Purification method of amine liquid

An amine liquid and lye tank technology is applied in the field of separation of processing liquids, which can solve the problems of short equipment utilization cycle, poor quality of purified amine liquid, and high production cost, so as to improve the use efficiency and utilization cycle, reduce filtration costs, and improve The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

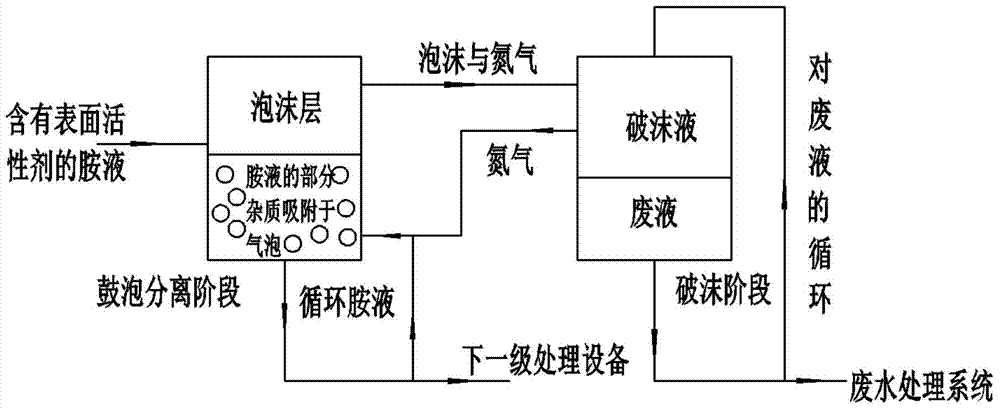

Method used

Image

Examples

Embodiment 1

[0038] A. The device used

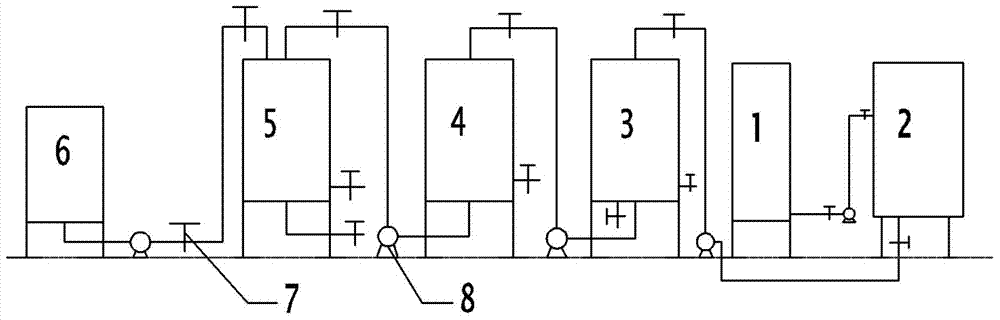

[0039] The device used in the purification method of amine liquid includes amine liquid tank 1 to be treated, foam separator 2, mechanical filter 3, activated carbon adsorber 4, anion exchanger 5 and lye tank 6, wherein foam separator 2 is equipped with insulation Layer gas self-circulating foam separator, mechanical filter 3 is a core filter, activated carbon adsorber 4 is a fixed-bed activated carbon adsorption tank, anion exchanger 5 is a fixed-bed anion exchanger, through valve 7, pump 8 and pipelines The amine solution tank 1 to be treated, the foam separator 2, the mechanical filter 3, the activated carbon adsorber 4, the anion exchanger 5 and the alkali solution tank 6 are sequentially connected to form the device used in the process flow of the purification method of the amine solution;

[0040] B. Process flow

[0041] The first step, the situation of the amine solution to be treated

[0042] The amine liquid to be treated in the amine li...

Embodiment 2

[0056] A. The device used

[0057] With embodiment 1.

[0058] B. Process flow

[0059] The first step, the situation of the amine solution to be treated

[0060] The amine liquid to be treated in the amine liquid tank 1 is the methyldiethanolamine solution being used in the natural gas desulfurization system of a petrochemical refinery, and no treatment is required before foam separation;

[0061] The second step, foam separation

[0062] In addition to making the flow range of the foam separator 2 be 12m 3 Except / h, other is with embodiment 1;

[0063] The third step, mechanical filtration

[0064] With embodiment 1;

[0065] The fourth step, activated carbon adsorption

[0066] With embodiment 1;

[0067] The fifth step, ion exchange

[0068] With embodiment 1.

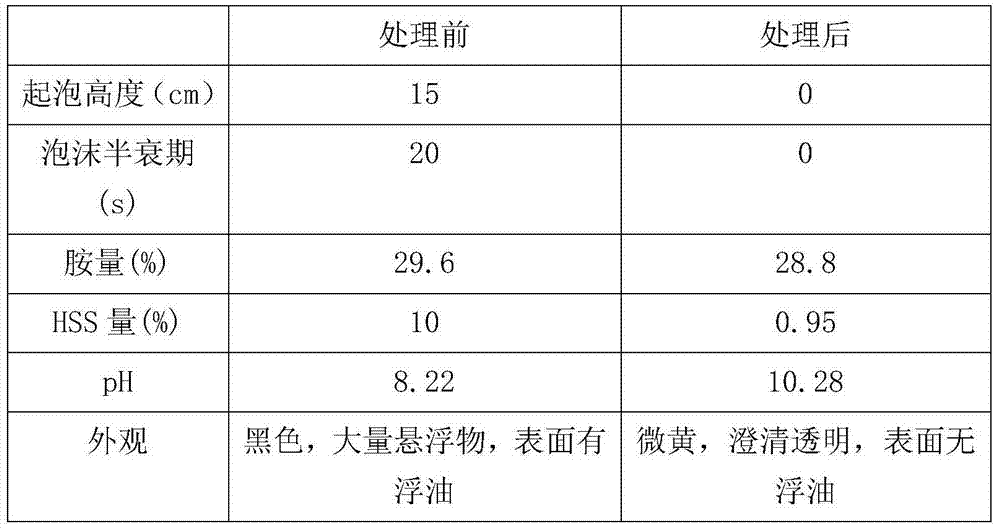

[0069] The comparison data of different methyldiethanolamine solution quality results before and after the treatment of this embodiment are shown in Table 2

[0070] Table 2. The quality data comparison...

Embodiment 3

[0073] A. The device used

[0074] With embodiment 1.

[0075] B. Process flow

[0076] The first step, the situation of the amine solution to be treated

[0077] The amine solution to be treated in the amine solution tank 1 is a waste methyldiethanolamine solution with strong foamability and high foam stability in a petrochemical refinery, and no treatment is required before foam separation.

[0078] The second step, foam separation

[0079] In addition to making the flow range of the foam separator 2 be 20m 3 Except / h, other is with embodiment 1;

[0080] The third step, mechanical filtration

[0081] With embodiment 1;

[0082] The fourth step, activated carbon adsorption

[0083] With embodiment 1;

[0084] The fifth step, ion exchange

[0085] With embodiment 1.

[0086] Table 3 shows the comparison data of the quality results of different waste methyldiethanolamine solutions before and after the treatment in this embodiment.

[0087] Table 3. Comparison of wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com