Method for removing sulfonic-group-containing dye in alkaline waste water by using magnetic chitosan adsorbent

A technology of chitosan and adsorbent, which is applied in the field of wastewater post-treatment to achieve the effects of low recycling cost, easy separation and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

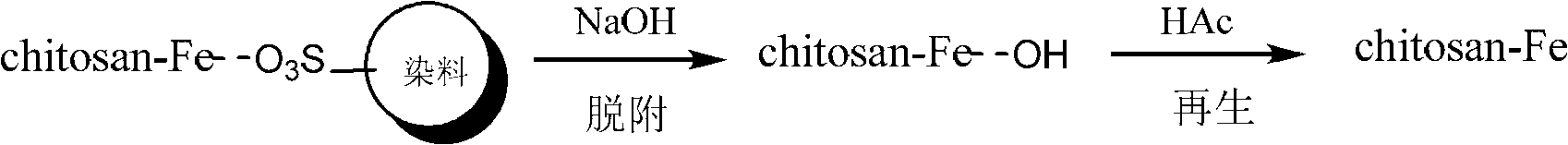

Method used

Image

Examples

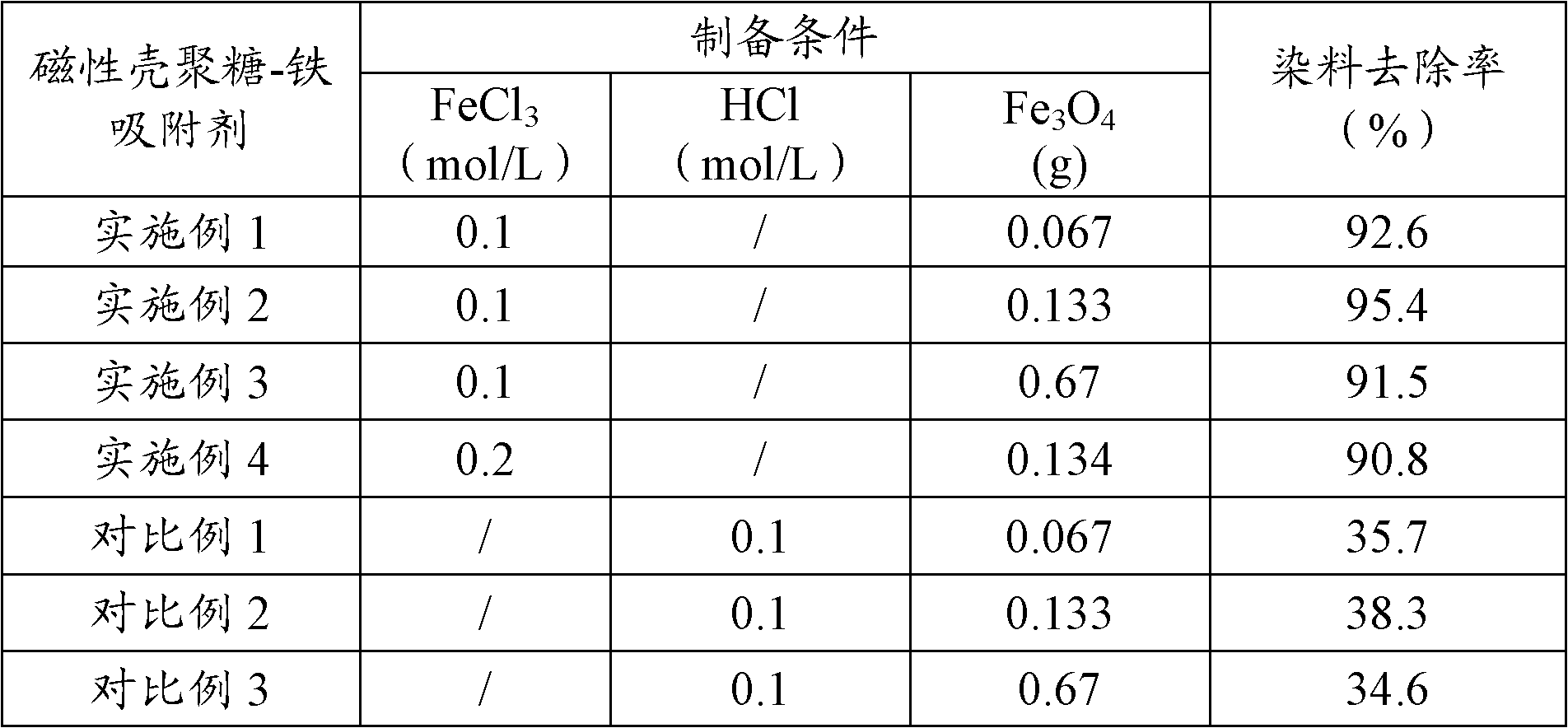

Embodiment 1

[0024] Prepare 0.1mol / L FeCl 3 Solution 50mL (0.005mol), slowly add chitosan 2.67g (molecular weight is 1,000,000, deacetylation degree is 91%), make chitosan and Fe 3+The molar ratio of the chitosan-iron complex is 3:1, keep stirring for 2 hours to make the two fully react, then slowly add 50mL of ethanol and stir slowly at the same time, after the chitosan-iron complex precipitation is gradually formed, centrifuge and wash with absolute ethanol to unreacted Fe 3+ , then add 0.067g nano Fe 3 o 4 Stir and mix well, then add 25% glutaraldehyde 5mL, cross-linking reaction for 2 hours, finally use absolute ethanol to wash glutaraldehyde again, magnetically separate, dry at 80°C, grind finely, and prepare magnetic chitosan-iron adsorption agent.

Embodiment 2

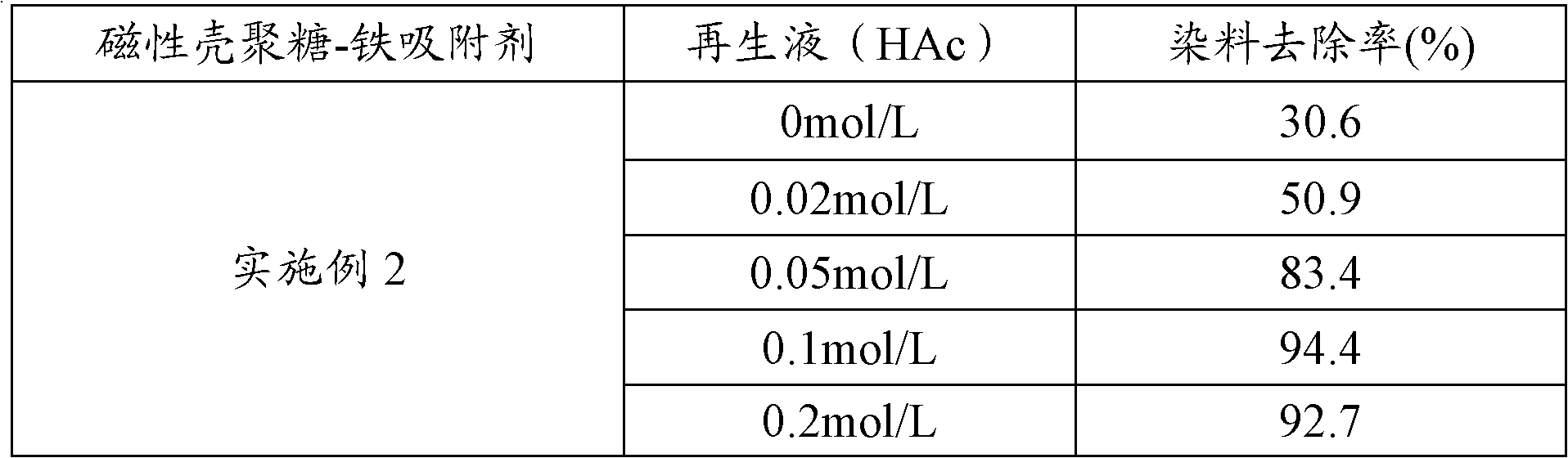

[0026] Prepare 0.1mol / L FeCl 3 Solution 50mL (0.005mol), slowly add chitosan 2.67g (molecular weight is 1,000,000, deacetylation degree is 91%), make chitosan and Fe 3+ The molar ratio of the chitosan-iron complex is 3:1, keep stirring for 2 hours to make the two fully react, then slowly add 50mL of ethanol and stir slowly at the same time, after the chitosan-iron complex precipitation is gradually formed, centrifuge and wash with absolute ethanol to unreacted Fe 3+ , then add 0.133g nano Fe 3 o 4 Stir and mix well, then add 25% glutaraldehyde 5mL, cross-linking reaction for 2 hours, finally use absolute ethanol to wash glutaraldehyde again, magnetically separate, dry at 80°C, grind finely, and prepare magnetic chitosan-iron adsorption agent.

Embodiment 3

[0028] Prepare 0.1mol / L FeCl 3 Solution 50mL (0.005mol), slowly add chitosan 2.67g (molecular weight is 1,000,000, deacetylation degree is 91%), make chitosan and Fe 3+ The molar ratio of the chitosan-iron complex is 3:1, keep stirring for 2 hours to make the two fully react, then slowly add 50mL of ethanol and stir slowly at the same time, after the chitosan-iron complex precipitation is gradually formed, centrifuge and wash with absolute ethanol to unreacted Fe 3+ , then add 0.67g nano Fe 3 o 4 Stir and mix well, then add 25% glutaraldehyde 5mL, cross-linking reaction for 2 hours, finally use absolute ethanol to wash glutaraldehyde again, magnetically separate, dry at 80°C, grind finely, and prepare magnetic chitosan-iron adsorption agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com