Graphene-reinforced conductive plastic and preparation method thereof

A conductive plastic and graphene technology, applied in the field of conductive materials, can solve the problems of inability to fully exert the enhancement effect, unstable performance of polymer materials, poor interface bonding force, etc., and achieve good application value, good mechanical properties, resistance to Good effect of acid and alkali corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

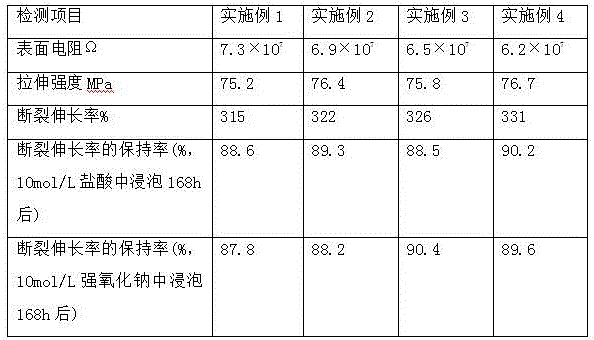

Examples

Embodiment 1

[0020] Graphene-enhanced conductive plastic, prepared from the following raw materials in parts by weight: 40-48 parts of polyvinylidene fluoride, 20-26 parts of ethylene vinyl acetate resin, 5-10 parts of ammonium perfluorooctanoate, 4-8 parts of acrylate, and 2 parts of graphene -6 parts, 3-8 parts of nano zinc powder, 1-5 parts of 2,6-dichlorobenzonitrile, 3-7 parts of boron fiber, 4-7 parts of chitin, 1-9 parts of calcium phosphate, molybdenum disulfide 3-6 parts, 1-4 parts of liquid paraffin, 4-9 parts of dioctyl sodium sulfosuccinate, 3-8 parts of silane coupling agent, 2-7 parts of antioxidant, 15-27 parts of toluene;

[0021] Wherein said graphene is alkylated graphene. The silane coupling agent is 3-aminopropyltriethoxysilane. The antioxidant is antioxidant PEPQ.

[0022] The preparation method of the above-mentioned graphene-enhanced conductive plastic, the preparation steps are:

[0023] (1) Stir graphene, boron fiber, liquid paraffin, silane coupling agent and t...

Embodiment 2

[0027] Graphene-enhanced conductive plastic, prepared from the following raw materials in parts by weight: 48 parts of polyvinylidene fluoride, 26 parts of ethylene vinyl acetate resin, 10 parts of ammonium perfluorooctanoate, 8 parts of acrylate, 6 parts of graphene, 8 parts of nano-zinc, 2 , 5 parts of 6-dichlorobenzonitrile, 7 parts of boron fiber, 7 parts of chitin, 9 parts of calcium phosphate, 6 parts of molybdenum disulfide, 4 parts of liquid paraffin, 9 parts of dioctyl sodium sulfosuccinate, silane disulfide 8 parts of joint agent, 7 parts of antioxidant, 27 parts of toluene;

[0028] Wherein said graphene is aminated graphene. The silane coupling agent is γ-glycidoxypropyltrimethoxysilane. The antioxidant is antioxidant 300.

[0029] The preparation method of the above-mentioned graphene-enhanced conductive plastic, the preparation steps are:

[0030] (1) Stir graphene, boron fiber, liquid paraffin, silane coupling agent and toluene at room temperature for 30 minu...

Embodiment 3

[0034] Graphene-enhanced conductive plastic, prepared from the following raw materials in parts by weight: 44 parts of polyvinylidene fluoride, 23 parts of ethylene vinyl acetate resin, 7 parts of ammonium perfluorooctanoate, 6 parts of acrylate, 4 parts of graphene, 5 parts of nano-zinc powder, 1-5 parts of 2,6-dichlorobenzonitrile, 3-7 parts of boron fiber, 4-7 parts of chitin, 5 parts of calcium phosphate, 4.5 parts of molybdenum disulfide, 2.5 parts of liquid paraffin, dioctyl sulfosuccinate 6 parts of sodium bicarbonate, 5 parts of silane coupling agent, 4 parts of antioxidant, 21 parts of toluene;

[0035] Wherein the graphene is alkylated graphene, aminated graphene or mercaptolated graphene. The silane coupling agent is γ-methacryloxypropyltrimethoxysilane. The antioxidant is antioxidant 1010.

[0036] The preparation method of the above-mentioned graphene-enhanced conductive plastic, the preparation steps are:

[0037] (1) Stir graphene, boron fiber, liquid paraffi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com