ABS composition and preparation method thereof

A composition and in-situ polymerization technology, applied in the field of materials, can solve the problems of not being able to exert the characteristics of mesoporous materials, and achieve the effect of not being easily distorted and deformed, and blocking air

- Summary

- Abstract

- Description

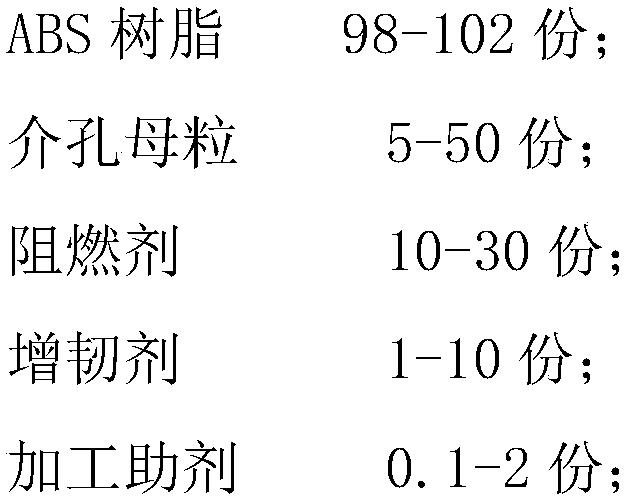

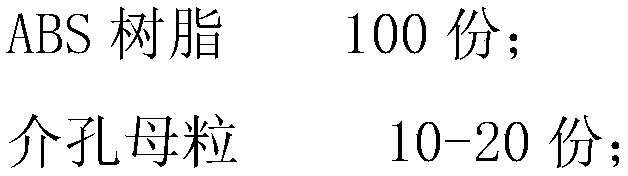

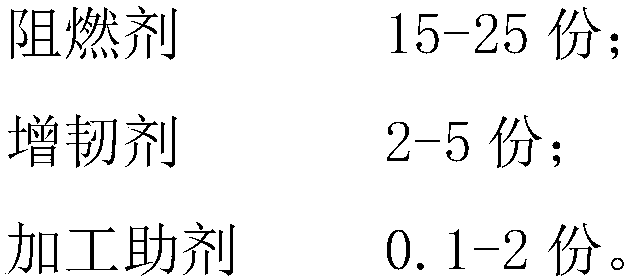

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1: Preparation of mesoporous masterbatch

[0047] Add 63 parts of styrene, 20 parts of polybutadiene rubber, and 10 parts of SBA-15 into a continuous stirring stainless steel kettle, stir and dissolve at room temperature, and disperse ultrasonically; then add 17 parts of acrylonitrile, 0.06 parts of hydrogen peroxide iso Propylbenzene, 20 parts of ethylbenzene, 0.02 parts of n-dodecylmercaptan continue to stir and disperse; control system pressure to 0.25MPa, reaction temperature to 90°C, stirring speed to 250r / min, react for 5 hours, in the first reaction After the polymerization reaction in the container is completed, it is transferred to the second deep reactor to continue the reaction. The control system pressure is 0.25MPa, the reaction temperature is 160°C, the stirring rate is 250r / min, and the reaction is 6 hours; the reaction melt is devolatilized, Granulating to obtain mesoporous masterbatch.

[0048] The temperature of the above-mentioned first re...

Embodiment 2-6、 comparative example 1-4

[0049] Embodiment 2-6, comparative example 1-4: the preparation of ABS composition

[0050] Embodiment 2-6, the raw material composition of comparative example 1-4, in parts by weight, specifically as shown in Table 1:

[0051] Table 1

[0052]

[0053] The above-mentioned ABS resin selects the acrylonitrile-butadiene-styrene copolymer of Taiwan Chemical Fiber Co., Ltd; Select the chlorinated polyethylene of Weifang Yaxing Group Co., Ltd. for use; Described antioxidant selects the beta-(4-hydroxyphenyl-3,5-di-tert-butyl) n-octadecyl propionate and phosphorous acid of Switzerland Ciba company Tris(2,4-di-tert-butylphenyl) ester, the mass ratio is 2:1; the lubricant is selected from the pentylenetetyl stearate of LONZA Company of the United States.

[0054] The preparation method of above-mentioned ABS composition is as follows:

[0055] (1) Stir the ABS resin, mesoporous masterbatch, flame retardant, toughening agent, and processing aid at high speed to obtain a mixture; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com