Graphene/molecular sieve composite catalyst and preparation method thereof

A composite catalyst, graphene technology, applied in molecular sieve catalysts, including molecular sieve catalysts, carbon compound catalysts, etc., can solve problems such as no report on catalytic performance, no report on catalytic activity of HZSM-5 and graphene acid, etc. Catalytic activity, the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

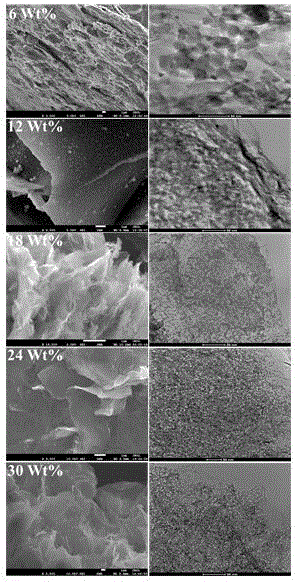

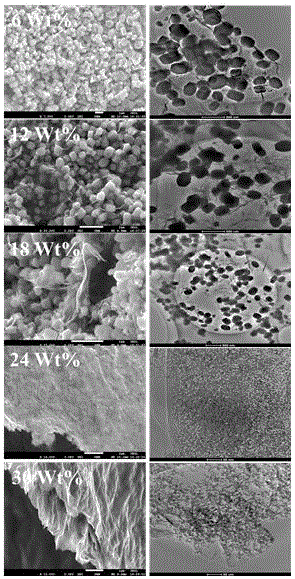

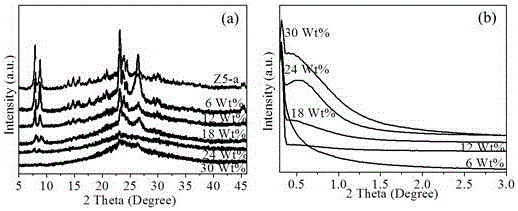

[0059] In this example, mesoporous ZSM-5 / graphene composites were prepared in the following manner, and the steps are as follows.

[0060] Weigh 120 mg of graphene, add 6 ml of deionized water, ultrasonically disperse evenly, weigh 1 g of tetrapropylammonium hydroxide and add it to the graphene aqueous solution, stir for 30 min to mix evenly, and record it as A solution; Add 60 mg of aluminum isopropoxide and 2 ml of tetraethyl orthosilicate in sequence and stir evenly, and record it as solution B; firstly stir solution B at 30 °C for 1 h, then raise the temperature to 90 °C and stir for 24 h; then use this solution B with After repeated washing with ethanol and deionized water for 2 to 3 times, it was transferred to a polytetrafluoroethylene-lined autoclave for crystallization at 180 °C for 3 days to obtain ZSM-a / graphene composites. After the product was washed with ethanol and deionized water for 3–5 times, it was vacuum-dried at 100 °C for 12 h, calcined at 600 °C for 5 h,...

Embodiment 2

[0064] Weigh 120 mg of graphene, add 8 ml of deionized water, ultrasonically disperse evenly, weigh 2 g of tetrapropylammonium hydroxide and add it to the graphene aqueous solution, stir for 30 min to mix evenly, and record it as A solution; Add 13.4 mg of sodium metaaluminate and 2 ml of tetraethyl orthosilicate in sequence and stir evenly, and record it as solution B; first stir solution B at 30 °C for 1 h, then at 60 °C for 2 h, then raise the temperature to 80 °C and stir for 6 h, then The B solution was repeatedly washed with ethanol and deionized water for 2 to 3 times, and then transferred to a polytetrafluoroethylene-lined autoclave for crystallization at 170 °C for 2 days to obtain the ZSM-b / graphene composite. After the product was washed with ethanol and deionized water for 3–5 times, it was vacuum-dried at 100 °C for 12 h, calcined at 600 °C for 5 h, and then treated with 0.2 mol / L NH 4 NO 3 The solution was exchanged at 80 °C for 6 h, and then washed, dried, and ...

Embodiment 3

[0069]Weigh 120 mg of graphene, add 6 ml of deionized water, ultrasonically disperse evenly, weigh 3.7 g of tetrapropylammonium hydroxide and add it to the graphene aqueous solution, stir for 30 min to mix evenly, and record it as A solution; Add 222 mg of aluminum isopropoxide and 7.4 ml of tetraethyl orthosilicate in sequence and stir evenly, and record it as solution B; first stir solution B at 30 °C for 1 h, then raise the temperature to 90 °C and stir for 24 h; then use this solution B with After repeated washing with ethanol and deionized water for 2 to 3 times, it was transferred to a polytetrafluoroethylene-lined autoclave for crystallization at 180 °C for 3 days to obtain ZSM-a / graphene composites. After the product was washed with ethanol and deionized water for 3–5 times, it was vacuum-dried at 100 °C for 12 h, calcined at 600 °C for 5 h, and then treated with 0.2 mol / L NH 4 NO 3 The solution was exchanged at 80°C for 6 h, and then washed, dried, and calcined to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com