Integrated circulating water culture system

A technology of circulating aquaculture and aquaculture water, which is applied in fish farming, chemical instruments and methods, multi-stage water/sewage treatment, etc. It can solve the problems of complex configuration of water treatment devices, affecting the degree of integration, and low treatment efficiency. Achieve the effect of improving fish anti-interference and anti-stress ability, reducing bait loss, reducing equipment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

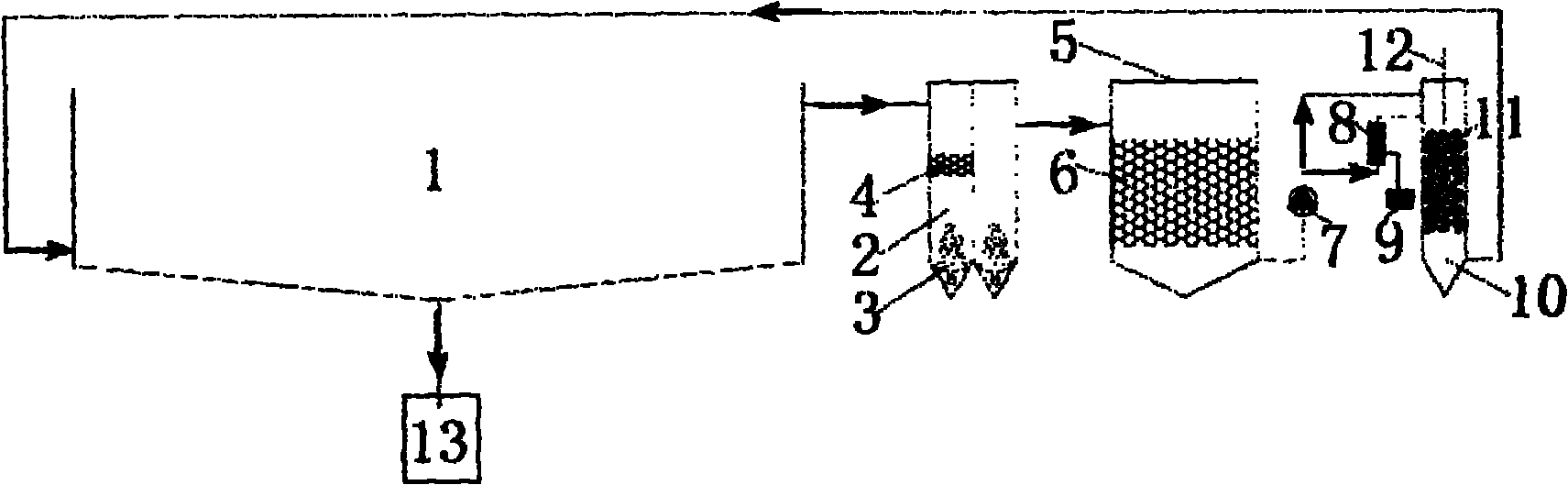

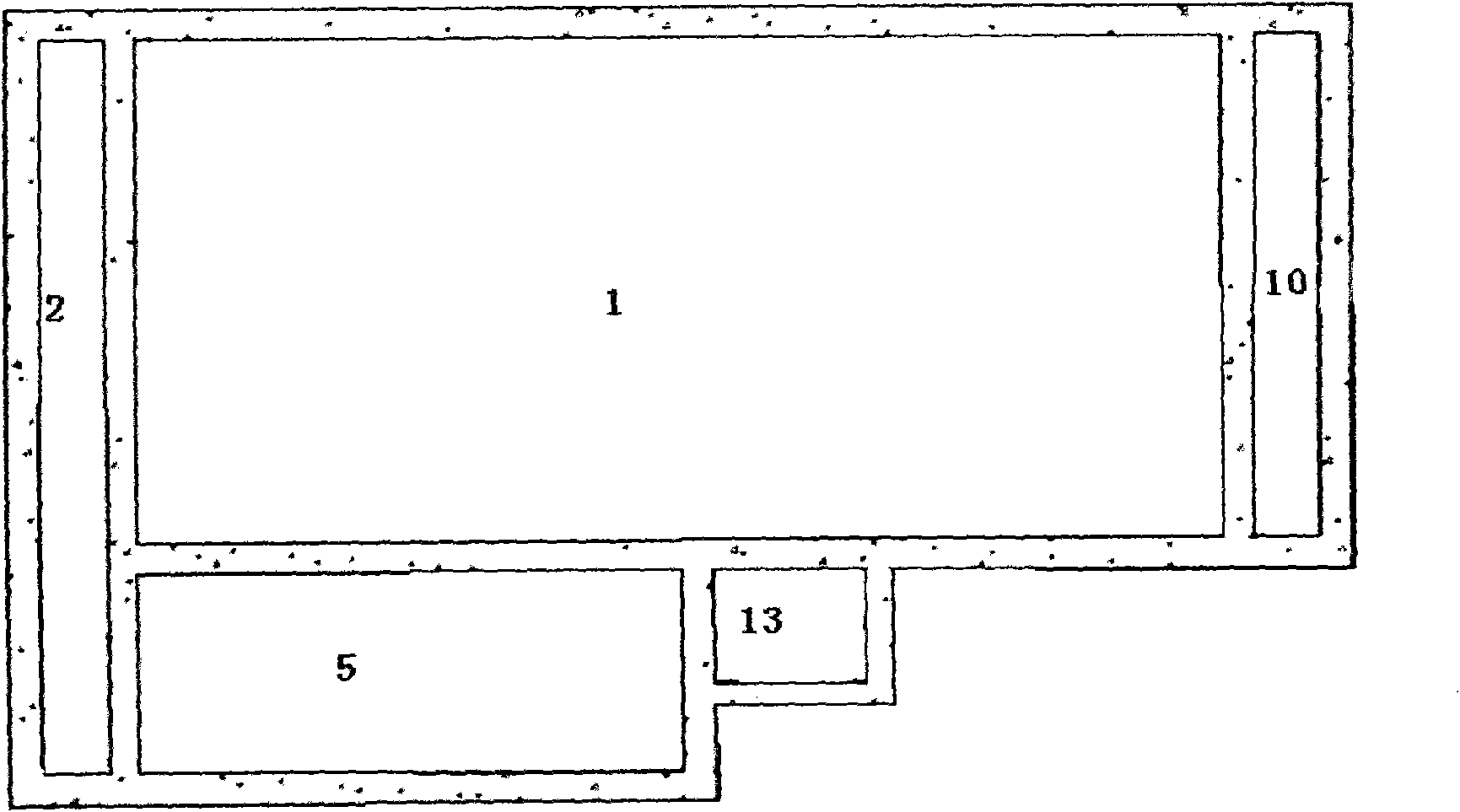

[0008] The working principle of the invention is as follows: fish are cultured in a culture tank, and fish production is carried out by feeding artificial feed. The aquaculture water discharge in the aquaculture tank adopts dual-channel discharge, and the water is discharged from the bottom of the aquaculture tank. The bottom of the aquaculture tank is a pointed bottom structure, and a drainage port is set at the pointed bottom structure. Using the water level difference inside and outside the aquaculture tank, a low-flow high The siphon environment of the flow rate forms a strong suction at the bottom of the aquaculture tank. When the sedimentable particulate organic matter produced by the cultured fish settles to the bottom of the aquaculture tank, it will be discharged out of the aquaculture tank along with the outlet water. For the rapid discharge of sedimentable particulate organic matter, the outlet flow of this channel is controlled by a valve, and the daily discharge is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com