Aquiculturing system process for works with circulating water

A technology for aquaculture and circulating water, applied in biological water/sewage treatment, degassed water/sewage treatment, water/sludge/sewage treatment, etc., to achieve the effect of reducing energy consumption, reducing the number of water pumps, and reducing energy consumption in operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

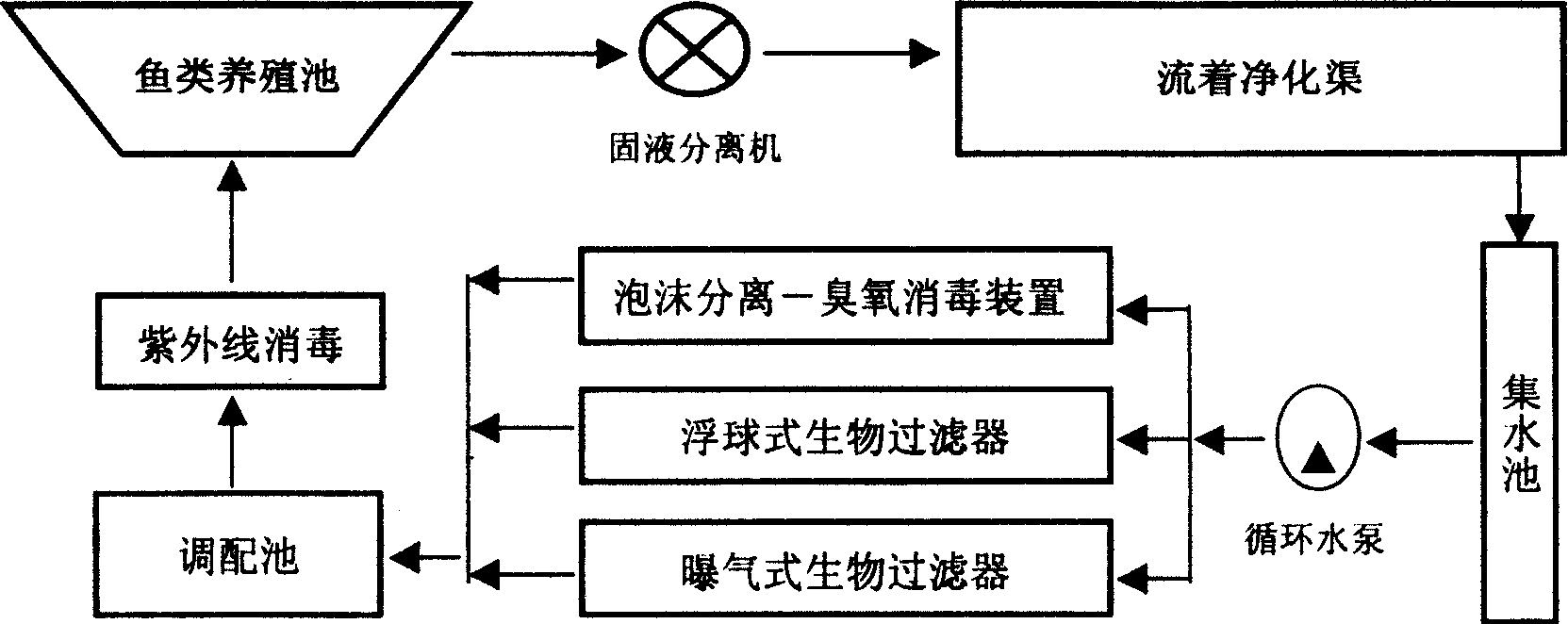

[0010] The circulating water industrial aquaculture system process includes a closed circulating water treatment system. The workshop adopts air heating and water body heating for heating. The circulating water treatment system includes a breeding pond, a drum type solid-liquid separation device, a flow purification device, and Type biological filter and floating ball type biological filter, foam separation-ozone disinfection device, blending tank, ultraviolet disinfection device; use circulating water pump to extract the breeding water from the sump to each water treatment unit, and all water treatment units can be independent Shutdown control, select and start each water treatment unit according to the system load and water quality conditions; the system water cycle is 8 times a day;

[0011] The total area of the workshop is 1940.4m 2 , the total area of the breeding pond is 1000m 2 , the total area of the breeding pond is 51.5% of the total area of the workshop; t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com