Thin film packaging structure and organic electroluminescent device

A thin-film encapsulation, organic technology, applied in circuits, electrical components, electrical solid-state devices, etc., can solve the problems of poor encapsulation effect of thin-film encapsulation materials, and achieve the effect of low density, many functional groups, and large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

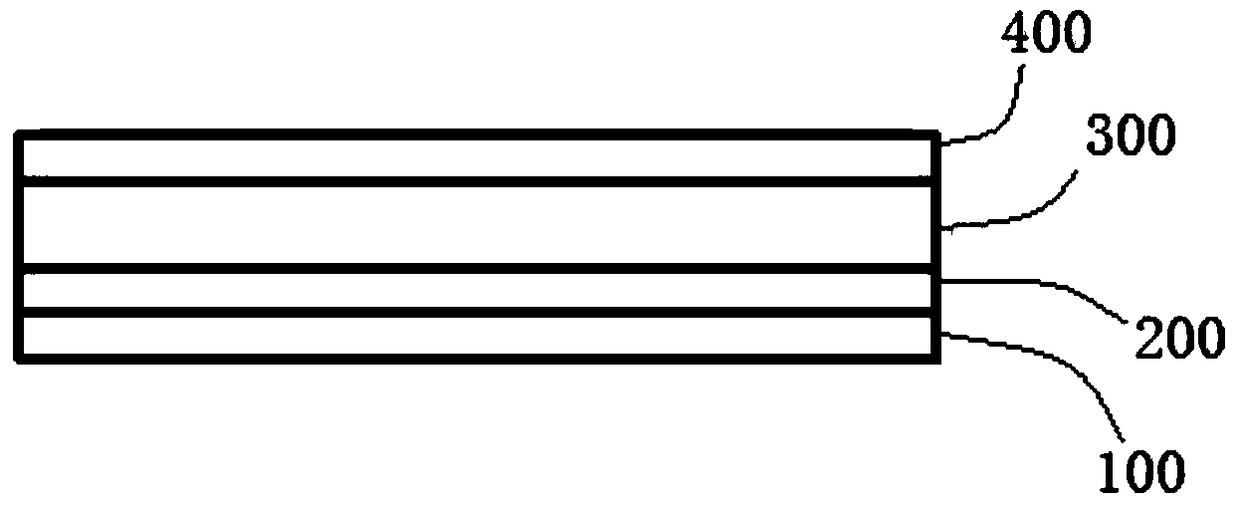

[0025] As mentioned in the background art, the encapsulation effect of the traditional thin film encapsulation structure is not ideal. The inventor found that this is because the organic encapsulation material of the organic encapsulation layer 300 and the inorganic encapsulation materials of the first inorganic encapsulation layer 200 and the second inorganic encapsulation layer 400 belong to two different materials, mainly on the microscopic or atomic scale. The mechanical combination of the two, the interface does not match, and the adhesion between the two is low, which is prone to film peeling, increases the probability of water and oxygen intrusion, and affects the packaging effect.

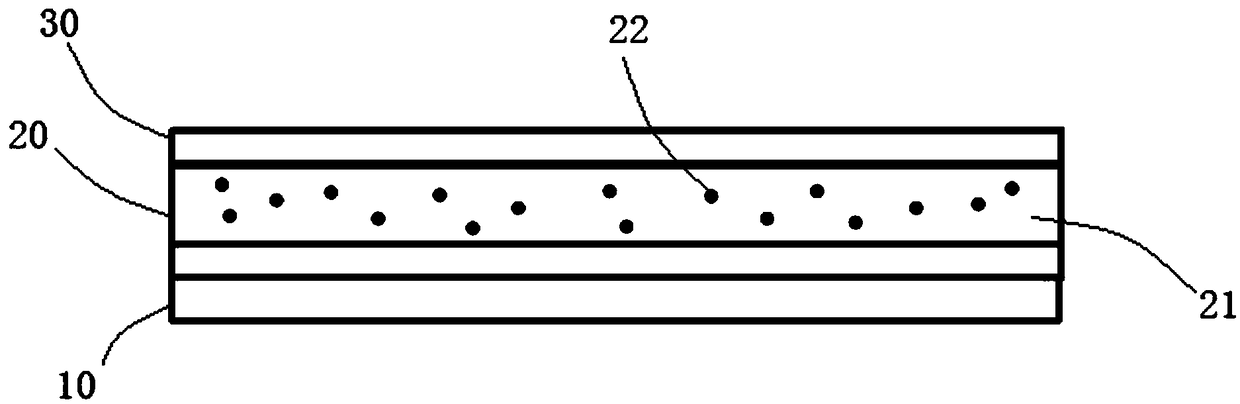

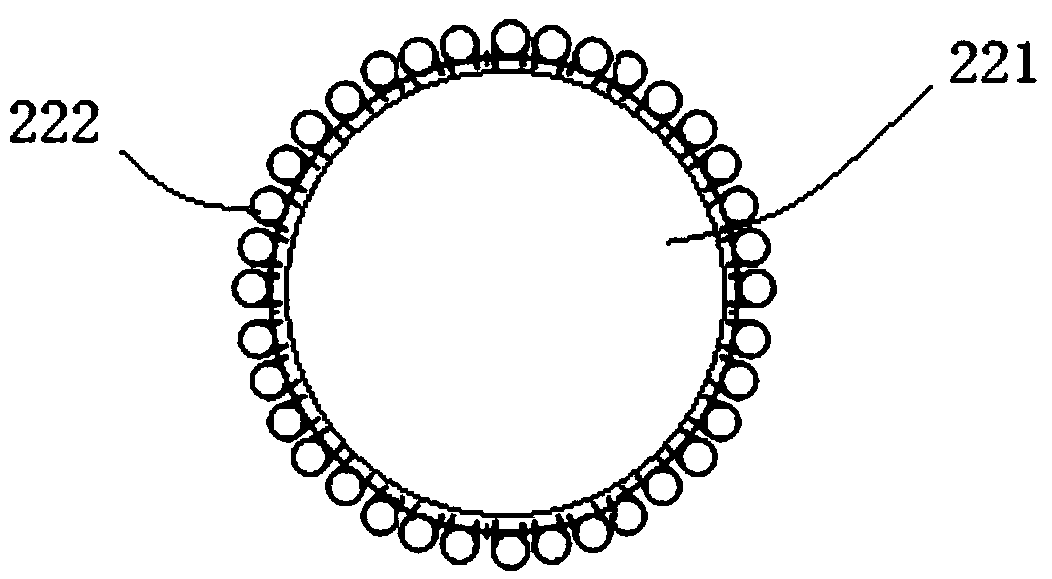

[0026] The inventors have found that using organic-inorganic nanocomposites as an alternative material for the organic encapsulation layer can improve the above problems. Specifically, inorganic nanoparticles (SiN X or SiO X Nanoparticles) dispersed in the composite matrix (polydimethylsil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com