Improvement method for performance of surface of silver-halide light-sensitive material

A technology of photosensitive materials and surface properties, applied in photosensitive materials, optics, instruments, etc., can solve the problems of reducing the expandability and drying speed, hindering the processing process, easy to adhere to the surface of the film, etc., to improve the anti-scratch performance , Reduced time, Improve the effect of developing penetrating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with experimental examples.

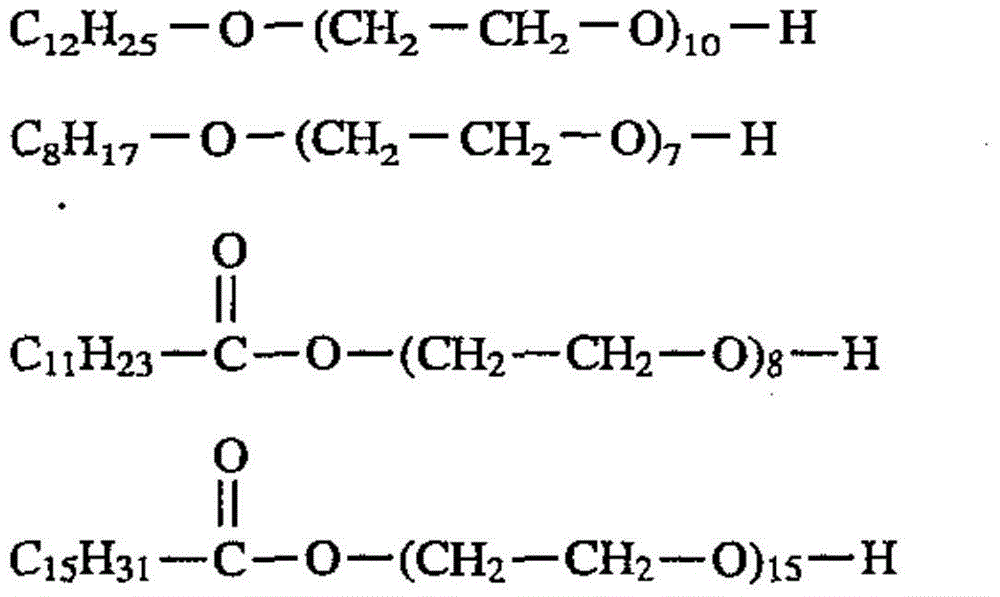

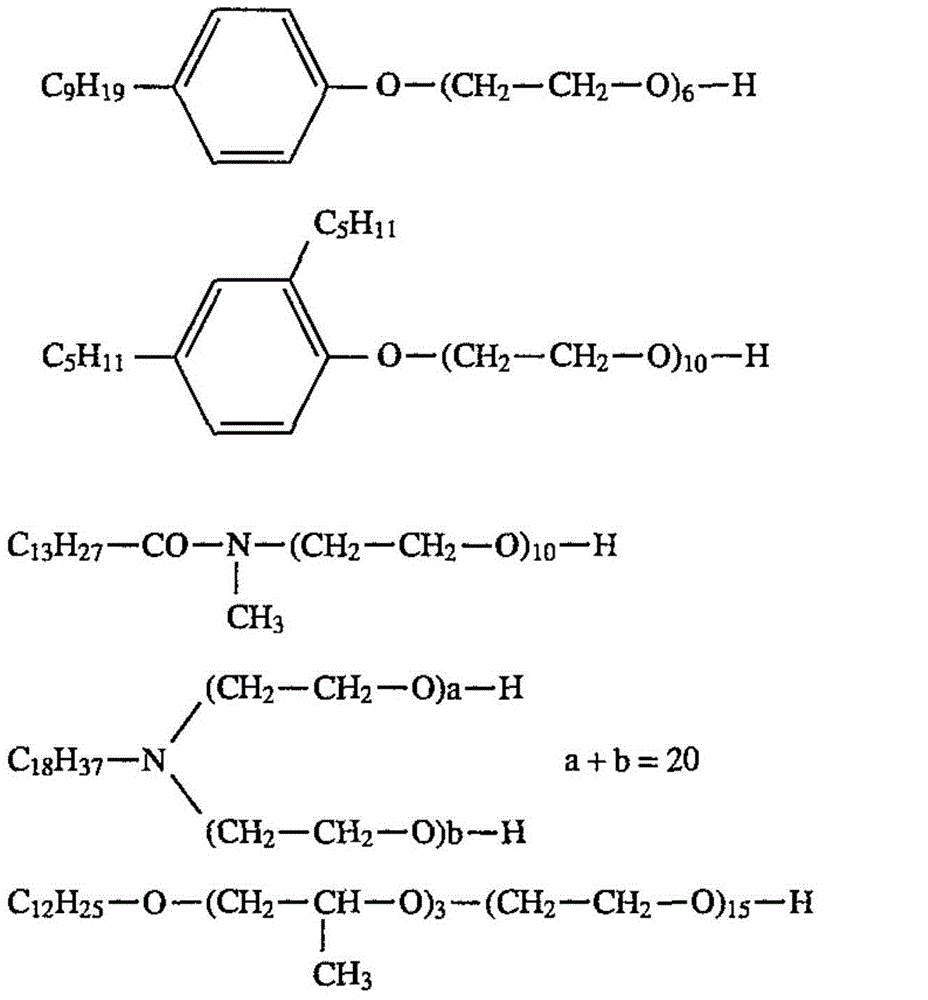

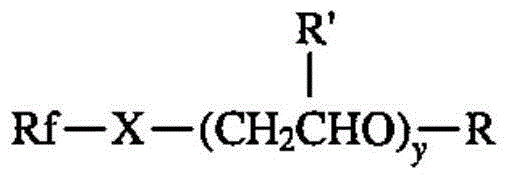

[0021] The invention discloses a method for improving the surface performance of a silver halide photosensitive material, which is realized by adopting some technical schemes. The adhesive protective layer contains ammonium perfluorooctanoate, oleic acid amide polyoxyethylene ether, perfluoroalkyl polyoxyethylene ether, water-soluble polyurethane, polyoxyethylene wax and silica sol; the dosage of ammonium perfluorooctanoate is 6-20mg / m 2 ;The dosage of oleic acid amide polyoxyethylene ether is 15~30mg / m 2 ; The dosage of perfluoroalkyl polyoxyethylene ether is 10~50mg / m 2 ;The dosage of water-soluble polyurethane is 0.4~0.9g / m 2 ;The dosage of polyoxyethylene wax is 80~200mg / m 2 ;The particle size of silica sol is 7nm, and the dosage is 10~20mg / m 2 ;The particle size of silica sol is 7nm, and the dosage is 10~20mg / m 2 .

[0022] The preferred polymers of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com