Graphene/molecular sieve/metal oxide composite catalyst and preparation method thereof

A composite catalyst and graphene technology, which is applied in the direction of molecular sieve catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of preparation that have not been reported, achieve excellent performance, and expand the effect of application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] In this example, mesoporous ZSM-5 / graphene composites were prepared in the following manner, and the steps are as follows.

[0072]Weigh 120 mg of graphene, add 6 ml of deionized water, ultrasonically disperse evenly, weigh 1 g of tetrapropylammonium hydroxide and add it to the graphene aqueous solution, stir for 30 min to mix evenly, and record it as A solution; Add 60 mg of aluminum isopropoxide and 2 ml of tetraethyl orthosilicate in turn and stir evenly, and record it as solution B; firstly stir solution B at 30°C for 1 h, then raise the temperature to 90°C and stir for 24 h; then use this solution B with After repeated washing with ethanol and deionized water for 2 to 3 times, it was transferred to a polytetrafluoroethylene-lined autoclave for crystallization at 180 °C for 3 days to obtain ZSM-a / graphene composites. After the product was washed with ethanol and deionized water for 3–5 times, it was vacuum-dried at 100 °C for 12 h, calcined at 600 °C for 5 h, and th...

Embodiment 2

[0074] This example prepares Co in the following manner 3 o 4 / ZSM-5 / graphene composite, the steps are as follows.

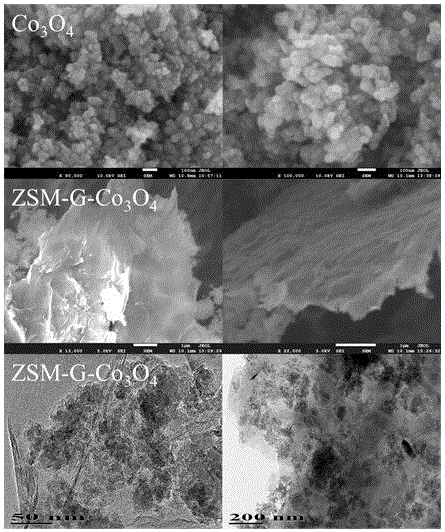

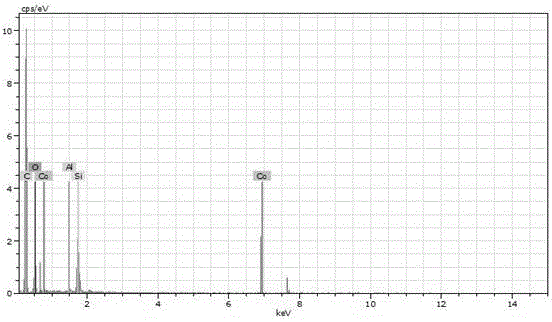

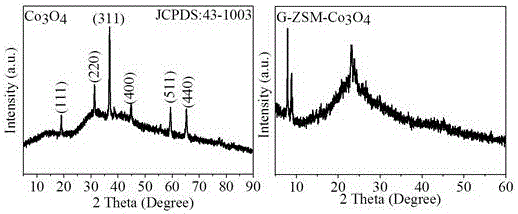

[0075] Take by weighing 50 mg of ZSM-5 / graphene prepared in Example 1, add 10 g of water and 6 g of ethanol for ultrasonic dispersion, then slowly add dropwise 3 ml of ethanol solution containing 0.02 gTPHAC (drop rate 2 ml / min), after stirring for 5 h, slowly add 1 ml (0.03 M) of Co(NO 3 ) 2 solution, then continued to stir for 2 h, and finally slowly added 1 ml (1.2M) of NH 3 h 2 O solution, stirred for 12 h, centrifuged and washed several times until the effluent was close to neutral, dried in vacuum at 60 °C for 12 h, and finally calcined at 500 °C for 3 h to obtain Co 3 o 4 / ZSM-5 / Graphene. Its SEM and TEM photos are attached figure 1 , EDS results see figure 2 And table 1, XRD result sees image 3 , XPS results see Figure 4 , the results of electrocatalytic oxidation of methanol are shown in Figure 5 .

[0076] Table 1

[0077] .

Embodiment 3

[0079] Take by weighing 50 mg of ZSM-5 / graphene prepared in Example 1, add 20 g water and 12 g ethanol ultrasonic dispersion, and then slowly add dropwise the ethanol solution 6 ml containing 0.04 g TPHAC (drop rate 2 ml / min), after stirring continuously for 5h, slowly add 2 ml (0.03 M) of Co(NO 3 ) 2 solution, then continued to stir for 2 h, and finally slowly added 2 ml (1.2 M) of NH 3 h 2 O solution, stirred for 12 h, centrifuged and washed several times until the effluent was close to neutral, dried in vacuum at 60 °C for 12 h, and finally calcined at 500 °C for 3 h to obtain Co 3 o 4 / ZSM-5 / Graphene. The results of electrocatalytic oxidation of methanol are shown in Figure 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com