Medical anti-adhesion hydrogel dressing and preparation method thereof

A hydrogel and anti-adhesive technology, applied in medical science, bandages, absorbent pads, etc., can solve the problems of easy growth of new granulation tissue on the wound surface, large pores of foam dressings that are not suitable for loading drugs or slow-release treatment of growth factors, and achieve Accelerates wound healing, avoids trauma or infection, and has the effect of simple types of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

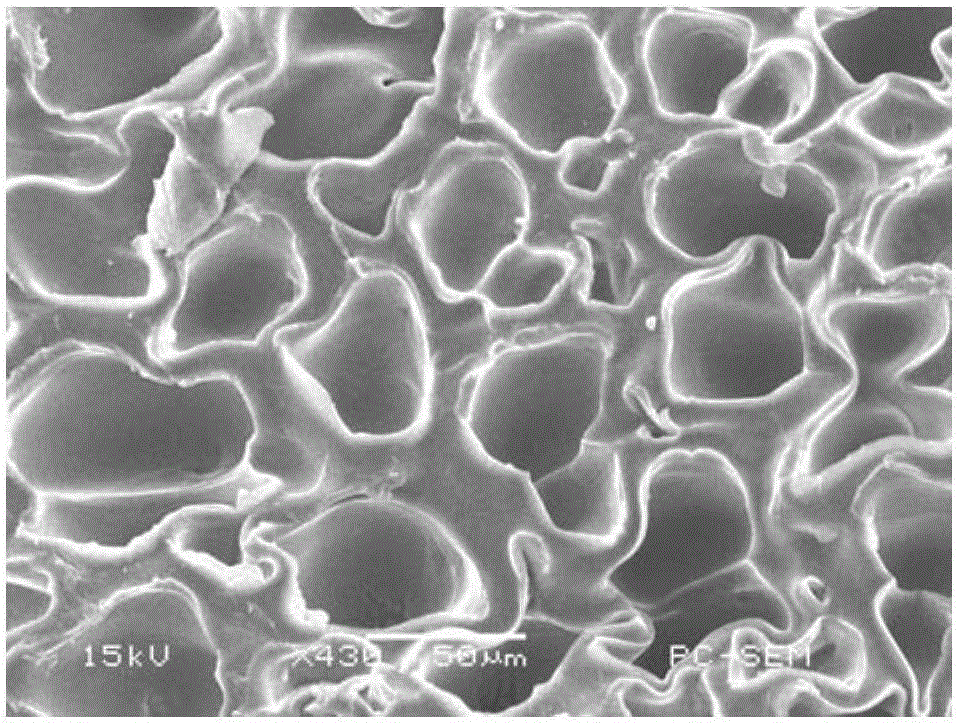

[0030] A kind of preparation method of medical anti-adhesive hydrogel dressing is as follows: use methyl methacrylate monomer as polymerization raw material, take polyethylene glycol tetraacrylate as crosslinking agent, ammonium persulfate as thermal initiator, with following weight Mixing ratio: 23% methyl methacrylate, 9% polyethylene glycol tetraacrylate, 67% water, 1% ammonium sulfate, after mixing evenly, pour into the mold, heat at 65°C for 12 hours, polymerize and crosslink to obtain transparency Hydrogel material, after cleaning and freeze-drying, a hydrogel with a micro-porous structure is obtained. The prepared hydrogel is not adhered to the wound, has strong hydrophilicity, and can quickly absorb water. The average swelling rate is 408%. The wound is moist and has good elasticity, and has a rich micro-porous structure with a pore diameter of 20 μm to 100 μm, such as figure 1 shown.

Embodiment 2

[0032] A kind of preparation method of medical antisticking hydrogel dressing is as follows: use butyl methacrylate monomer as polymerization raw material, take polyethylene glycol divinyl sulfone as crosslinking agent, 2-hydroxyl-4'-(2-hydroxyl Ethoxyl)-2-methylpropiophenone is used as a photoinitiator, mixed with the following weight ratio: butyl methacrylate 32%, polyethylene glycol divinyl sulfone 10%, water 57%, 2-hydroxyl-4 '-(2-hydroxyethoxy)-2-methylpropiophenone 1%, after mixing evenly, pour into the mold, and initiate cross-linking and polymerization under ultraviolet light with a wavelength of 320-400nm and a light intensity of 800uv / cm3 for 15-60 minutes , polymerized and cross-linked to obtain a hydrogel material, and after washing and freeze-drying, a hydrogel with a micro-porous structure was obtained. The prepared hydrogel was tested by experiments without sticking to the wound, with strong hydrophilicity, fast absorption of water, and an average swelling rate ...

Embodiment 3

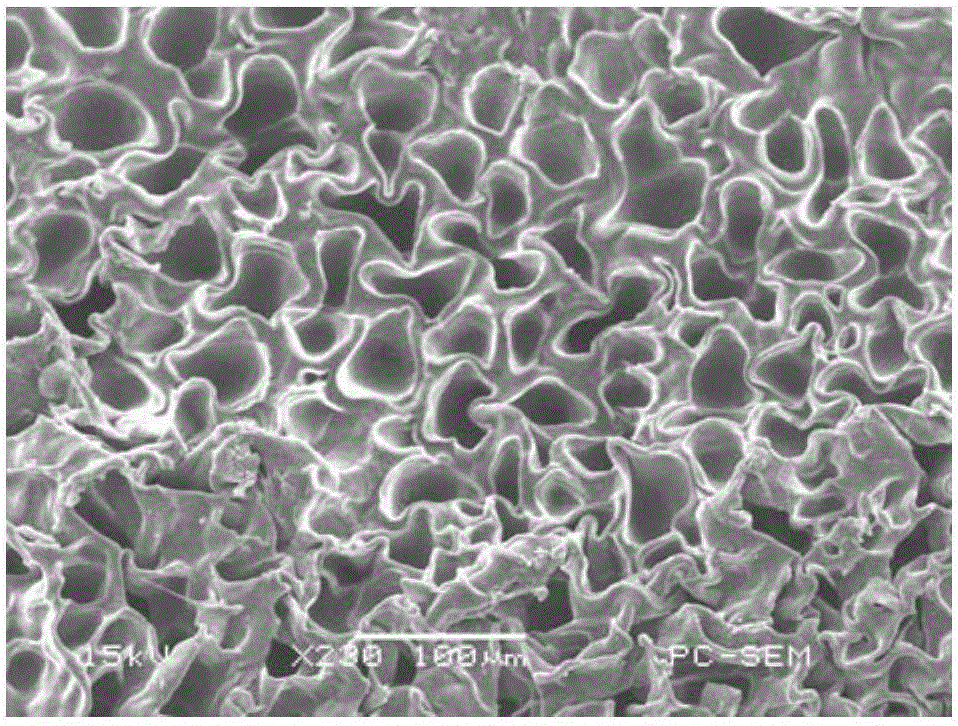

[0034]A preparation method of a medical anti-adhesive hydrogel dressing is as follows: use hydroxyethyl methacrylate monomer as a polymerization raw material, polyethylene glycol dimethacrylate as a crosslinking agent, ammonium persulfate as a thermal initiator, and Mix in the following weight ratio: 20% hydroxyethyl methacrylate, 20% polyethylene glycol dimethacrylate, 59.5% water, 0.05% ammonium sulfate, after mixing evenly, pour into the mold, heat at 65°C for 24 hours, Polymerization and cross-linking to obtain a transparent hydrogel material, washing and freeze-drying to obtain a micro-porous hydrogel material, the prepared hydrogel has been tested by experiments without sticking to the wound, has strong hydrophilicity, can quickly absorb water, and has an average swelling rate of 724%, keep the wound moist, and have good elasticity, with rich micro-porous structure, such as figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com