Method for catalytic preparation of resorcinol by using multi-component composite metal oxide catalyst

A composite metal and resorcinol technology, which is applied in metal/metal oxide/metal hydroxide catalyst, catalyst activation/preparation, peroxygen compound preparation, etc., can solve the problems of low yield and many by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1 NiO-MgO-Pt three-way composite catalyst

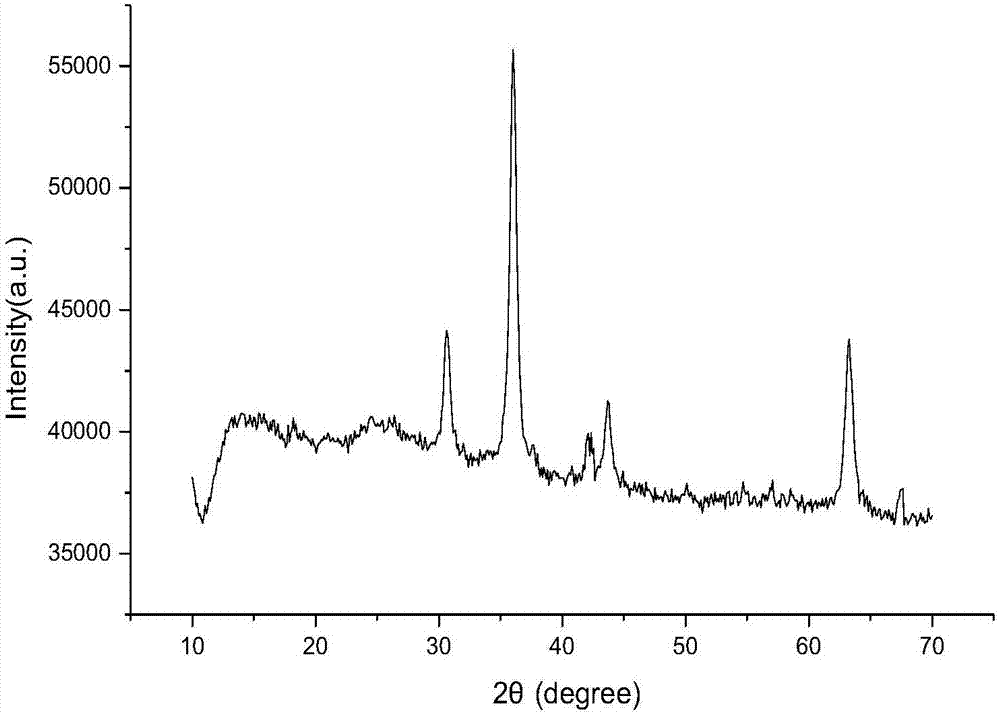

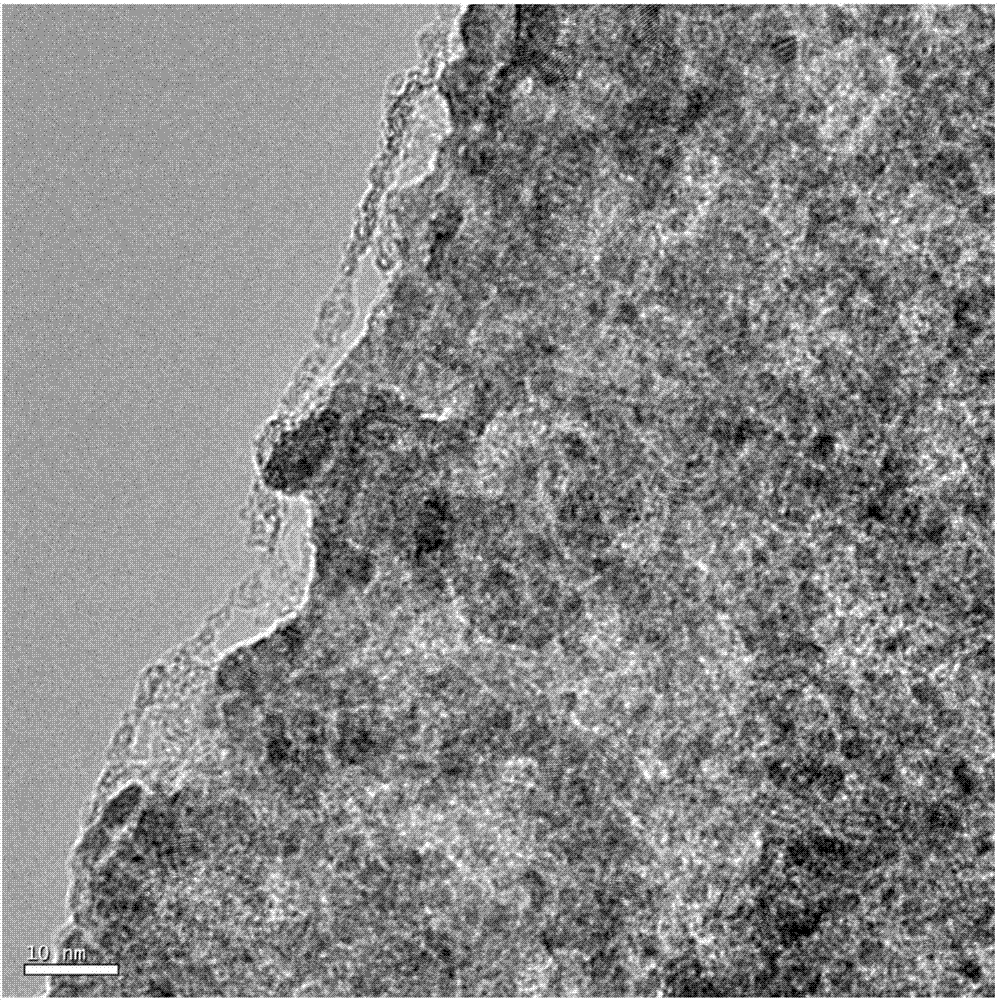

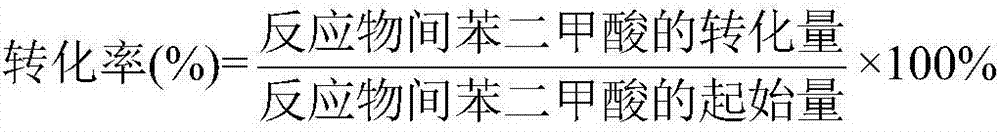

[0050] Weigh 47.9340g Ni(NO 3 ) 2 ·6H 2 O and 3.4965g Mg(NO 3 ) 2 ·2H 2 O is dissolved in deionized water, and concentrated ammonia is added dropwise while stirring to adjust the pH to about 9.5. Filtration, drying at room temperature for 10 hours, and drying at 80°C for 12 hours; the obtained solid is heated to 600°C and calcined for 5 hours to obtain a binary composite oxide. Weigh 4.2870g of the above-mentioned NiO-MgO binary composite catalyst oxide, immerse it in an equal volume of chloroplatinic acid solution with a concentration of 0.01g / mL, dry, roast it in the air at 600℃ for 5h, and then add it to the nitrogen and hydrogen mixture. (The ratio of nitrogen to hydrogen is 1:1) NiO-MgO-Pt three-way composite catalyst was reduced at 180℃. The structure of the obtained NiO-MgO-Pt three-way composite catalyst is characterized as Figure 1~2 As shown, Figure 1~2 It can be seen that the particle size of platinum is 1...

Embodiment 2

[0060] Example 2 NiO-MgO-Pd three-way composite catalyst

[0061] This example is the same as Example 1, except that the NiO-MgO binary composite oxide is immersed in a palladium chloride solution with an equal volume concentration of 0.01 g / mL to obtain a NiO-MgO-Pd ternary composite catalyst.

[0062] The catalytic effect of the catalyst is as follows: the conversion rate of isophthalic acid is 93%, the selectivity of resorcinol is 31%, and the yield is 28.83%.

Embodiment 3

[0063] Example 3 NiO-Fe 2 O 3 -Pt three-way composite catalyst

[0064] Weigh 31.9560g Ni(NO 3 ) 2 ·6H 2 O and 10.1196g Fe(NO 3 ) 3 ·9H 2 O is dissolved in deionized water, and concentrated ammonia is added dropwise while stirring to adjust the pH to about 9.4. Filtration, drying at room temperature for 10 hours, and drying at 80°C for 12 hours; the obtained solid is heated to 600°C and calcined for 5 hours to obtain a binary composite oxide. Weigh 5.1038g of the above NiO-Fe 2 O 3 Binary composite oxide, immersed in an equal volume of 0.01g / mL chloroplatinic acid solution, dried, calcined in air at 600℃ for 5h, and then mixed with nitrogen and hydrogen (the ratio of nitrogen to hydrogen is 1:1) NiO-Fe reduced at 180℃ 2 O 3 -Pt three-way composite catalyst.

[0065] The application method of the catalyst in the catalytic oxidative decarboxylation reaction of isophthalic acid is the same as that of Example 1, except that the decomposition temperature is 190°C.

[0066] The catalytic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com