A production device of graphene and a preparing method

A production device and graphene technology, which is applied in the production device and preparation field of two-dimensional nano-materials, can solve the problems of insufficient performance, difficulty in grasping shear force, product edge burrs, etc., to achieve automatic management and high efficiency The effect of shear strength and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

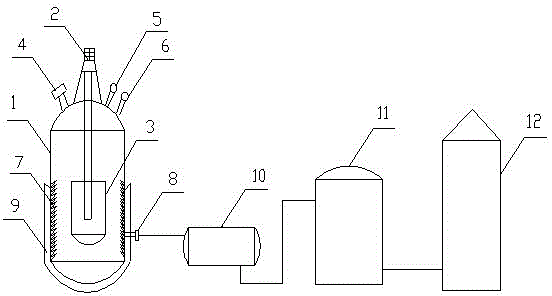

Embodiment 1

[0050] Pour 50kg of graphite flakes and 350kg of distilled water into the reaction kettle, add 1kg of sodium cholate dispersant, start the motor to stir the mixture, and mix the materials evenly. After stirring evenly, the reaction kettle was closed. By means of steam heating, keep the temperature at 80 degrees Celsius, and increase the speed of the shearer to 3000rpm / min. At this time, due to the high speed in the reactor, the shear between the materials themselves and the interaction with the shear grooves on the inner wall , so that the graphite is peeled off layer by layer. Keep the constant temperature and rotation speed, stop the reaction after 5 hours, discharge the upper suspension into the storage tank through the discharge port, and let it stand for 24 hours. Transfer the graphene suspension in the storage tank to the centrifuge, the centrifuge speed is 1000-6000rpm / min, centrifuge for 10min, through centrifugation, the unstripped graphite has multi-layer graphene p...

Embodiment 2

[0052] Inject 20kg of graphite flakes and 400kg of N-methylpyrrolidone into the reactor, start the motor to stir, and mix the materials evenly. After stirring evenly, the reaction kettle was closed. Put water vapor into the jacket, keep the temperature in the reactor at 90 degrees Celsius, and increase the speed of the shearer to 3500rpm / min. Due to the higher speed, the shearing between the materials themselves and the shearing grooves on the inner wall The interaction makes the graphite peeled off layer by layer. Keep the constant temperature and rotation speed, stop the reaction after 3 hours, discharge the upper suspension into the storage tank through the discharge port, and let it stand for 15 hours. Transfer the graphene suspension in the storage tank to the centrifuge, the centrifuge speed is 2000-5000rpm / min, centrifuge for 1h, through centrifugation, the unstripped graphite has multi-layer graphene precipitated at the bottom, take the supernatant liquid, vacuum fil...

Embodiment 3

[0054] Inject 30kg of graphite flakes and 500kg of N,N-dimethylformamide into the reactor, start the motor to stir, and mix the materials evenly. After stirring evenly, the reaction kettle was closed. By means of steam heating, keep the temperature at 100 degrees Celsius, and increase the speed of the shearer to 4500rpm / min. Due to the high speed, the shear between the materials themselves and the interaction with the shear grooves on the inner wall, the graphite is crushed. Peel off layer by layer. Keep the constant temperature and rotation speed, stop the reaction after 7 hours, discharge the upper layer suspension into the storage tank through the discharge port, and let it stand for 12 hours. Transfer the graphene suspension in the storage tank to the centrifuge, the centrifuge speed is 1000~6000rpm / min, and centrifuge for 2 hours. After centrifugation, the graphite that has not been peeled off has been precipitated by multi-layer graphene at the bottom, and the supernata...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com