One-dimensional porous nanocomposite and preparation method thereof and application in water electrolysis

A nano-composite material and porous graphite technology, applied in the field of composite catalysts, can solve the problems of complex preparation method, high temperature energy consumption, low crystallinity and purity, etc., and achieve the effects of easy availability of raw materials, cheap raw materials and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

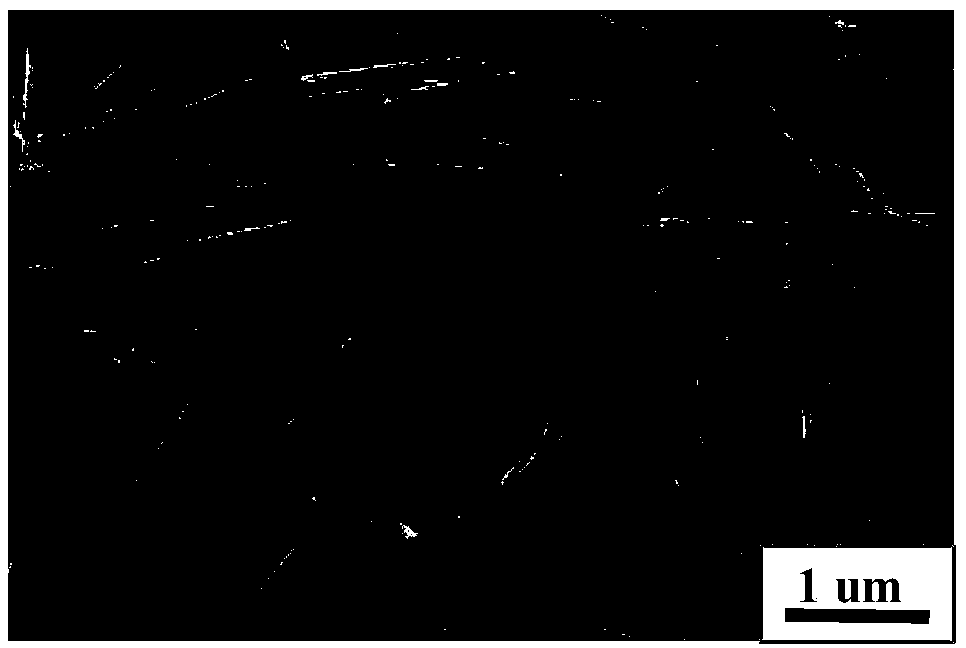

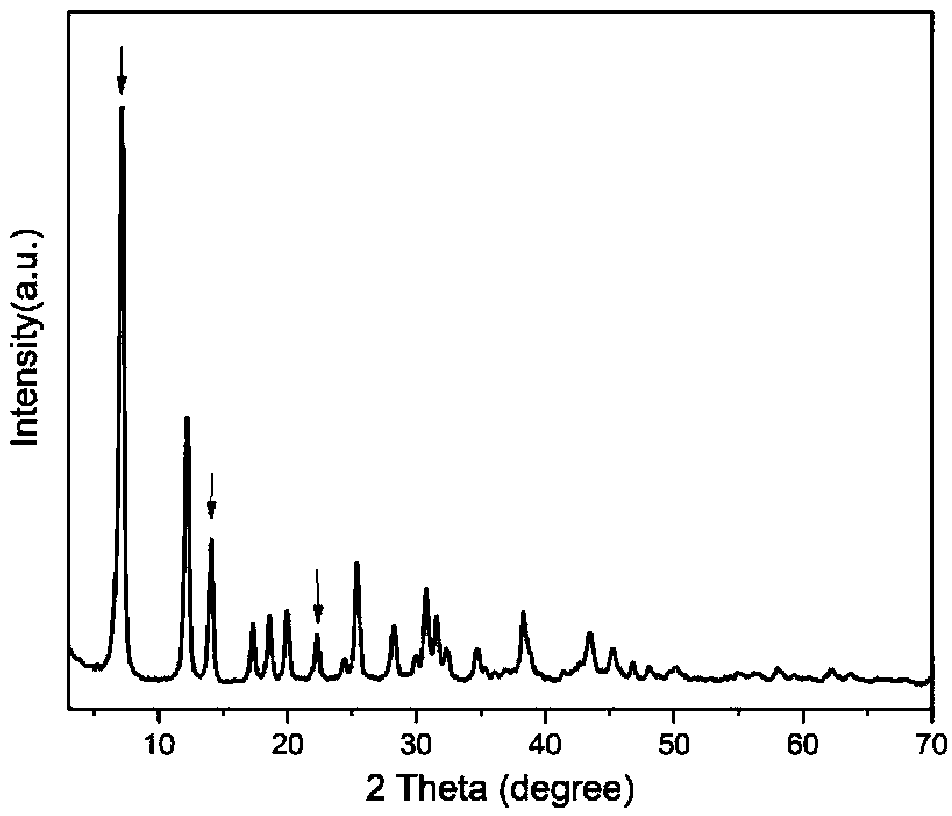

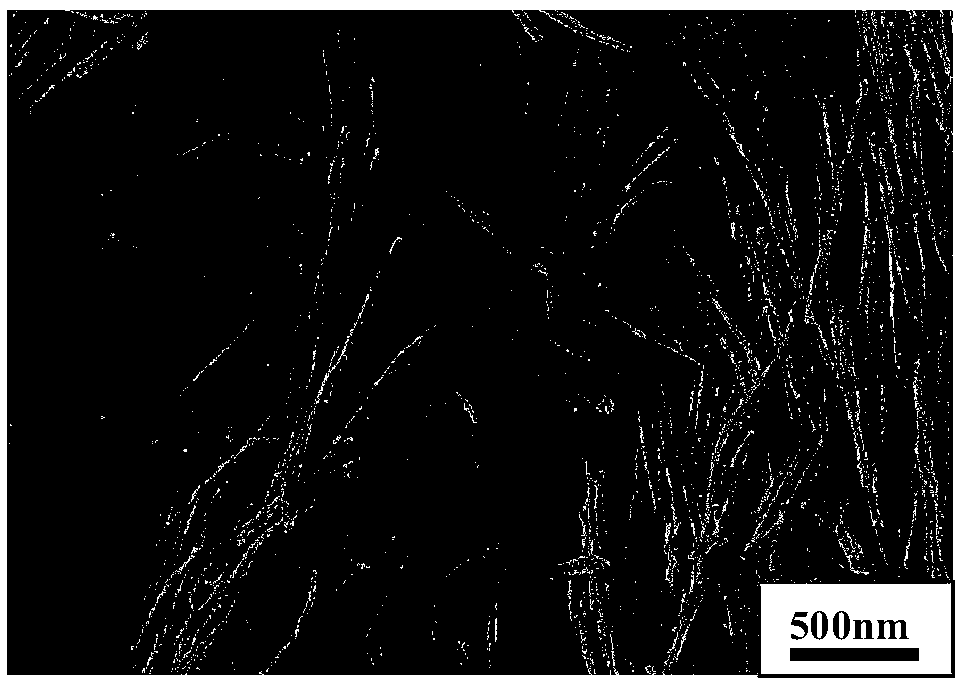

[0036] (1) Weigh 8.724g nickel nitrate hexahydrate, 2.974g zinc nitrate hexahydrate and 12.809g sodium salicylate, dissolve them in 200mL deionized water at room temperature to form a salt solution, pour the prepared salt solution into four In the flask, and start stirring with an electric stirrer at a constant speed to mix the salt solution evenly.

[0037] (2) Weigh 4g of sodium hydroxide and dissolve it in 200mL of deionized water to prepare lye, then slowly add lye to the mixed salt solution to adjust the pH of the solution to 6.9, raise the temperature to 95°C, and react at this temperature 24 hours. After the reaction, the product was taken out, centrifuged, washed four times with deionized water, and then dried in an oven at 55°C for 6 hours to obtain a one-dimensional salicylate-intercalated layered nickel-zinc hydroxide precursor body.

[0038] (3) The one-dimensional salicylate-intercalated layered nickel-zinc hydroxide precursor obtained in step 2) was roasted for...

Embodiment 2

[0051] (1) Weigh 8.724g nickel nitrate hexahydrate, 2.974g zinc nitrate hexahydrate and 12.809g sodium salicylate, dissolve them in 200mL deionized water at room temperature to form a salt solution, pour the prepared salt solution into four In the flask, and start stirring with an electric stirrer at a constant speed to mix the salt solution evenly.

[0052] (2) Weigh 4g of sodium hydroxide and dissolve it in 200mL of deionized water to prepare lye, then slowly add lye to the mixed salt solution to adjust the pH of the solution to 6.9, raise the temperature to 95°C, and react at this temperature 24 hours. After the reaction, the product was taken out, centrifuged, washed four times with deionized water, and then dried in an oven at 55°C for 6 hours to obtain a one-dimensional salicylate-intercalated layered nickel-zinc hydroxide precursor body.

[0053] (3) The one-dimensional salicylate-intercalated layered nickel-zinc hydroxide precursor obtained in step 2) was roasted at ...

Embodiment 3

[0055] (1) Weigh 8.724g nickel nitrate hexahydrate, 2.974g zinc nitrate hexahydrate and 12.809g sodium salicylate, dissolve them in 200mL deionized water at room temperature to form a salt solution, pour the prepared salt solution into four In the flask, and start stirring with an electric stirrer at a constant speed to mix the salt solution evenly.

[0056] (2) Weigh 4g of sodium hydroxide and dissolve it in 200mL of deionized water to prepare lye, then slowly add lye to the mixed salt solution to adjust the pH of the solution to 6.9, raise the temperature to 95°C, and react at this temperature 24 hours. After the reaction, the product was taken out, centrifuged, washed four times with deionized water, and then dried in an oven at 55°C for 6 hours to obtain a one-dimensional salicylate-intercalated layered nickel-zinc hydroxide precursor body.

[0057] (3) The one-dimensional salicylate-intercalated layered nickel-zinc hydroxide precursor obtained in step 2) was roasted for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Hole diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com