Method for treating wastewater with low-concentration ammonium perfluorooctanoate through all-film method

A low-concentration ammonium perfluorooctanoate technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as non-continuous operation, high energy consumption by distillation and concentration, and pollution , to achieve high economic and environmental benefits, no secondary pollution, simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

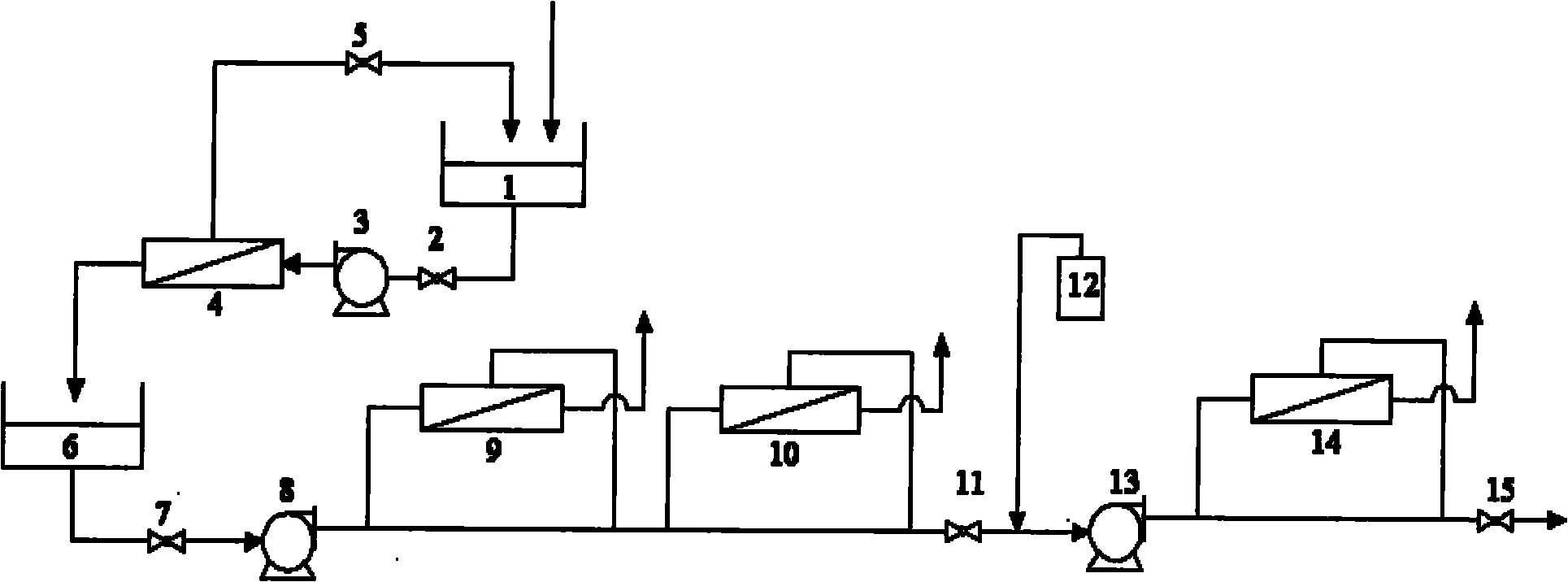

[0033] See figure 1 . A device for treating wastewater containing low-concentration ammonium perfluorooctanoate by a full-membrane method includes a raw water tank 1, a feed valve 2, a feed pump 3, a microfiltration module 4, a return valve 5, a clarified feed liquid tank 6, and a feed valve 7. Feed pump 8, primary nanofiltration 9, secondary nanofiltration 10, discharge valve 11, pH adjustment system 12, feed pump 13, tertiary nanofiltration 14, discharge valve 15.

[0034] First, the ammonium perfluorooctanoate wastewater with a concentration of 500ppm is cooled to room temperature and stored in the raw water tank 1, the suspended particulate matter in the wastewater is removed by the microfiltration membrane module 4, and the clarified feed liquid is put into the clarified feed liquid tank 6. Use the pump 8 to pump the clarified feed liquid into the primary and secondary nanofiltration membrane systems for preliminary concentration, and adjust the permeation flux of the na...

Embodiment 2

[0036] See figure 1 . A device for treating wastewater containing low-concentration ammonium perfluorooctanoate by a full-membrane method includes a raw water tank 1, a feed valve 2, a feed pump 3, an ultrafiltration module 4, a return valve 5, a clarified feed liquid tank 6, and a feed valve 7. Feed pump 8, primary nanofiltration 9, secondary nanofiltration 10, discharge valve 11, pH adjustment system 12, feed pump 13, tertiary nanofiltration 14, discharge valve 15.

[0037] First, the ammonium perfluorooctanoate wastewater with a concentration of 500ppm is cooled to room temperature and stored in the raw water pool 1, the suspended particulate matter in the wastewater is removed by the ultrafiltration membrane module 4, and the clarified feed liquid is put into the clarified feed liquid tank 6. Use the pump 8 to pump the clarified feed liquid into the first and second nanofiltration membrane systems for preliminary concentration, and adjust the permeation flux of the nanofi...

Embodiment 3

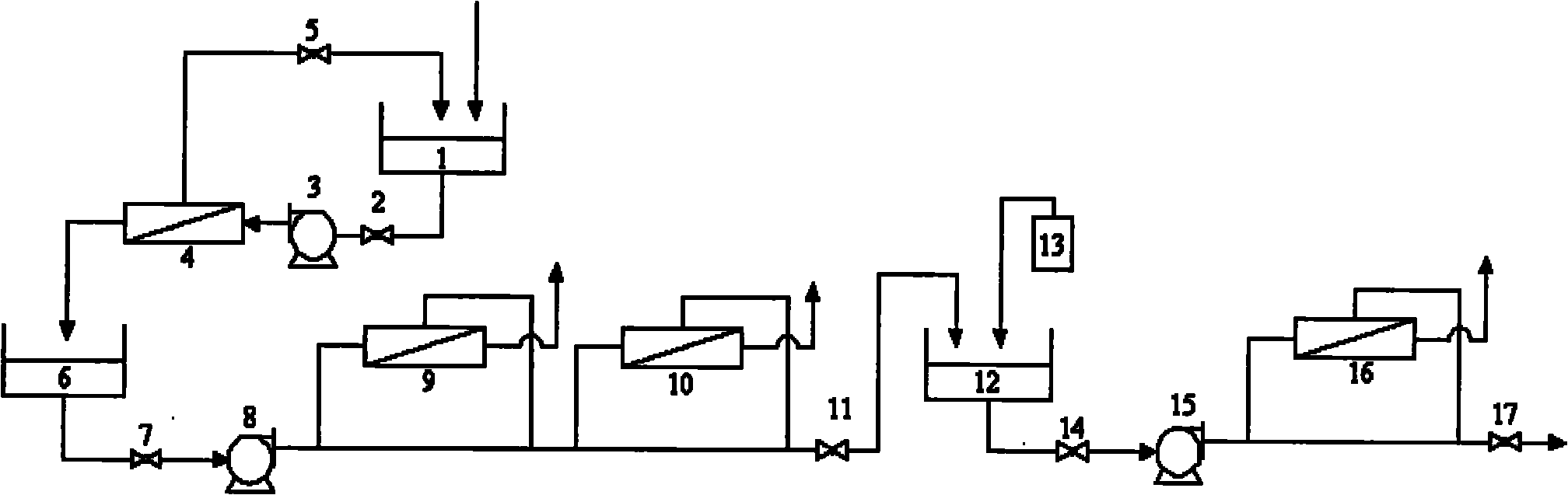

[0039] See figure 2. A device for treating wastewater containing low-concentration ammonium perfluorooctanoate by a full-membrane method includes a raw water tank 1, a feed valve 2, a feed pump 3, an ultrafiltration module 4, a return valve 5, a clarified feed liquid tank 6, and a feed valve 7. Feed pump 8, primary nanofiltration 9, secondary nanofiltration 10, discharge valve 11, concentrated liquid storage tank 12, pH adjustment system 13, feed valve 14, feed pump 15, tertiary nanofiltration 16, outlet Feed valve 17.

[0040] First, the ammonium perfluorooctanoate wastewater with a concentration of 500ppm is cooled to room temperature and stored in the raw water pool 1, the suspended particulate matter in the wastewater is removed by the ultrafiltration membrane module 4, and the clarified feed liquid is put into the clarified feed liquid tank 6. Use the pump 8 to pump the clarified feed liquid into the primary and secondary nanofiltration membrane systems for preliminary...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com