Method and apparatus for treating waste water containing low-concentration perfluoro ammonium caprylate

A technology for ammonium perfluorooctanoate and waste water treatment, applied in water/sewage treatment, flotation water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of high energy consumption and uneconomical, and achieve the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

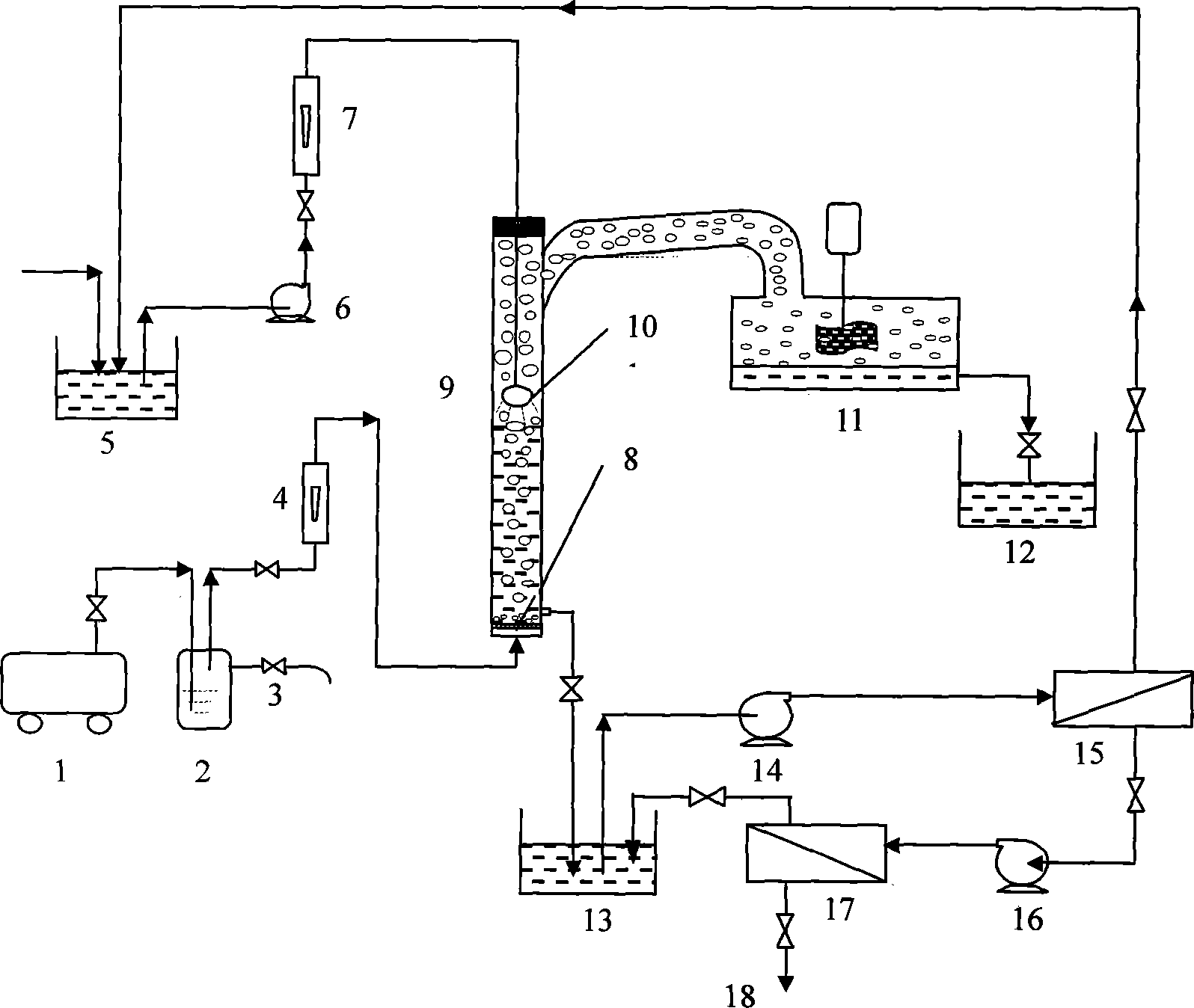

[0015] As shown in the drawings, the waste water storage tank 5 of the present invention is connected with the clear and transparent waste water input pipe containing ammonium perfluorooctanoate from centrifugation, the concentrated nanofiltration retentate liquid input pipe and the waste water output pipe, and the waste water is output through the water pump 6, the first valve, The liquid rotameter 7 is connected from the top of the foam separation tower 9, and the end of the connection pipe is equipped with a liquid distributor 10; the compressed air of the air compressor 1 is connected to the buffer humidification tank 2 and the buffer humidification tank through the second valve 2 is divided into two roads, one road is connected to the bottom of the foam separation tower 9 through the third valve, the gas rotameter 4, and the bottom of the foam separation tower 9 is equipped with a gas distribution plate 8, and the other road is connected to the vent valve 3, and connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com