Self-stripping rectorite/carbon nitride nano composite catalytic material and preparation method and application thereof

A technology of nanocomposite and catalytic materials, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, water/sewage treatment, etc., can solve the problems of secondary pollution and dependence, reduce water consumption, simplify the preparation process, avoid The effect of mutual reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

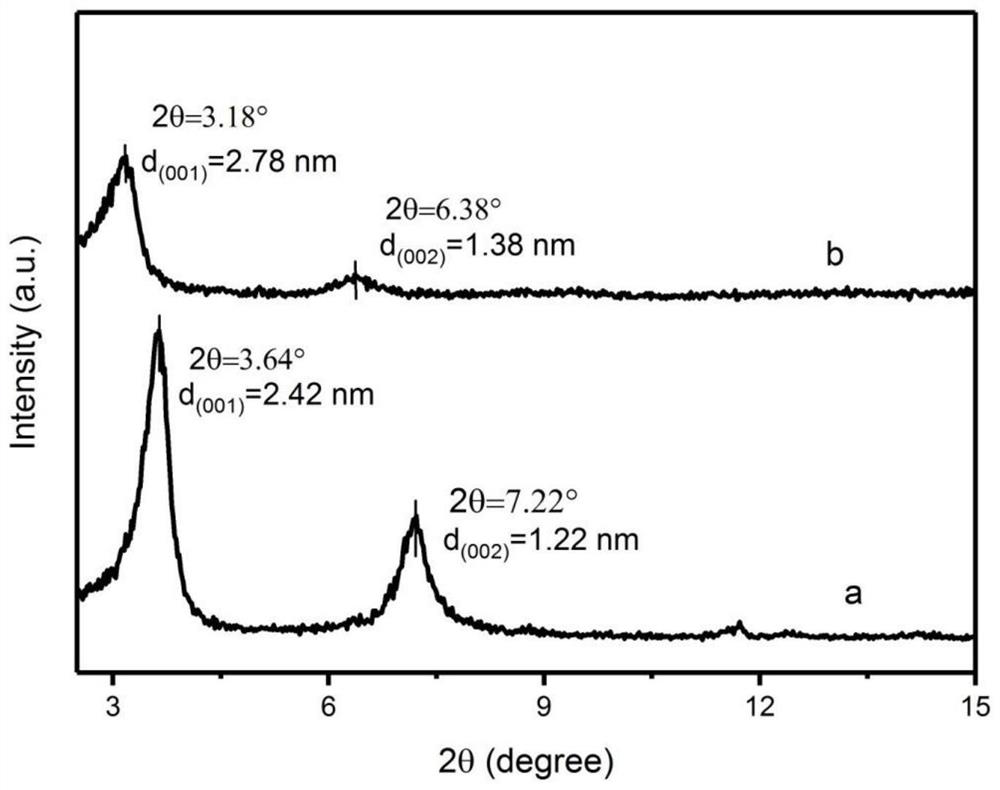

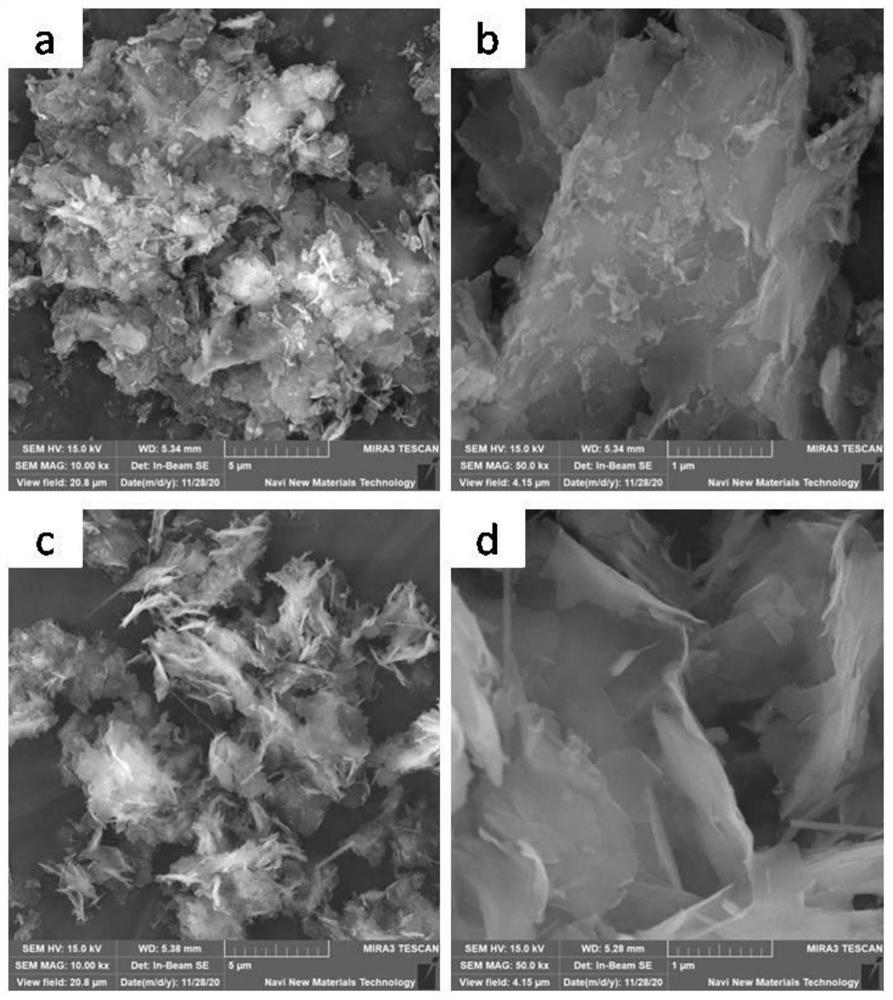

[0027] Step 1: Put 1 g of rectorite and 10 g of urea into a mortar, mix and grind for 30 minutes to obtain a urea rectorite composite.

[0028] Step 2: move the urea rectorite compound into a crucible and seal it, put it in a muffle furnace and bake it at 550 degrees for 3 hours, and after natural cooling, collect the reactants obtained to obtain a rectorite / carbon nitride nanocomposite catalytic material .

Embodiment 2

[0030] Step 1: Take 1g of rectorite and 1g of water and put them into a mortar, mix and grind for 5 minutes to fully wet the rectorite and form a hydration layer on the surface and between layers, then add 10g of urea and continue grinding for 10 minutes to make the urea It is easy to enter the interlayer of rectorite that hydrates and expands to obtain a rectorite-urea sandwich compound.

[0031] Step 2: Move the rectorite urea interlayer compound into a crucible and seal it, put it into a muffle furnace and bake it at 550 degrees for 2.5 hours, and after natural cooling, collect the reactants obtained to obtain a rectorite / carbon nitride nanocomposite catalytic material.

Embodiment 3

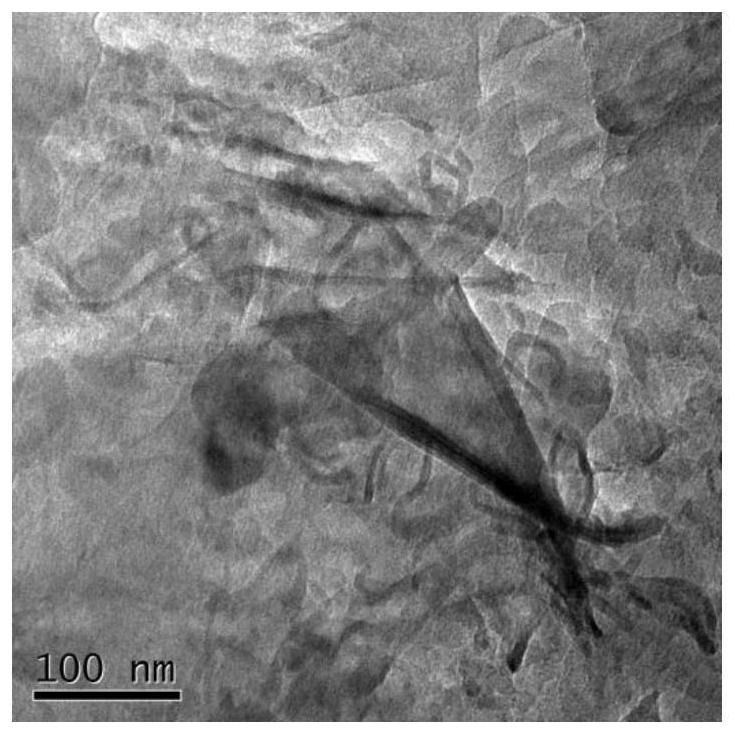

[0033] Step 1: Take 1g of rectorite and 3g of water and put them into a mortar, mix and grind for 3 minutes to make the rectorite fully wet and form a hydration layer on the surface and between layers, then add 10g of urea and continue grinding for 10 minutes to make the urea It is easy to enter the interlayer of rectorite that hydrates and expands to obtain a rectorite-urea sandwich compound.

[0034] Step 2: Move the rectorite urea interlayer compound into a crucible and seal it, put it in a muffle furnace and bake it at 550 degrees for 3 hours, and after natural cooling, collect the reactants obtained to obtain a self-exfoliating rectorite / carbon nitride nanocomposite catalytic materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com