Patents

Literature

63results about How to "Strong interfacial interaction" patented technology

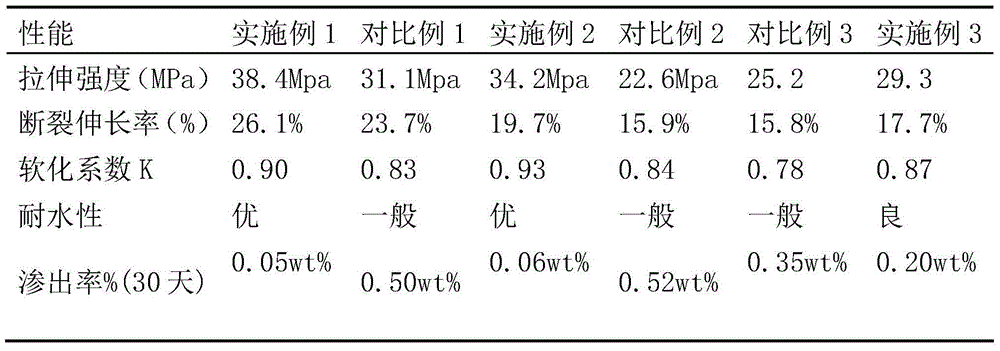

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

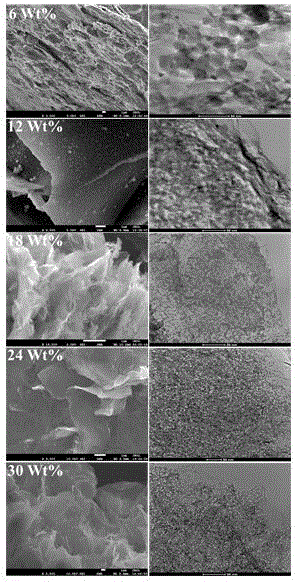

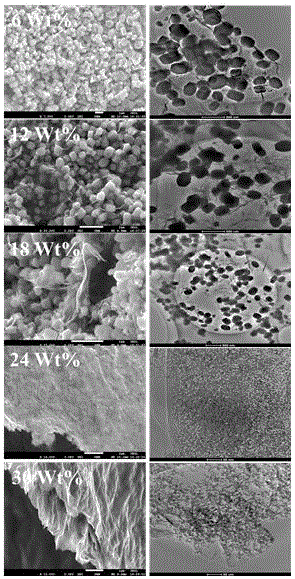

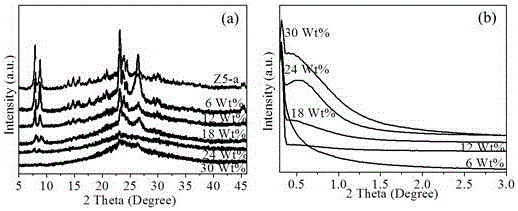

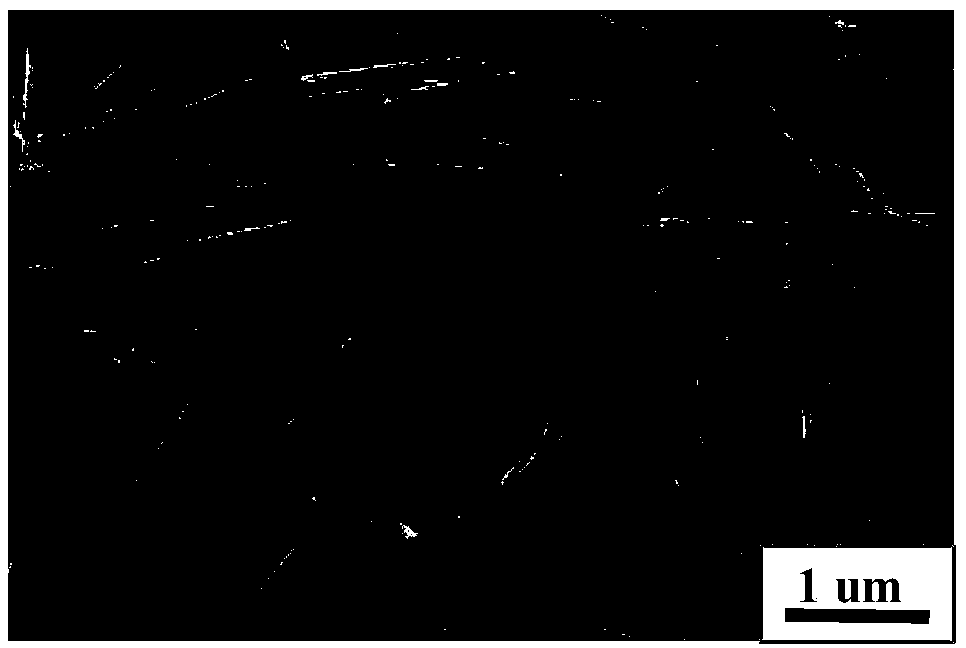

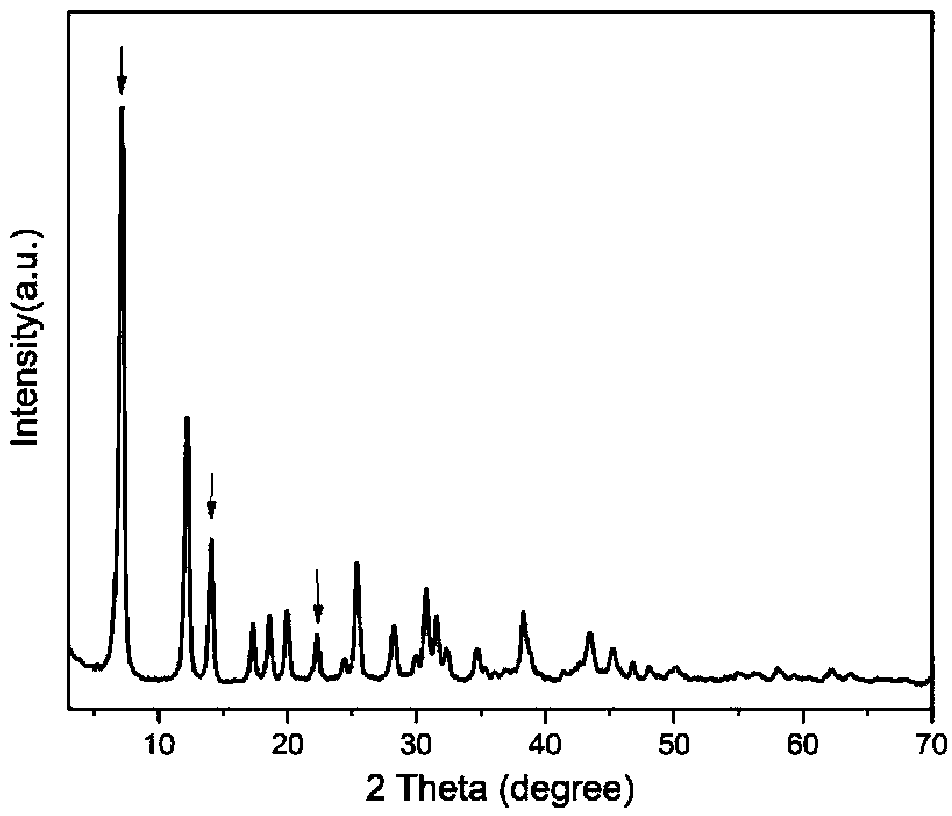

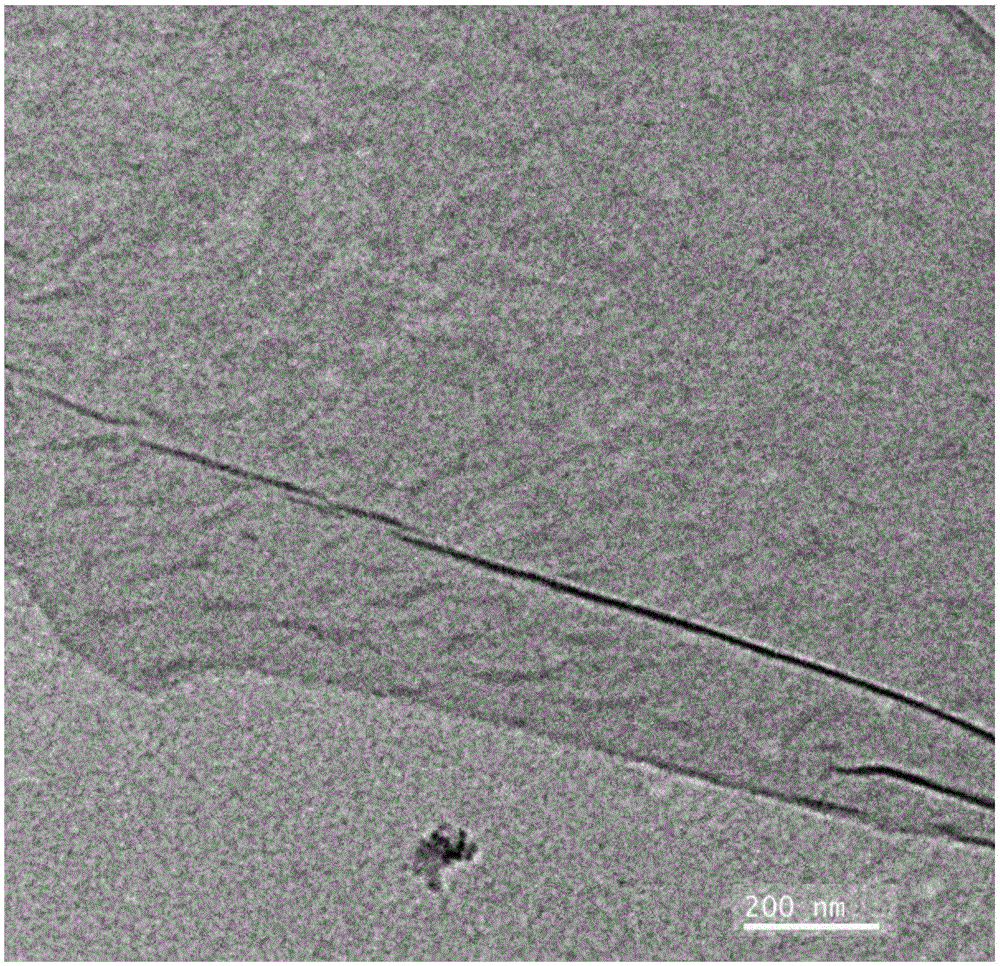

Graphene/molecular sieve composite catalyst and preparation method thereof

ActiveCN106475131AStrong interfacial interactionHigh yieldMolecular sieve catalystsMolecular sieve catalystMolecular sieveMicrometer

The invention discloses a graphene / molecular sieve composite catalyst and a preparation method thereof. The composite catalyst comprises, by weight, 5-40% of graphene and 60-95% of molecular sieve. The composite material has a quasi-two-dimensional lamellar structure, the ratio of the area of a single lamella to the thickness of the single lamella is more than 100 micrometers, the molecular sieve is evenly loaded on the surface of the graphene, and mesopore diameter is 2-30 nanometers. The preparation method includes: mixing the graphene, a silicon source, an aluminum source and a surfactant, separating out a graphene-containing part, crystalizing, purifying, and removing the surfactant. The graphene / molecular sieve composite catalyst has the advantages that the composite catalyst serving as a solid acid catalyst has enhanced catalytic activity, product yield and reusability can be evidently increased while the catalytic activity is not lowered when the catalyst is used in CBG and EHB reaction, and accordingly the catalyst is promising in application prospect.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

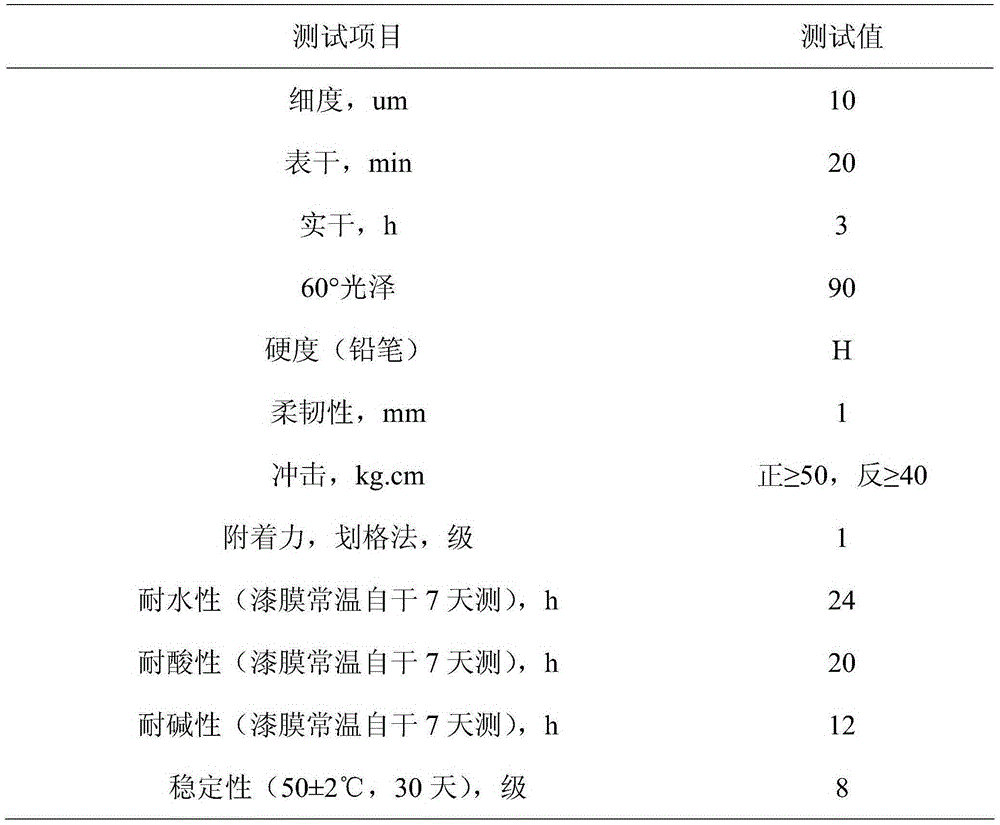

Preparation method of silicon modified waterborne epoxy resin

The invention relates to a preparation method of silicon modified waterborne epoxy resin. The preparation method comprises the following steps: (1) modifying organosilicon with a silane coupling agent to prepare silica sol; and (2) carrying a reaction between silica sol and waterborne epoxy resin under the action of a catalyst, and adding a neutralizer to prepare silicon modified waterborne epoxy resin. By combining silica sol and water-borne epoxy resin by a chemical bond, the silicon modified waterborne epoxy resin with excellent performance is obtained. The silicon modified waterborne epoxy resin is a novel resin coating having excellent properties of both an organic polymer and an inorganic material. The silicon modified waterborne epoxy resin is a combination of an organic polymer and an inorganic phase at the nanoscale, producing a strong interfacial interaction between the organic polymer and the inorganic phase. The prepared silicon modified waterborne epoxy resin has superior organic and inorganic properties, has characteristics of high strength, high toughness, good adhesive force, good high temperature resistance, good ageing resistance and the like, and overcomes performance defects of traditional waterborne epoxy resin.

Owner:佛山市高明同德化工有限公司

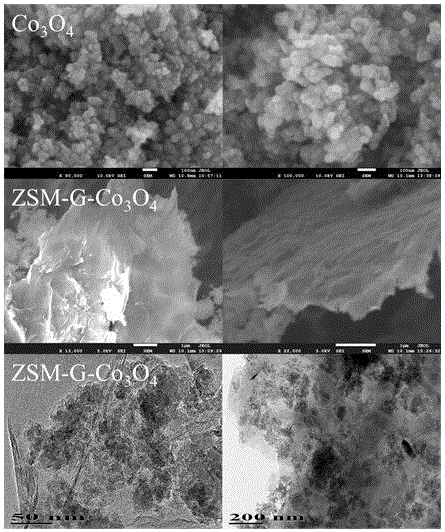

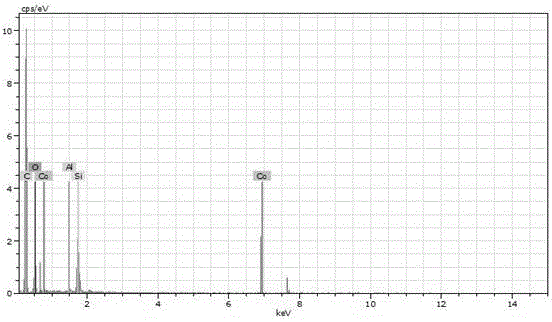

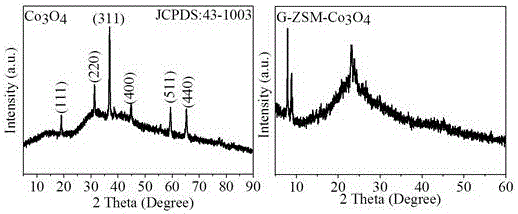

Graphene/molecular sieve/metal oxide composite catalyst and preparation method thereof

ActiveCN106475132AHas catalytic propertiesHas electrocatalytic propertiesElectrolysis componentsMolecular sieve catalystsMolecular sieveCatalytic oxidation

The invention discloses a graphene / molecular sieve / metal oxide composite catalyst and a preparation method thereof. The catalyst comprises graphene, molecular sieve and metal oxide. The weight ratio of the three materials is 3-38% of the graphene, 40-91% of molecular sieve and 4-37% of metal oxide. The prepared composite material has quasi -2D laminated structure. The metal oxide particle size is 10-20 nanometers. The preparation method comprises the steps of 1, mixing the graphene, silicon source, aluminum source and surface active agent, separating the part containing graphene, conducting crystallization, at last conducting purification and removing the surface active agent to acquire the graphene / molecular sieve composite material, 2, loading the metal oxide on the graphene / molecular sieve. The three element composite material can be used for the methanol electro-catalysis and oxidation, oxygen reduction (ORR), OER, CO2 electro-catalysis reduction, and exert very good catalytic activity. The stability and the poison resistance are enormously elevated, thus having promising application prospect.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

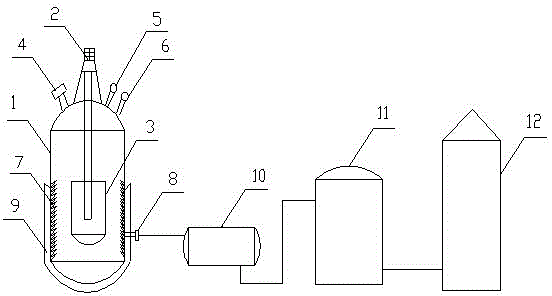

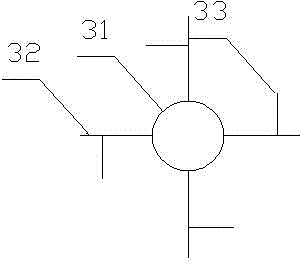

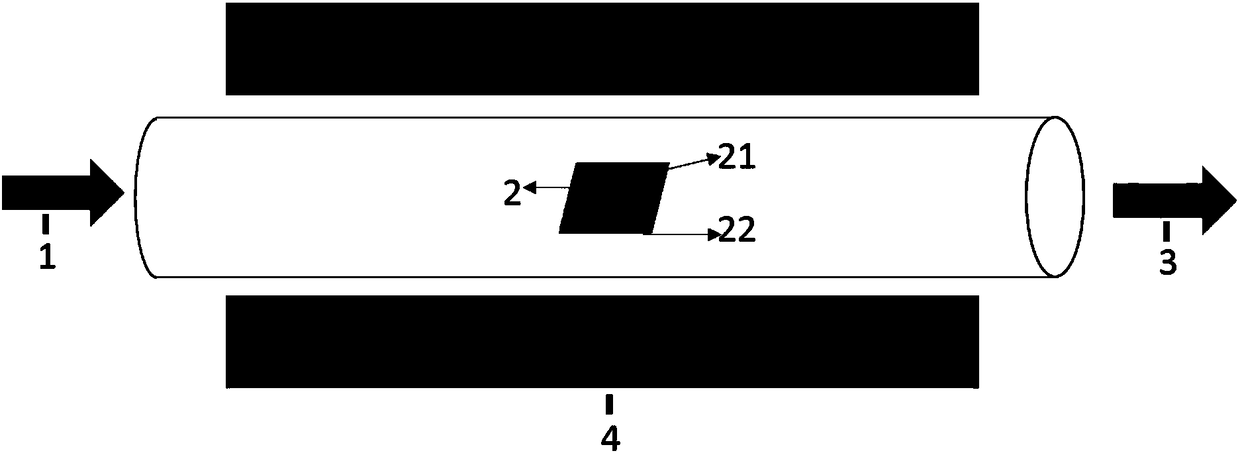

A production device of graphene and a preparing method

The invention relates to a production device of graphene. The device is characterized in that the device comprises a reaction kettle (1) and a motor (2), the motor is mounted at the top of the reaction kettle (1), the output end of the motor (2) is connected to a shearing machine (3), the top of the reaction kettle (1) is provided with a feeding port (4), a pressure gage (5) and a temperature meter (6), the inner wall of the reaction kettle (1) is provided with shearing slots (7), a material discharging port (8) is disposed in the middle and lower part of the reaction kettle (1), and a jacket (9) is disposed outside the reaction kettle (1) and is provided with a hot-medium inlet and an outlet. When the device is used for graphene production, the yield is high, the cost is low and the prepared graphene is high in quality.

Owner:江苏碳谷二维世界科技有限公司

Preparation method of high-strength and corrosion-resistant composite heat exchanger tube

The invention discloses a preparation method of a high-strength and corrosion-resistant composite heat exchanger tube. The composite heat exchanger tube consists of a copper base, alloy metal and filling particles, wherein the alloy metal comprises the following components in percentage by weight: 0.5-0.6% of magnesium, 0.08-0.09% of silver, 0.2-0.4% of tin, 0.012-0.014% of zirconium, 0.012-0.014% of niobium, 0.05-0.06% of nickel, 0.005-0.008% of titanium and 0.02-0.04% of mixed rare earth; the mixed rare earth consists of yttrium, berkelium and lanthanum at a mass ratio of 1: (0.15-0.2): (0.4-0.5); and the filling particles comprise the following components in percentage by weight: 0.010-0.012% of tetrapod-like zinc oxide whiskers, 0.008-0.009% of silicon carbide, 0.005-0.006% of aramid fiber, 0.004-0.005% of glass fiber and 0.002-0.003% of nano titanium oxide. The oxygen content of the prepared composite heat exchanger tube is in an oxygen-free copper level; the crystal grain is tiny; and the mechanical strength, the high-temperature resistance, the corrosion resistance and the wear resistance are improved greatly compared with the existing copper tube.

Owner:QUANZHOU SHENGXIN MACHINERY

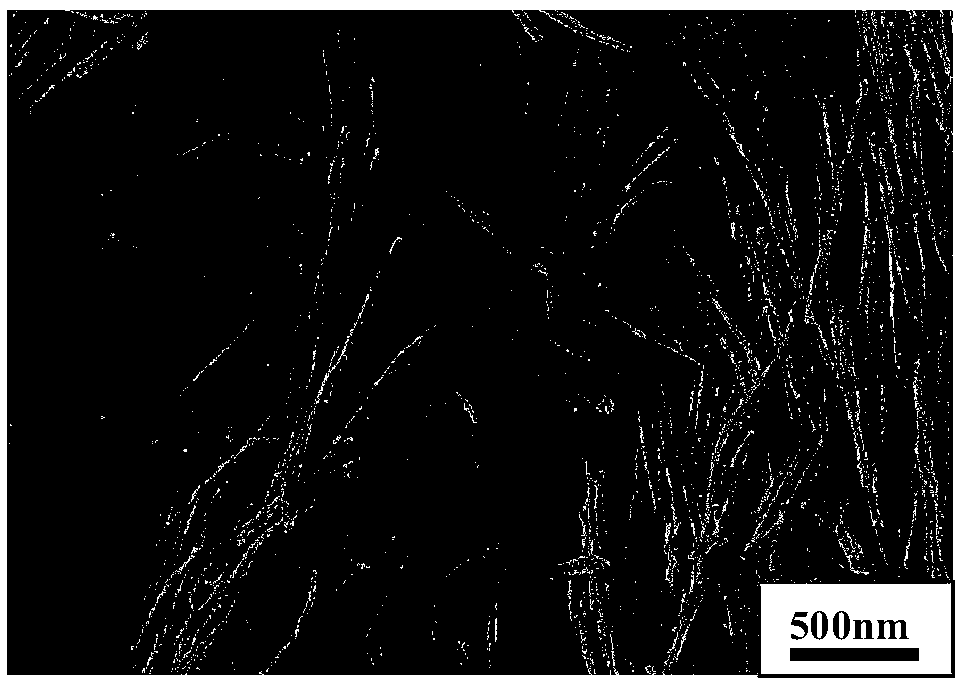

One-dimensional porous nanocomposite and preparation method thereof and application in water electrolysis

ActiveCN108611658AEasy to prepareEconomical method of preparationMaterial nanotechnologyElectrodesElectrolysisNickel zinc

The invention provides a Ni3ZnC0.7@C one-dimensional porous nanocomposite and a preparation method thereof and application in water electrolysis. The one-dimensional novel zinc-nickel carbide / graphitecarbon porous nanocomposite (Ni3ZnC0.7@C) is obtained through simple one-step solid-state pyrolysis in an inert atmosphere by taking organic molecule-intercalated layered nickel-zinc hydroxides as single precursors. The Ni3ZnC0.7@C porous nanorods have the structural characteristics of the uniform morphology, the uniform particle size, the high dispersion, the high crystallization degree, the large specific surface area, the high interfacial interaction and the like. When the prepared Ni3ZnC0.7@C porous nanorods are applied to catalytic water electrolysis hydrogen production, the Ni3ZnC0.7@Cporous nanorods show the high catalytic activity, the overpotential can be as low as 151 mV(i=10 mA / cm<2>), and meanwhile the Ni3ZnC0.7@C porous nanorods have the excellent stability (the testing performance keeps 98% or above in 10 h) and the high corrosion resistance.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method of filler particle enhanced aluminium alloy composite material

ActiveCN103290343AImprove heat resistanceImproved dimensional thermal stabilityThermal expansionStressed state

The invention relates to the field of new materials and in particular relates to a preparation method of a filler particle enhanced aluminium alloy composite material. A cast aluminium alloy ZAlSi8MgBe is selected as a matrix alloy; filler particles include tetrapod-like zinc oxide whiskers, aramid fibers, glass fibers, nano titanium dioxide and silicon carbide, wherein the weights of tetrapod-like zinc oxide whiskers, aramid fibers, glass fiber, nano titanium dioxide and silicon carbide account for 6-8%, 4-5%, 3-4%, 1-2% and 2-3% of the mass of the cast aluminium alloy ZAlSi8MgBe, respectively; and all the filler particles are modified or pre-processed, and then stirred and cast with the matrix aluminium alloy, so that the filler particle enhanced aluminium alloy composite material is obtained. The aluminium alloy composite material prepared by using the preparation method disclosed by the invention is low in weight, high in specific strength and specific rigidity, low in coefficient of thermal expansion, and excellent in thermal conductivity and abrasive resistance, and further easy to prepare and low in cost; and the enhancement phase is dispersively distributed in the matrix and has isotropy; and therefore, the composite material is suitable for various complex stress states.

Owner:江阴戴勒姆动力设备有限公司

Chitosan-nano laponite composite gel wound dressing and preparation method thereof

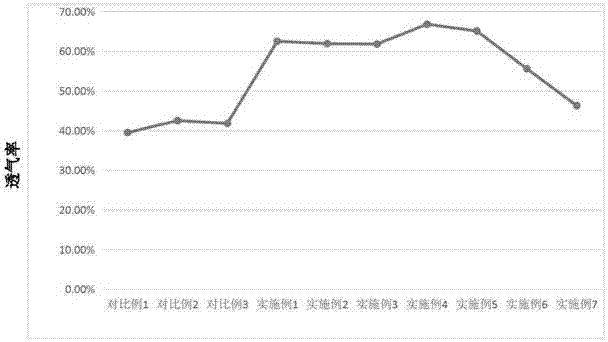

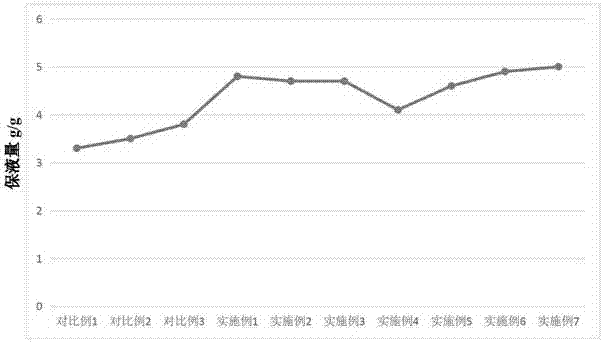

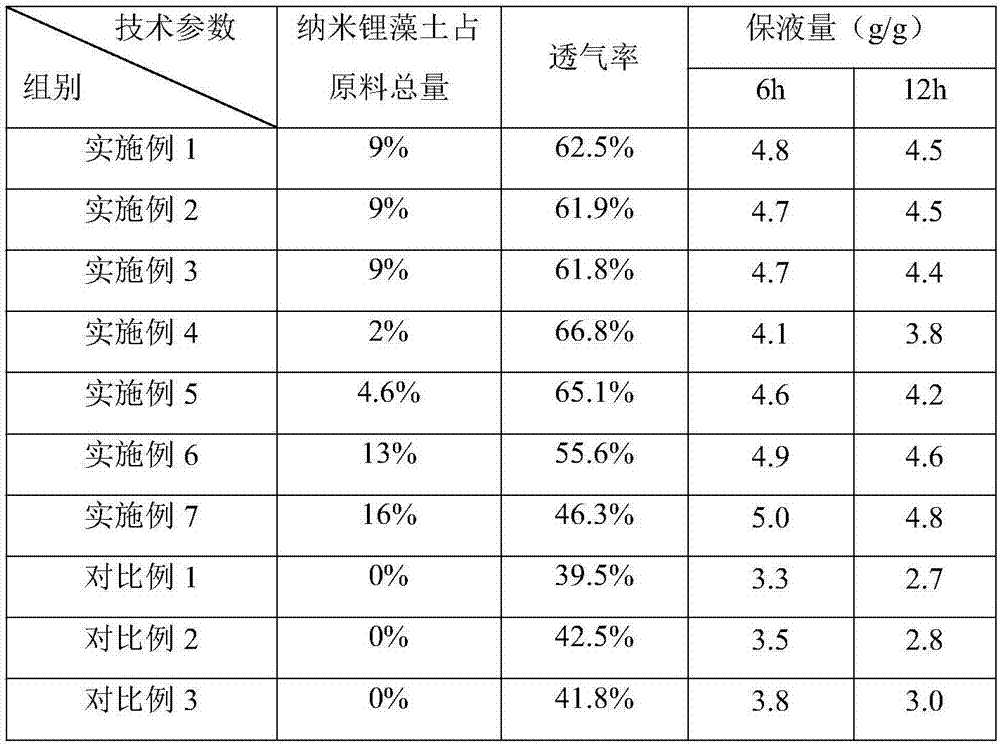

ActiveCN107261200AHigh temperature resistantGood biocompatibilityPharmaceutical delivery mechanismBandagesWound dressingPlasticizer

The invention discloses a chitosan-nano laponite composite gel wound dressing and a preparation method thereof. The chitosan-nano laponite composite gel wound dressing is prepared from the following raw materials in parts by weight: 1 to 16 parts of chitosan, 0.6 to 20 parts of nano laponite, 0.1 to 0.5 part of sodium pyrophosphate, 1.2 to 3.5 parts of plasticizer, 8.5 to 20 parts of moisturizing agent, and 67 to 85 parts of water. The gel wound dressing is simple in preparation process and low in production cost; and by combining the chitosan and nontoxic nano laponite, the product has good biological compatibility, antibacteria and hemostasia performance and moisturizing performance, can effectively prevent the fat liquefaction of a wound, can promote the rapid healing of the wound, and has remarkable nursing effect for the wound that is difficult to heal or the scald wound.

Owner:湖北中创医疗用品有限公司

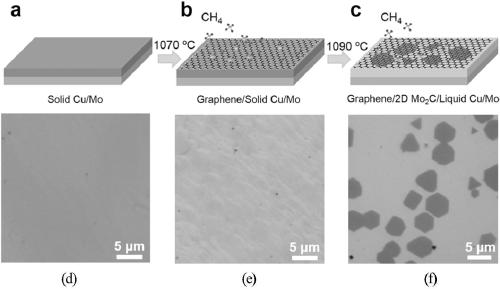

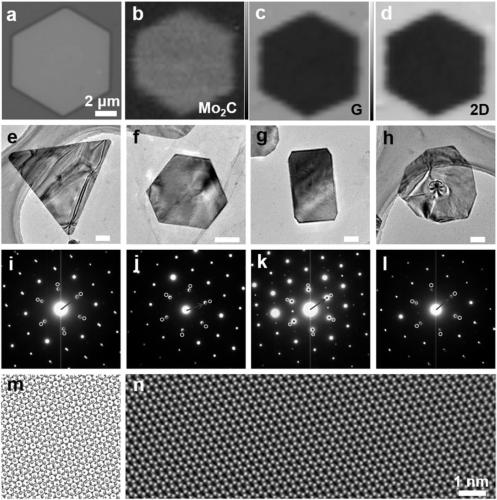

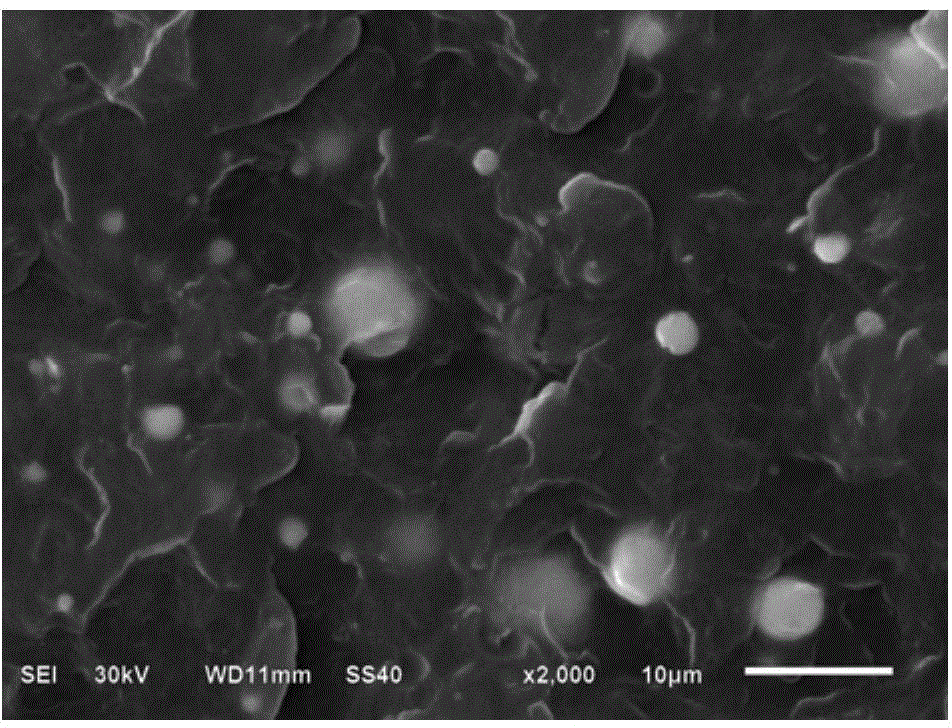

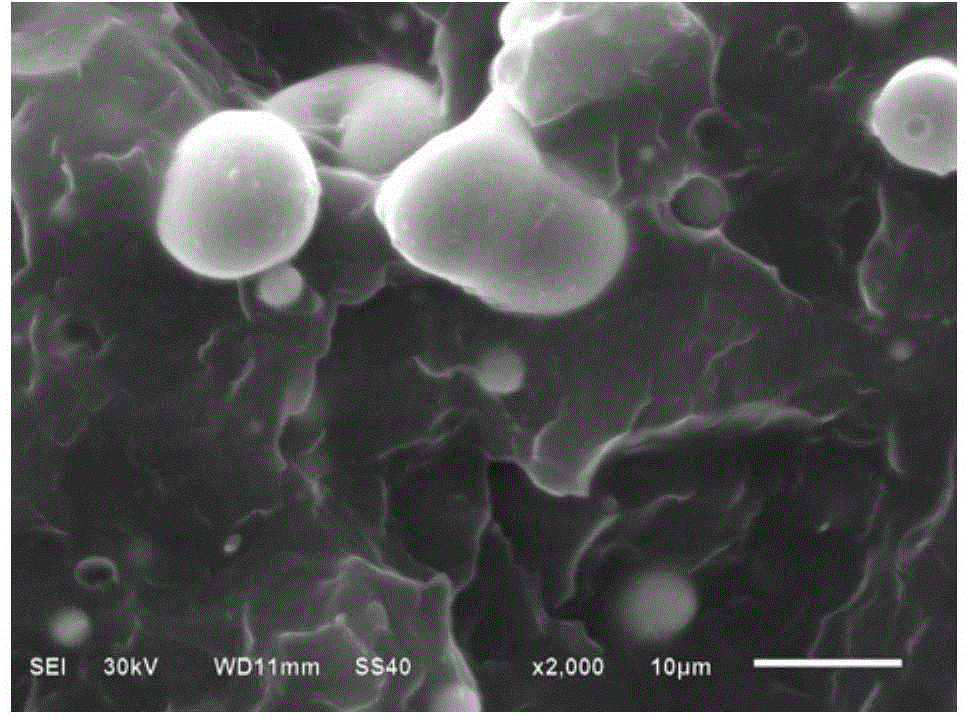

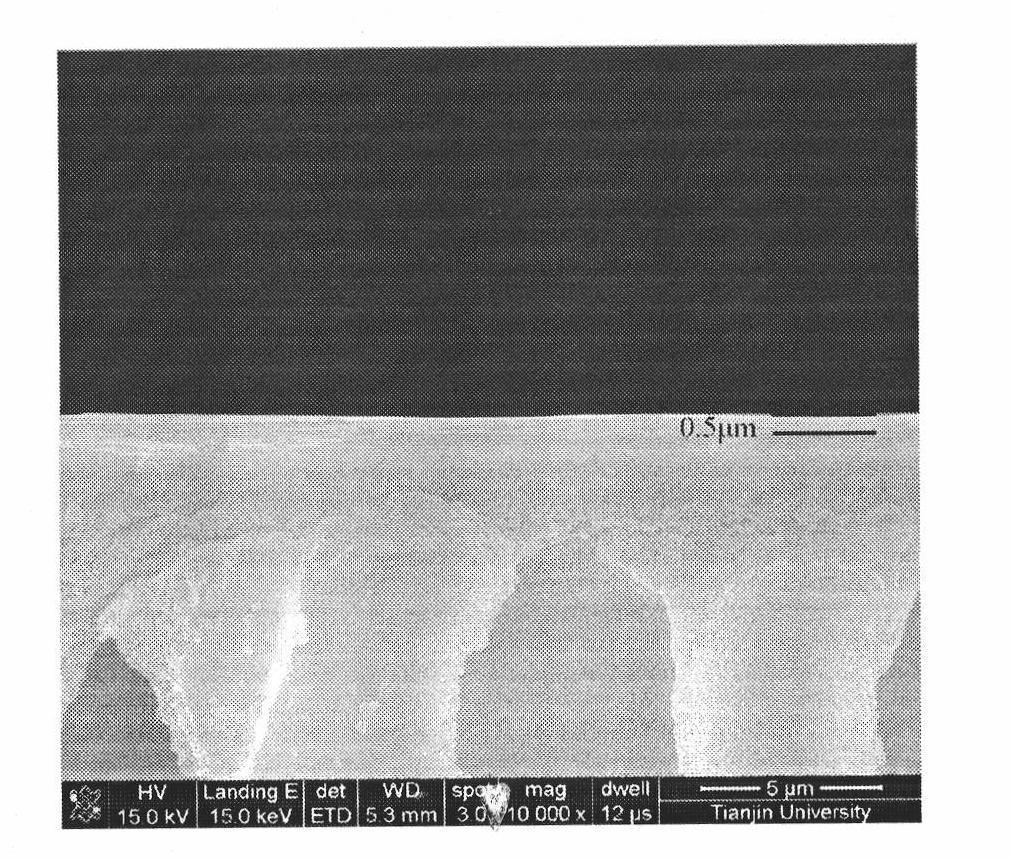

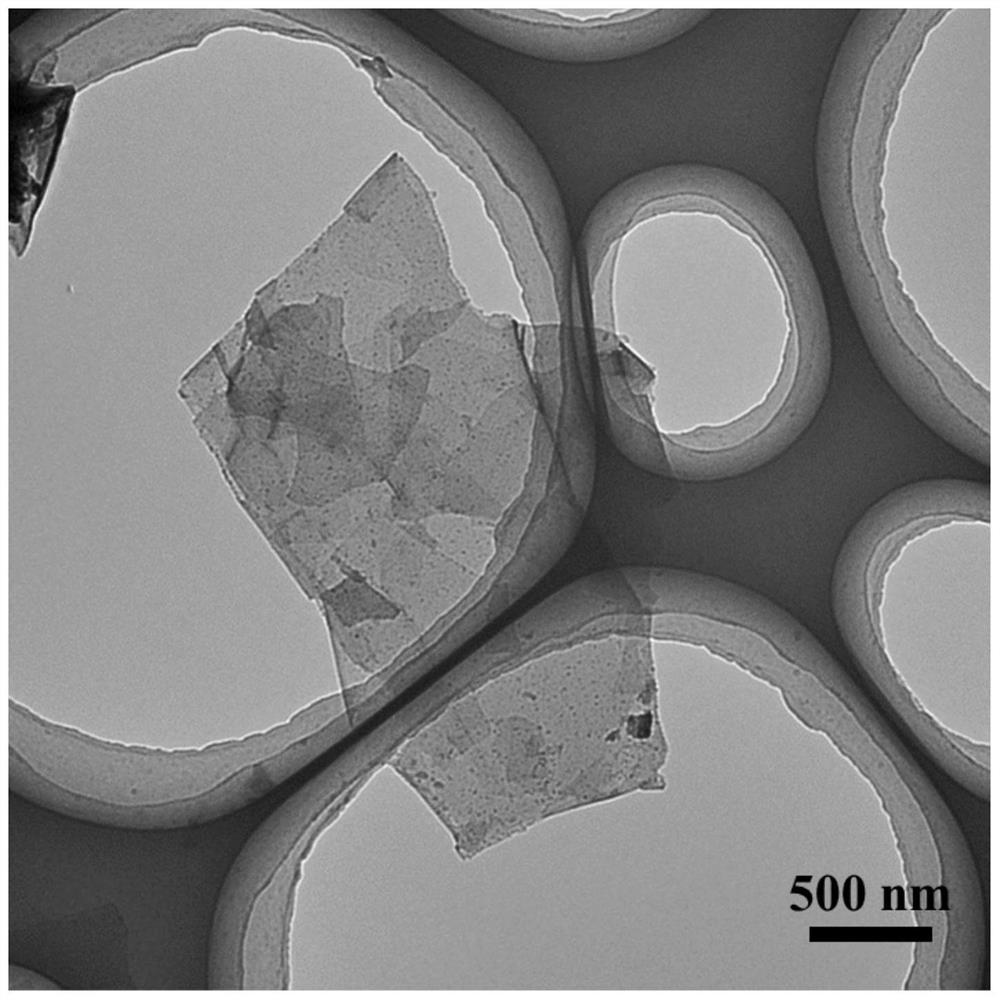

High-quality graphene/two-dimensional metal carbide crystal vertical heterostructure material and preparation method thereof

ActiveCN109019569AHas a clean interfaceConsistent crystal orientationMaterial nanotechnologyGrapheneMetal foilCopper foil

The invention relates to the field of new materials, particularly to a high-quality graphene / two-dimensional metal carbide crystal vertical heterostructure material and a preparation method thereof. According to the preparation method, a bimetal laminate formed by a copper foil / metal foil sheet is used as a growth substrate, graphene grows at a high temperature through catalytic cracking of a carbon source by using a CVD technology, and a two-dimensional transition metal carbide crystal grows under the graphene by increasing the temperature, or graphene and a two-dimensional transition metal carbide directly grow at a temperature of higher than the melting point of copper so as to prepare a graphene / two-dimensional metal carbide vertical heterostructure; and subsequently the copper substrate is etched off to obtain the graphene / two-dimensional metal carbide vertical heterostructure. According to the present invention, the foundation is established for the research and applications of high-quality graphene / two-dimensional metal carbide vertical heterostructure in the fields of catalysis, laser detection, transparent electric-conduction films, thermal management, two-dimensional superconductivity, high transparent Josephson junctions.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Preparation method of modified packing ion enhanced polytetrafluoroethylene composite

InactiveCN103275448AImproved dimensional thermal stabilityImprove mechanical propertiesMechanical propertyAramid

The invention relates to a preparation method of a modified packing ion enhanced polytetrafluoroethylene composite. A matrix of the composite is polytetrafluoroethylene; filling ions comprise tetrapod-like zinc oxide whiskers, aramid fibers, glass fibers and nano titanium dioxide; the masses of the tetrapod-like zinc oxide whiskers, the aramid fibers, the glass fibers and nano titanium dioxide account for 10-12%, 5-7%, 3-4% and 2-3% of the mass of polytetrafluoroethylene powder; the polytetrafluoroethylene powder is in 120-150 meshes; the tetrapod-like zinc oxide whiskers are 12-14 micrometers in length; the diameters of roots of the tetrapod-like zinc oxide whiskers are 3-5 micrometers; the aramid fibers are 2-2.5mm in length; each monofilament is 8-10 micrometers in diameter; the glass fibers are glass fiber powder in 120-140 meshes; and the particle size of nano titanium dioxide is 15-30nm. The modified enhanced polytetrafluoroethylene composite has the advantages of high mechanical strength, good abrasive resistance, good thermal conductivity, lower linear expansion coefficient and excellent antistatic property, the mechanical properties and thermostability of the polytetrafluoroethylene composite are improved greatly, and the application field of the composite is further extended.

Owner:佛山市南海区明扬电线厂

Method for preparing aluminum-based composite material subjected to enhanced particle-copper alloy interface compatibility treatment

The invention discloses a method for preparing an aluminum-based composite material subjected to enhanced particle-copper alloy interface compatibility treatment. The preparation raw materials comprise 100 weight parts of matrix alloy, 8-10 weight parts of enhanced particles and 0.05-0.08 weight part of refining agent, wherein the matrix alloy selects 75-80 weight parts of cast aluminum alloy ZAlSi8MgBe, 15-20 weight parts of copper alloy Cu20Ni20Mn and 5-8 weight parts of copper alloy Cu20Ni35Mn; the enhanced particles refer to combinations of tungsten carbide, tetrapod-like zinc oxide whiskers, silicon carbide and nanometer titania; and the weight ratio of the four enhanced particles is (4-4.5):(3-3.5):(1-1.5):(2-2.5). The aluminum-copper-based composite material prepared by the method disclosed by the invention is light in weight, high in specific strength, high in specific stiffness and low in thermal expansion coefficient and has high thermal conductivity and high wear and corrosion resistance. Moreover, the preparation is simple, the cost is low, the enhanced phase is in dispersed distribution in the matrix and has isotropy, and the composite material is applied to various complex stress states.

Owner:福铂斯(天津)科技有限公司

In-situ fiber-forming strengthened degradable medical elastic composite material and preparation method thereof

ActiveCN101623516AHigh tensile strengthAppropriate compatibilityCatheterProsthesisPoly-L-lactideFiber

The invention discloses an in-situ fiber-forming strengthened degradable medical elastic composite material and a preparation method thereof. The composite material is prepared by premixing polyglycolic acid or poly-(L-lactic acid) and poly-(L-lactide-tao-caprolactone) by a weight ratio of 20:80 to 5:95 in an inert gas atmosphere; extruding the mixture in a plastic extruder with a screw rotation speed of 10-80 r / min; hauling the extruded mixture by a hauling machine at a hauling speed of 1-30 m / min; controlling a die diameter / a spline diameter to be 1-6; and quenching with water in a hauling process. The composite material can be fully biologically degraded, has obviously improved tensile strength, enables fused mass to have little abrasion on the inner wall of an equipment cavity in the processing process and can be used in medical fields, such as degradable catheters, elastic fascia, artificial skin, and the like.

Owner:ZHEJIANG APELOA JIAYUAN BIOMEDICAL MATERIAL +1

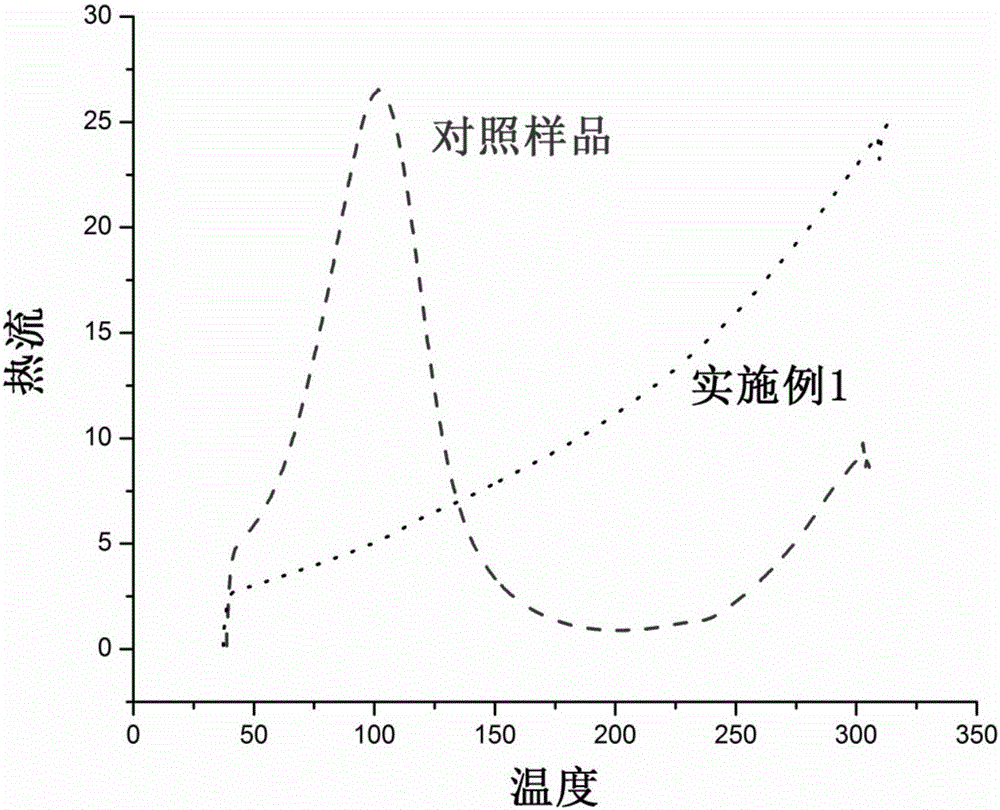

Modified tin fluorphosphate glass/polypropylene hybrid material and preparing method thereof

The invention discloses a modified tin fluorphosphate glass / polypropylene hybrid material and a preparing method thereof and belongs to the technical field of high polymer materials. The hybrid material comprises the following ingredients, by weight part, of 70-90 parts of modified polypropylene, 10-30 parts of modified tin fluorphosphate glass and 0.4 part of antioxidant. The modified tin fluorphosphate glass is formed by tin fluorphosphate glass, and the surface of the modified tin fluorphosphate glass is processed by silane coupling agents. The modified polypropylene is formed by polypropylene, and the polypropylene is processed by maleic anhydride in a grafting mode. By means of modifying treatment, the interaction between the tin fluorphosphate glass and the polypropylene is enhanced, the compatibility between the tin fluorphosphate glass and the polypropylene is improved, and the mechanical property of the material is improved. The preparing method for the modified tin fluorphosphate glass / polypropylene hybrid material is simple and low in cost. The modified tin fluorphosphate glass / polypropylene hybrid material can be widely applied to fields of fibers and plastics and has good application prospect.

Owner:XIANGTAN UNIV

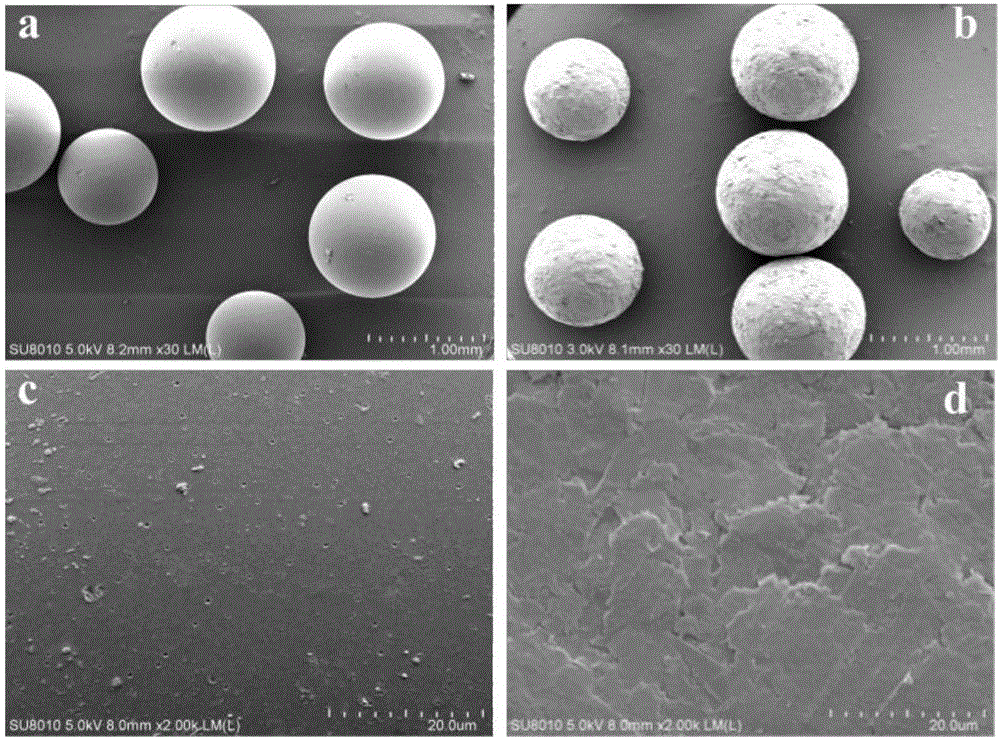

Graphene modified ultralow-density propping agent and preparation method thereof

InactiveCN106833601AHigh strengthLow thermal conductivityFluid removalDrilling compositionCross-linkMicrosphere

The invention belongs to the field of petroleum and gas fracturing extraction and in particular relates to a graphene modified ultralow-density propping agent and a preparation method thereof. The preparation method comprises the following steps: uniformly mixing graphene, an olefin monomer, a cross-linking agent (divinyl benzene) and an initiator under ultrasonic or stirring conditions so as to obtain a monomer mixture in which a Pi-Pi assembly effect is achieved between graphene and aromatic ring components; adding the monomer mixture into an aqueous solution of dispersing agents, performing the processes of balling, cross-linking and curing under the heating condition so as to obtain a microsphere precipitate; and filtering, washing and drying, thereby obtaining the graphene modified ultralow-density propping agent. According to the method disclosed by the invention, the organic polymer microsphere has low density, while the graphene has the performances of ultrahigh strength, high thermal conductivity and high temperature resistance, and then the composite material has ultralow density as well as the characteristics of high strength and high temperature resistance, so that the deep-well hydraulic fracturing requirement is met.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

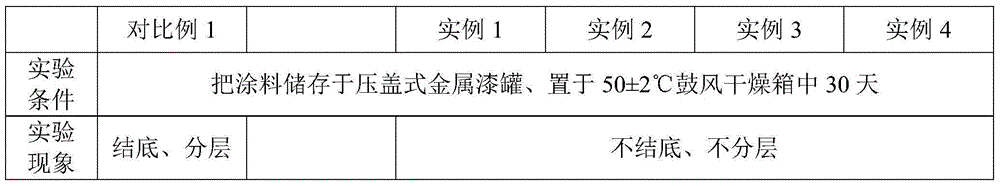

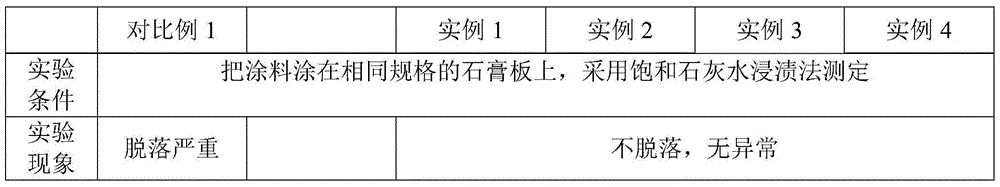

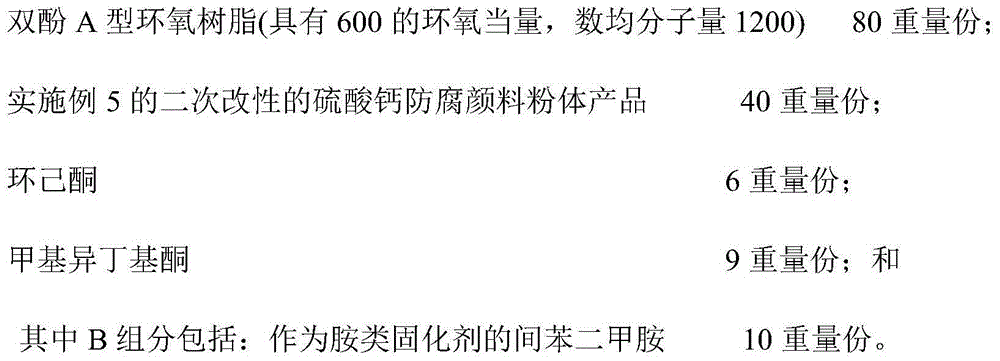

Modified calcium sulphate anticorrosive pigment as well as preparation method and application thereof

ActiveCN104945955AHigh temperature resistantWith acid and alkali corrosion resistanceAnti-corrosive paintsPigment treatment with organosilicon compoundsGas phaseBall mill

The invention discloses a modified calcium sulphate anticorrosive pigment as well as a preparation method and an application thereof. The preparation method comprises the following steps: preparing calcium sulphate extracted from industrial by-product gypsum into a suspension with a certain solid content, adding a modifier according to a certain mass percent, and then placing the modifier in a ball mill and uniformly mixing and grinding; drying the ground mixture for 3-6 hours at 80-150 DEG C, cooling the mixture and then grinding the mixture into a powder and crushing, wherein preferably, aminosilane-modified gas-phase silica is added during the grinding and crushing process. The calcium sulphate anticorrosive pigment disclosed by the invention is capable of effectively solving the pressure brought to an environment by the industrial by-product gypsum, and capable of improving the industrial by-product gypsum, wear resistance and corrosion resistance of a coating film in case of being mixed and used with other anticorrosive pigments; the pigment is good in dispersibility in resin, simple in production process, low in production cost, and capable of bringing good social and economic benefits.

Owner:HUNAN RUISHI SCI & TECH DEV

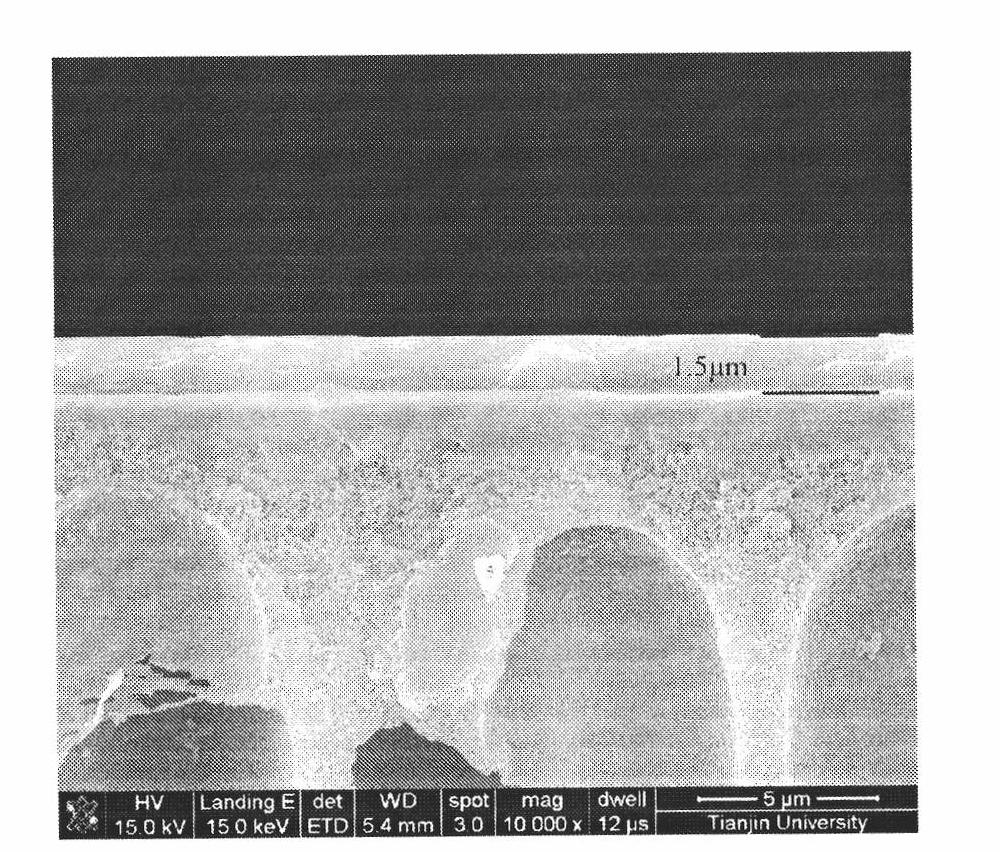

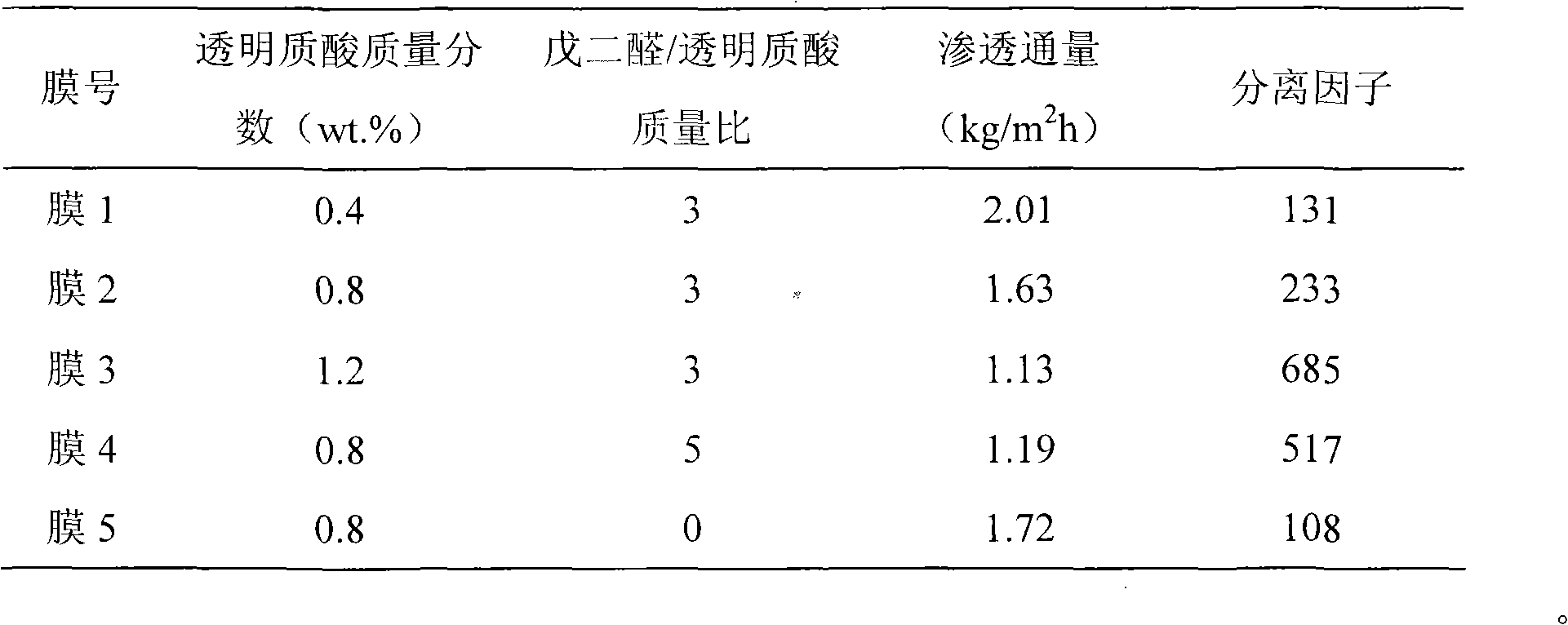

Hyaluronic acid/polyacrylonitrile compound film, method for preparing same and application thereof

ActiveCN101785975AImprove hydrophilic abilityStrong interfacial interactionSemi-permeable membranesSolubilityPervaporation

The invention relates to a hyaluronic acid / polyacrylonitrile compound film, a method for preparing the same and application thereof. The compound film is prepared by using hyaluronic acid, glutaraldehyde and a polyacrylonitrile basal film as raw materials, wherein the mass ratio of the glutaraldehyd to the hyaluronic acid is 1-10:1, and the thickness ratio of the polyacrylonitrile basal film to the hyaluronic acid layer is 135-400:1. Particularly, the preparation method comprises the following steps of: coating acid casting solution of the glutaraldehyde-containing hyaluronic acid on the polyacrylonitrile basal film which is treated by water, alkali and acid in sequence, drying, and heating the polyacrylonitrile basal film for 0.5 to 3 hours. The preparation method has the advantages of simple method, mild conditions and low cost; and the hyaluronic acid separation layer is high in hydrophilicity, and simultaneously due to the bonding characteristics, the hyaluronic acid separation layer is closely combined with a support layer, so that the prepared hyaluronic acid / polyacrylonitrile compound film is high in stability and separation property, and can be widely applied to the film realizing the separation based on a solubility diffusion mechanism such as pervaporation.

Owner:南通诚恩机械有限公司

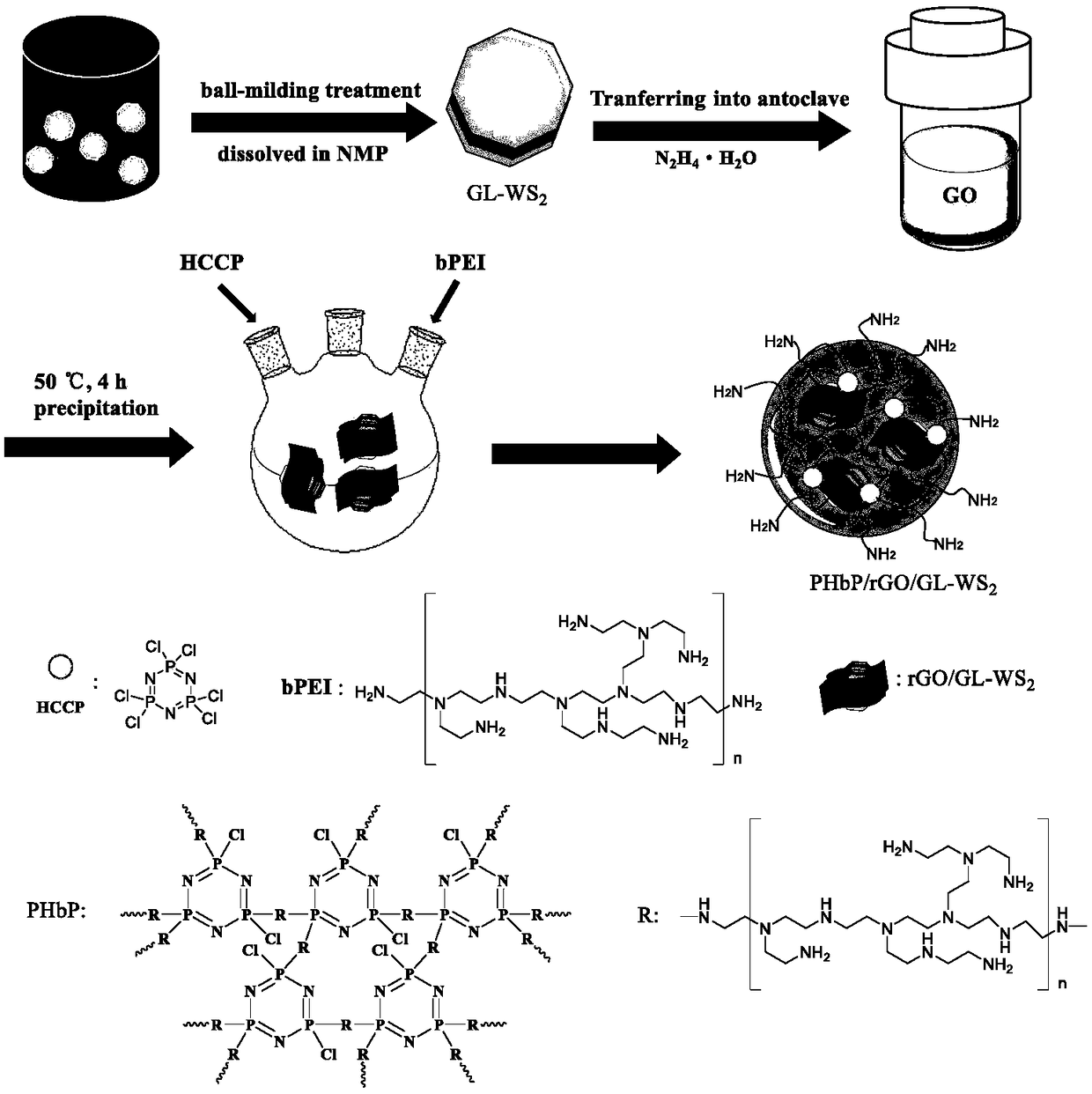

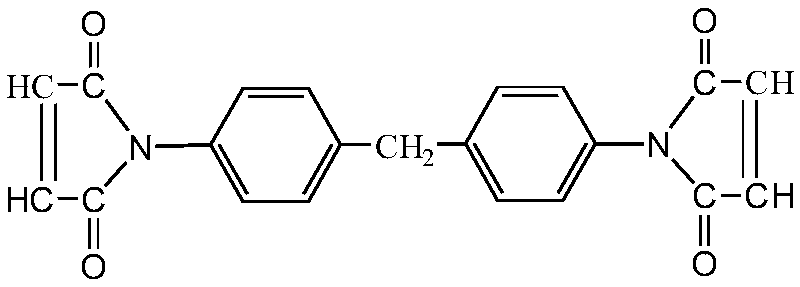

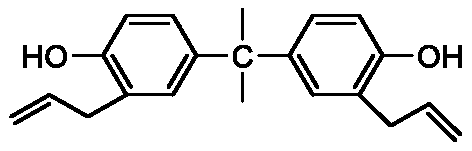

Graphene/graphene analogue WS2/bismaleimide composite material modified by cyclotriphosphazene polymer and preparation method thereof

InactiveCN108641356AGood dispersionImprove the bonding strength of the interfacePolymer scienceHigh pressure

The invention relates to a graphene / graphene analogue WS2 / bismaleimide composite material modified by cyclotriphosphazene polymer and a preparation method thereof. Firstly, WS2 is stripped into grapheme analogue WS2 by using methods of low-energy ball milling and ultrasonic, then, the grapheme analogue WS2 is added into a high-temperature high-pressure reaction kettle together with an oxidized graphite, a proper amount of hydrazine hydrate is added and a pot hydrothermal method is used to prepare the graphene / graphene analogue WS2. Then, the graphene / graphene analogue WS2, phosphonitrilic chloride trimer, and branched polyethyleneimine are used as a raw materials, triethylamine is used as an acid-binding agent, and the graphene / graphene WS2 modified by cyclotriphosphazene polymer is prepared by using an in-situ template method. Finally, the composite material is prepared by mixing the graphene / graphene WS2 modified by cyclotriphosphazene polymer, diphenylethane dimaleimide and diallylbisphenol A in a certain proportion. The prepared composite material has good interface bonding strength, and excellent mechanical property and tribology performance.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

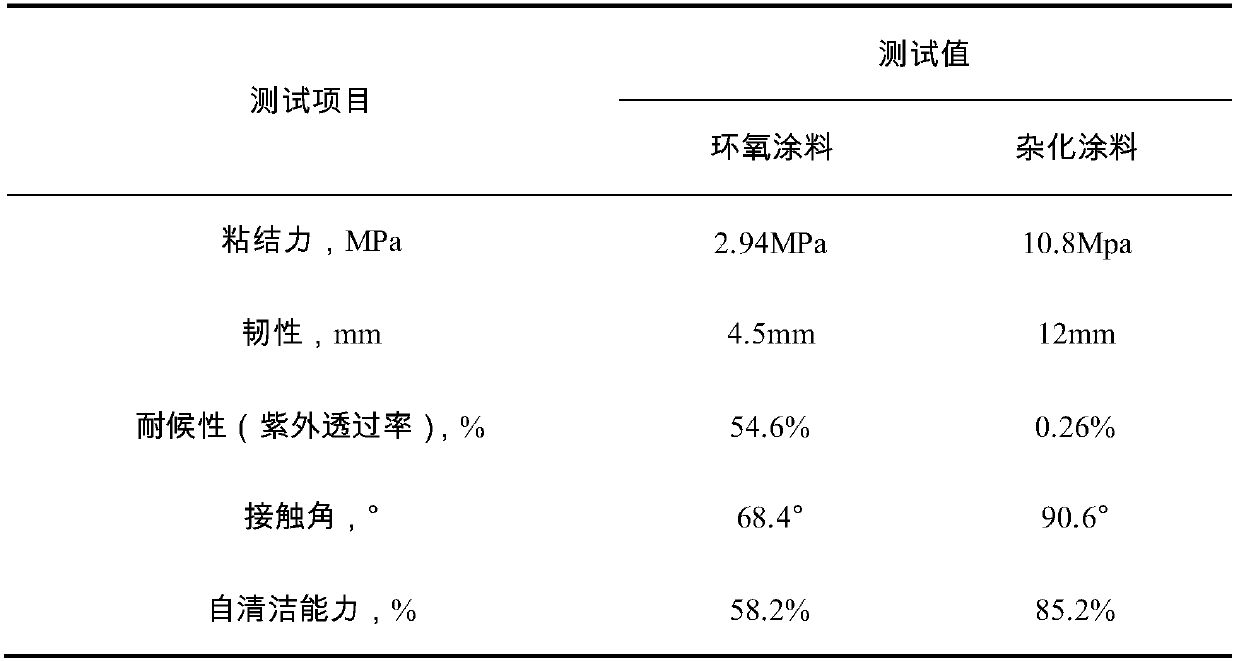

Method for producing hybrid material on the basis of Si/Ti composite sol modified epoxy resin

InactiveCN109535652AImprove featuresImprove stabilityAnti-corrosive paintsEpoxy resin coatingsEpoxyNanoscopic scale

A method for producing a hybrid material on the basis of Si / Ti composite sol modified epoxy resin includes: 1) performing co-hydrolysis on a silane coupling agent with a functional group, tetraethoxysilane and tetrabutyl titanate to prepare Si / Ti composite sol; 2) performing a reaction on the Si / Ti composite sol and epoxy resin with a curing agent to prepare the epoxy / Si / Ti organic-inorganic hybrid material. Herein, the sol and the epoxy group are bonded through chemical bonds, thus forming the epoxy / Si / Ti organic-inorganic hybrid material having great performance. The hybrid material, as a composite coating, has the advantages of both organic resin and inorganic materials, so that combination between the organic high-polymer and the inorganic phase on nano-scale is achieved and strong interfacial interaction between the two phases is achieved, which manifest as by adding a less amount of the composite sol, the toughness and anti-aging effect of epoxy resin and binding strength with metal are all improved greatly.

Owner:UNIV OF SCI & TECH BEIJING

Reinforced type aluminum-copper-based composite friction material

The invention discloses a reinforced type aluminum-copper-based composite friction material which is prepared by carrying out procedures of raw material mixing, hot press molding and curing, wherein the raw materials comprise the following components in parts by weight: 15-20 parts of cast aluminum alloy ZAlSi8MgBe powder, 8-10 parts of copper alloy Cu30Ni15Mn powder, 8-10 parts of silicon carbide, 6-8 parts of potassium titanate fiber, 5-6 parts of aramid fiber, 5-6 parts of zirconia, 3-4 parts of tetrapod-like zinc oxide whisker, 1-2 parts of molybdenum disulfide, 1-2 parts of barium sulfate, 1-2 parts of tungsten carbide, 1.5-2 parts of nitrile rubber and 1-2 part of nano-titanium dioxide. According to the reinforced type aluminum-copper-based composite friction material, aluminum alloy and copper alloy are adopted to replace steel in a base material, as the heat radiation of the aluminum alloy and copper alloy is greatly higher than that of ordinary steel, the heat generated from brake friction can be radiated in time, the temperature of the surface of a brake pad is reduced, the high-temperature head fading property is alleviated, and the wear rate is small; and meanwhile the experiment shows that the noise frequency is less than 450Hz, so that people cannot hear conspicuous noise in an automobile.

Owner:TAIZHOU ANTENG HUB FACTORY GROUP

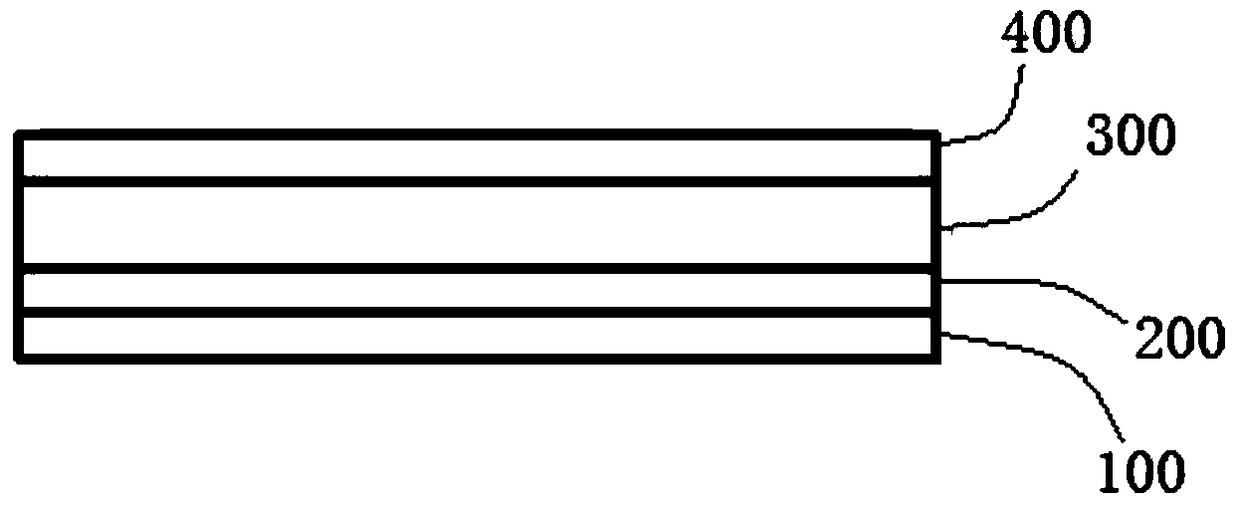

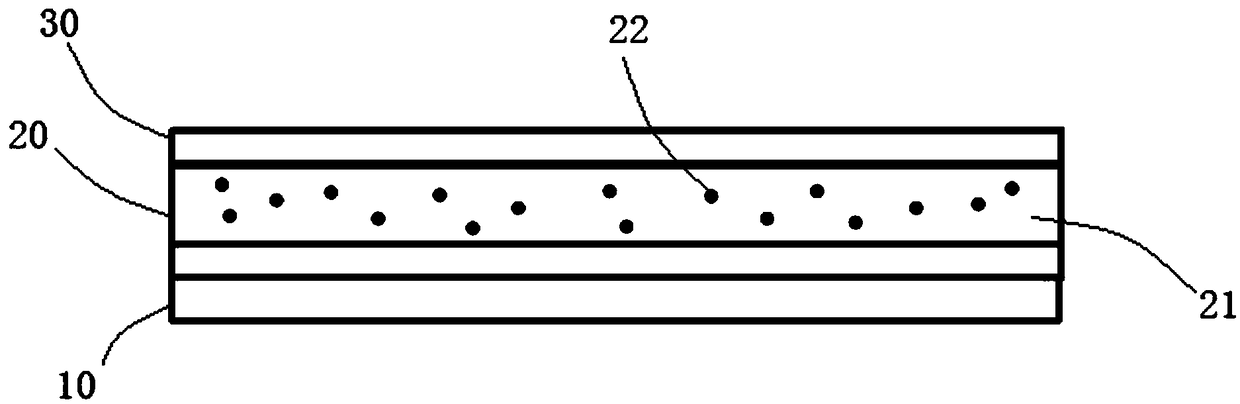

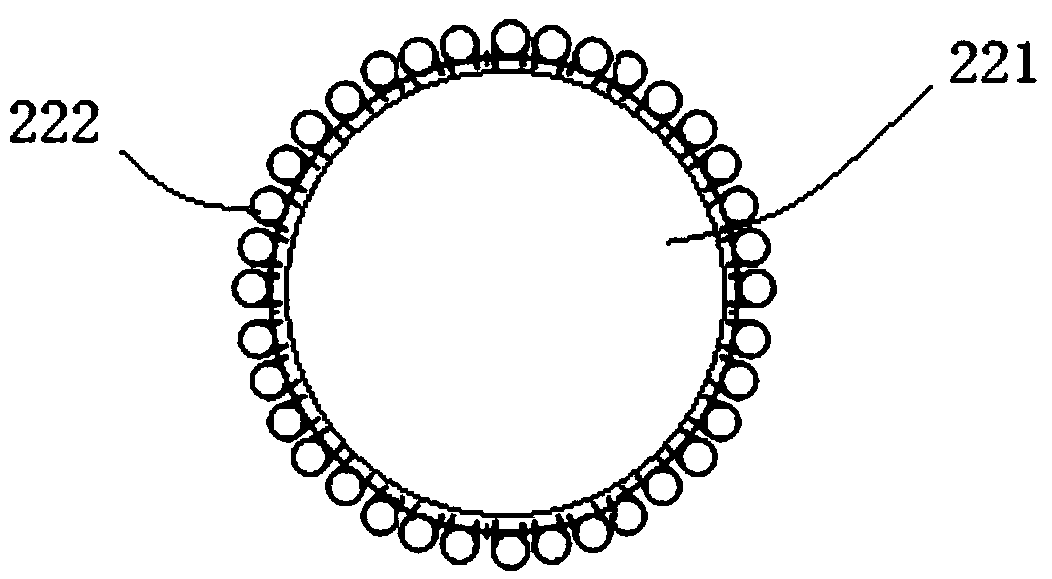

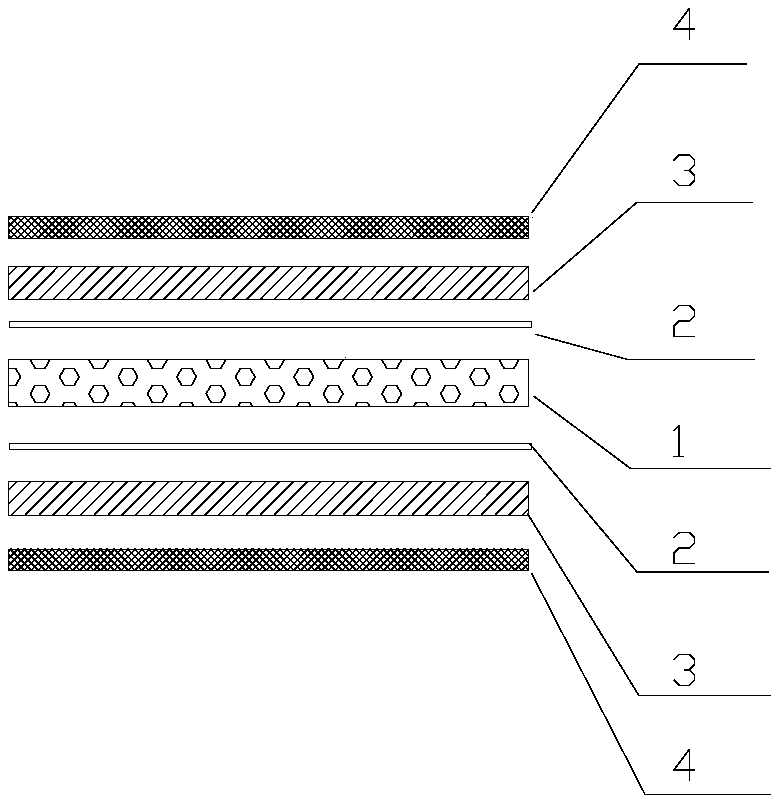

Thin film packaging structure and organic electroluminescent device

ActiveCN108258152AImprove adhesionImprove color castSolid-state devicesSemiconductor/solid-state device manufacturingMicrosphereOptoelectronics

The invention provides a thin film packaging structure and an organic electroluminescent device. The thin film packaging structure comprises one or more layers of inorganic packaging layer and an organic / inorganic microsphere layer covering the inorganic packaging layer, or covered by the inorganic packaging layer, or between the inorganic packing layers; the material of the organic / inorganic microsphere layer is a high-molecular composite material. The organic / inorganic microsphere layer comprises a composite matrix and a hollow nano microsphere dispersed in the composite matrix. In the thinfilm packaging material and the organic electroluminescent device provided by the invention, organic / inorganic microsphere layer is adopted for replacing organic sealing material. The adhesive force of the inorganic microsphere layer and the inorganic packaging layer is increased and the packaging effect is improved. In addition, the uniformity of the hollow nano-spheres in the inorganic microsphere layer can improve the color deviation of the film packaging structure.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

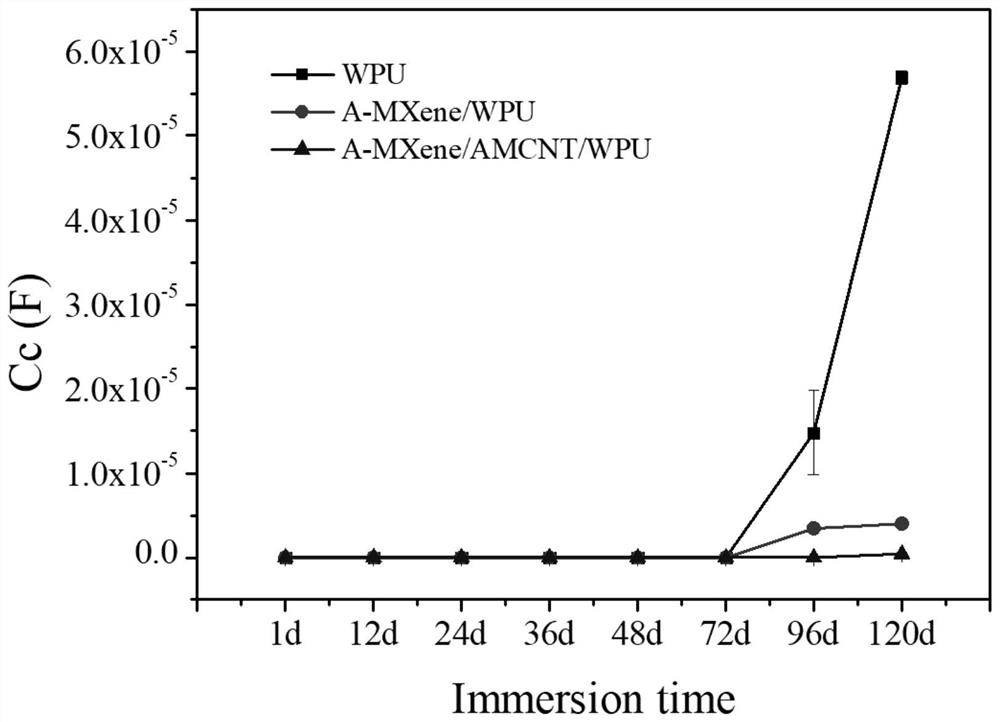

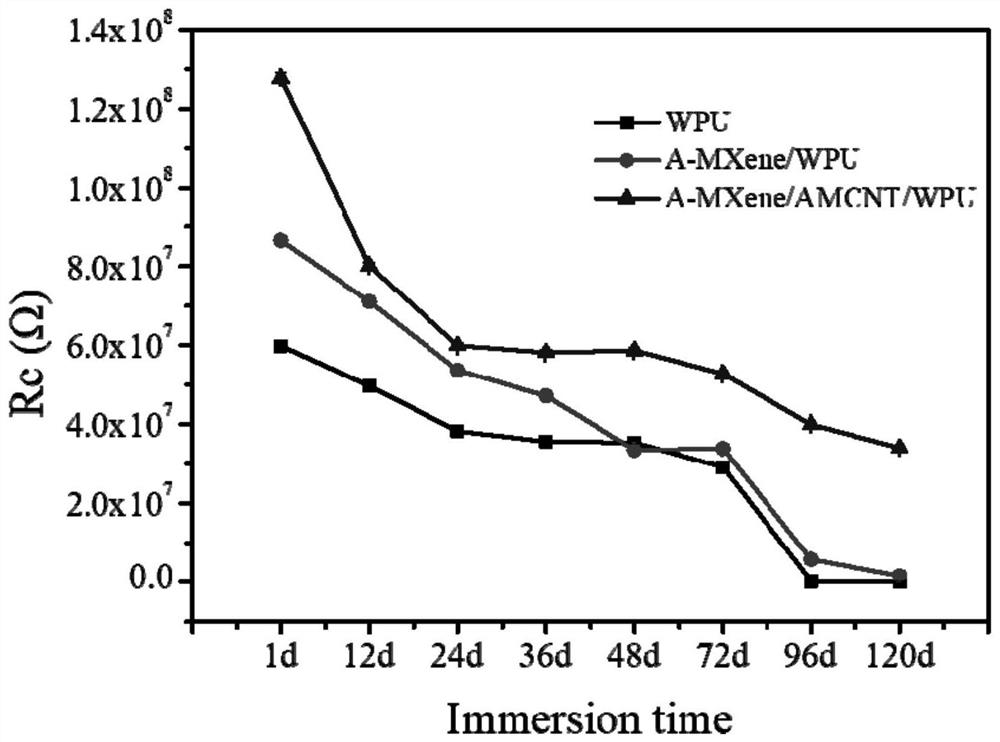

MXene and carbon nano tube synergistically modified polyurethane anticorrosive paint as well as preparation method and construction process thereof

ActiveCN114276743APrevent diffusion and penetrationGood mechanical properties and anti-corrosion propertiesPretreated surfacesAnti-corrosive paintsSilane couplingCarbon nanotube

The invention discloses an MXene and carbon nanotube synergistically modified polyurethane anti-corrosion coating as well as a preparation method and a construction process thereof, and relates to the field of anti-corrosion coatings. Comprising the following steps: S1, taking MXene nanosheets, and adding a silane coupling agent for modification to obtain functionalized MXene nanosheets; s2, dispersing the functionalized MXene nanosheets and the aminated carbon nanotubes in deionized water, and carrying out ultrasonic treatment until the functionalized MXene nanosheets and the aminated carbon nanotubes are uniformly dispersed, so as to obtain A-MXene / AMCNT dispersion liquid; and S3, adding the A-MXene / AMCNT dispersion liquid into waterborne polyurethane, and uniformly stirring, so as to obtain the MXene and carbon nanotube synergistically modified polyurethane anticorrosive coating. According to the preparation method disclosed by the invention, the MXene nanosheet can have good compatibility and relatively strong interface interaction with the WPU substrate, so that the MXene and the carbon nanotubes of the coating are uniformly dispersed in the WPU substrate, and the coating has excellent corrosion resistance and mechanical properties.

Owner:HENAN INST OF ENG

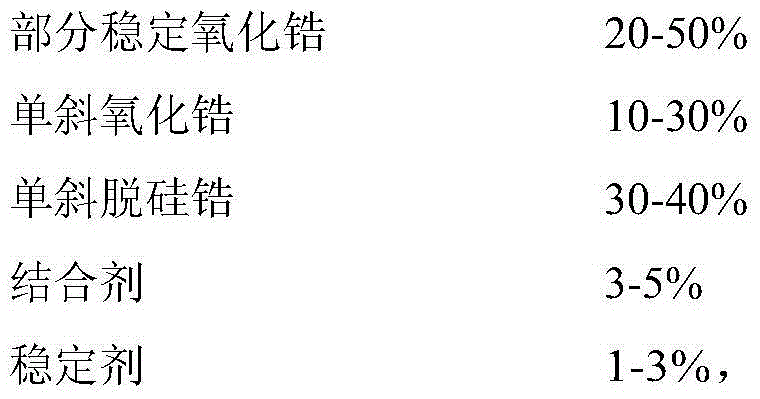

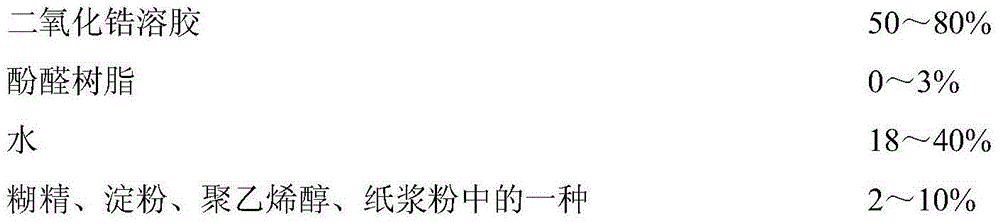

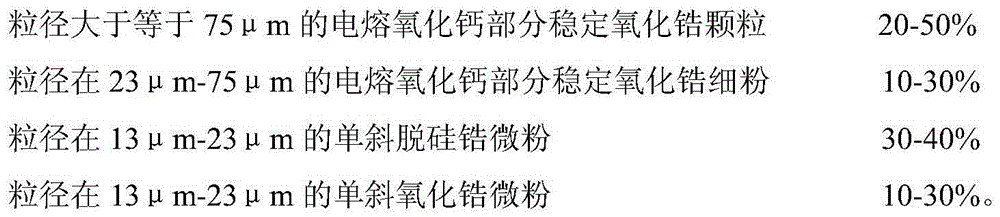

Zirconia metering nozzle preparing method adding zirconium sol in two steps

The invention provides a zirconia metering nozzle preparing method adding zirconium sol in two steps. The method includes steps of material mixing, compression moulding, drying, sintering, and vacuum soaking. The mixed materials comprise 20-50% by weight of partially-stable zirconia, 10-30% by weight of monoclinic zirconia, 30-40% by weight of monoclinic silicon-removed zirconium, 1-3% by weight of a stabilizing agent, and 3-5% by weight of a binding agent that including zirconia sol. In the subsequent vacuum soaking step, a sintered product is added into the zirconia sol and subjected to vacuumizing and soaking. According to the method, nanometer zirconia is introduced by a manner of adding the zirconium sol in two steps. The nanometer zirconia decomposed by utilization of the zirconium sol has functions of resisting high temperature, stress-induced transformation toughening and microcrack toughening, thus enhancing the washing resistance, corrosion resistance and thermal shock resistance of the zirconia metering nozzle, prolonging the service lifetime of the metering nozzle, and increasing the working efficiency of a continuous casting machine.

Owner:CENT SOUTH UNIV

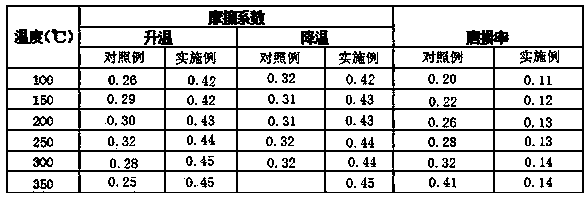

Nanometer composite heat-insulating material and preparation method thereof

ActiveCN108673977AStrong interactionImprove bond strengthLaminationLamination apparatusResin compositeFormamide

The invention provides a nanometer composite heat-insulating material. The nanometer composite heat-insulating material comprises a flame-resistant bubble layer and is characterized in that a flame-resistant glue layer, an aluminum foil layer and an aerogel layer are arranged on one side of the flame-resistant bubble layer sequentially; the aerogel layer is prepared from the following components in parts by weight: 5 to 20 parts of silicon dioxide-phenolic resin composite aerogel, 20 to 30 parts of epoxypropane, 80 to 130 parts of acetic acid, 50 to 70 parts of polyethylene glycol 600, 10 to 30 parts of formamide, 20 to 30 parts of toluene diisocynate tripolymer and 10 to 15 parts of isophorone diisocyanate tripolymer. Through the silicon dioxide-phenolic resin composite double-network structure aerogel, the adhesiveness of the aerogel and the aluminum foil can be improved and the heat-insulating property of the material is improved.

Owner:ZHEJIANG PENGYUAN NEW MATERIAL TECH GRP CO LTD

Preparation method of modified packing ion enhanced polytetrafluoroethylene composite

InactiveCN103275448BImproved dimensional thermal stabilityImprove mechanical propertiesMechanical propertyAramid

The invention relates to a preparation method of a modified packing ion enhanced polytetrafluoroethylene composite. A matrix of the composite is polytetrafluoroethylene; filling ions comprise tetrapod-like zinc oxide whiskers, aramid fibers, glass fibers and nano titanium dioxide; the masses of the tetrapod-like zinc oxide whiskers, the aramid fibers, the glass fibers and nano titanium dioxide account for 10-12%, 5-7%, 3-4% and 2-3% of the mass of polytetrafluoroethylene powder; the polytetrafluoroethylene powder is in 120-150 meshes; the tetrapod-like zinc oxide whiskers are 12-14 micrometers in length; the diameters of roots of the tetrapod-like zinc oxide whiskers are 3-5 micrometers; the aramid fibers are 2-2.5mm in length; each monofilament is 8-10 micrometers in diameter; the glass fibers are glass fiber powder in 120-140 meshes; and the particle size of nano titanium dioxide is 15-30nm. The modified enhanced polytetrafluoroethylene composite has the advantages of high mechanical strength, good abrasive resistance, good thermal conductivity, lower linear expansion coefficient and excellent antistatic property, the mechanical properties and thermostability of the polytetrafluoroethylene composite are improved greatly, and the application field of the composite is further extended.

Owner:佛山市南海区明扬电线厂

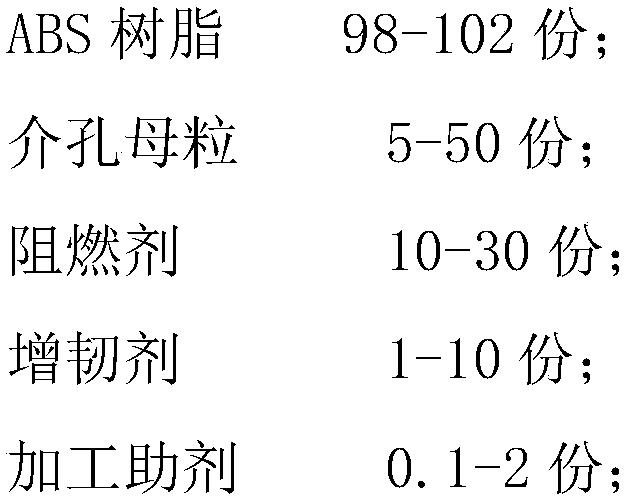

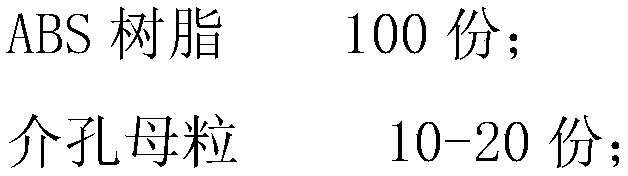

ABS composition and preparation method thereof

InactiveCN109517327AImprove adsorption capacityLarge specific surface areaElastomerIn situ polymerization

The invention relates to an ABS composition and a preparation method thereof. The ABS composition is prepared from the following raw materials in parts by weight: 98-102 parts of ABS resin, 5-50 partsof mesoporous masterbatch, 10-30 parts of a flame retardant, 1-10 parts of a flexibilizer and 0.1-2 parts of a processing aid. The mesoporous masterbatch is prepared from 50-99 parts of a vinyl aromatic hydrocarbon monomer, 1-50 parts of an unsaturated nitrile monomer, 1-40 parts of a solvent, 1-30 parts of a grafted elastomer, 0.001-0.1 part of an initiator, 0.01-0.08 part of a chain transfer agent and 5-20 parts of a mesoporous material through in-situ polymerization. The ABS composition has good flame retardance and mechanical properties.

Owner:GUANGDONG ALDEX NEW MATERIAL CO LTD

Preparation method of aluminum alloy composite material reinforced by filler particles

ActiveCN103290343BGood thermal propertiesImprove thermal conductivityAlloy compositeThermal expansion

The invention relates to the field of new materials and in particular relates to a preparation method of a filler particle enhanced aluminium alloy composite material. A cast aluminium alloy ZAlSi8MgBe is selected as a matrix alloy; filler particles include tetrapod-like zinc oxide whiskers, aramid fibers, glass fibers, nano titanium dioxide and silicon carbide, wherein the weights of tetrapod-like zinc oxide whiskers, aramid fibers, glass fiber, nano titanium dioxide and silicon carbide account for 6-8%, 4-5%, 3-4%, 1-2% and 2-3% of the mass of the cast aluminium alloy ZAlSi8MgBe, respectively; and all the filler particles are modified or pre-processed, and then stirred and cast with the matrix aluminium alloy, so that the filler particle enhanced aluminium alloy composite material is obtained. The aluminium alloy composite material prepared by using the preparation method disclosed by the invention is low in weight, high in specific strength and specific rigidity, low in coefficient of thermal expansion, and excellent in thermal conductivity and abrasive resistance, and further easy to prepare and low in cost; and the enhancement phase is dispersively distributed in the matrix and has isotropy; and therefore, the composite material is suitable for various complex stress states.

Owner:江阴戴勒姆动力设备有限公司

Resin/clay nano composite material and preparation process thereof

The invention relates to carbon dioxide based resin / layer silicate clay nm compounding material that could be biology degraded. The process includes the following steps: mixing the carbon dioxide based resin with layer silicate clay powder at the condition of certain temperature and rotating speed; extruding to grain under certain temperature and pressure. The benefit of the invention is that it could improve the mechanical property and thermal property of carbon dioxide based resin, and it has simple technology.

Owner:WUHAN UNIV OF TECH

Flame-retardant grafted composite elastic material and preparation method thereof

InactiveCN106750052AStrong interfacial interactionAvoid stress concentrationDimethyl formamideN-butyl acrylate

The invention discloses a flame-retardant grafted composite elastic material which is prepared from the following raw materials in parts by weight: 0.6-1 part of 8-hydroxyquinoline, 3-4 parts of 4-dimethylamino pyridine, 1-2 parts of triethylamine, 0.1-0.3 part of 2-bBromo-2-methylpropionyl bromide, 1-2 parts of sodium myrastate, 1-2 parts of 1-allyl-3methylimidazolium chloride, 50-60 parts of methyl methacrylate, 10-13 parts of carbon nanotubes, 40-51 parts of n-butyl acrylate, 0.7-1 part of copper bromide, 1.6-2 parts of pentamethyldiethylenetriamine, 1-2 parts of copper powder, 3-4 parts of allyl-polyethylene glycol, 1-2 parts of hydroxyl stearic acid, 2-3 parts of calcium fluoride, 2-4 parts of diisodecyl phthalate, 0.5-1 part of hexadecyl trimethyl ammonium chloride, 3-4 parts of water and zinc borate, 6-8 parts of tetrahydrofuran, a proper amount of ethylene glycol, a proper amount of dimethyl formamide, a proper amount of 95-98% nitric acid, a proper amount of chloroform, and a proper amount of thionyl chloride. Through the water, zinc borate, carbon nanotube and the like added, the flame-retardant performance of the finished material can be effectively enhanced, and the safety fireproof property of the finished product can be improved.

Owner:ANHUI HUAYU PIPELINE MFG

Coating agent and preparation method thereof

InactiveCN108516889AImprove fertilizer efficiencyGood chemical propertiesLayered/coated fertilisersFertilizer mixturesChemical industryControlled release

The invention discloses a coating agent and a preparation method thereof, and belongs to the field of chemical industry. The preparation method comprises the following steps: taking 6-13 parts of a sustained-release component complex, 5-10 parts of a disintegrant, 7-14 parts of a surfactant, 30-40 parts of deionized water, 8-15 parts of a polyurethane emulsion, 5-10 parts of tannin acid; stirringand mixing the above components at 20-25 DEG C, heating to 110-120 DEG C, carrying out heat insulation for 1.5-2h, cooling to 30-40 DEG C, adding the polyurethane emulsion and tannic acid, stirring and mixing, and cooling to 20-25 DEG C to obtain the coating agent. The problem that commonly used coating agents are difficult to degrade in the soil, will destroy the soil structure after long-term application and have poor controlled release effect is solved in the invention.

Owner:陈建峰

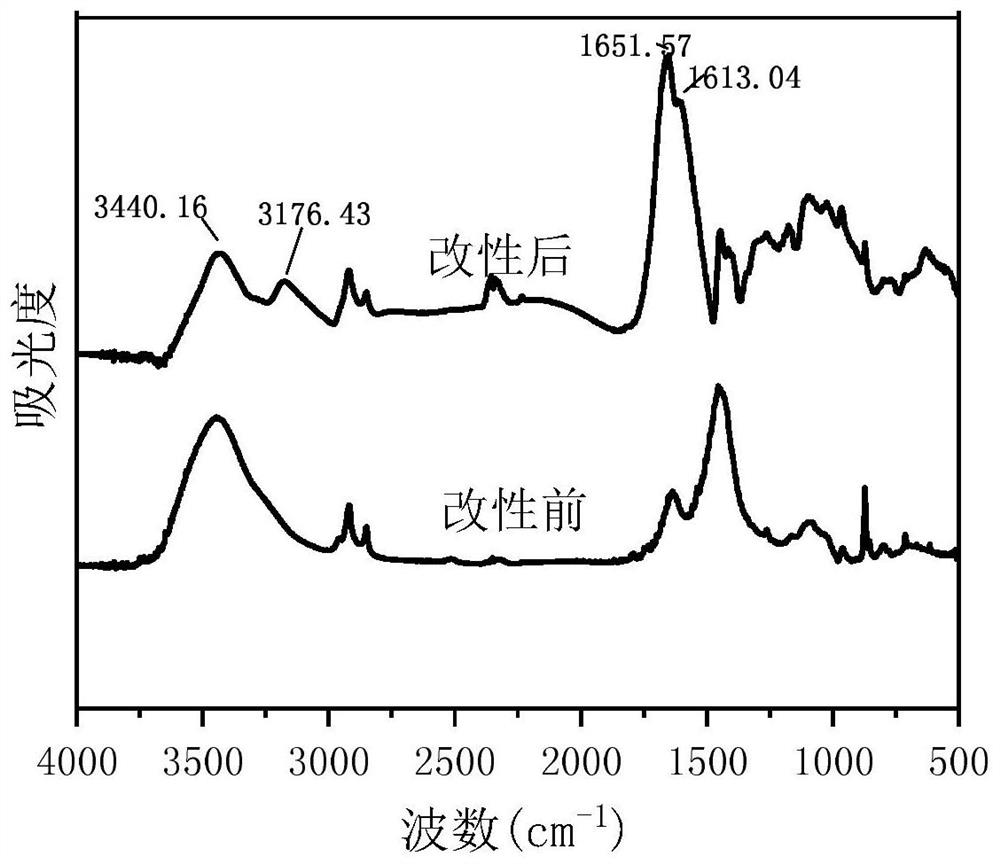

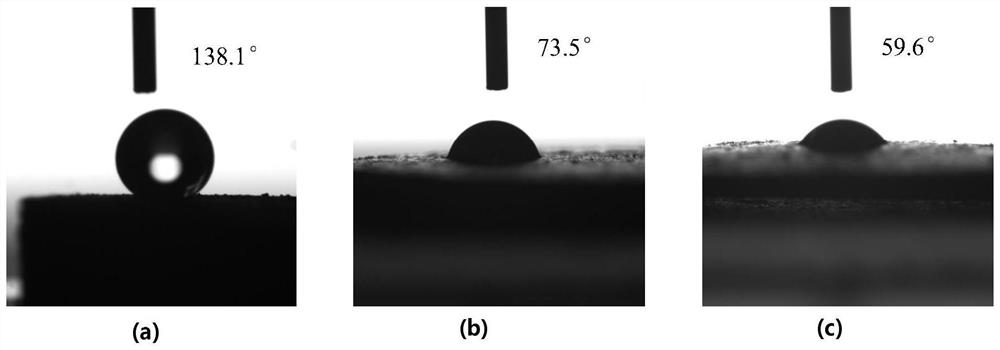

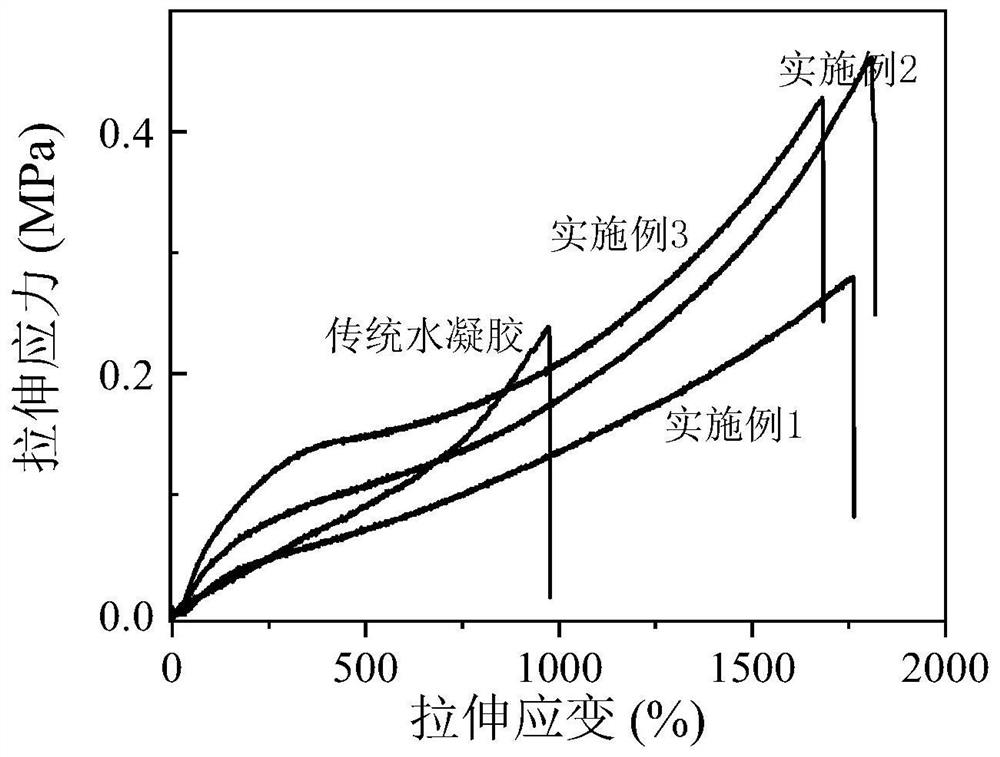

Hydrophilic waste rubber powder, high-strength composite hydrogel as well as preparation method and application thereof

ActiveCN113461866AStrong interfacial interactionImprove mechanical propertiesDrilling compositionHydrophilic monomerPolymer science

The invention discloses hydrophilic waste rubber powder, high-strength composite hydrogel as well as a preparation method and application thereof. The method comprises the following steps: introducing an initiator on the surface of waste rubber powder by adopting a solvent soaking method, and then initiating hydrophilic monomer polymerization by utilizing the initiator on the surface of the waste rubber powder, so the surface of the waste rubber powder has a hydrophilic polymer chain, and the hydrophilic waste rubber powder is obtained. The high-strength waste rubber powder composite polyacrylamide hydrogel is further prepared by using the waste rubber powder with high mechanical property as a reinforcing and toughening filler, and a hydrogel matrix and the waste rubber powder have strong physical entanglement interaction. The prepared high-strength composite hydrogel is expected to be used as an oil and gas field water shutoff agent.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com