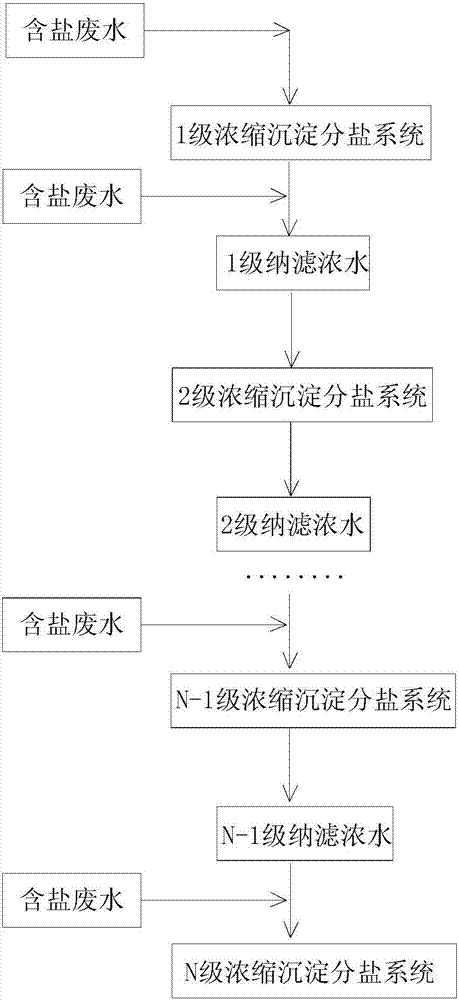

Multistage continuous precipitation and concentration type salt fractionation process method

A process method and salt separation technology, applied in chemical instruments and methods, multi-stage water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problems of insufficient removal of precipitable substances and low efficiency, and achieve Improve efficiency and effect, improve efficiency, and improve the effect of separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

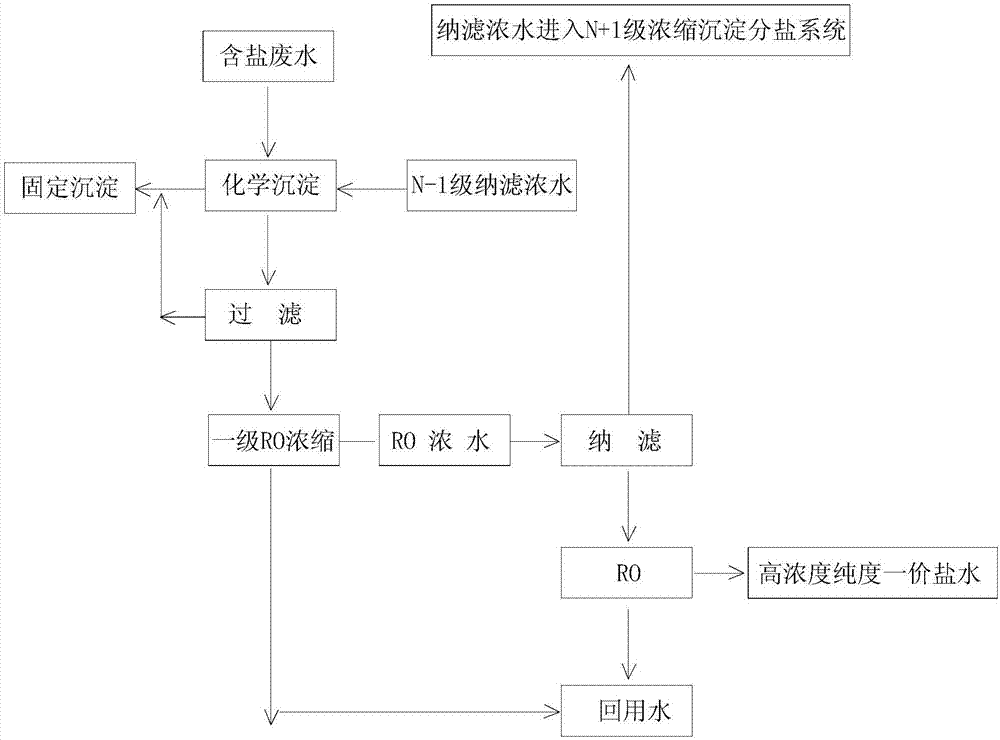

Method used

Image

Examples

Embodiment

[0032] For example: the TDS of a certain saline wastewater is about 1%, and the main components are Ca2+, Mg2+, Na+, SO42-, Cl- and a mixed solution composed of a small amount of anions and cations. The raw material enters the primary treatment unit, adding lime and NaCO3 to remove 80% of the hardness first, and then passes through natural precipitation and precision filter clarification and filtration into the RO membrane for concentration, the recovery rate is controlled at 65%, and the salt content of the permeate is 3% and a purity >99%, and the permeate contains salt Amount <1000ppm.

[0033] The concentrated water of nanofiltration is mixed concentrated water containing Ca2+, Mg2+, Na+, SO42-, Cl- and miscellaneous salts. The relative concentration of Ca2+ and Mg2+ has been greatly increased. After mixing with raw water, it enters the secondary treatment unit, adding lime and NaCO3 removes 85% of the hardness first, and the efficiency of nanofiltration salt separation is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com