Nanometer composite heat-insulating material and preparation method thereof

A thermal insulation material and nano-composite technology, applied in the field of thermal insulation materials, can solve problems such as poor adhesion of aluminum foil, easy to fall off, affect the application, etc., and achieve the effects of small thermal conductivity, improved thermal insulation performance, and strong interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

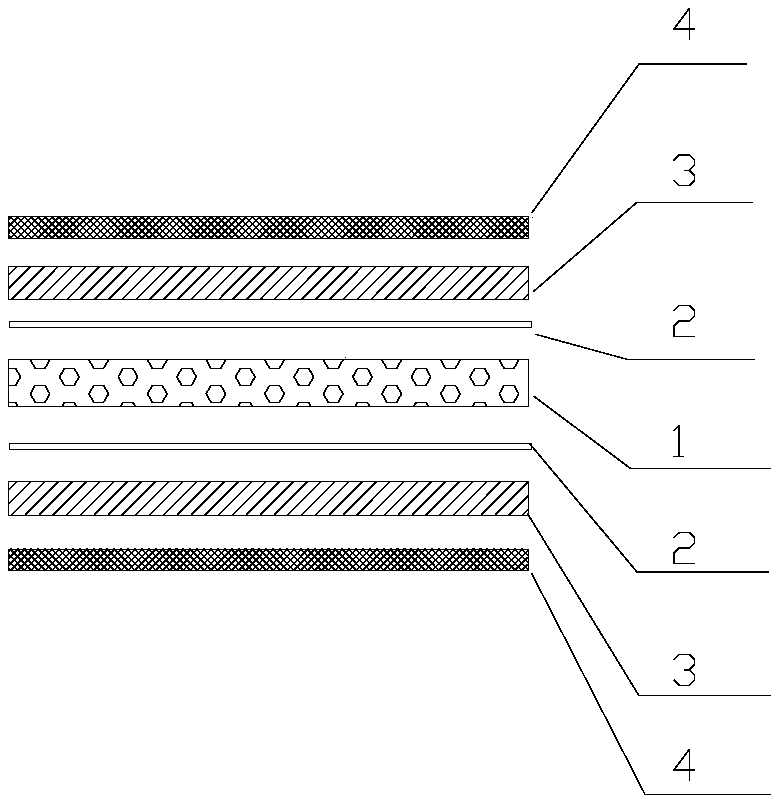

[0036] A nanocomposite heat insulation material, comprising an airgel layer 4, an aluminum foil layer 3, a flame-retardant adhesive layer 2, an air-resistant bubble layer 1, a flame-retardant adhesive layer 2, an aluminum foil layer 3, and an airgel layer 4. Among them, the airgel layer 4 is made of the following components by weight: 10 parts of silica-phenolic resin composite airgel, 25 parts of propylene oxide, 100 parts of acetic acid, 60 parts of polyethylene glycol 600 , 20 parts formamide, 25 parts toluene diisocyanate (TDI) trimer, 12 parts isophorone diisocyanate (IPDI) trimer.

[0037] The preparation method of the above-mentioned nanocomposite heat insulating material is as follows:

[0038] 1) Material preparation of the airgel layer:

[0039]Mix 25 parts of propylene oxide, 100 parts of acetic acid, 60 parts of polyethylene glycol 600, and 20 parts of formamide with a high-speed micro-powder mixer for 5-10 minutes, adjust the solvent temperature to 5-8 degrees; a...

Embodiment 2

[0050] A nanocomposite heat insulation material, comprising an airgel layer 4, an aluminum foil layer 3, a flame-retardant adhesive layer 2, an air-resistant bubble layer 1, a flame-retardant adhesive layer 2, an aluminum foil layer 3, and an airgel layer 4. Among them, the airgel layer 4 is made of components comprising the following parts by weight: 5 parts of silica-phenolic resin composite airgel, 20 parts of propylene oxide, 80 parts of acetic acid, 50 parts of polyethylene glycol 600 , 10 parts formamide, 20 parts toluene diisocyanate (TDI) trimer, 10 parts isophorone diisocyanate (IPDI) trimer.

[0051] The preparation method of the above-mentioned nanocomposite heat insulating material is as follows:

[0052] 1) Material preparation of the airgel layer:

[0053] Stir 20 parts of propylene oxide, 80 parts of acetic acid, 50 parts of polyethylene glycol 600, and 10 parts of formamide with a high-speed micro-powder mixer for 5-10 minutes, adjust the solvent temperature t...

Embodiment 3

[0064] A nanocomposite heat insulation material, comprising an airgel layer 4, an aluminum foil layer 3, a flame-retardant adhesive layer 2, an air-resistant bubble layer 1, a flame-retardant adhesive layer 2, an aluminum foil layer 3, and an airgel layer 4. Among them, the airgel layer 4 is made of the following components by weight: 20 parts of silica-phenolic resin composite airgel, 30 parts of propylene oxide, 130 parts of acetic acid, 70 parts of polyethylene glycol 600 , 30 parts formamide, 30 parts toluene diisocyanate (TDI) trimer, 15 parts isophorone diisocyanate (IPDI) trimer.

[0065] The preparation method of the above-mentioned nanocomposite heat insulating material is as follows:

[0066] 1) Material preparation of the airgel layer:

[0067] Stir 30 parts of propylene oxide, 130 parts of acetic acid, 70 parts of polyethylene glycol 600, and 30 parts of formamide with a high-speed micro-powder mixer for 5-10 minutes, adjust the solvent temperature to 5-8 degrees;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com