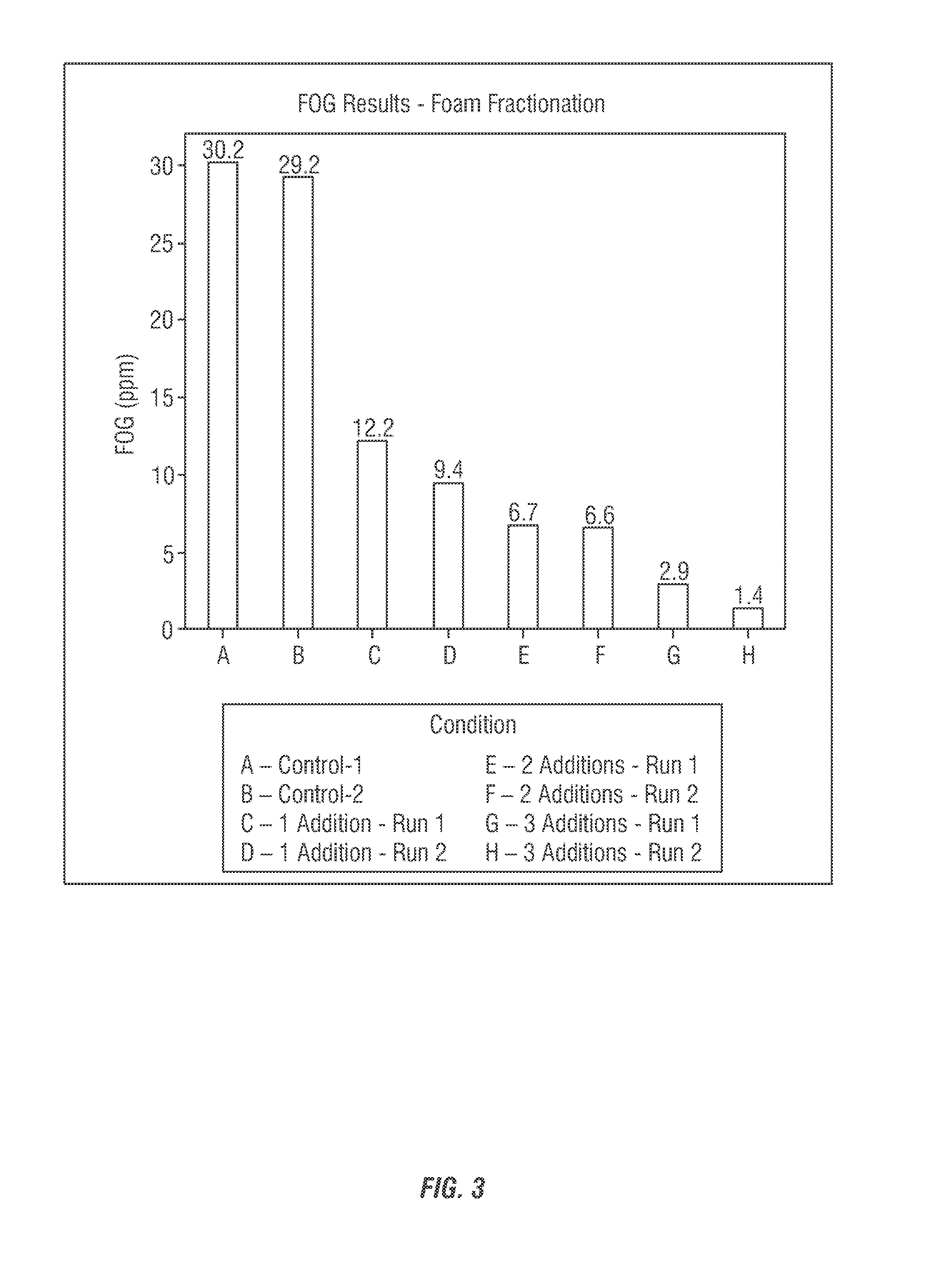

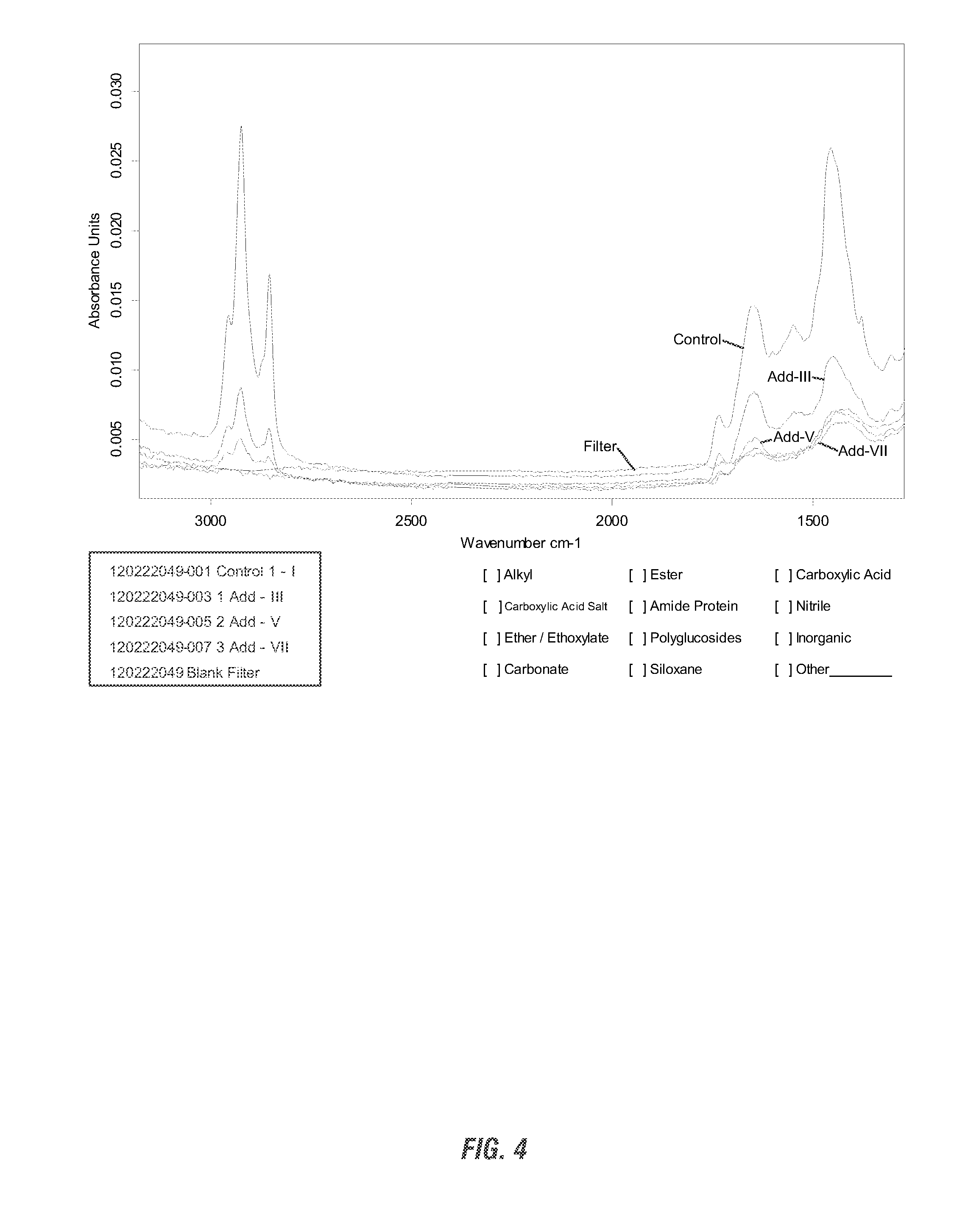

Enhanced foam fractionation of oil phase from aqueous/oil mixed phase via increased viscoelasticity

ActiveUS10435308B2General water supply conservationContaminated soil reclamationOil phaseSURFACTANT BLEND

The present invention provides improved methods for purifying and / or removing oily particles, and / or contaminants suspended or dissolved in water. In particular the process relates to an additive composition that has the appropriate surfactant characteristics for effectively removing an oil phase from an oil / aqueous mixed phase via foam fractionation. According to the invention, a hydrophobically modified polymer that acts as an associative thickener is combined with surfactant in appropriate ratios to facilitate oil removal for water purification in any of a number of commercial, environmental and industrial applications.

Owner:ECOLAB USA INC

Enhanced foam fractionation of oil phase from aqueous/oil mixed phase via increased viscoelasticity

ActiveUS20140251919A1Enhance foam fractionationGeneral water supply conservationContaminated soil reclamationOil phaseImproved method

The present invention provides improved methods for purifying and / or removing oily particles, and / or contaminants suspended or dissolved in water. In particular the process relates to an additive composition that has the appropriate surfactant characteristics for effectively removing an oil phase from an oil / aqueous mixed phase via foam fractionation. According to the invention, a hydrophobically modified polymer that acts as an associative thickener is combined with surfactant in appropriate ratios to facilitate oil removal for water purification in any of a number of commercial, environmental and industrial applications.

Owner:ECOLAB USA INC

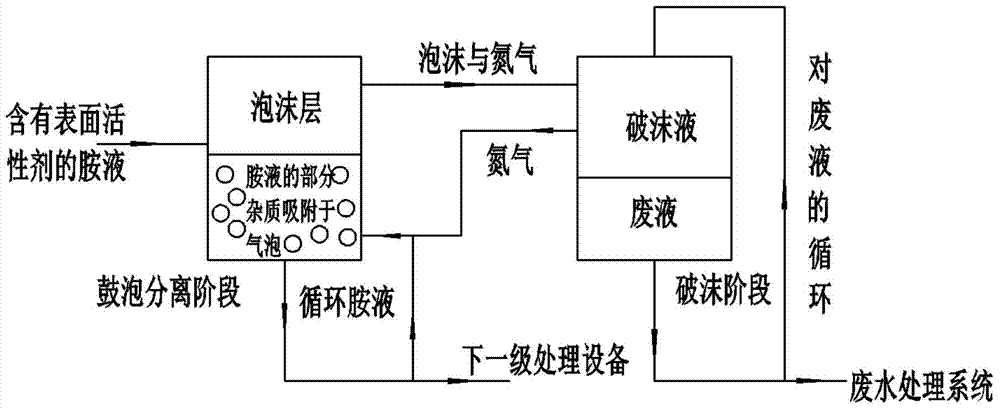

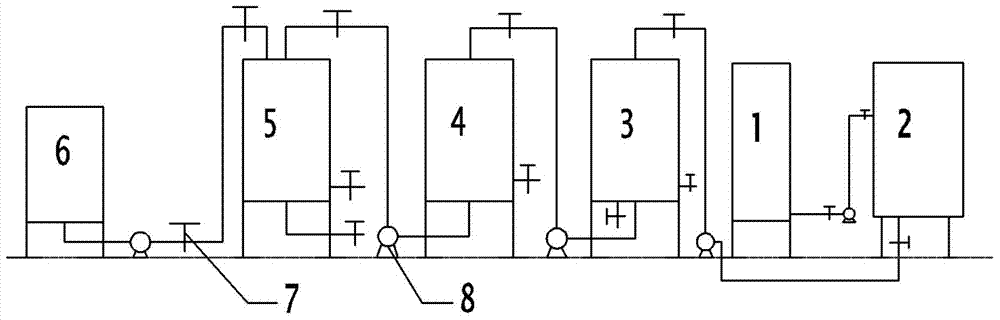

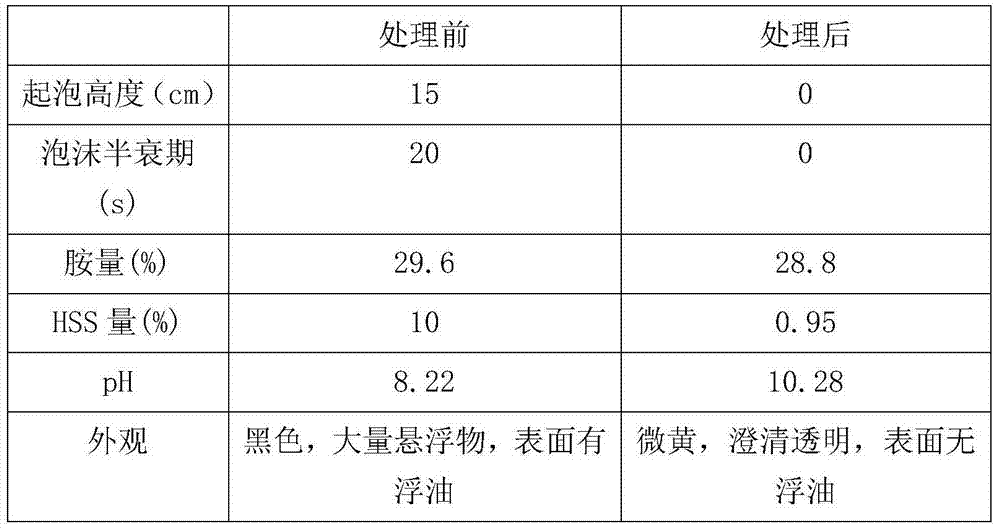

Purification method of amine liquid

ActiveCN103693777AOutstanding FeaturesHighlight significant progressMultistage water/sewage treatmentActivated carbonPurification methods

The invention discloses a purification method of amine liquid, relates to a separation method of processing liquid of taking a separating machine device as characteristics, and in particular relates to an amine liquid purification method based on foam separation. The existing mechanical filtering, activated carbon adsorption and ion exchange devices for purifying the amine liquid are utilized, and a foam separator is added in front of the devices and used for removing a surface active material of causing foaming of the amine liquid. Thus, the cleaning cycle of subsequent mechanical filtering, the replace cycle of activated carbon adsorption, and the regeneration cycle of the ion exchange device are prolonged, the defects that the existing simple mechanical filtering method is poor in amine liquid purification quality, short in equipment utilization cycle, and high in production cost are overcome, and the defects of high price and serious membrane pollution of the existing membrane separation method are also overcome.

Owner:HEBEI UNIV OF TECH

Feed delivery system for a solid-liquid separation vessel

InactiveUS20130140249A1Easy to separateSeparation efficiency can be improvedSettling tanks feed/dischargeSeparation devicesBi modalParallel plate

A method of delivering feed, for example a paraffinic solvent treated bitumen froth, to a separation vessel, for example a froth separation unit (FSU). The feed is delivered from one or more inlets into the side of a series of parallel plates that form a series of channels which may be either vertical or inclined at an intermediate angle. This feed inlet flow conditioning system is characterized by a Channel Reynolds number of less than 3000. Such inlet flow conditioning is particularly useful where the feed has particles with a bi-modal size distribution to be separated from an overflow stream. The low Reynolds number combined with the influence of the walls serves to mitigate the upward flux of the smaller particles, for example mineral solids, by trapping the smaller particles within a matrix of larger particles, for example precipitated asphaltene aggregates.

Owner:EXXONMOBIL UPSTREAM RES CO

Device and method for foam separation of polysaccharides in Polyporus polysaccharide extract

The invention discloses a device and a method for extracting polysaccharides from agaric polysaccharide extracting solution by foam fractionation. The device comprises a foam fractionation tower, an air supply system and a foam collector, wherein the foam fractionation tower comprises a bubbling area, a foam area and a foam collection elbow pipe; and an air distributor is arranged at the bottom of the foam fractionation tower. By the device and the process, the defects of long concentration time of the extracting solution, more energy consumption and large using amount of ethanol in the conventional process for extracting and separating the polysaccharides are overcome.

Owner:SHAANXI UNIV OF TECH

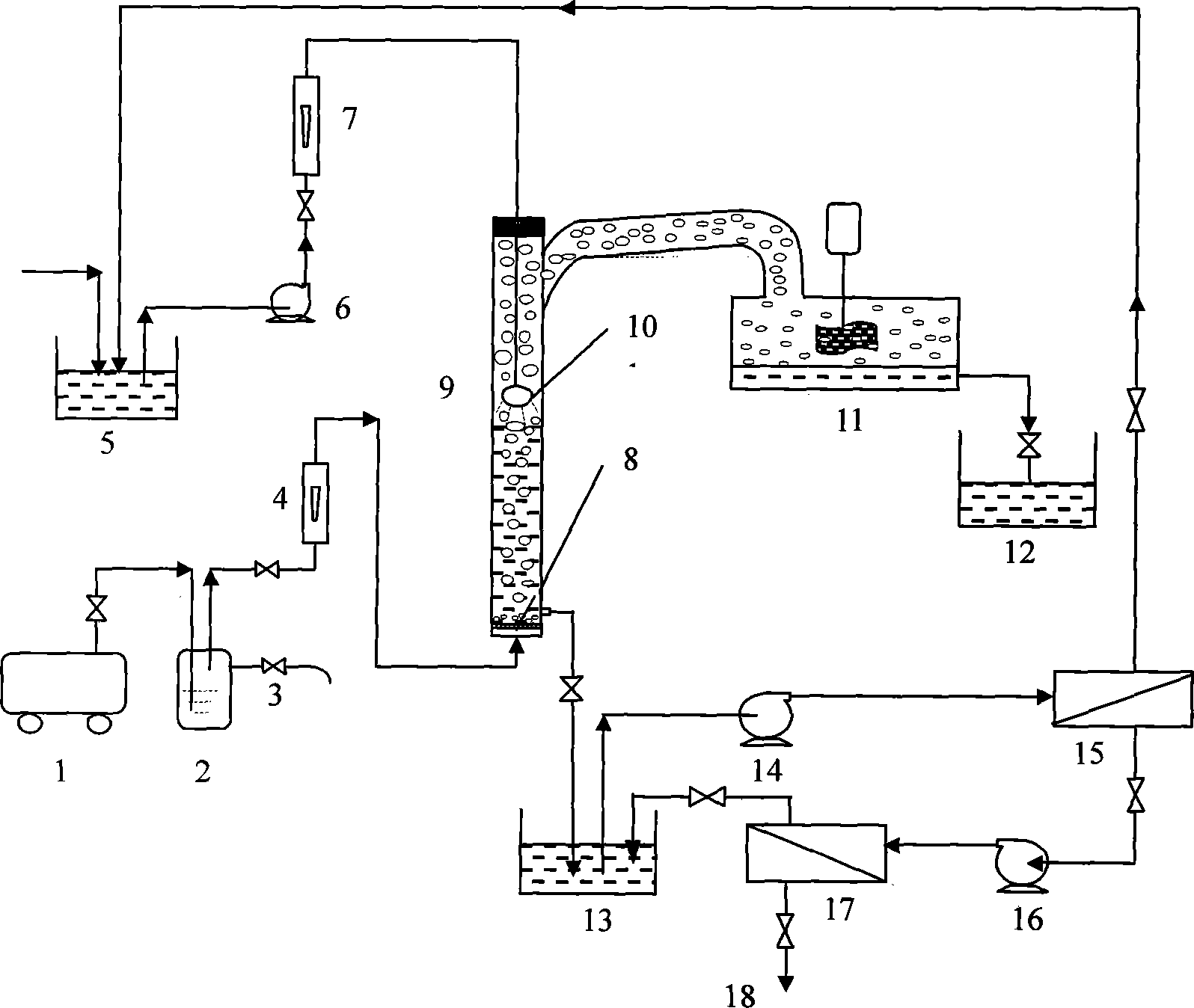

Method and apparatus for treating waste water containing low-concentration perfluoro ammonium caprylate

InactiveCN101070204AReduce energy consumptionWater/sewage treatment by centrifugal separationWater contaminantsHigh concentrationFiltration

This invention relates to a treatment methods and device of low concentration perfluoro ammonium caprylate waste water. Pump clear perfluoro ammonium caprylate waste water into foam separation tower to carry out foam separation, defoam the wastewater tower top spume to gain high concentration perfluoro ammonium caprylate water solution which can be reutilized; gain lower concentration perfluoro ammonium caprulate water solution at tower bottom; use first order nano filter membrane to filter perfluoro ammonium caprylate water solution ejected by tower bottom, condense nano filtration trapped fluid, return it to foam separation tower to carry out foam separation; the permeation liquid of first order nano filter membrane enter secondary nano filter membrane; permeance liquid of secondary nano filter membrane can reach state waste water effluent standard; concentrated solution of secondary nano filter membrane return to first order nano filter membrane; then complete recycling and cleaning of waste water.

Owner:ZHEJIANG UNIV

Industrial production method for simultaneously extracting tea seed oil and tea saponin

ActiveCN104479853AGood miscibilityEasy extractionSugar derivativesFatty-oils/fats refiningCamellia oleiferaSolvent

The invention discloses an industrial production method for simultaneously extracting tea seed oil and tea saponin. The industrial production method comprises the following steps: softening camellia seeds at a low temperature and separating shells and kernels to obtain camellia seed kernels; puffing the camellia seed kernels at a low temperature; extracting with an ether and alcohol homogeneous-phase mixing solvent to obtain homogeneous-phase mixing solvent extract; recycling the solvent from the homogeneous-phase mixing solvent extract; washing with water and separating by a centrifugal machine to obtain an alcohol phase and an ether phase; after recycling the solvent from the alcohol phase, separating the solvent by a foam separation tower and drying in vacuum to obtain the finished-product tea saponin; and after recycling the solvent from the ether phase, refining to obtain the tea seed oil, and adding alkali liquid to remove soap, de-coloring, deodorizing and winterizing in sequence to obtain the finished-product tea seed oil. According to the industrial production method, low-molecular-weight ether and low-molecular-weight alcohol can be mutually dissolved so that a homogeneous-phase mutually-soluble system is formed, and the tea seed oil and the tea saponin are effectively extracted; and meanwhile, tea seed meal with higher protein content also can be obtained, an application range of the camellia seeds is further expanded, the investment of extraction equipment is effectively reduced and the production cost is reduced.

Owner:CHENGUANG BIOTECH GRP CO LTD

Method and apparatus for removing overproof iron and manganese in underground seawater

InactiveCN101333026AEasy to handleSmall footprintMultistage water/sewage treatmentWater/sewage treatment by sorptionManganeseTreated water

The invention relates to a method for removing overproof iron and manganese from underground seawater and is characterized in that: underground seawater is pumped by a water pump and firstly flows through a foam separator to be treated; during the treatment, ozone O3 is pumped in for aeration, the strong oxidizing property of the ozone is used for oxidizing the bivalent manganous ions and / or bivalent ferrous irons which are difficult to be oxidized in water into insoluble precipitate, and the formed precipitate is removed by the interception, adsorption and filtration of a sand filter; the treated water is further filtered and adsorbed by mature manganese sand so as to remove the overproof iron and manganese from the underground seawater. The invention also discloses a device for removing the overproof iron and manganese from the underground seawater which is suitable for the removal method. The method and the device in the invention for removing the overproof iron and manganese from the underground seawater have rapid treatment, economical and applicable properties, small occupied space and convenient operation and management, can effectively remove the heavy metals in underground seawater such as iron, manganese, and the like, and break through technical bottleneck which affects and limits the normal production of aquaculture for a long time.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI +1

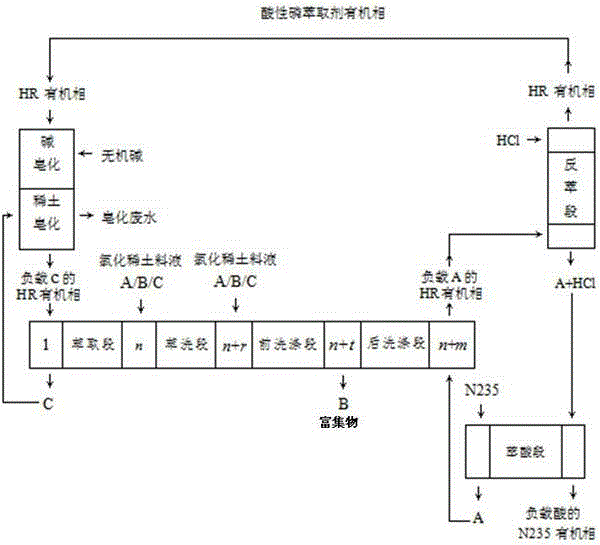

Method for separating rare earth by using two-inlet three-outlet full-load fractionation and extraction

InactiveCN104561612AReduce acid and alkali consumptionReduce consumptionProcess efficiency improvementChemistryFoam fractionation

The invention discloses a method for separating rare earth by using two-inlet three-outlet full-load fractionation and extraction. According to the method, P507 serves as a rare earth extraction agent, rare earth chloride serves as a raw material, a third outlet is formed in a scrubbing section of a two-inlet three-outlet fractionation and extraction system, and an acid extraction section which takes N235 as an acid extraction agent and takes TBP as a demulsifying agent is arranged between the scrubbing section and the stripping section. According to the acid extraction action of N235, side effects of hydrogen ions are eliminated, so that the rare earth separation coefficient is not reduced, and the extraction amount of rare earth is not lower than the rare earth saponification amount. Compared with the conventional two-inlet three-outlet fractionation and extraction process, the method disclosed by the invention has the advantages that the acid-base consumption in the rare earth separation process can be greatly reduced, the consumption of alkaline reagents is reduced by 54.6-58.8 percent, and the consumption of hydrochloric acid is reduced by 16.1-23.7 percent; the wastewater discharge amount in the rare earth extraction and separation process is greatly reduced, and the greening degree of rare earth separation is greatly improved; and moreover, the grade number of the extraction tank can be reduced by 9.5-24.6 percent, and the total investment of the rare earth extraction and separation process is reduced.

Owner:NANCHANG HANGKONG UNIVERSITY

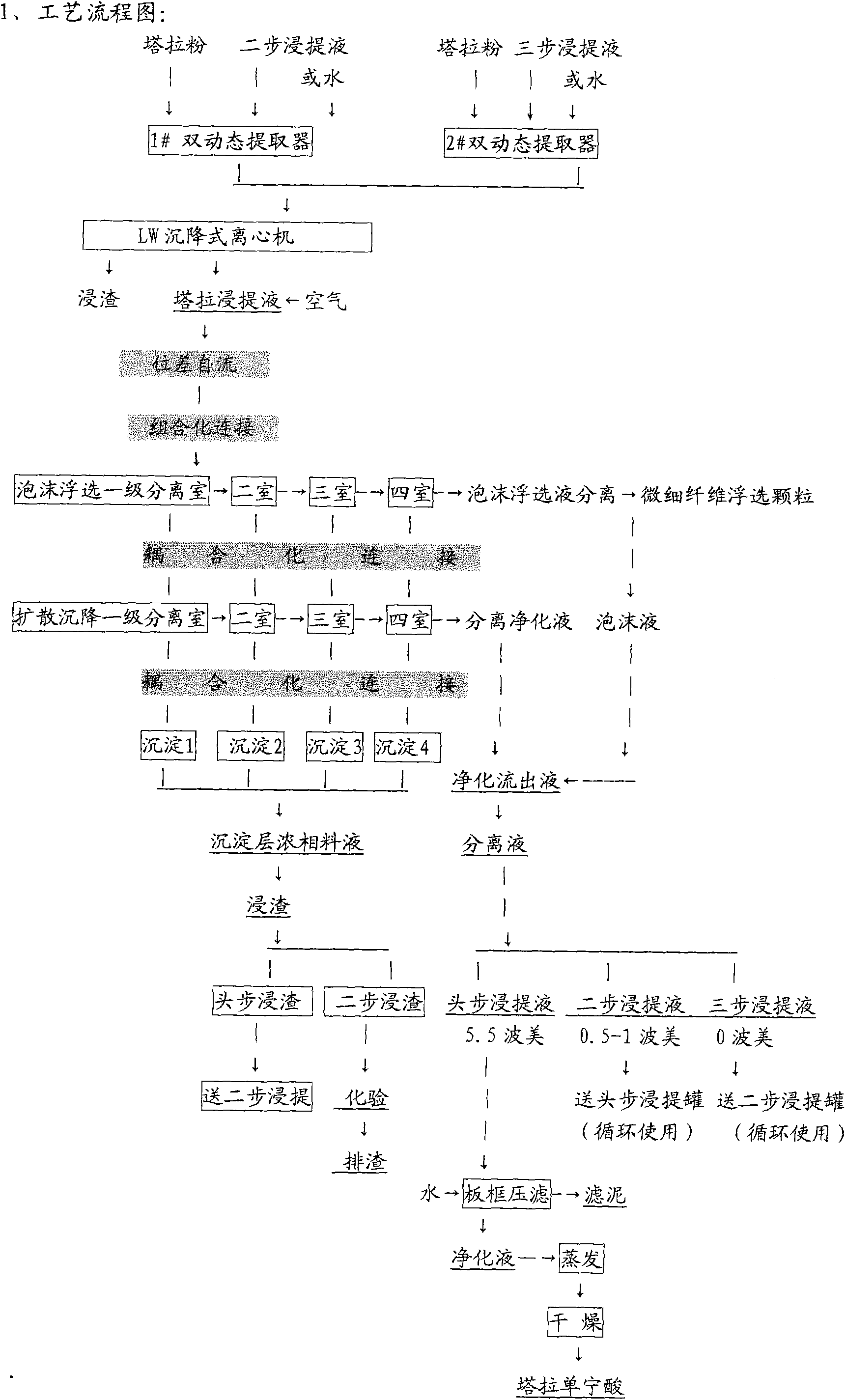

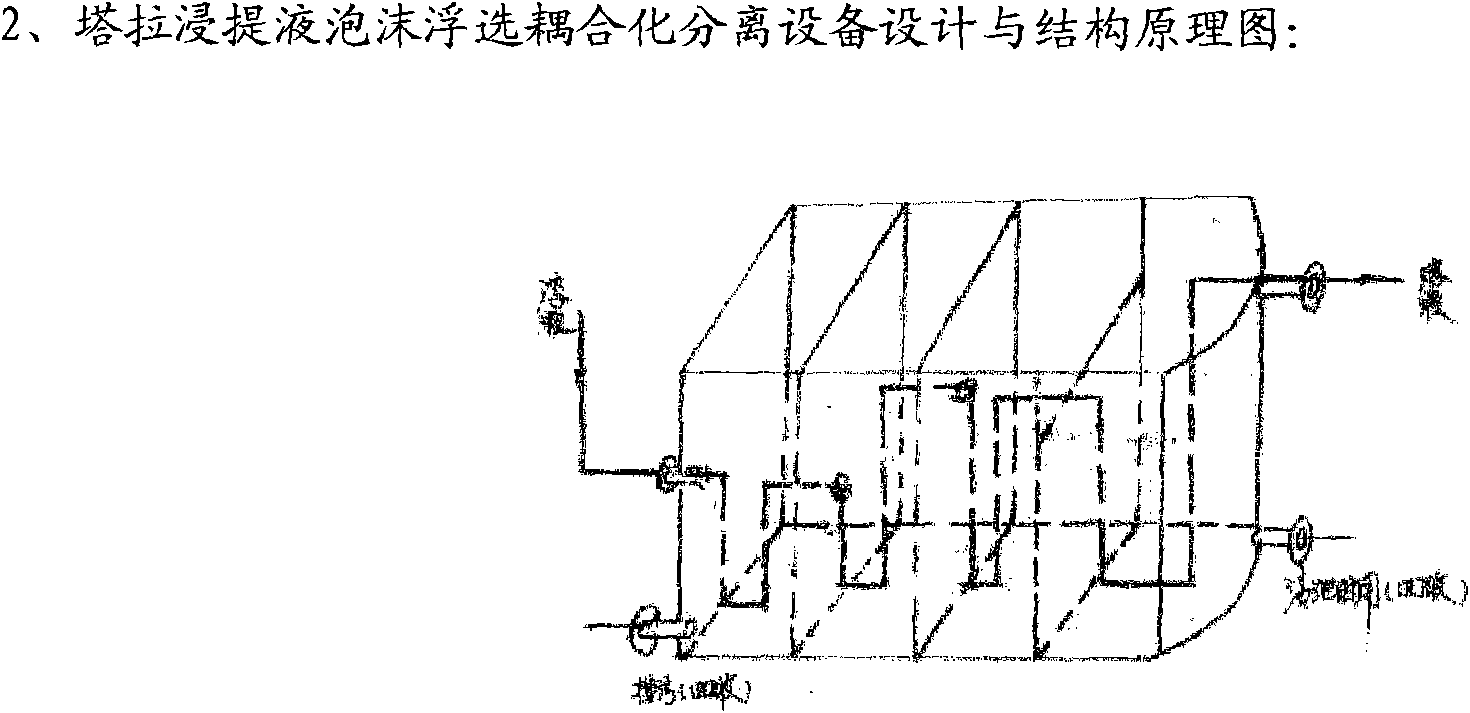

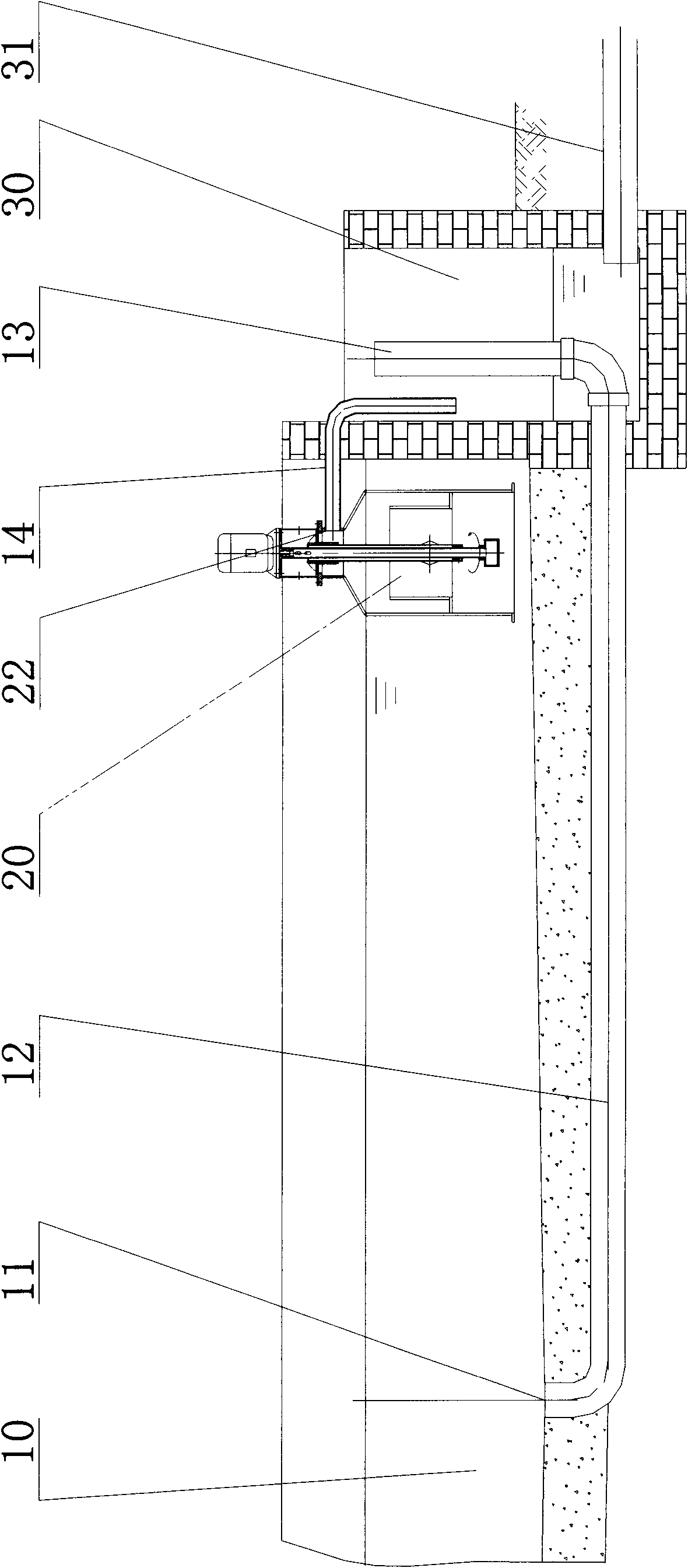

Preparation method of tara industrial tannic acid

The invention relates to a preparation method of tara industrial tannic acid. In the preparation method, tara powder is taken as a raw material, the problems of filtration, sol, superfine fiber particles, undissolved substances, high non tannis and the like in the producing and processing technology of tara tannis are successfully solved through combination and coupling technologies such as double dynamic lixiviation, spiral sedimentation centrifugal separation (horizontal type spiral unloading centrifugal separation), foam separation, sedimentation separation, plate-frame pressure filtration and the like and equipment processing, so as to obtain the qualified tara industrial tannic acid. The preparation method has the advantage of advanced technology; and by using the preparation method, low-temperature, efficient and industrialized production, combination and coupling extraction and a novel solid-liquid separation technique of the tara powder are achieved.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

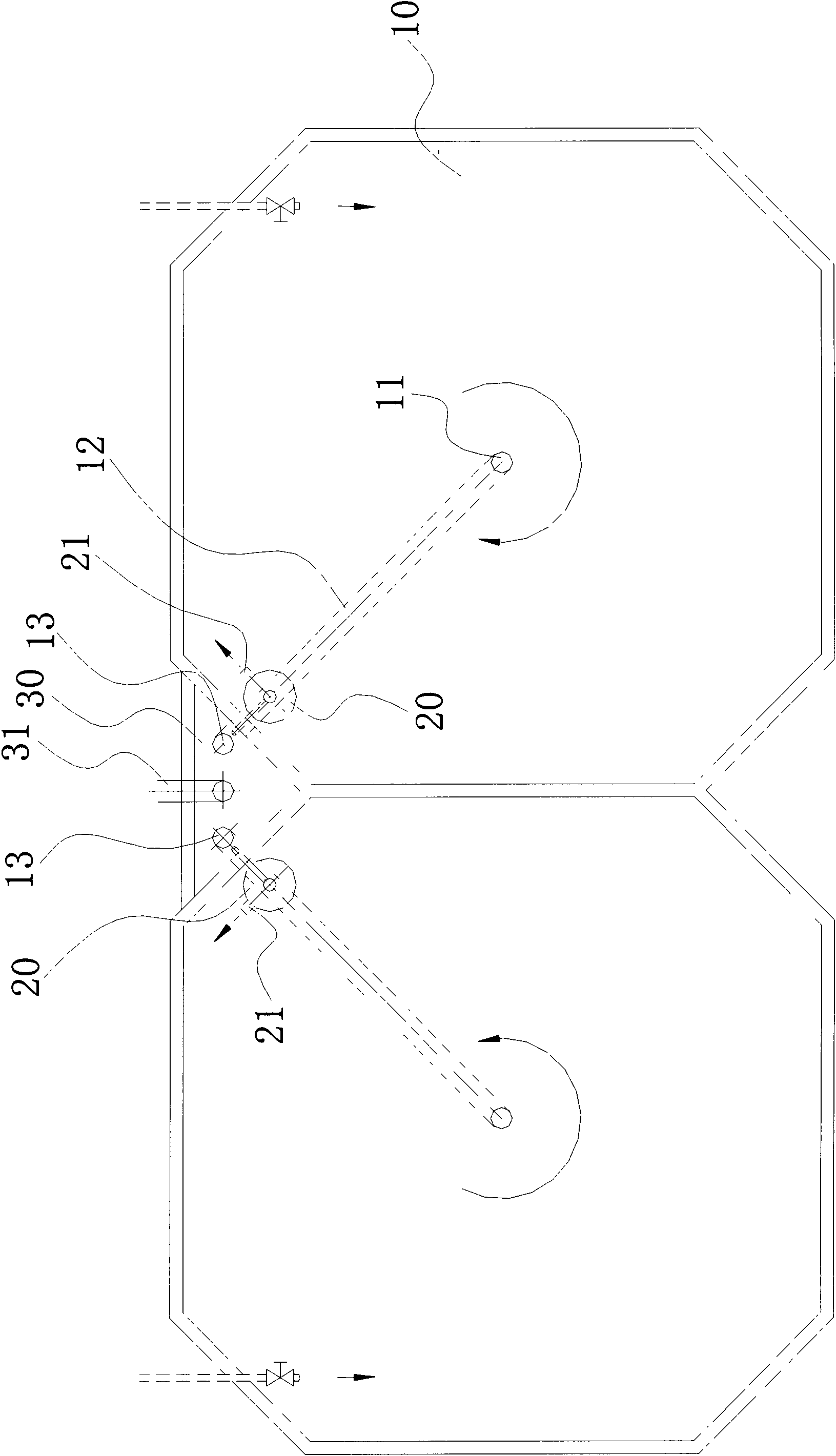

Water-saving marine fish culture water purification plant and method

InactiveCN101653105AWith oxygen functionMeet oxygen needsPisciculture and aquariaSuspended particlesFeces

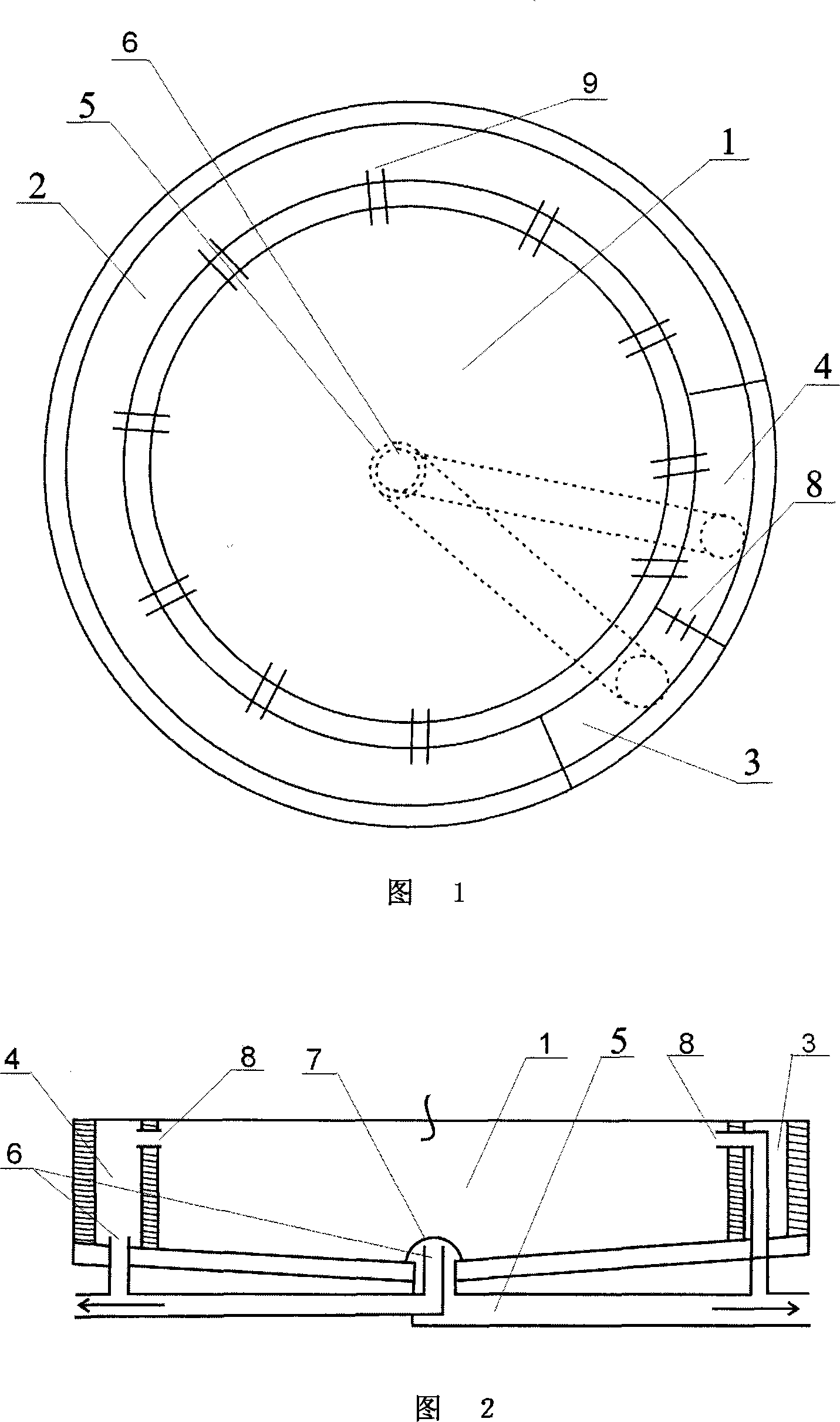

The invention provides a water-saving marine fish culture water purification plant which comprises a drain outlet arranged in the center of a fish pond and a mechanical foam separator arranged in thefish pond, wherein outlet water flow of a water outlet of the mechanical foam separator pushes a water body in the fish pond to rotate around the drain outlet along the flowed water direction of the mechanical foam separator, sewage is drained from the drain outlet through a sewage pipe, and foam which is rich of tiny suspended particles and soluble organic substances and is generated by the mechanical foam separator is drained from a pipeline on the lateral wall of the fish pond; by utilizing push flow, oxygenation and other functions of the mechanical foam separator, on one hand, the foam rich of a large quantity of tiny suspended particles and soluble organic substances in the fish pond is drained, and on the other hand, sewage such as uneaten food, fish feces, and the like deposited atthe bottom of the fish pond can be collected to the drain outlet through push flow to drain. The invention has the oxygenation function and can completely meet the requirement on oxygen under the condition of 8-10kg / m<2>.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

Defoaming device and wall-breaking foam separating and purifying system containing same

PendingCN108479122ALiquid degasification by filtrationFoam dispersion/preventionDistributorFoam fractionation

Owner:TIANJIN ANHAO PHARMATECH CO LTD

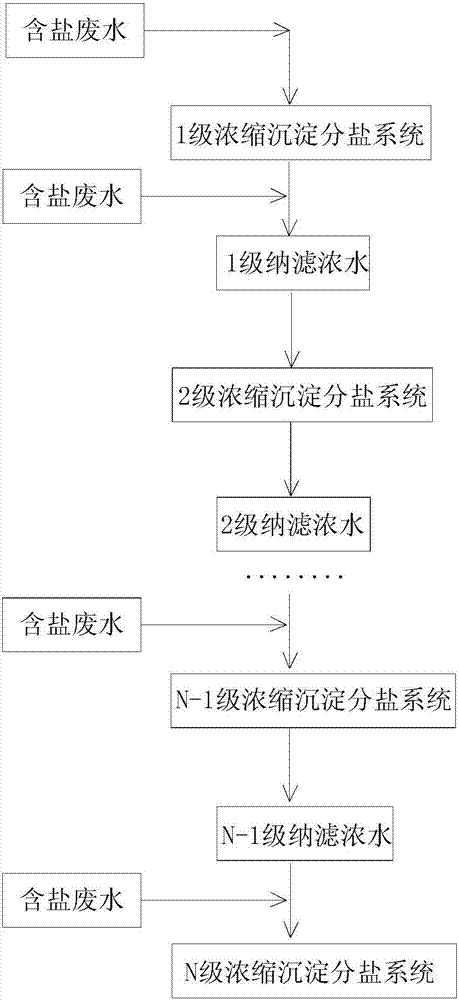

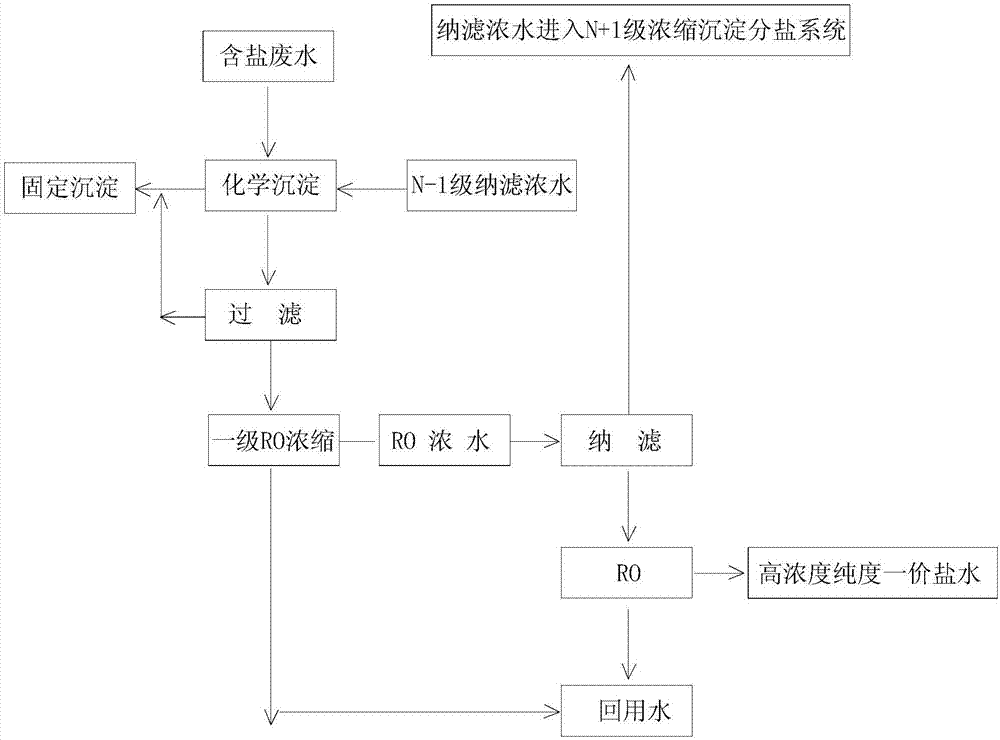

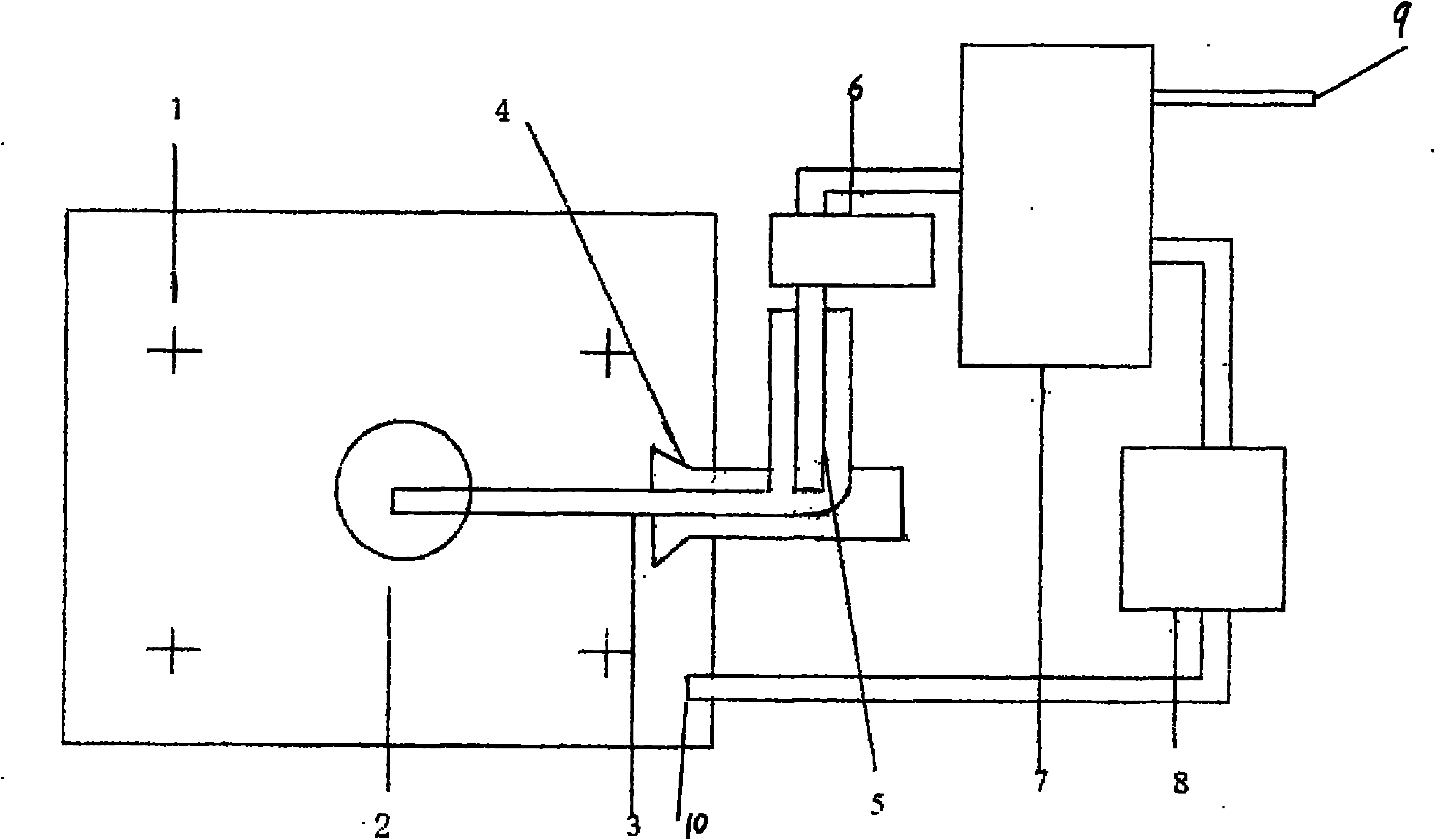

Multistage continuous precipitation and concentration type salt fractionation process method

InactiveCN107055862AIncrease concentrationSufficient precipitationWater/sewage treatment by electrochemical methodsTreatment involving filtrationHigh concentrationInorganic salts

The invention relates to a multistage continuous precipitation and concentration type salt fractionation process method. By utilizing a multistage continuous precipitation and concentration type salt fractionation process, each stage of processing unit can be continuously used, precipitable inorganic salt is removed by virtue of a chemical precipitation method, and monovalence salt and high-valence salt are fractionated by virtue of nanofiltration salt fractionation; by concentrating, the precipitation efficiency and the salt fractionation efficiency can be improved, the concentration of concentrated water can be increased, and recyclable clean water can be obtained; and by treating wastewater by virtue of a first-stage treatment unit, partial recycle water, high-purity and high-concentration monovalence salt, precipitated inorganic salt and nanofiltration concentrated water can be obtained, the nanofiltration concentrated water is mixed with raw water, and mixed water enters a second-stage treatment unit again and is subjected to precipitation, concentration and salt fractionation, so that precipitable substances can be adequately precipitated, and meanwhile, a relatively good separation effect can be achieved through nanofiltration.

Owner:SUZHOU XINER ENVIRONMENTAL TECH CO LTD

Method for processing and recycling aquaculture water in intensive culture pond

InactiveCN101946742AReduce usageReduce pollutionPisciculture and aquariaAquaculture industryAquatic species

The invention discloses a method for processing and recycling aquaculture water in an intensive culture pond, which comprises the following steps: (1) performing oxygenation measures, and then gathering pollutants in a central sewage draining exit; (2) arranging a discharge pipe at the central sewage draining exit, wherein the discharge pipe is communicated with a gate of a drainage sluice; (3) pumping sewage in the pond from a pump pipeline by using pumping equipment; (4) separating the sewage by a foam separator; and (5) dealing with pathogens in the obtained clean water by an ozone generator and then discharging the clean water to the pond for recycling, collecting the obtained sewage and then carrying out biochemical treatment on the sewage, after the sewage is up to the standard, discharging the sewage. In the intensive culture pond implementing the technology of the invention, the aquaculture water consumption can be reduced by 70 to 80 percent, the sewage discharge is reduced, the environmental pollution is alleviated, and the aquaculture output is raised; and meanwhile, the method of the invention is beneficial for cutting off the horizontal transmission route of the pathogens, and can be used for processing and recycling the water in the intensive culture ponds for culturing the economic aquatic species such as fishes, prawns, macrobrachium rosenbergii and crabs, and the like in the process of cultivation, therefore, the method is helpful for the healthy and sustainable development of the aquaculture industry, and has high use value.

Owner:GUANGDONG OCEAN UNIVERSITY

Preparation method for multistage separation extraction of earthworm active proteins and method

InactiveCN105273038AHigh enrichment ratioHigh recovery ratePeptide preparation methodsActive proteinEnrichment ratio

The invention discloses a preparation method for multistage separation extraction of earthworm active proteins and a method. The preparation device comprises a constant temperature foam separating column, an air pump, an air distributer, a rotor flowmeter and a foam collection device. The preparation method comprises the following steps: firstly, collection and detection of an earthworm protein homogenate material liquid is carried out; secondly, the earthworm protein homogenate material liquid is subjected to pretreatment; thirdly, first stage foam separation is carried out; fourthly, second-stage foam separation is carried out. A two-stage foam separation technology is established at a high temperature based on influences on earthworm active protein foam separating effects, and the two-stage foam separation technology can raise the enrichment ratio and can raise the recovery rate.

Owner:TIANJIN BAIMING SCI & TECH DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com