Patents

Literature

59 results about "Ammonium perfluorooctanoate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polytetrafluoroethylene aqueous dispersion and its product

ActiveUS7709566B2Improve stabilityImprove wettabilityTransportation and packagingMixingHydrogen atomMechanical stability

Owner:ASAHI GLASS CO LTD

Aqueous polytetrafluoroethylene emulsion, polytetrafluoroethylene fine powder and porous material obtained therefrom

ActiveUS20080200571A1High molecular weightNatural cellulose pulp/paperSynthetic cellulose/non-cellulose material pulp/paperPolymer chemistryAlkali metal

To provide an aqueous polytetrafluoroethylene (PTFE) emulsion which does not substantially contain ammonium perfluorooctanoate, and which is obtained by emulsion polymerization. Further, to provide a PTFE fine powder which is obtained from the aqueous PTFE emulsion and is excellent in a paste extrusion processability, and a porous material.An aqueous polytetrafluoroethylene emulsion obtained by carrying out emulsion polymerization of tetrafluoroethylene alone or together with another copolymerizable monomer in an aqueous medium, wherein a fluorinated emulsifier of the formula (1):XCF2CF2(O)mCF2CF2OCF2COOAwherein X is a hydrogen atom or a fluorine atom, A is a hydrogen atom, an alkali metal or NH4, and m is an integer of 0 or 1, is used in an amount of from 1,500 to 20,000 ppm, based on the final yield of polytetrafluoroethylene.

Owner:ASAHI GLASS CO LTD

Method for producing melt-processable fluororesin

ActiveUS20080200627A1High molecular weightEasy to disassembleTransportation and packagingMixingHydrogen atomEmulsion

To provide a method for producing a melt-processable fluororesin, which is capable of increasing the molecular weight of the fluororesin and preventing coloration of the fluororesin, by using a specific fluorinated emulsifier other than ammonium perfluorooctanoate.A method for producing a melt-processable fluororesin which is characterized in that a fluorinated monomer is emulsion-polymerized in an aqueous medium containing a fluorinated emulsifier of a formula (1)XCF2CF2(O)mCF2CF2OCF2COOA wherein X is a hydrogen atom or a fluorine atom, A is a hydrogen atom, an alkali metal or NH4, and m is an integer of 0 or 1.

Owner:ASAHI GLASS CO LTD

Aqueous dispersion of polytetrafluoroethylene and process for its production

InactiveUS20070015857A1Low viscosityImprove frictional stabilityFatty oils/acids recovery from wasteOrganic compound preparationCooking & bakingCarboxylic acid

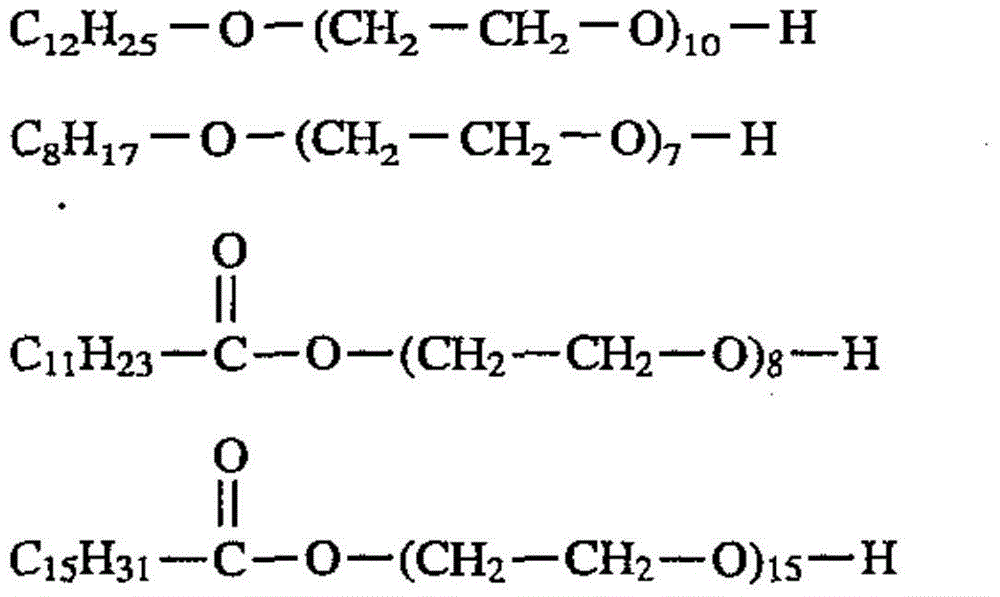

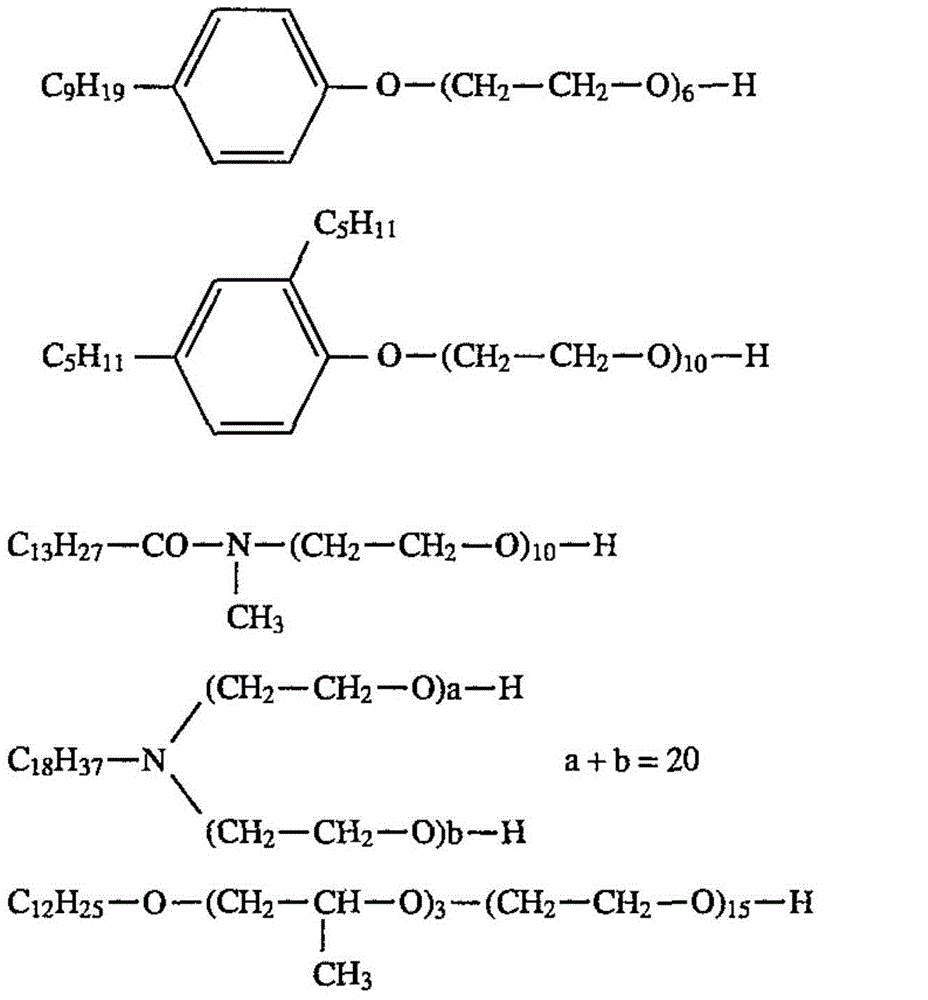

An aqueous dispersion of polytetrafluoroethylene (PTFE) comprising from 55 to 70 mass % of PTFE fine particles having an average particle diameter of from 0.1 to 0.5 μm, from 0.0001 to 0.02 mass %, based on PTFE, of a specific C8 fluorine-containing carboxylic acid salt (APFO) such as ammonium perfluorooctanoate, from 1 to 20 mass %, based on PTFE, of a specific nonionic surfactant and from 0.01 to 0.3 mass %, based on PTFE, of a specific C5-7 fluorine-containing carboxylic acid salt such as ammonium perfluorohexanoate. The aqueous dispersion of PTFE has excellent properties which can form crack-resistant coatings which do not undergo coloration during baking or form problematic ionic impurities by improving the friction stability of aqueous PTFE dispersions even at APFO concentrations without viscosity increase.

Owner:ASAHI GLASS CO LTD

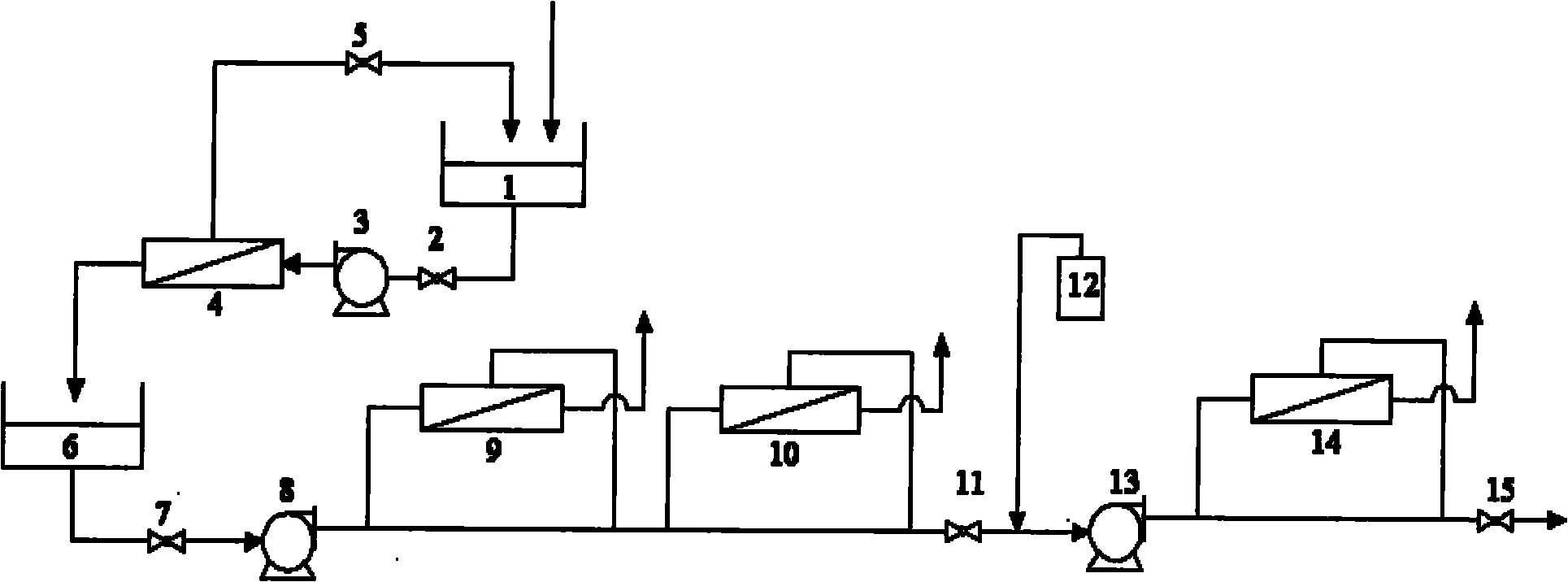

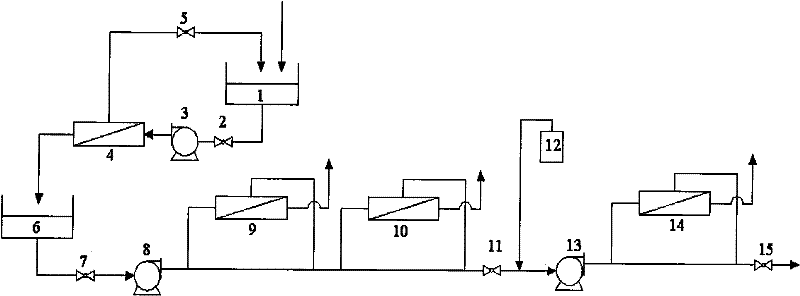

Method for treating wastewater with low-concentration ammonium perfluorooctanoate through all-film method

ActiveCN101928078AReduce recycling costsSimple operation processWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentHigh concentrationThree level

The invention belongs to the chemical wastewater treatment field, in particular relates to a method for treating wastewater with low-concentration ammonium perfluorooctanoate through all-film method which combines the ultra microfiltration technology and the nanofiltration technology. The method comprises the following steps: firstly adopting microfiltration or ultrafiltration to remove insoluble particles in the wastewater with low-concentration ammonium perfluorooctanoate; and secondly using a nanofiltration system to concentrate ammonium perfluorooctanoate in the pretreated and clarified wastewater, wherein the nanofiltration system is divided to three levels, each level adopts the concentrated water inner circulation mode to concentrate ammonium perfluorooctanoate to a higher concentration step by step, the permeate of each level of nanofiltration can be directly charged or used as the process water of other processes, and the zero emission of industrial wastewater can be realized. The method of the invention has simple operation, low energy consumption and no secondary pollution; and high-value-added perfluorooctanoic acid can be recycled and the industrial wastewater can meet the direct emission standard or the reuse standard.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

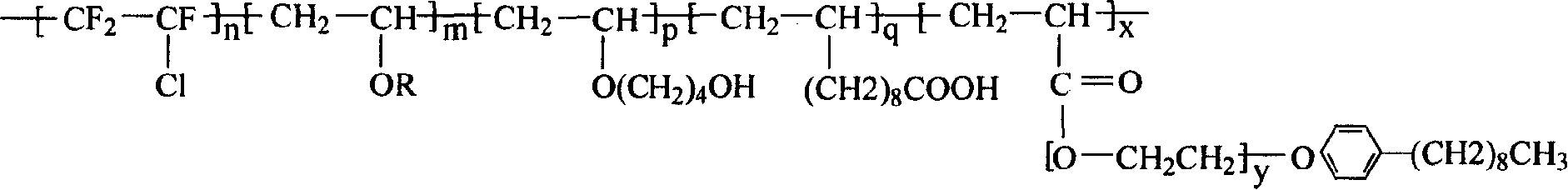

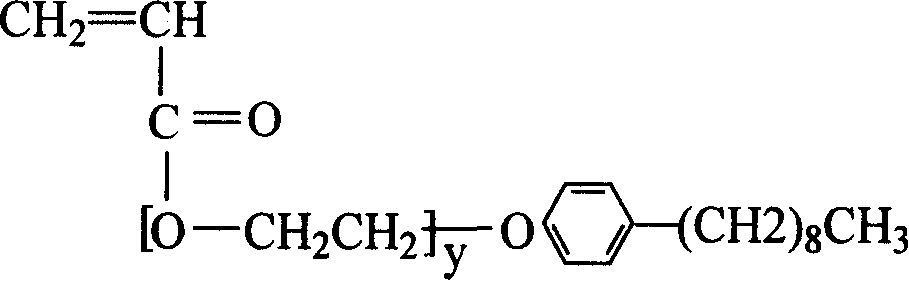

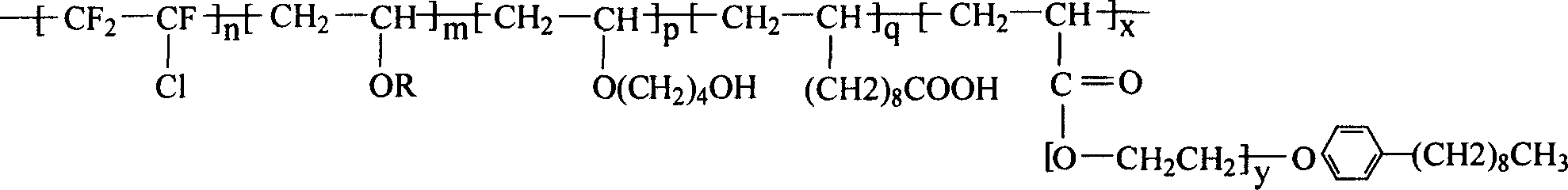

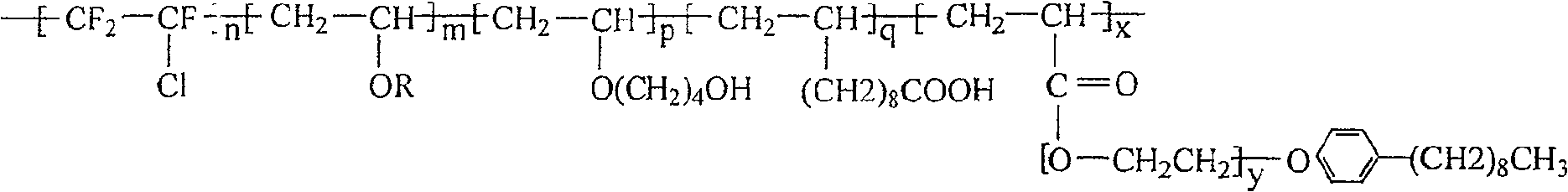

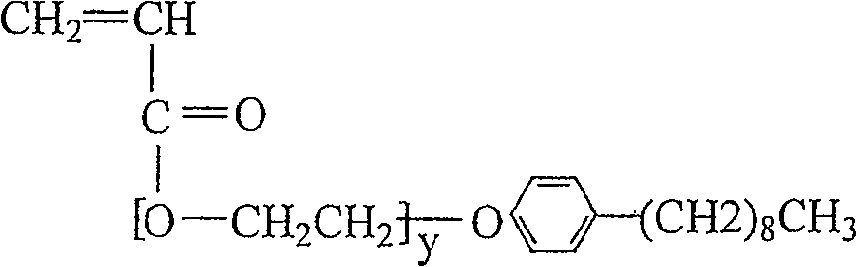

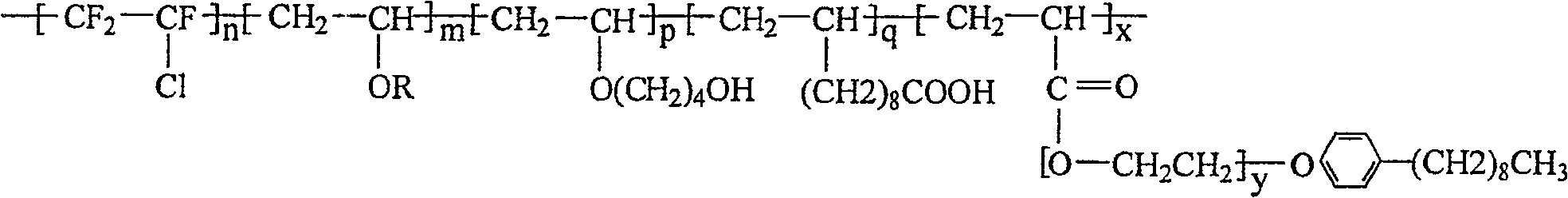

Preparation method and application of water-based fluoropolymer emulsion

The present invention relates to preparation process of water thinned fluoric polymer emulsion for paint. The preparation process is one emulsion copolymerization process with trifluorochloro ethylene, alkyl vinyl ether or vinyl acetate, hydroxyl butyl vinyl ether, undecylenic acid and polyoxyethylene acrylate as monomers, non-ionic emulsifier NP and anionic ammonium perfluoro octoate as composite emulsifier, and composition of ammonium persulfate or potassium persulfate and sodium bisulfite as redox initiation system. The polymerization may be completed in room temperature and is simple, and the product has excellent chemical stability, mechanical stability and mechanical performance. The emulsion has relatively high fluorine content, so that the prepared paint has excellent corrosion resistance, weather resistance and antifouling performance.

Owner:TONGJI UNIV

Aqueous dispersion of polytetrafluorethylene and process for its production

To obtain a high concentration aqueous PTFE dispersion containing PTFE at a concentration of from 60 to 75 mass% by dissolving from 0.001 to 0.1 mass%, based on the mass of PTFE, of a specific carboxylic acid salt such as ammonium laurate in a low concentration aqueous dispersion of polytetrafluoroethylene (PTFE) comprising from 1 to 40 mass% of PTFE fine particles, from 0.0001 to 0.02 mass%, based on the mass of PTFE, of a specific fluorine-containing carboxylic acid type emulsifier (for example, ammonium perfluorooctanoate), and from 1 to 20 mass%, based on the mass of PTFE, of a specific nonionic surfactant, and then concentrating the low concentration aqueous dispersion of PTFE. The present invention provides a process for producing a high concentration aqueous PTFE dispersion containing PTFE at a high concentration by using, as a starting material, a low concentration aqueous dispersion of PTFE containing a fluorine-containing carboxylic acid type emulsifier (PFCA) at a low concentration, and an aqueous PTFE dispersion obtained from the high concentration aqueous PTFE dispersion.

Owner:ASAHI GLASS CO LTD

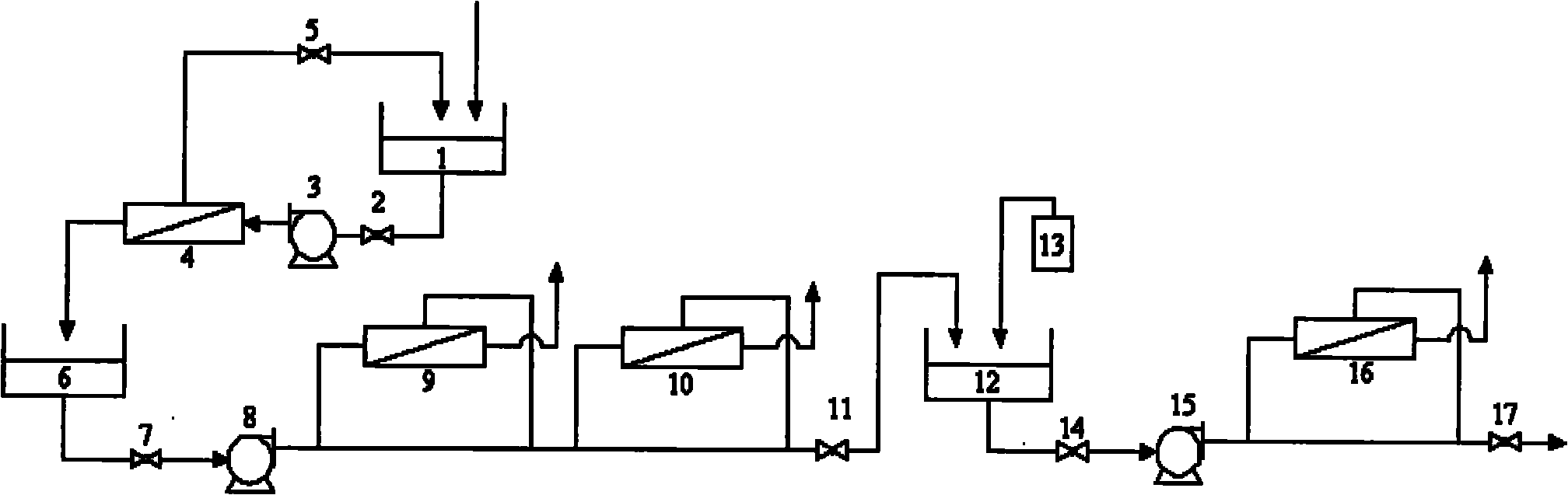

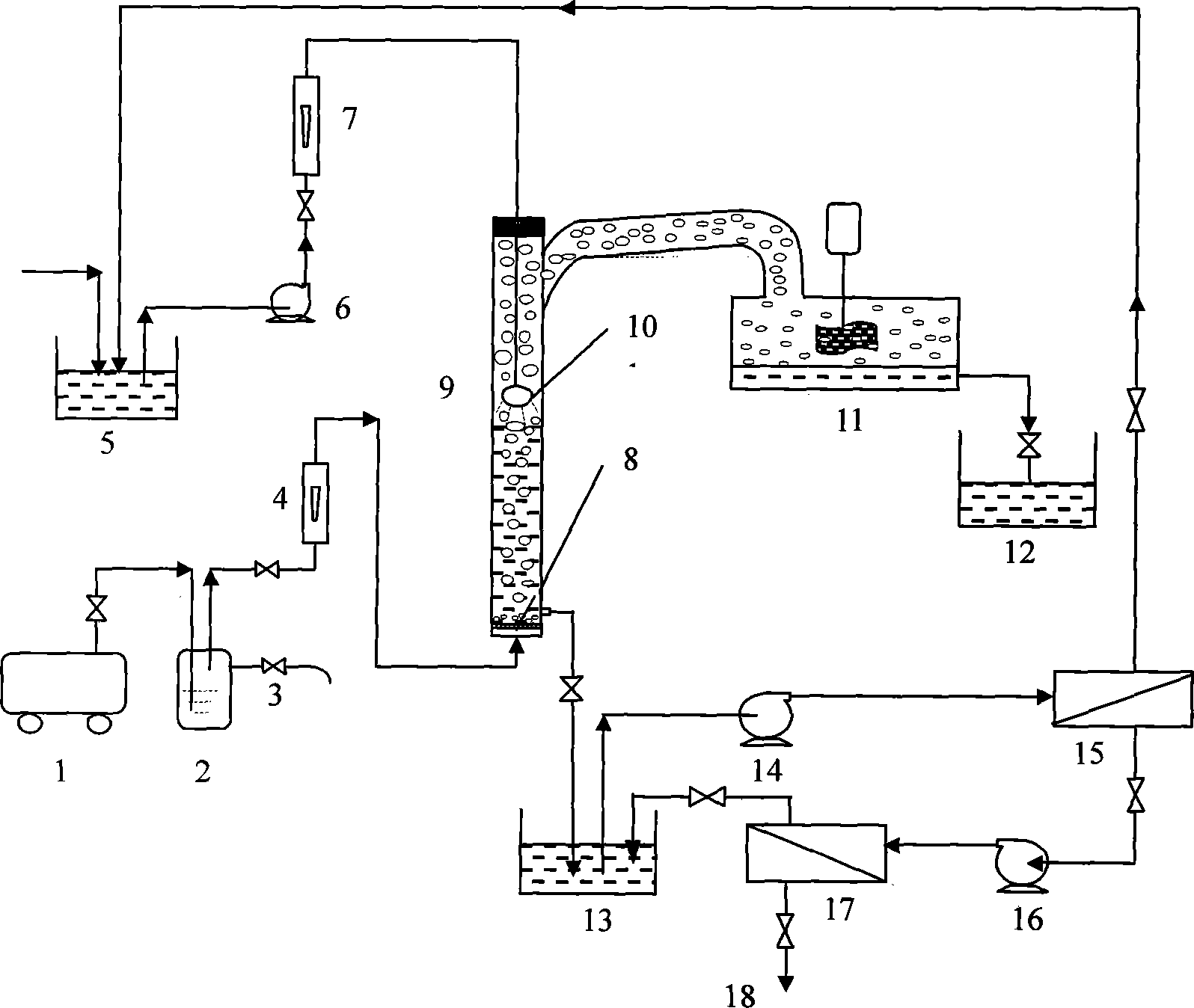

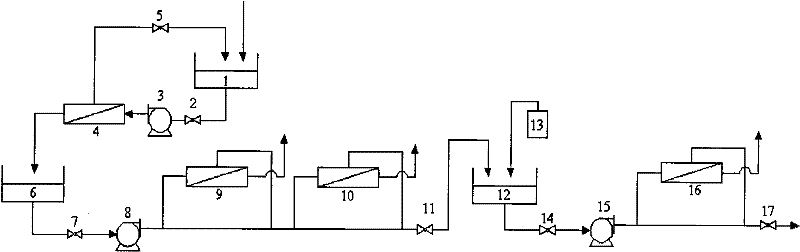

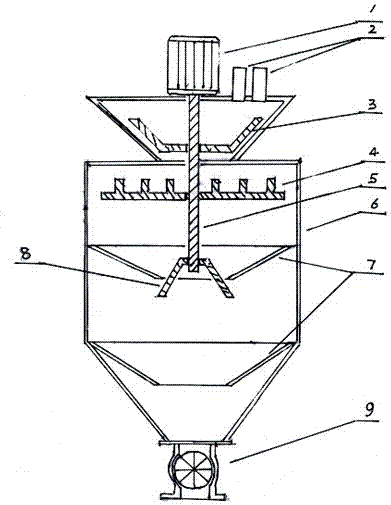

Method and apparatus for treating waste water containing low-concentration perfluoro ammonium caprylate

InactiveCN101070204AReduce energy consumptionWater/sewage treatment by centrifugal separationWater contaminantsHigh concentrationFiltration

This invention relates to a treatment methods and device of low concentration perfluoro ammonium caprylate waste water. Pump clear perfluoro ammonium caprylate waste water into foam separation tower to carry out foam separation, defoam the wastewater tower top spume to gain high concentration perfluoro ammonium caprylate water solution which can be reutilized; gain lower concentration perfluoro ammonium caprulate water solution at tower bottom; use first order nano filter membrane to filter perfluoro ammonium caprylate water solution ejected by tower bottom, condense nano filtration trapped fluid, return it to foam separation tower to carry out foam separation; the permeation liquid of first order nano filter membrane enter secondary nano filter membrane; permeance liquid of secondary nano filter membrane can reach state waste water effluent standard; concentrated solution of secondary nano filter membrane return to first order nano filter membrane; then complete recycling and cleaning of waste water.

Owner:ZHEJIANG UNIV

Method for treating perfluoro ammonium caprylate in waste water for PTFE dispersion resin production

ActiveCN1935771ASolve processing problemsSimple processWater/sewage treatmentCarboxylic compound separation/purificationPerfluorooctanoic acidPolytetrafluoroethylene

The invention is a method of processing ammonium perfluoro octoate in the waste water of teflon dispersion resin production, belonging to the field of processing waste water of teflon dispersion resin production, adopting deposition process to process the waste water, using bivalent metal salts as precipitator and trivalent metal salts as flocculant, processing the waste water by different metallic ions and in different proportions, able to make the concentration of ammonium perfluoro octoate in the obtained clear solution is below 10mg / L, reaching the secondary pollutant effluent concentration (the primary standard 10mg / L ) and completely able to meet the effluent requirements. And the recovered ammonium perfluoro octoate has purity up to 95%, and can be reused in polymerization or act as other fluorine-containing organic matter intermediates.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

Method for recovering and treating perfluoro ammonium caprylate for PTFE resin production by dispersion method

ActiveCN1935770AImprove economyImprove environmental benefitsWater/sewage treatmentCarboxylic compound separation/purificationPhysical chemistryPerfluorooctanoic acid

The invention is a method of recovering ammonium perfluoro octoate in the teflon resin production by dispersion method, belonging to chemical waste gas processing field, comprising bubbling absorbing, condensing, acidifying, and rectifying and purifying of the exhaust gas from cyclic oven, where the recovered ammonium perfluoro octoate has purity able to be up to 99% and can be reused in dispersion polymerization or other fluorine-containing organic matter intermediates. And the concentration of the ammonium perfluoro octoate in the processed gas is below 11mg / m3 (the highest allowable effluent concentration of fluoride is 11mg / m3), and can completely meet the effluent requirements.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

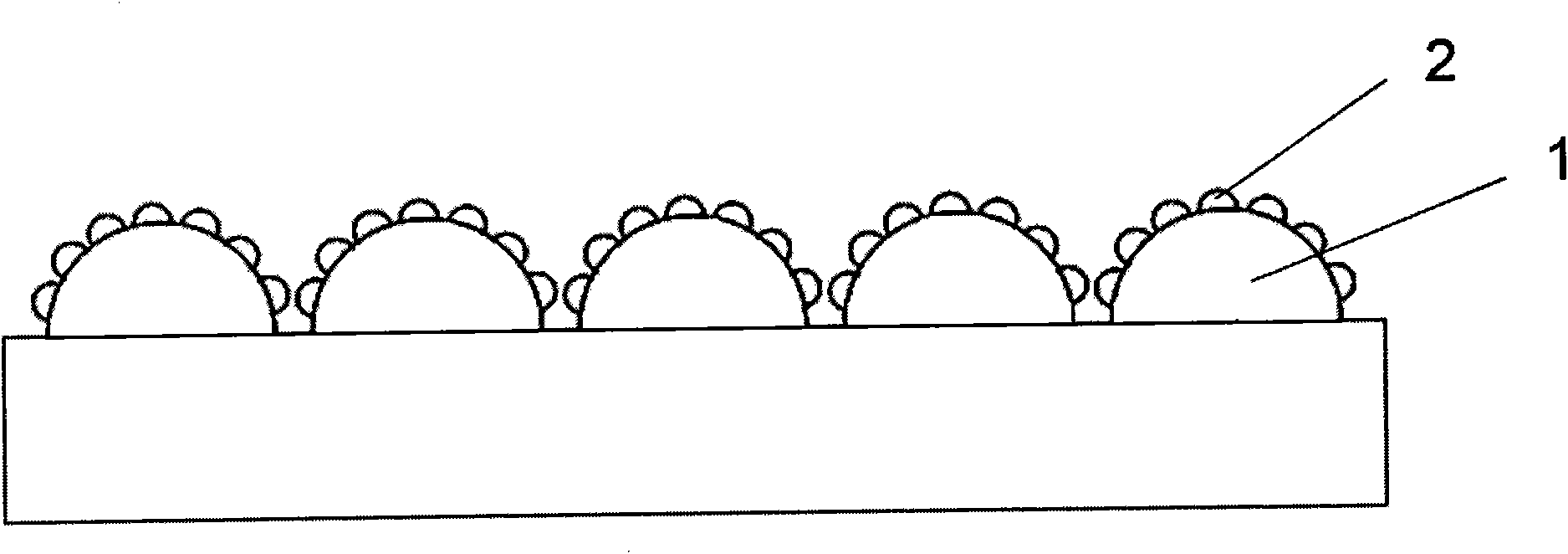

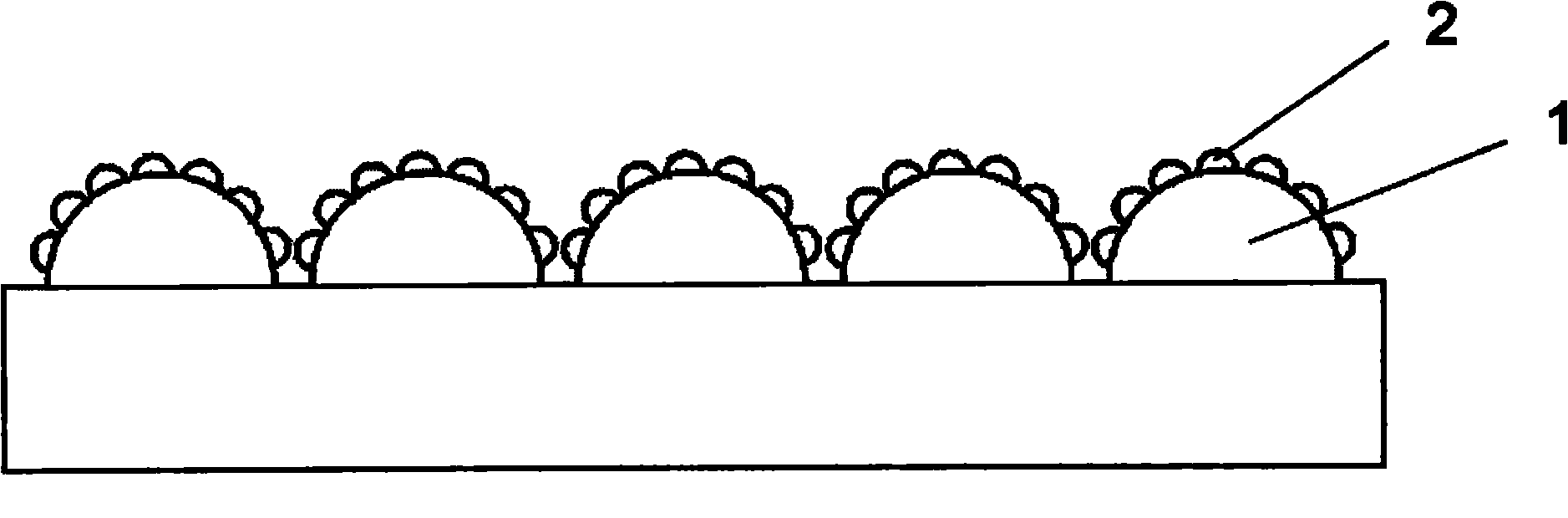

Material with specific surface structure for preparing non-sticky pan

InactiveCN101785629AAvoid mutual reunionOvercoming gravityCooking-vessel materialsStructure of the EarthEngineering

The invention discloses a material with a specific surface structure for preparing a non-sticky pan. The lower surface of the material is planar, the upper surface of the material is concave-convex and is formed by the regular arraying of micron-sized hemispheres in an HCP (hexagonal close packed) manner, and nano-sized hemispheres are respectively distributed on the surface of each micron-sized hemisphere. By adopting the specific surface structure, the material can realize the non-sticky effect, thereby fundamentally avoiding damage and pollution to human beings and the environment by a harmful component namely PFOA (perfluorocaprylic acid) in Teflon used at present for producing the non-sticky pan.

Owner:ZHEJIANG UNIV

Aqueous polytetrafluoroethylene emulsion, polytetrafluoroethylene fine powder and porous material obtained therefrom

ActiveUS7851573B2High molecular weightNatural cellulose pulp/paperSynthetic cellulose/non-cellulose material pulp/paperPolymer chemistryPolytetrafluoroethylene

To provide an aqueous polytetrafluoroethylene (PTFE) emulsion which does not substantially contain ammonium perfluorooctanoate, and which is obtained by emulsion polymerization. Further, to provide a PTFE fine powder which is obtained from the aqueous PTFE emulsion and is excellent in a paste extrusion processability, and a porous material. An aqueous polytetrafluoroethylene emulsion obtained by carrying out emulsion polymerization of tetrafluoroethylene alone or together with another copolymerizable monomer in an aqueous medium, wherein a fluorinated emulsifier of the formula (1): CF2CF2(O)mCF2CF2OCF2COOA wherein X is a hydrogen atom or a fluorine atom, A is a hydrogen atom, an alkali metal or NH4, and m is an integer of 0 or i, is used in an amount of from 1,500 to 20,000 ppm, based on the final yield of polytetrafluoroethylene.

Owner:ASAHI GLASS CO LTD

Removal and recovery of ammonium perfluorooctanoate (APFO) from contaminated water

InactiveUS7404907B2Electrolysis componentsLiquid separation by electricityAmmonium perfluorooctanoateSURFACTANT BLEND

Ammonium perfluorooctanoate—also called APFO, PFOA or C8—is a surfactant associated with the production of Teflon®, and is also present in products such as fire-fighting foams and may be formed from the microbial degradation of grease-resistant coatings applied to items such as pizza boxes. APFO itself does not hydrolyze, photolyze, or biodegrade under environmental conditions and is biologically additive. A process by which APFO may be removed and recovered from water by electrosorption is discovered. Removal and recovery by electrosorption form an inexpensive and environmentally friendly method of removal and recovery of APFO.

Owner:WELCKER KELYDRA ELIZABETH

Aqueous dispersion of polytetrafluoroethylene and process for its production

InactiveUS7514483B2Low viscosityIncrease frictionFatty oils/acids recovery from wasteOrganic compound preparationCarboxylic acidImpurity

Owner:ASAHI GLASS CO LTD

Production method of tetrafluoroethylene polymer used for processing wide breadth oilless low-density raw material sealing belt

The invention belongs to the field of high molecular, which provides a process for preparing tetrafluoroethylene polymer, and the invention adopts an emulsion polymerization method to polymerize. The invention is characterized in that the process comprises utilizing tetrafluoroethylene monomer be raw material, utilizing deionized water be medium, polymerizing under the condition that reaction pressure which is 0.8-3.0MPa, reaction temperature which is 60-110 DEG C and under the exisisting of stabilizing agent which is paraffin wax, surface activator which is perfluorooctanoic acid ammonium, initiating agent which is hyperoxide, and composite molecular weight conditioning agent, and getting suspension latex whose primary particles are about 20 nanometer, and density is between 16% and 33%, and at last getting polytetrafluoroethylene resin whose average particle size is 350-650um through batching, condensing and drying. The invention adopts a process of adding conditioning agent namely binary acid anhydride in polymerization, and the polymerization process is safe and easy to control, emulsion is stable, elongation percentage of resin products is high. The invention is suitable for preparing wide-coverage non-oil low-density seal tapes of raw material, which ha the advantages of white and soft, even thickness and thinness, balance calendering width and the like.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

Clothing finishing agent and preparation method thereof

InactiveCN103669001AWearableReasonable formulaFibre treatmentPerfluorooctanoic acidAmmonium perfluorooctanoate

The invention discloses a clothing finishing agent and a preparation method thereof. The clothing finishing agent comprises the following raw materials in parts by mass: 20-28 parts of amino silicone oil, 10-15 parts of nanometer titanium dioxide, 0.1-0.2 part of fatty alcohol-polyoxyethylene ether, 0.5-1.2 part(s) of chitosan, 0.05-0.1 part of perfluorooctanoic acid ammonium, and 35-42 parts of water. The clothing finishing agent disclosed by the invention is reasonable in formulation, obvious in sterilization and bacteriostatic effects, capable of effectively inhibiting the growth and reproduction of bacteria on clothes so as to provide healthy and sanitary living environment for people. The clothing finishing agent can enable the clothes to be soft and comfortable, and have relatively strong wearability; the raw materials of the finishing agent are easy to get, and the preparation process is simple and easy to operate, so that the clothing finishing agent can be widely popularized and applied.

Owner:NANTONG TONGZHOU DISTRICT CHUANJIANG TOWN SUNWORLD DYNASTY HOME TEXTILE DESIGN STUDIO

Improvement method for performance of surface of silver-halide light-sensitive material

InactiveCN104536257AImprove antistatic performanceImprove scratch resistancePhotosensitive materialsPolymer scienceFilm base

The invention discloses an improvement method for the performance of the surface of a silver-halide light-sensitive material. The silver-halide light-sensitive material consists of a film base, at least one light-sensitive emulsion layer and at least one hydrophilic-gel protective layer, wherein the used amount of perfluoro ammonium caprylate in the hydrophilic-gel protective layer is 6-20mg / m<2>; the used amount of oleamide polyoxyethylene ether is 15-30mg / m<2>; the used amount of perfluoroalkyl polyoxyethylene ether is 10-50mg / m<2>; the used amount of water-soluble polyurethane is 0.4-0.9g / m<2>; the used amount of polyoxyethylene wax is 80-200mg / m<2>; the particle diameter of silica sol is 7nm, and the used amount of the silica sol is 10-20mg / m<2>; and the particle diameter of the silica sol is 7nm, and the used amount of the silica sol is 10-20mg / m<2>. The improvement method disclosed by the invention has the advantages that water-soluble polymer is used for replacing partial gelatin, so that the silver-halide light-sensitive material has good anti-static performance and excellent scratch resistance, and after washing and processing, no residual water stains and highly-bright surfaces are caused.

Owner:TIANJIN MEDIA IMAGING MATERIALS

Production method of high molecular weight polytetrafluoroethylene dispersion resin suitable for processing biaxial stretching film

The invention belongs to the high polymer field, which provides a production method which is suitable for processing the high molecular weight fluon dispersed resin of the bilateral stretching film. The method adopts emulsion polymerization method to perform the free radical polymerization. The invention is characterized in that high purity tetrafluorethylene monomer is taken as raw material, deionized water is taken as polymerization medium, under the existence of stabilizing agent paraffin, surface active agent fluorine chlorine bromine iodine astatine, initiator peroxide and pH value moderator succinic acid, and under the conditions that the reaction pressure is 2.0 to 5.0 MPa and reaction temperature is at 60 to 107 DEG C, the polymerization is performed to obtain broken emulsion of which the diameter of a primary particle is 20 nanometers and the thickness is 20 to 30 percent; through blending, conglomeration and drying, and fluon resin with average particle diameter of 350 to 650 micron is obtained. The invention has the advantages that the polymerization process is secure and easy to be controlled, the emulsion is stable, the process is advanced, the cost is low, the product performance is good, and the molecular weight reaches 8*10<6> etc; the invention is suitable for processing the bilateral stretching film, also has the advantages that the pore diameter is even, and the pore distribution is good, etc.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

Dacron textile easy to decontaminate

The invention discloses dacron textile easy to decontaminate. A water sucking oil repellent resin film is covered on the surface of single fibres of the textile. Residual quantity of perfluor octanoic acid ammonium compound in the water sucking oil repellent resin film is more than 0 and less than or equals to 0.05mu g / g. Residual quantity of perfluor octane sulfonic acid compound is greater than 0 or less than or equals to 0.05mu g / g. Sweat can be absorbed when a person wears clothes made from the dacron textile easy to decontaminate. Oily dirt is prevented from permeating to the inner portion of the fibre. The dirt is removed simply under the condition of the combined effect of a dewatering component and a hydrophilic component. The decontamination ability is good when the dacron textile easy to decontaminate is washed while a detergent is not added at the same time.

Owner:TORAY IND INC

Method for producing melt-processable fluororesin

ActiveUS7855259B2High molecular weightEasy to disassembleTransportation and packagingMixingEmulsionHydrogen atom

To provide a method for producing a melt-processable fluororesin, which is capable of increasing the molecular weight of the fluororesin and preventing coloration of the fluororesin, by using a specific fluorinated emulsifier other than ammonium perfluorooctanoate. A method for producing a melt-processable fluororesin which is characterized in that a fluorinated monomer is emulsion-polymerized in an aqueous medium containing a fluorinated emulsifier of a formula (I)XCF2CF2(O)mCF2CF2OCF2COOA wherein X is a hydrogen atom or a fluorine atom, A is a hydrogen atom, an alkali metal or NH4, and m is an integer of 0 or 1.

Owner:ASAHI GLASS CO LTD

Production method of high molecular weight polytetrafluoroethylene dispersion resin suitable for processing biaxial stretching film

The invention belongs to the high polymer field, which provides a production method which is suitable for processing the high molecular weight fluon dispersed resin of the bilateral stretching film. The method adopts emulsion polymerization method to perform the free radical polymerization. The invention is characterized in that high purity tetrafluorethylene monomer is taken as raw material, deionized water is taken as polymerization medium, under the existence of stabilizing agent paraffin, surface active agent fluorine chlorine bromine iodine astatine, initiator peroxide and pH value moderator succinic acid, and under the conditions that the reaction pressure is 2.0 to 5.0 MPa and reaction temperature is at 60 to 107 DEG C, the polymerization is performed to obtain broken emulsion of which the diameter of a primary particle is 20 nanometers and the thickness is 20 to 30 percent; through blending, conglomeration and drying, and fluon resin with average particle diameter of 350 to 650 micron is obtained. The invention has the advantages that the polymerization process is secure and easy to be controlled, the emulsion is stable, the process is advanced, the cost is low, the product performance is good, and the molecular weight reaches 8*10<6> etc; the invention is suitable for processing the bilateral stretching film, also has the advantages that the pore diameter is even, andthe pore distribution is good, etc.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

A method for treating wastewater containing low-concentration ammonium perfluorooctanoate using modified molecular sieve as a catalyst

InactiveCN103991948BStrong special effectsSimple processWater contaminantsWater/sewage treatment by oxidationMolecular sieveNitrate

The invention discloses a method for treating wastewater containing low-concentration ammonium perfluorooctanoate by taking modified molecular sieves as a catalyst. The method comprises the following steps: preparation of the modified molecular sieves, namely preparing a mixed solution containing cerous nitrate, lead nitrate, manganous nitrate or ferric nitrate, dipping molecular sieves in the mixed solution, taking out the molecular sieves and then drying and roasting the molecular sieves; catalytic ozonation, namely pouring the obtained modified molecular sieves and wastewater which has the temperature of 20-100 DEG C and the ammonium perfluorooctanoate concentration of 50-500mg / L into a container, introducing ozone, and meanwhile, starting stirring for 30-120 minutes; recovery of the modified molecular sieves, namely standing, centrifuging or filtering the turbid solution obtained by virtue of catalytic ozonation, thereby separating out the modified molecular sieves from the solution for recycling in the next catalytic oxidization process. The method has the advantages of high treatment efficiency, simplicity and convenience in operation, no secondary pollution, low operation cost and the like.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

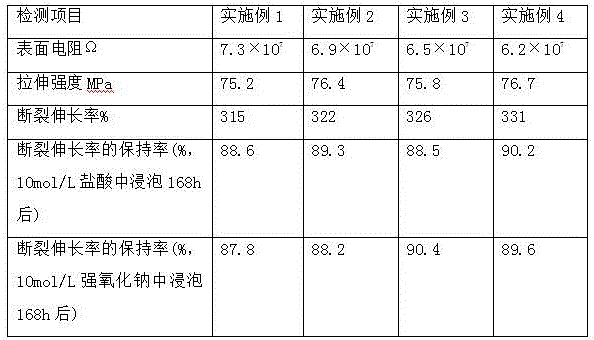

Graphene-reinforced conductive plastic and preparation method thereof

The invention provides a graphene-reinforced conductive plastic and a preparation method thereof. The graphene-reinforced conductive plastic is prepared from the following raw materials in parts by weight: polyvinylidene fluoride, an ethylene-vinyl acetate resin, ammonium perfluorooctoate, acrylate, graphene, nano zinc powder, 2,6-dichlorocyanobenzene, boron fibers, chitin, calcium phosphate, molybdenum disulfide, liquid paraffin, sodium diethylhexyl sulfosuccinate, a silane coupling agent, an antioxidant and methylbenzene. The graphene-reinforced conductive plastic fully displays excellent properties of the graphene material, has the advantages of favorable conductivity, favorable mechanical properties, favorable acid / alkali corrosion resistance and high use safety, and has favorable application value.

Owner:中山市华塑塑胶科技有限公司

Method for treating wastewater with low-concentration ammonium perfluorooctanoate through all-film method

ActiveCN101928078BReduce recycling costsSimple operation processOrganic chemistryWater/sewage treatment bu osmosis/dialysisThree levelHigh concentration

The invention belongs to the chemical wastewater treatment field, in particular relates to a method for treating wastewater with low-concentration ammonium perfluorooctanoate through all-film method which combines the ultra microfiltration technology and the nanofiltration technology. The method comprises the following steps: firstly adopting microfiltration or ultrafiltration to remove insolubleparticles in the wastewater with low-concentration ammonium perfluorooctanoate; and secondly using a nanofiltration system to concentrate ammonium perfluorooctanoate in the pretreated and clarified wastewater, wherein the nanofiltration system is divided to three levels, each level adopts the concentrated water inner circulation mode to concentrate ammonium perfluorooctanoate to a higher concentration step by step, the permeate of each level of nanofiltration can be directly charged or used as the process water of other processes, and the zero emission of industrial wastewater can be realized. The method of the invention has simple operation, low energy consumption and no secondary pollution; and high-value-added perfluorooctanoic acid can be recycled and the industrial wastewater can meet the direct emission standard or the reuse standard.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Ammonium perfluorooctanate wastewater treatment method

InactiveCN107162250AReduce energy consumptionWater/sewage treatment by centrifugal separationWater contaminantsHigh concentrationFiltration membrane

The invention provides a method for treating ammonium perfluorooctanoate wastewater. Pump the clear and transparent wastewater containing ammonium perfluorooctanoate into the foam separation tower for foam separation. After defoaming the foam at the top of the wastewater tower, a high-concentration ammonium perfluorooctanoate aqueous solution can be obtained, which can be reused; the aqueous solution of ammonium perfluorooctanoate with a lower concentration is obtained at the bottom of the tower; the foam is separated The ammonium perfluorooctanoate aqueous solution discharged from the bottom of the tower is filtered by the first-stage nanofiltration membrane, the nanofiltration retentate is concentrated, and returned to the foam separation tower for foam separation; the permeate of the first-stage nanofiltration membrane enters the second-stage nanofiltration membrane; the permeate of the second-stage nanofiltration membrane has reached the national wastewater discharge standard; the concentrated solution of the second-stage nanofiltration membrane is returned to the first-stage nanofiltration membrane; the recycling of useful substances in wastewater and waste water cleaning treatment. The invention does not add any chemical agent in the treatment process, does not produce new pollution, achieves zero discharge, and recovers useful substances, and the treatment process is at normal temperature, and the energy consumption is low.

Owner:江阴宇博科技有限公司

Granulating method for filling material powder of thermosetting plastic

ActiveCN107199649AContinuous Mixing RequirementsUniform Mixing RequirementsCoatingsFilling materialsAmmonium perfluorooctanoate

The invention provides a granulating method for filling material powder of thermosetting plastic. The granulating method for the filling material powder of the thermosetting plastic comprises the following steps that (1) thermosetting plastic powder and required filling materials are mixed in a required proportion, and the material temperature is controlled to 0-5 DEG C; (2) a solvent and a surface active agent are added into the mixed materials in the proportion of 1%-10% after being mixed according to the ratio of 100:1 to 1000:1; and (3) the materials added with the solvent and the surface active agent are granulated, compacted, screened and dried. According to the granulating method for the filling material powder of the thermosetting plastic, in the granulating process, the materials are mixed through upper stirring paddles and then mixed again through a rotary mixing tray, afterwards, the raw materials pass through a baffle plate to be mixed for the third time through lower stirring paddles, and thus the requirement for continuous and uniform mixing is met. In the granulating process, deionized water and perfluoro caprylic acid ammonium salt are used as the solvent, consumption of the solvent is low, and the solvent is completely recovered in the drying process, so that the influence of the solvent on the environment is avoided, and the whole process is environmentally friendly.

Owner:QINGDAO ORIENTALFLON NEW MATERIAL

Water-based fluoropolymer emulsion, preparation method and application thereof

InactiveCN100586968CSimple processGood chemical stabilityCoatingsPotassium persulfateCarvacryl acetate

The present invention relates to preparation process of water thinned fluoric polymer emulsion for paint. The preparation process is one emulsion copolymerization process with trifluorochloro ethylene, alkyl vinyl ether or vinyl acetate, hydroxyl butyl vinyl ether, undecylenic acid and polyoxyethylene acrylate as monomers, non-ionic emulsifier NP and anionic ammonium perfluoro octoate as compositeemulsifier, and composition of ammonium persulfate or potassium persulfate and sodium bisulfite as redox initiation system. The polymerization may be completed in room temperature and is simple, andthe product has excellent chemical stability, mechanical stability and mechanical performance. The emulsion has relatively high fluorine content, so that the prepared paint has excellent corrosion resistance, weather resistance and antifouling performance.

Owner:TONGJI UNIV

Method for treating perfluoro ammonium caprylate in waste water for PTFE dispersion resin production

ActiveCN100420666CSolve processing problemsSimple processWater/sewage treatmentCarboxylic compound separation/purificationPerfluorooctanoic acidPolytetrafluoroethylene

Owner:SHANDONG DONGYUE POLYMER MATERIAL

Preparation method and application of highly-antibacterial far-infrared fluorinated graphene/SEBS composite elastomer

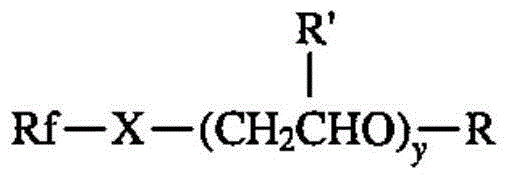

InactiveCN111548595AUniform and stable dispersionGood chemical resistanceGenitals massageElastomerPolymer science

The invention relates to the field of composite materials and adult products, in particular to a preparation method and application of a highly-antibacterial far-infrared fluorinated graphene / SEBS composite elastomer. The preparation method comprises the following steps: carrying out ball-milling modification on 1-10 parts by weight of fluorinated graphene, 5-30 parts by weight of softening oil, 1-10 parts by weight of erucyl amide, 2-10 parts by weight of ammonium perfluorooctanoate and 1-5 parts by weight of oleamide to obtain a prepared material; fully mixing 80-100 parts of SEBS elastomerwith the prepared material to obtain a fluorinated graphene / SEBS composite rubber compound; then putting the composite rubber compound into a fluorination chamber, carrying out a fluorination treatment; and finally, carrying out extrusion granulation on the fluorinated graphene / SEBS composite elastomer rubber compound. The prepared composite material has excellent mechanical properties and lubricating performance, has sterilization and bacteriostasis functions, can generate a far infrared effect at the room temperature, and can be widely applied to adult toy plane cups, false penis and other products.

Owner:辽宁格莱菲尔健康科技有限公司

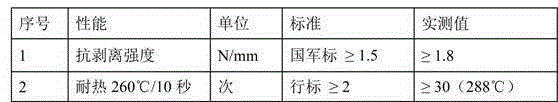

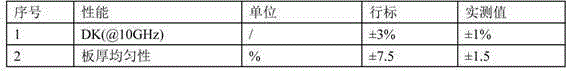

Method for preparing low pollution and high uniformity PTFE copper clad laminate and PTFE copper clad laminate thereof

InactiveCN106696398AReduce usageEmission reductionLamination ancillary operationsSynthetic resin layered productsAmmonium perfluorooctanoatePerfluorooctanoic acid

The invention discloses a method for preparing low pollution and high uniformity PTFE copper clad laminate and a PTFE copper clad laminate thereof. The method consists of the preparation of adhesive tape and the preparation of dielectric layer billets. The preparation of adhesive tape comprises using polytetrafluoroethylene dispersing agent to process dipping and coating once on fiberglass cloth, and then, preparing single coating adhesive tape through drying and baking; the preparation of dielectric layer billets comprises preparing dielectric layer billets comprises by preliminary combining the single coating adhesive tape and the relevant PTFE membrane. The PTFE copper clad laminate comprises a dielectric layer. The dielectric layer comprises a single coating adhesive tape layer and a PTFE membrane layer. The method for preparing low pollution and high uniformity PTFE copper clad laminate and the PTFE copper clad laminate thereof can mitigate the environmental hazards of perfluorooctanoic acid ammonium and lower the energy consumption by significantly reducing the dosage of PTFE dispersing agent.

Owner:JIANGXI PROVINCE HANGYU NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com