Foam separating and eliminating technology and production line of surface activator

A surfactant and foam separation technology, applied in the direction of foam dispersion/prevention, can solve the problems of high processing cost, strong heat radiation, waste of engineering investment, etc., and achieve the effect of convenient operation and management, simple processing technology, stable and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

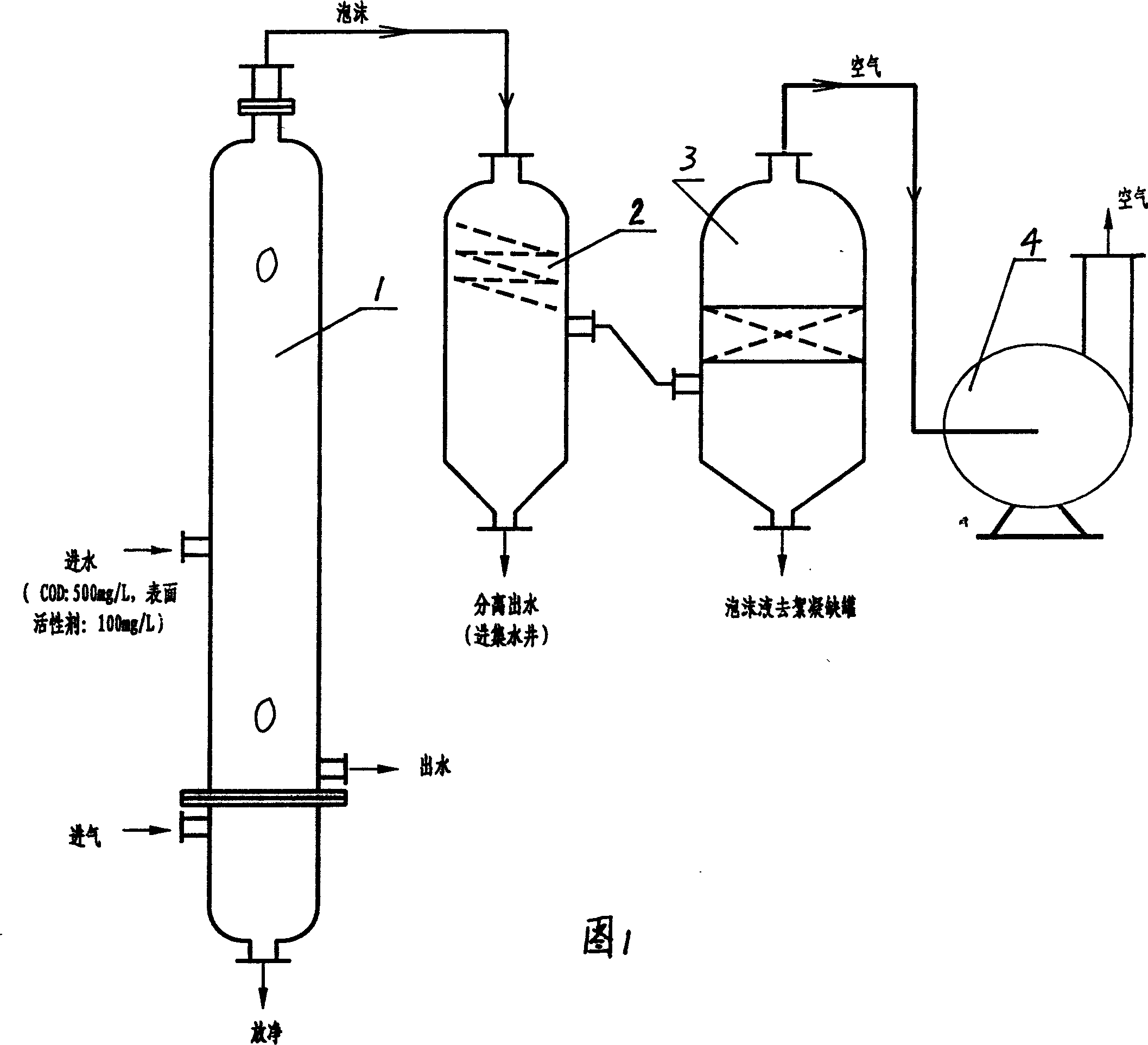

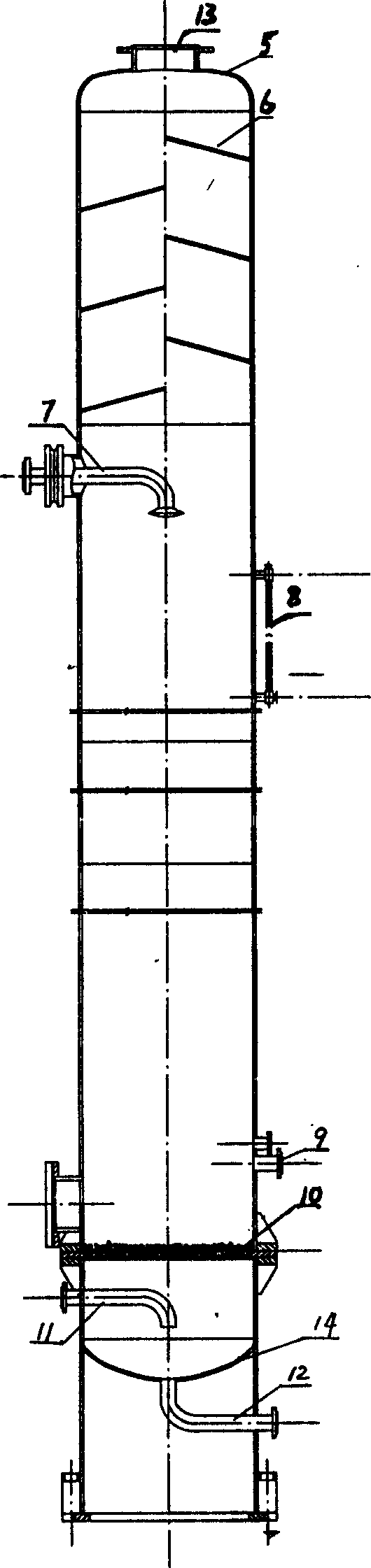

[0024] With reference to Fig. 1, production line equipment of the present invention is made up of foam separation tower (1), gas-liquid separator (2), bubble breaker (3), blower fan (4) with pipeline connection successively by technological process. The foam separation tower (1) is equipped with several semicircular baffles (6) from top to bottom in the tower shell (5). The semicircular baffles are inclined from inside to outside and arranged in a staggered manner to block water Liquid overflow. Below the semicircular baffle is the water inlet nozzle (7), and there is a microporous nozzle (10) in the lower part of the tower. Hole the tube to release tiny air bubbles. The lower end of the tower is sealed with a head plate (14) below the microporous nozzle and a drain pipe (12) is left, and an air inlet pipe (11) is arranged on the housing above the head plate for entering compressed air. A water outlet (9) is arranged on the housing above the micropore nozzle.

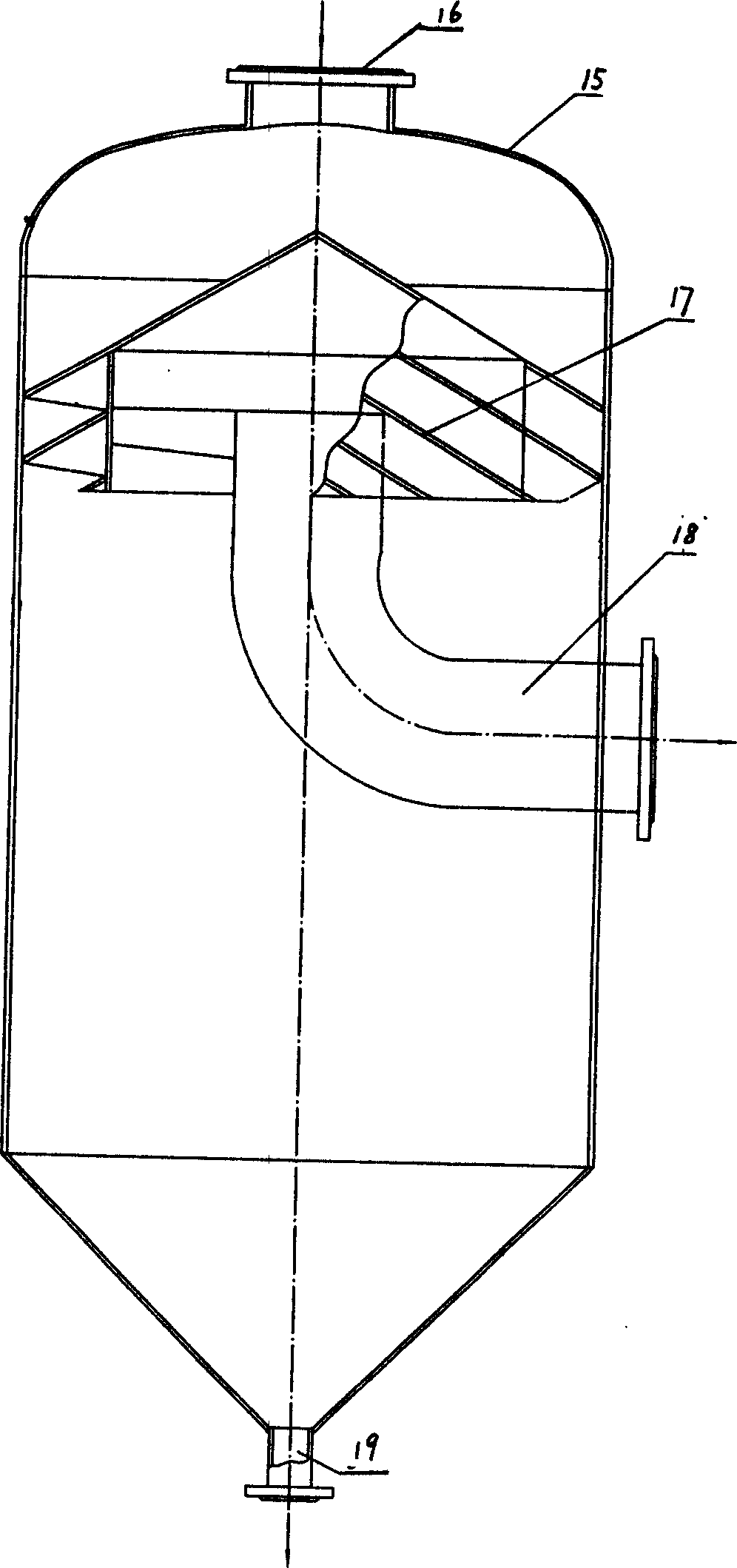

[0025] The g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com