Preparation method of silicon modified waterborne epoxy resin

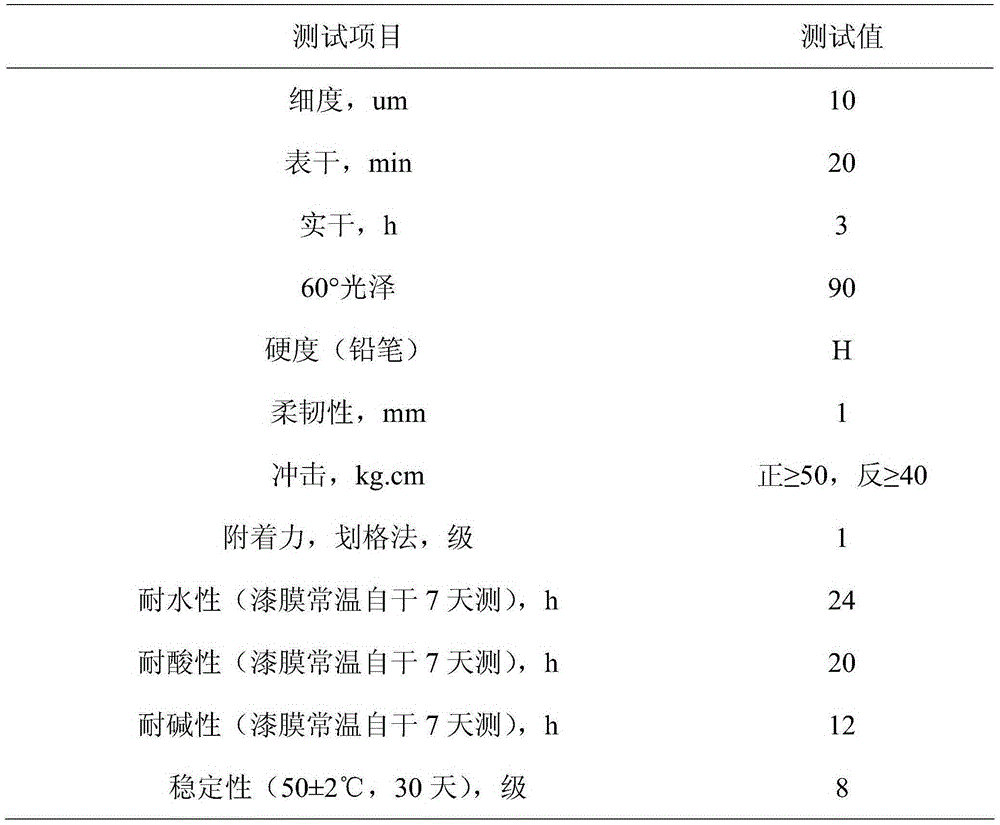

A water-based epoxy resin, epoxy resin technology, applied in the coating and other directions, can solve the problems of water-based epoxy resin drying, poor weather resistance, environmental protection people's health threats, easy to produce precipitation and other problems, to achieve excellent acid and alkali resistance high hardness and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Weigh 60 parts of methyltriethoxysilane, 64 parts of absolute ethanol, 20 parts of distilled water and 20 parts of 3-triethoxysilyl-1-propylamine, mix and adjust to an acidic system, at 50~75℃ Under reaction for 8h, the modified silica sol is obtained.

[0022] Esterify 70 parts of epoxy resin E-06 (epoxy equivalent 800-3000), 50 parts of linoleic acid and 1 part of zinc oxide at 220°C, add ethylene glycol butyl ether to dilute after esterification, and cool down Slowly add a mixed solution of 12 parts of n-butyl acrylate, 14 parts of styrene, 8 parts of acrylic acid and 20 parts of silica sol (synthesized in this experiment, with a solid content of 20%), and react under the action of the catalyst benzoyl peroxide, After the reaction is completed, the silicon-modified water-based epoxy resin can be obtained.

Embodiment 2

[0024] Weigh 60 parts of methyltriethoxysilane, 64 parts of absolute ethanol, 20 parts of distilled water and 20 parts of 3-triethoxysilyl-1-propylamine, mix and adjust to an acidic system, at 50~75℃ Under reaction for 8h, the modified silica sol is obtained.

[0025] Esterify 70 parts of epoxy resin E-06 (epoxy equivalent 800-3000), 50 parts of linoleic acid and 1 part of zinc oxide at 220°C, add ethylene glycol butyl ether to dilute after esterification, and cool down Slowly add a mixed solution of 12 parts of n-butyl acrylate, 14 parts of styrene, 8 parts of acrylic acid and 30 parts of silica sol (synthesized in this experiment, with a solid content of 20%), and react under the action of the catalyst benzoyl peroxide, After the reaction is completed, the silicon-modified water-based epoxy resin can be obtained.

Embodiment 3

[0027] Weigh 60 parts of methyltriethoxysilane, 54 parts of absolute ethanol, 22 parts of distilled water and 22 parts of 3-triethoxysilyl-1-propylamine, mix and adjust to an acidic system, at 50~75℃ Under reaction for 8h, the modified silica sol is obtained.

[0028] Esterify 70 parts of epoxy resin E-06 (epoxy equivalent 800-3000), 30 parts of linoleic acid and 1 part of zinc oxide at 220°C. After the esterification is completed, add ethylene glycol butyl ether for dilution. Slowly add a mixed solution of 18 parts of n-butyl acrylate, 21 parts of styrene, 12 parts of acrylic acid and 20 parts of silica sol (synthesized in this experiment, with a solid content of 20%), and react under the action of the catalyst benzoyl peroxide, After the reaction is completed, the silicon-modified water-based epoxy resin can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com