Hydrophilic waste rubber powder, high-strength composite hydrogel as well as preparation method and application thereof

A technology of composite hydrogel and waste rubber powder, which is applied in the preparation of hydrophilic waste rubber powder and the preparation of high-strength composite hydrogel based on hydrophilic waste rubber powder, which can solve the problems of poor compatibility and achieve mechanical properties Improvement, excellent mechanical properties, and highlight the effect of environmental protection contribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

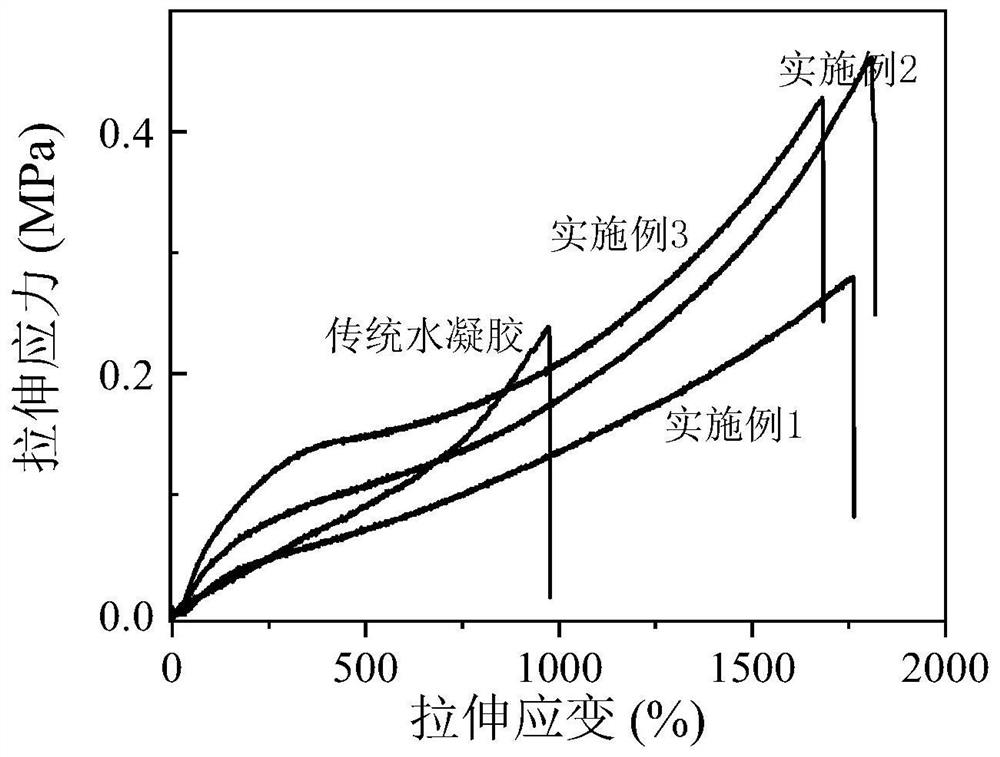

Examples

Embodiment A-G

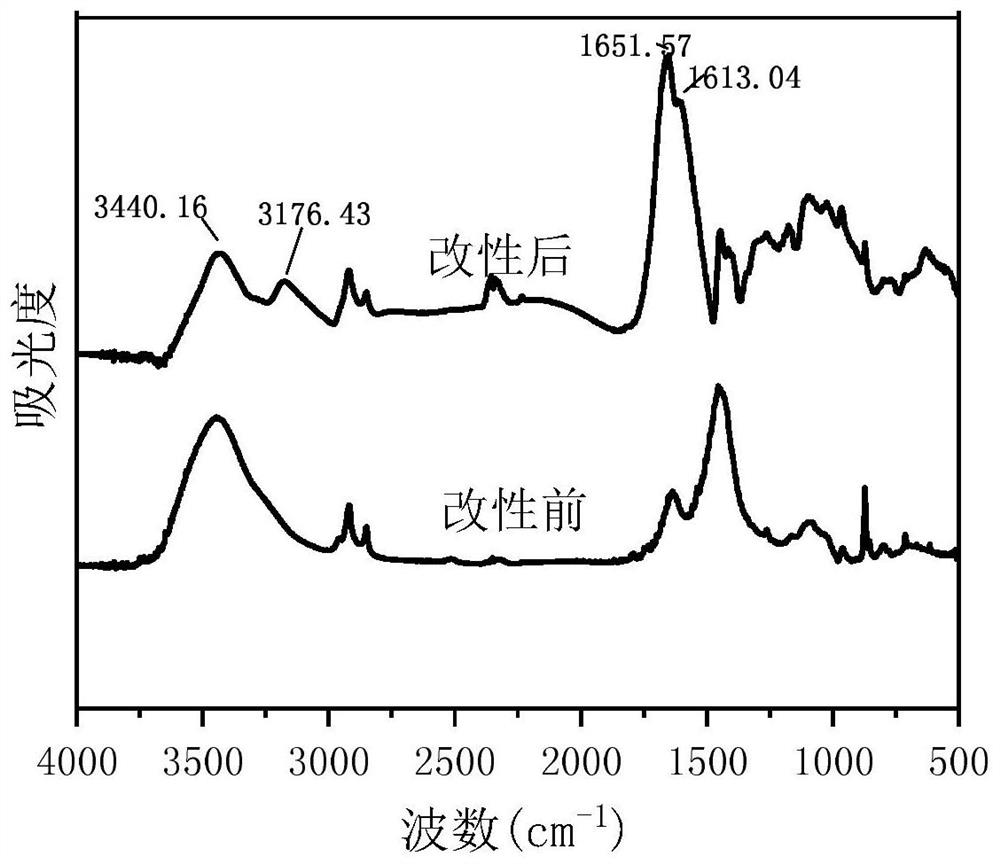

[0032] Embodiment A-G: Preparation of hydrophilic modified waste rubber powder

[0033] The cleaning method of the waste rubber powder in Examples A-G is as follows: the crushed and sieved waste rubber powder with a mesh number of 50-300 is washed with acetone until the color of the lotion is clear and transparent, and then dried in a blast oven at 50°C for later use .

Embodiment A

[0035] The waste rubber used in this embodiment is nitrile rubber.

[0036] The preparation method of hydrophilic waste rubber powder provided by the present embodiment comprises the following:

[0037] (1) Weigh 0.005 parts of clean waste rubber powder with a mesh number of 150, mix and stir with 1 part of toluene, then add 0.01 parts of benzoyl peroxide, stir at room temperature for 12 hours, and then filter the resulting mixture to obtain surface-rich The waste rubber powder of the initiator;

[0038] (2) Add 0.05 parts of the treated waste rubber powder and 100 parts of distilled water into the container in sequence, stir for 12 hours, then inject nitrogen into the container for 10 minutes, add 0.01 parts of acrylamide, and then place it in a water bath at 60°C for 6 hours after stirring; Obtain a reaction solution containing hydrophilic waste rubber powder; filter the obtained reaction solution, wash the filtered product with a large amount of water to remove impurities,...

Embodiment B

[0040]The waste rubber used in this embodiment is nitrile rubber.

[0041] The preparation method of hydrophilic waste rubber powder provided by the present embodiment comprises the following:

[0042] (1) Weigh 0.05 parts of clean waste rubber powder with a mesh number of 150, mix and stir with 1 part of toluene, then add 0.06 parts of benzoyl peroxide, stir at room temperature for 24 hours, and then filter the resulting mixture to obtain a surface rich in The waste rubber powder of the initiator;

[0043] (2) Add 0.05 parts of the treated waste rubber powder and 100 parts of distilled water into the container in turn, stir for 12 hours, then inject nitrogen gas into the container for 13 minutes, add 0.1 parts of acrylamide, and then place it in a water bath at 60°C for 6 hours and stir to react. Obtain a reaction solution containing hydrophilic waste rubber powder; filter the obtained reaction solution, wash the filtered product with a large amount of water to remove impuri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com