Preparation method of highly dispersible core-shell type mh@cmss flame retardant

A high-dispersion, core-shell type technology, applied in the field of inorganic flame retardant preparation, can solve the problems of composite material mechanical properties decline, uneven dispersion, etc., and achieve the effect of simple preparation method, high dispersion and high flame retardant efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

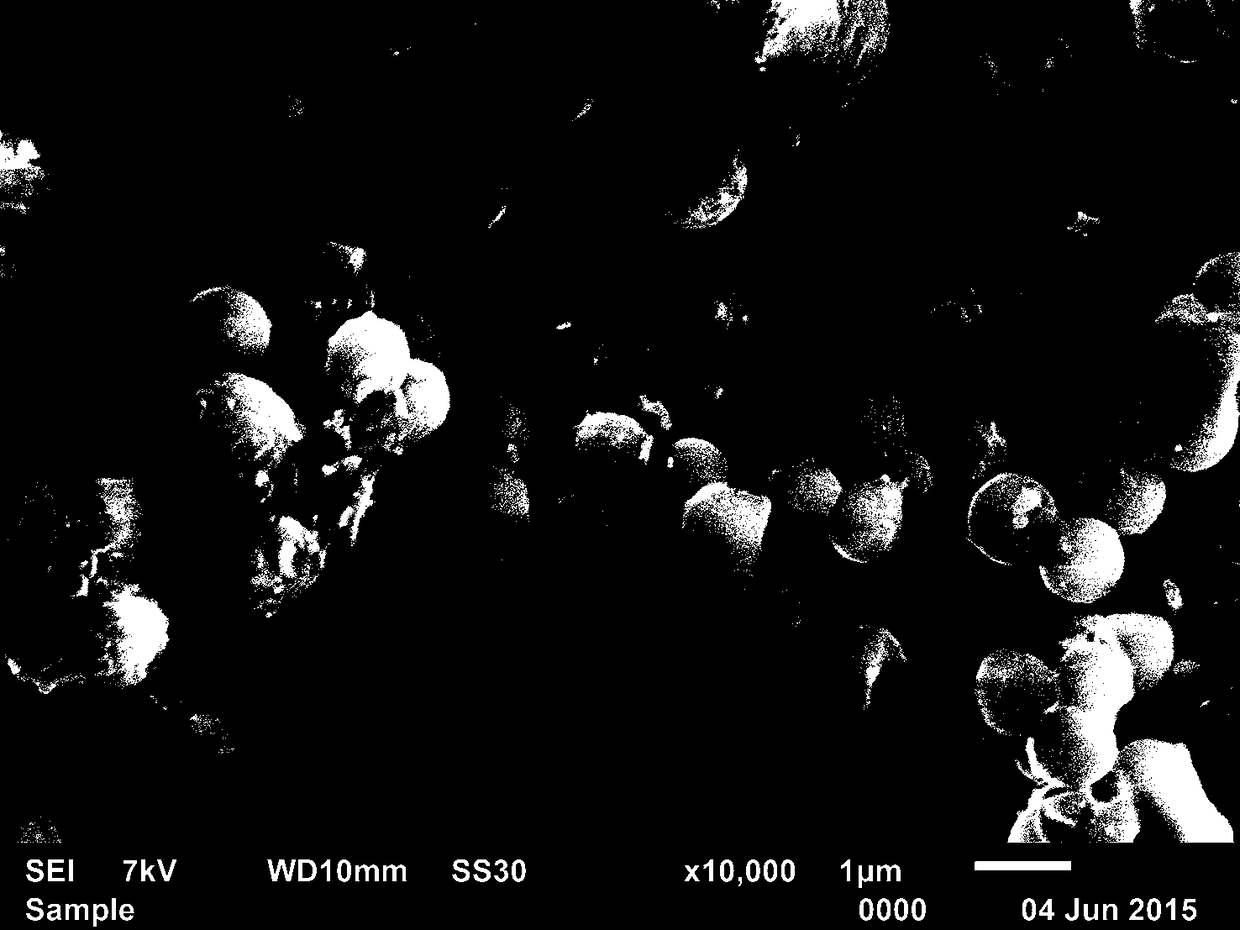

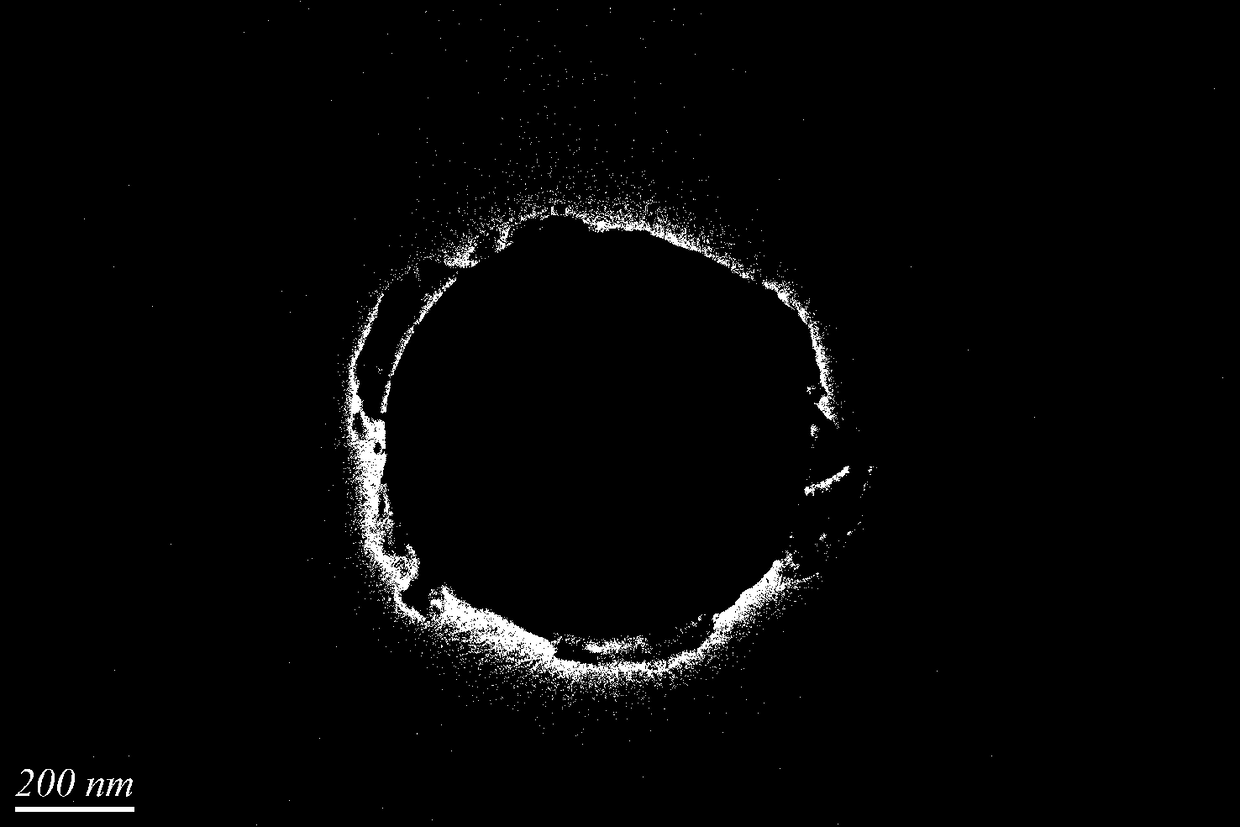

Image

Examples

Embodiment 1

[0026] Weigh 41.62g of glucose powder into 600mL of deionized water, stir and dissolve evenly, and prepare a 0.35mol / L glucose solution; add the glucose solution to a 1L autoclave, and heat up to a constant temperature of 280°C at a rotational speed of 150r / min. After 6 hours of reaction, cooled to room temperature, the reaction product was taken out, filtered, washed with absolute ethanol and deionized water until the filtrate was clear, the obtained solid product was dried at 120 °C for 4 hours, and ground to obtain 7.6 g of CMSs black powder.

[0027] Dissolve 4g NaOH powder in a mixed solvent consisting of 50mL absolute ethanol and 50mL deionized water to prepare a 1.0mol / L NaOH solution; weigh 10.15g MgCl 2 ·6H 2 O powder, dissolved in a mixed solvent consisting of 50 mL of absolute ethanol and 50 mL of deionized water, to prepare 0.5 mol / L MgCl 2 solution; take 5.8g of PEG6000 and dissolve it in 100mL of deionized water to obtain a 5.48% PEG6000 aqueous solution.

[00...

Embodiment 2

[0032] Dissolve 3.2g NaOH powder in a mixed solvent consisting of 50mL absolute ethanol and 50mL deionized water to prepare a 0.8mol / L NaOH solution; weigh 8.12g MgCl 2 ·6H 2 O powder, dissolved in a mixed solvent consisting of 50 mL of absolute ethanol and 50 mL of deionized water, to prepare 0.4 mol / L MgCl 2 solution; take 2.9g of PEG6000 and dissolve it in 100mL of deionized water to obtain a 2.8% PEG6000 aqueous solution.

[0033] Weigh 5.8g of CMSs, mix it with the above NaOH solution, heat to 60°C, and add the above MgCl dropwise at a rate of 5mL / min under the stirring speed of 400r / min. 2 In the solution, after reacting for 30 min, 1 mL of 2.8% PEG6000 aqueous solution was added, and the constant temperature reaction was continued for 18 h. After the reaction, cooled to room temperature, filtered, the filter cake was washed with absolute ethanol until the filtrate was clear, then washed with distilled water until neutral, dried at 120 °C for 4 h, and ground to obtain ...

Embodiment 3

[0035] Dissolve 4.8g NaOH powder in a mixed solvent consisting of 33mL absolute ethanol and 67mL deionized water to prepare a 1.2mol / L NaOH solution; weigh 12.18g MgCl 2 ·6H 2 O powder, dissolved in a mixed solvent consisting of 33 mL of absolute ethanol and 67 mL of deionized water, to prepare 0.6 mol / L MgCl 2 solution; take 8.7g of PEG6000 and dissolve it in 100mL of deionized water to obtain an 8% PEG6000 aqueous solution.

[0036] Weigh 2.9g of CMSs, mix it with the above NaOH solution, heat to 40°C, and add the above MgCl dropwise at a rate of 4mL / min under the stirring speed of 800r / min. 2 In the solution, after the reaction for 30min, 1mL of 8% PEG6000 aqueous solution was added, and the constant temperature reaction was continued for 21h. After the reaction, cooled to room temperature, filtered, the filter cake was washed with absolute ethanol until the filtrate was clear, then washed with distilled water until neutral, dried at 120 °C for 4 h, and ground to obtain M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com