Modified tin fluorphosphate glass/polypropylene hybrid material and preparing method thereof

A technology of tin fluorophosphate and hybrid materials, which is applied in the field of inorganic/organic hybrid materials and their preparation, and can solve problems such as the influence of hybrid materials performance, development limitations of tin fluorophosphate glass, and large surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

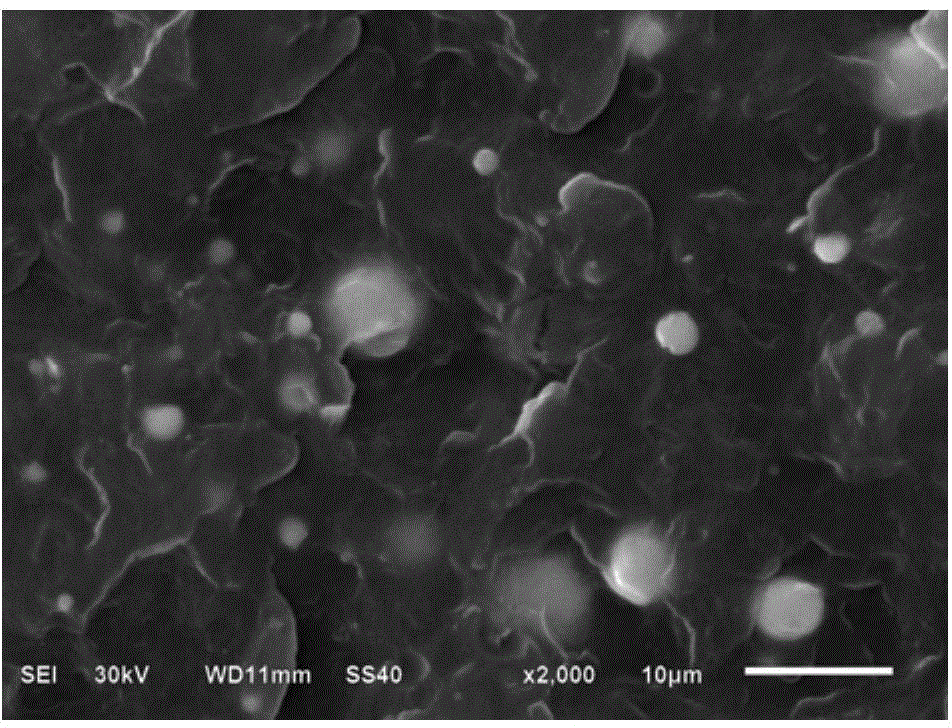

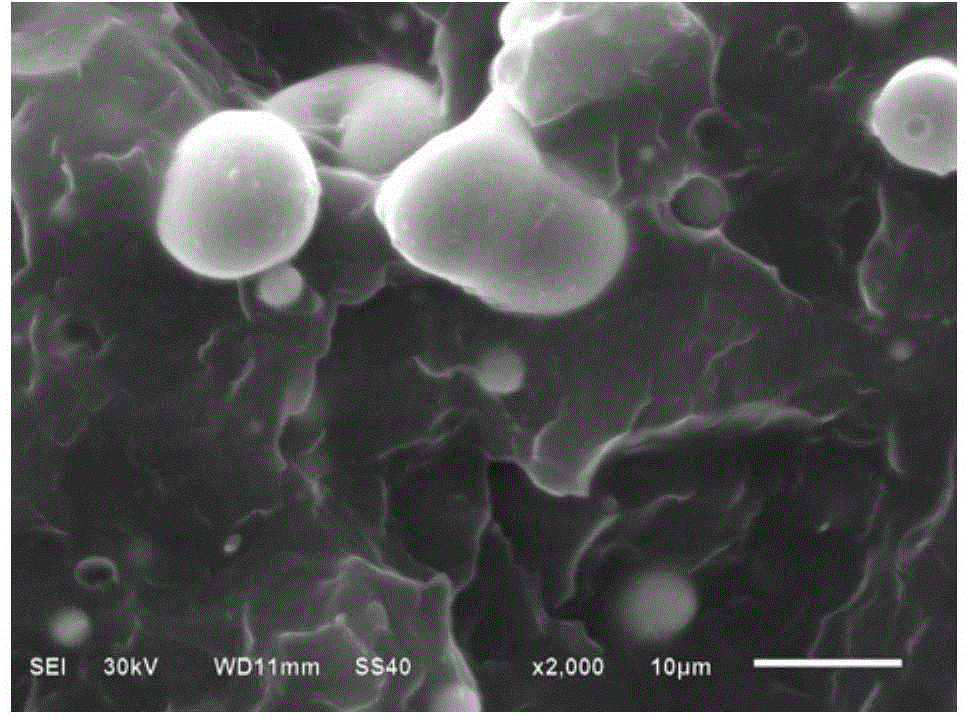

Image

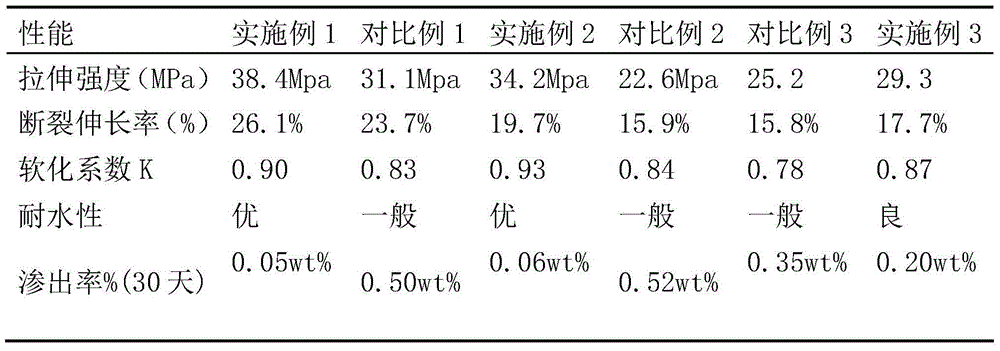

Examples

Embodiment 1

[0093] (1) Preparation of modified tin fluorophosphate glass:

[0094] Take 3 parts by weight of 5 wt% silane coupling agent KH-550 solution, mix it with 90 parts by weight of tin fluorophosphate glass, and keep stirring in a beaker heated by a water bath at 75°C. After fully stirring for 1 hour, put it into a blast drying oven at 90°C for 24 hours, grind and disperse.

[0095] (2) Preparation of modified polypropylene:

[0096] Weigh 100 parts by weight of PP powder, add 3.5 parts by weight of MAH, 0.2 parts by weight of DCP and 0.1 part by weight of AIBN, simply mix the weighed reagents and pour them into a high-speed mixer to start mixing. 2.5 parts by weight of styrene was slowly added dropwise to the sample being mixed. After the dropwise addition, keep the mixing state of the mixer for 5 minutes until all the reagents are mixed evenly, then add the mixture into the feeding barrel of the twin-screw extruder, melt and graft under the action of the initiator AIBN and DCP,...

Embodiment 2

[0100] 30 parts of modified tin fluorophosphate glass prepared in Example 1, 70 parts of modified polypropylene and 0.4 parts of tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol parts by weight are uniformly mixed, melted and blended by a micro-injection molding machine for 5 minutes, and extruded into injection molding to obtain a modified tin fluorophosphate glass / polypropylene hybrid material. Processing temperature: 190° C., the prepared sample is a dumbbell-shaped spline of 35×10×2 mm.

Embodiment 3

[0108] (1) Preparation of modified tin fluorophosphate glass:

[0109] Take 3 parts by weight of 5 wt% silane coupling agent KH-550 solution, mix it with 90 parts by weight of tin fluorophosphate glass, and keep stirring in a beaker heated by a water bath at 75°C. After fully stirring for 1 hour, put it into a blast drying oven at 90°C for 24 hours, grind and disperse.

[0110] (2) Preparation of modified polypropylene:

[0111] Weigh 100 parts by weight of PP powder, add 6.5 parts by weight of MAH, 0.2 parts by weight of DCP and 0.1 part by weight of AIBN, briefly mix the weighed reagents and pour them into a high-speed mixer to start mixing. Keep the mixing state of the mixer for 5 minutes until all the reagents are mixed evenly, then add the mixture into the feeding barrel of the twin-screw extruder, melt and graft under the action of the initiator AIBN and DCP, and extrude to pelletize. Dry the prepared sample pellets. The graft ratio of maleic anhydride was 6.2%.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com