Hyaluronic acid/polyacrylonitrile compound film, method for preparing same and application thereof

A technology of polyacrylonitrile-based membrane and hyaluronic acid, which is applied in the direction of semipermeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problems of few reports and no reports, and achieve simple preparation method and improved phase Satisfied effect of capacitive and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

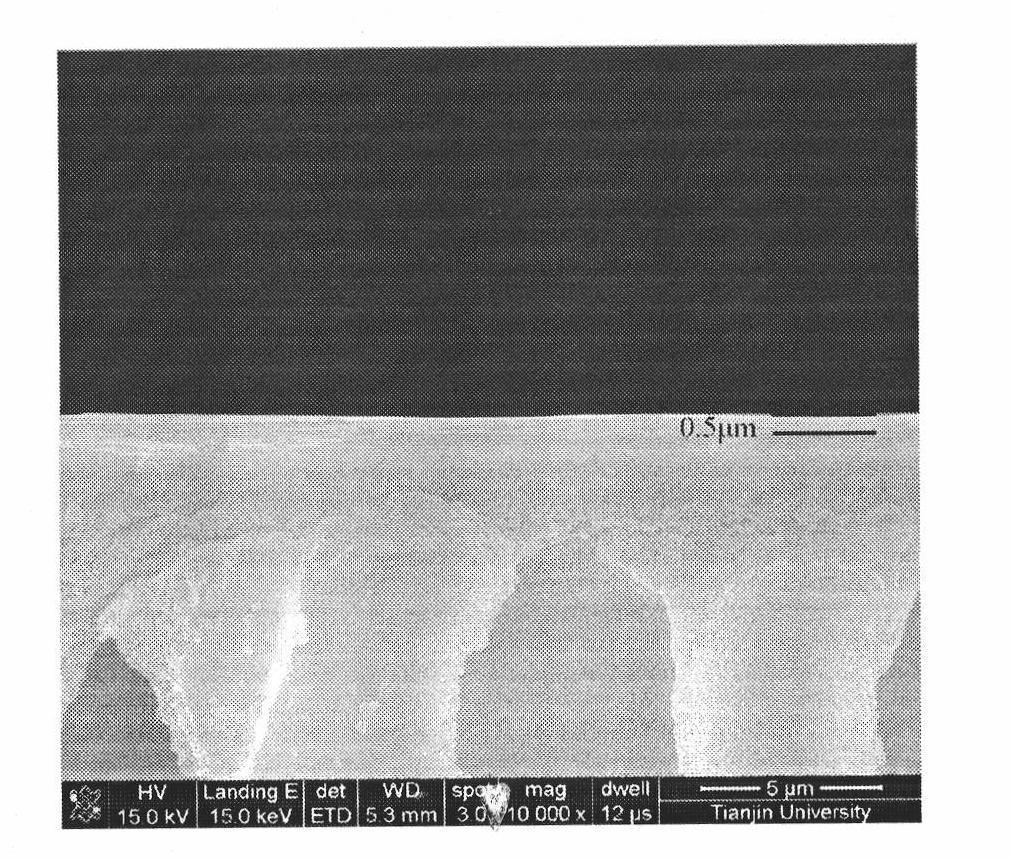

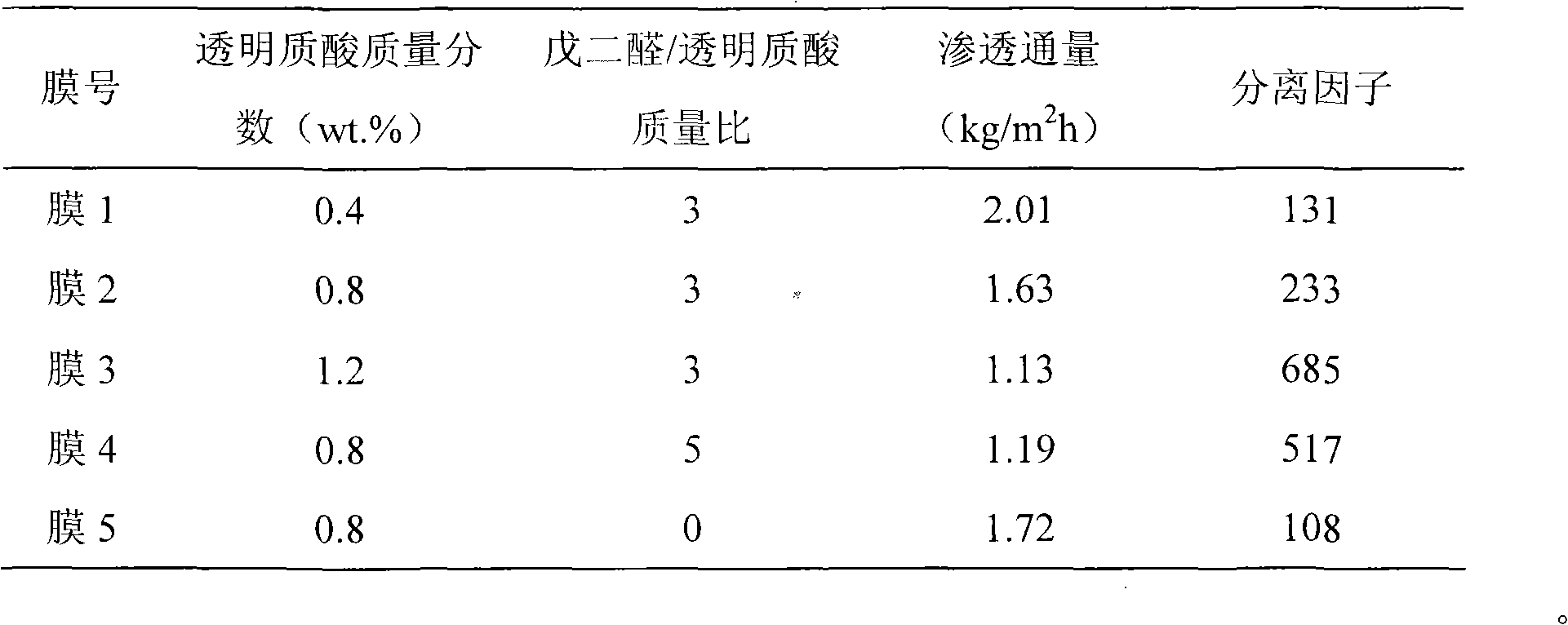

[0020] (1) Modification of polyacrylonitrile-based membrane: Soak a polyacrylonitrile-based membrane (Shanghai Lanjing Membrane Technology Co., Ltd., PAN10w, pore size range 20-50nm) with a size of 10cm×10cm in deionized water for 1 day to remove the membrane Glycerol on the surface, then soaked in 2M sodium hydroxide solution, soaked at 50 ° C for 1h, during this process, the cyano group on the polyacrylonitrile was hydrolyzed into carboxyl group, the color of the basement film turned orange, and then 0.1M After repeated washing with hydrochloric acid solution and deionized water, the color of the basement membrane turned yellow, and was air-dried. (2) Preparation of casting solution: 0.2g of hyaluronic acid with a viscosity-average molecular weight of 120w Da was dissolved in 50g of deionized water, stirred rapidly to make it completely dissolved, and prepared into 0.4wt.% hyaluronic acid solution, and then Add 0.6g of 2.5wt.% glutaraldehyde cross-linking agent, and slowly a...

Embodiment 2

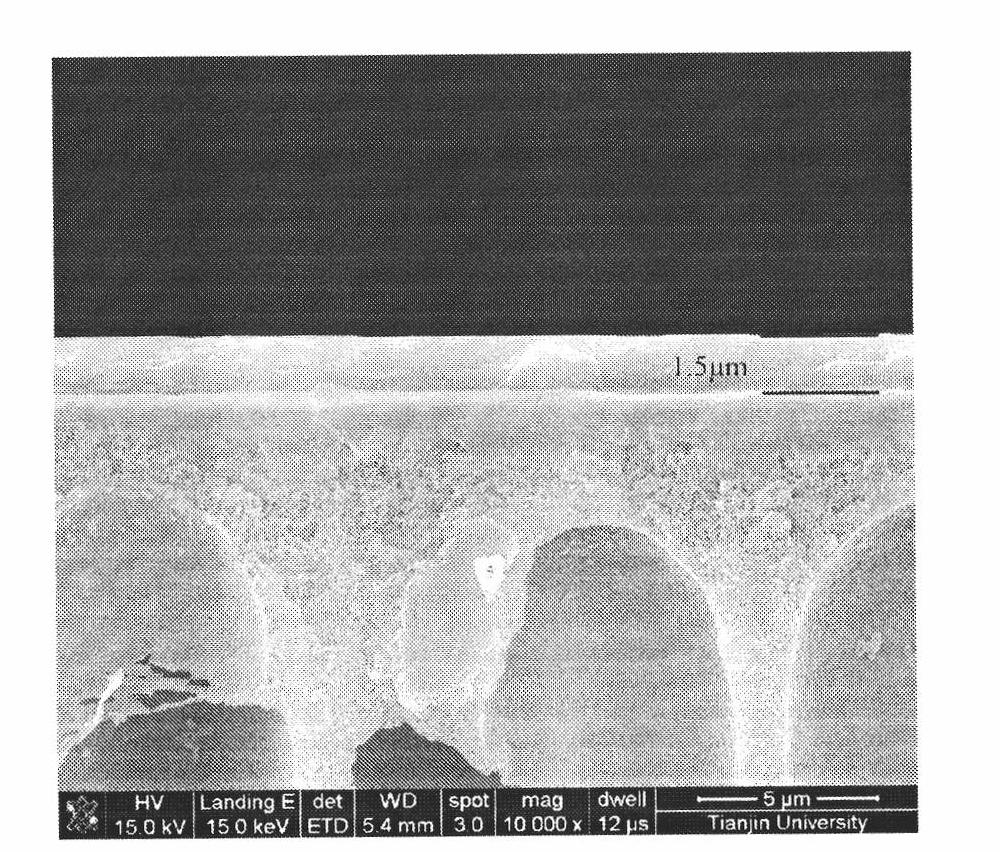

[0022] (1) Modification of polyacrylonitrile-based membrane: the steps are the same as shown in Example 1. (2) Preparation of casting solution: 0.4g of hyaluronic acid with a viscosity-average molecular weight of 120w Da was dissolved in 50g of deionized water, stirred rapidly to make it completely dissolved, and prepared into 0.8wt.% hyaluronic acid solution, and then Add 1.2g of 2.5wt.% glutaraldehyde crosslinking agent, and slowly add 0.01M hydrochloric acid dropwise to adjust the pH, control the pH test paper to make it between 3-5, stir for 1h, and let the resulting gel stand overnight. (3) Preparation of composite film: the steps are the same as those shown in Example 1 (film 2).

Embodiment 3

[0024] (1) Modification of polyacrylonitrile-based membrane: the steps are the same as shown in Example 1. (2) Preparation of casting solution: 0.6g of hyaluronic acid with a viscosity-average molecular weight of 120wDa was dissolved in 50g of deionized water, stirred rapidly to make it completely dissolved, prepared into 1.2wt.% hyaluronic acid solution, and then added 1.8g 2.5wt.% glutaraldehyde crosslinking agent, slowly add 0.01M hydrochloric acid dropwise to adjust the pH, control the pH test paper to make it between 3-5, stir for 1h, and let the resulting gel stand overnight . (3) Preparation of composite film: the steps are the same as those shown in Example 1 (film 3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com