Material with specific surface structure for preparing non-sticky pan

A non-stick pan, a specific technology, applied in the direction of special materials for cooking utensils, etc., can solve the problem that non-stick pans cannot make acidic food, and achieve the effect of avoiding harm and pollution

Inactive Publication Date: 2010-07-28

ZHEJIANG UNIV

View PDF5 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This standard sets two restrictions on the use of non-stick pans. One is that non-stick pans cannot be used to make acidic food, and the other is that the use temperature should be limited below 250°C.

However, restricting production alone cannot fundamentally solve the problem. It is a long-term solution to change the existing traditional preparation methods that use chemical coatings to achieve non-stick effects.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

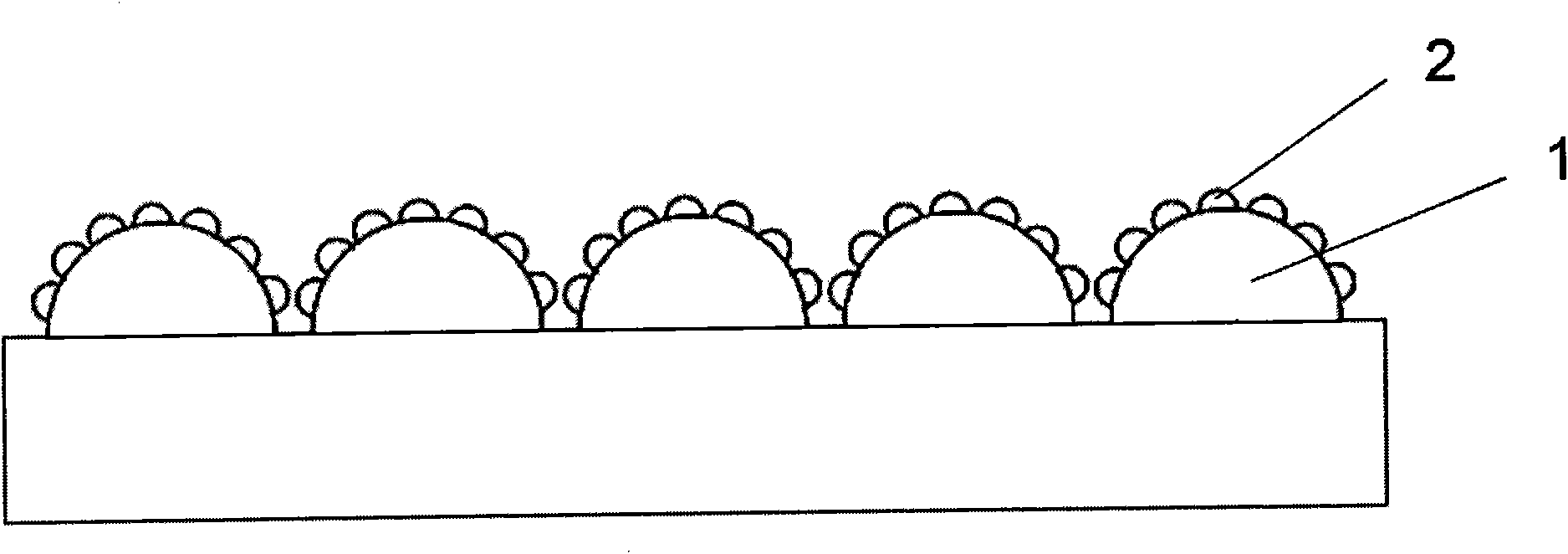

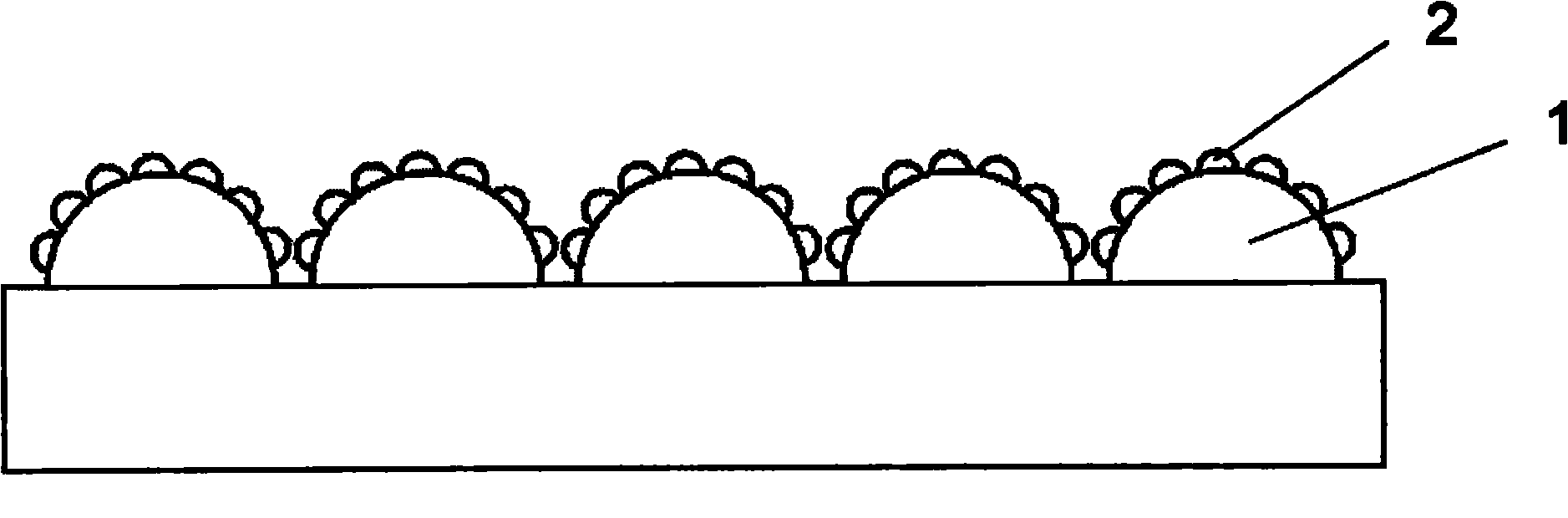

[0010] refer to figure 1 , the material with specific surface structure for preparing non-stick pans of the present invention, its lower surface is a plane, and its upper surface is a concavo-convex surface formed by micron-sized hemispheres 1 arranged according to the hexagonal close-packed (hcp) rule, each micron Nanoscale hemispheres 2 are evenly distributed on the surface of the nanoscale hemisphere.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a material with a specific surface structure for preparing a non-sticky pan. The lower surface of the material is planar, the upper surface of the material is concave-convex and is formed by the regular arraying of micron-sized hemispheres in an HCP (hexagonal close packed) manner, and nano-sized hemispheres are respectively distributed on the surface of each micron-sized hemisphere. By adopting the specific surface structure, the material can realize the non-sticky effect, thereby fundamentally avoiding damage and pollution to human beings and the environment by a harmful component namely PFOA (perfluorocaprylic acid) in Teflon used at present for producing the non-sticky pan.

Description

technical field [0001] The invention relates to a material with a specific surface structure, especially a material with a specific surface structure for preparing a non-stick pan. Background technique [0002] Since the product of non-stick pan came out, its "health" has always attracted people's attention. The non-stick pans currently on the market are able to achieve non-stick, mainly relying on the layer of "Teflon" coating on the bottom of the pan. This substance is the general term for fluorine-containing resins, including polytetrafluoroethylene, polyperfluoroethylene propylene and various fluorine-containing copolymers. Perfluorooctanoic acid ammonium (PFOA) is a necessary additive in the production of Teflon. PFOA with stable chemical properties will exist for a long time after entering the natural environment and human body, rather than decomposing quickly. Studies have shown that low doses of PFOA not only appear in rivers, oceans and soil, but also in people's ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): A47J36/02

Inventor 黄靖云刘莎王晔叶志镇

Owner ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com