Patents

Literature

41 results about "Sulphur granules" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Continuous production method of insoluble sulfur

InactiveCN103193205AGuaranteed batch stabilityAvoid pollutionSulfur preparation/purificationPhysical chemistryEngineering

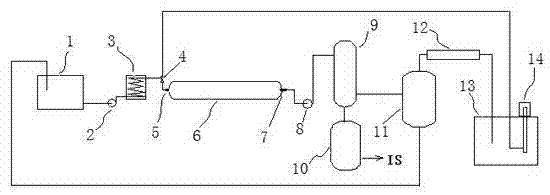

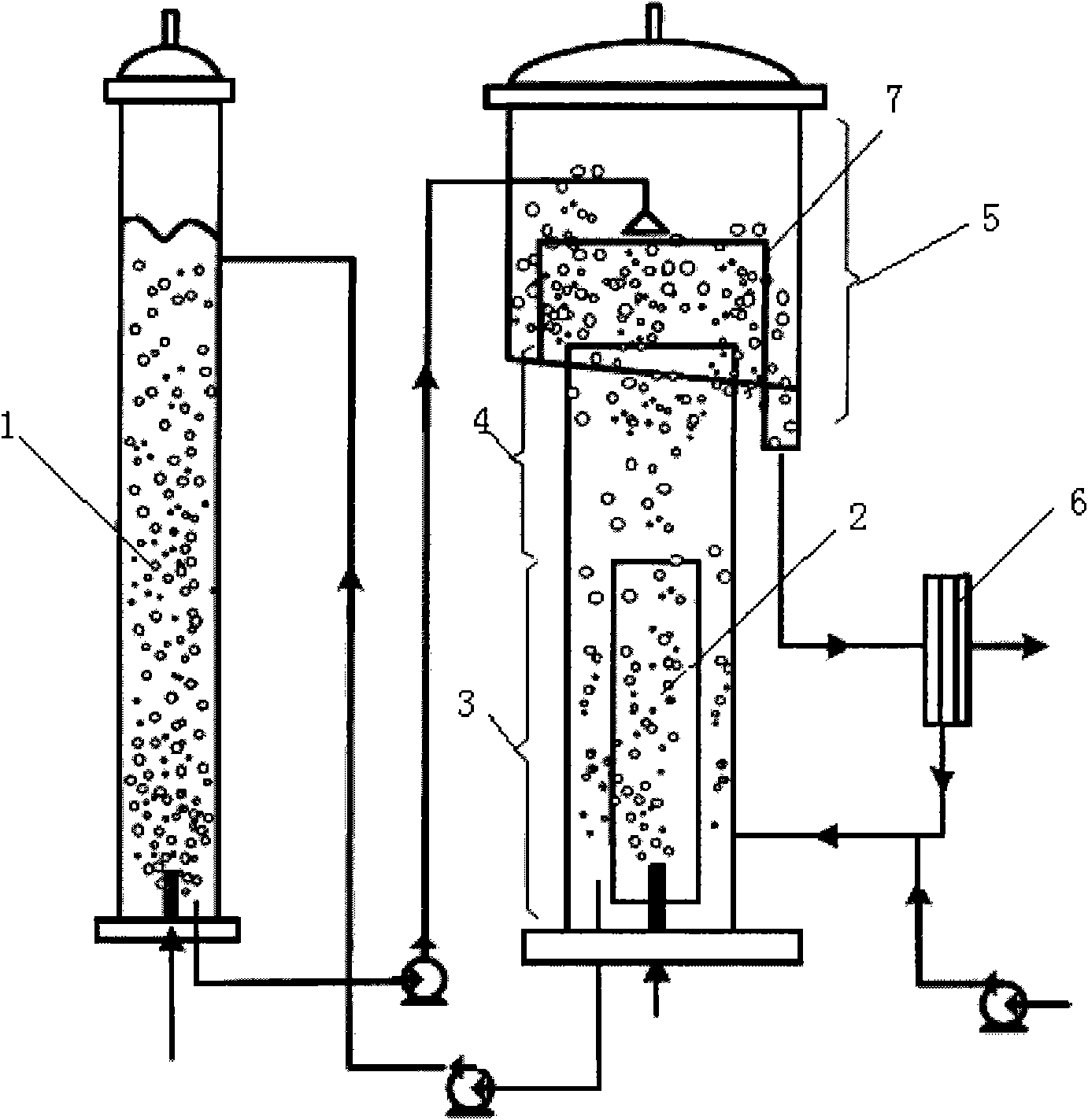

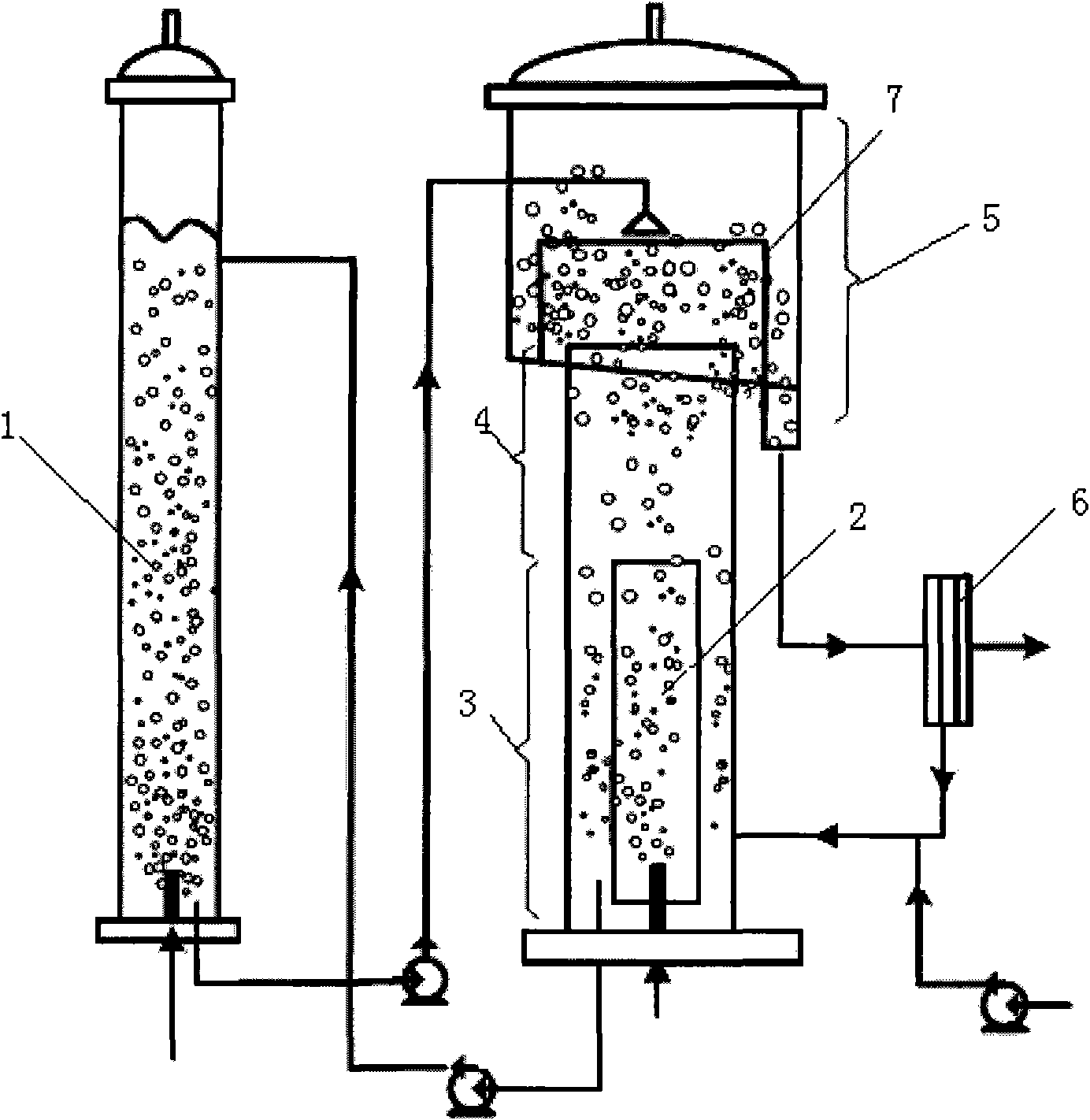

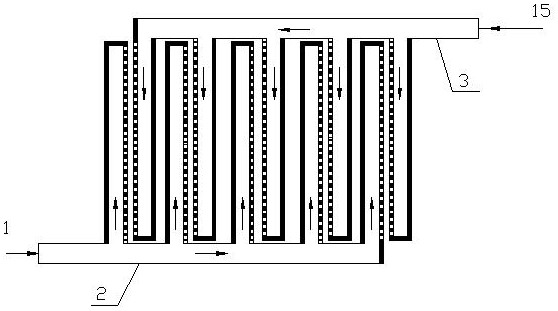

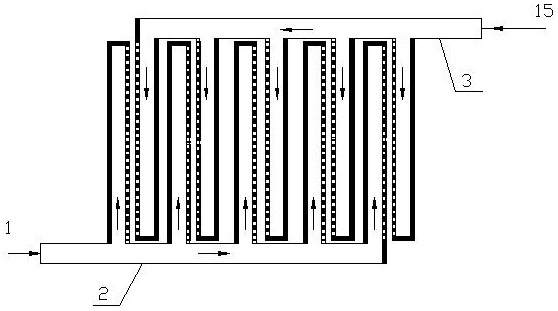

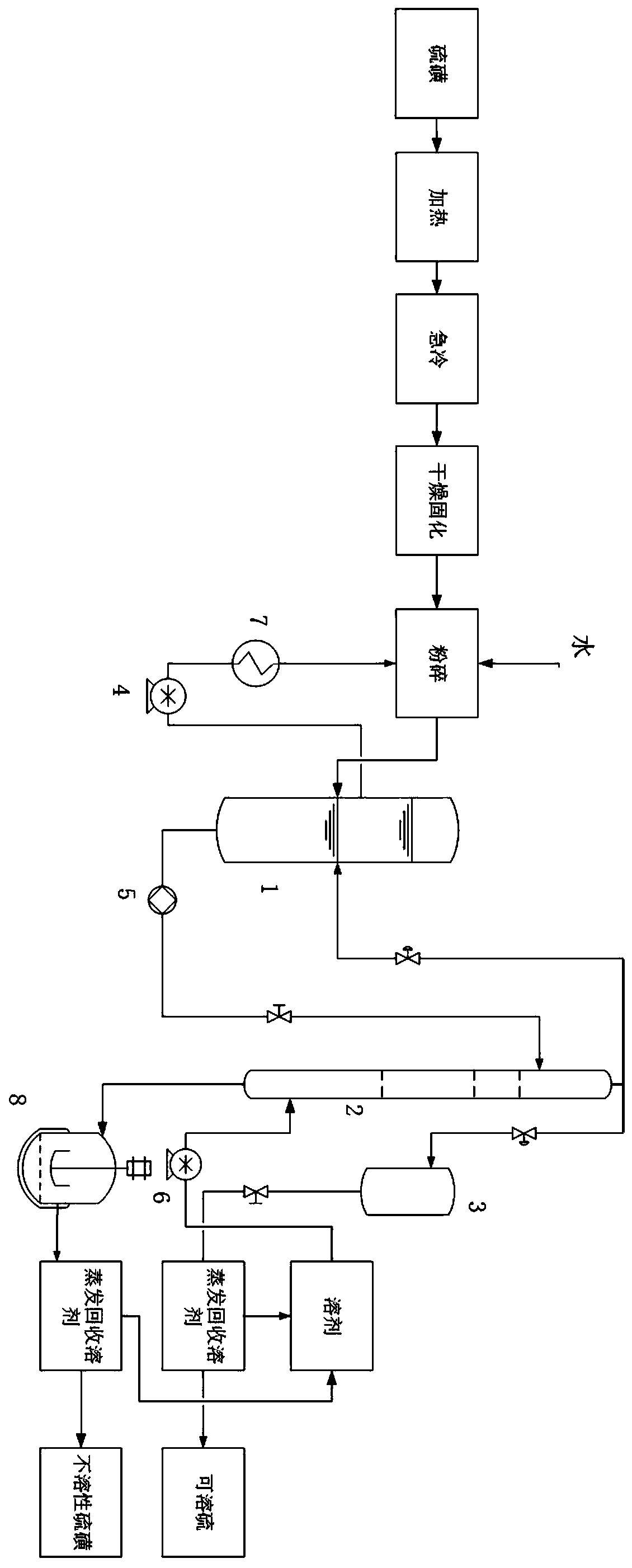

A continuous production method of insoluble sulfur comprises the steps of sulfur melting, extraction, curing, crushing and drying. The continuous production method of insoluble sulfur is carried out under a totally closed condition. The method concretely comprises the following steps: 1, placing sulfur in a sulfur melting pool (1), melting, pumping the molten sulfur to a heating coil tube (3) through a metering pump (2), heating, and mixing high-temperature sulfur with low-temperature carbon disulfide in an ejector (4) to complete quenching; 2, letting the quenched mixed liquid comprising insoluble sulfur and carbon disulfide into a continuous-rotation rotary kiln (6) through a rotary joint (5) to form a mixed liquid containing cured insoluble sulfur particles and carbon disulfide; 3, conveying the mixed liquid obtained in step 2 to a crushing pump (8), and crushing; 4, sending the mixed liquid containing crushed insoluble sulfur and carbon disulfide to a material crushing pot (9), and carrying out solid-liquid separation through a filter screen; and 5, sending insoluble sulfur to a vacuum dryer (10), and drying. The method has the advantages of continuous production of the insoluble sulfur under the totally closed condition, safety, environmental protection, stable product quality, high efficiency, and low energy consumption.

Owner:江西恒兴源化工有限公司

Preparation method of composite anode material for lithium element sulphur secondary battery

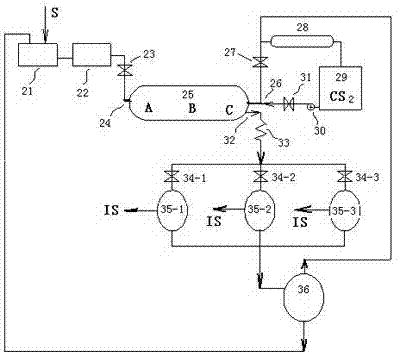

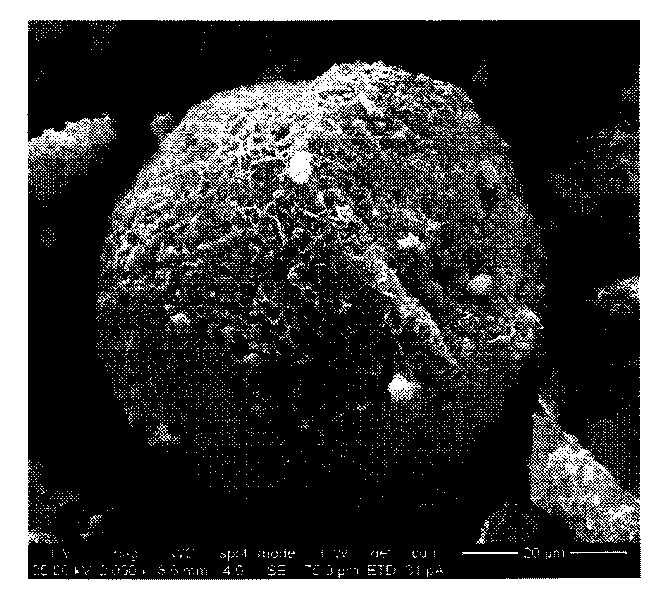

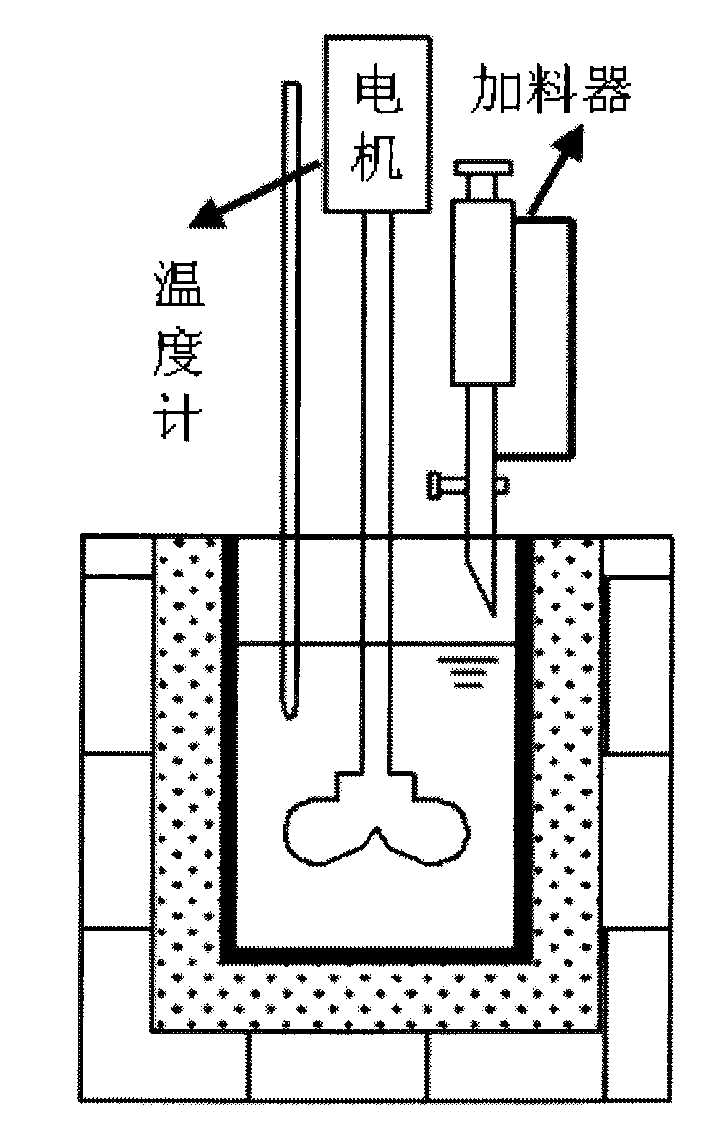

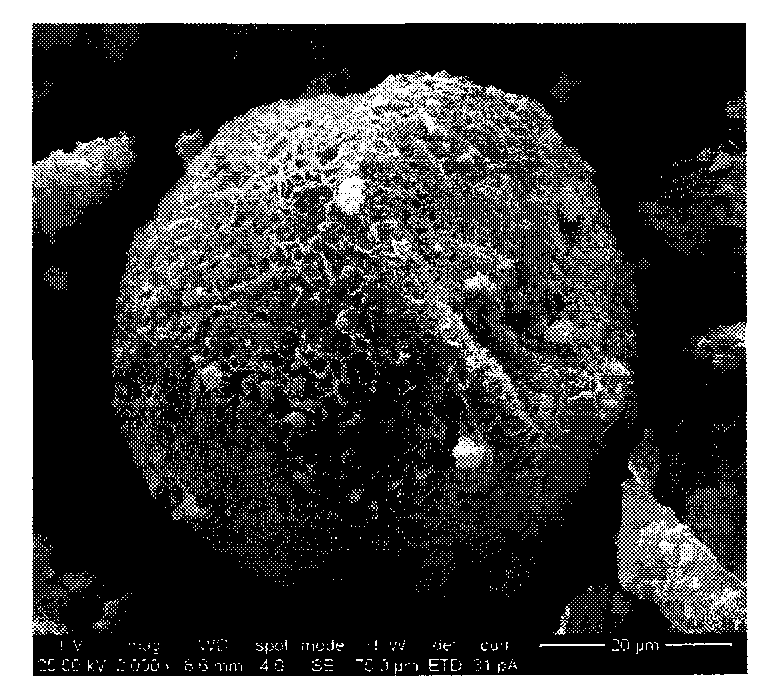

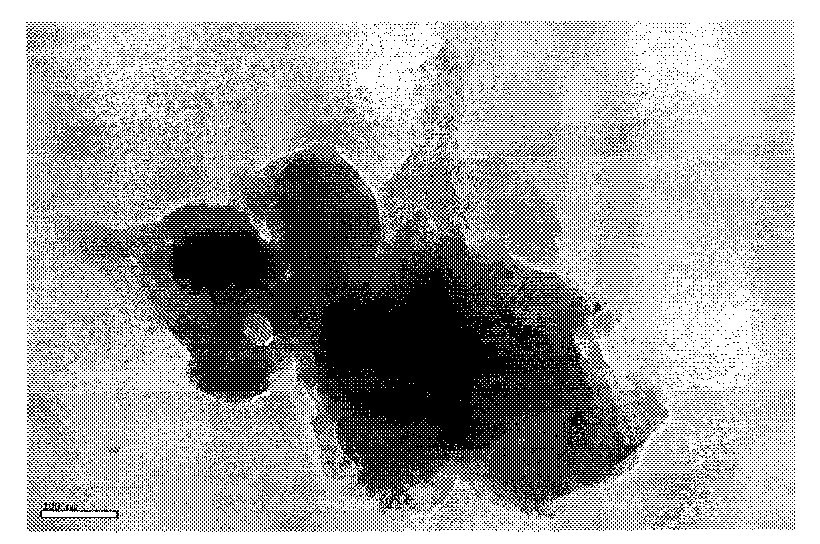

The invention comprises a preparation method of composite anode material for lithium element sulphur secondary battery, belonging to the field of chemical energy storage battery. The composite material is formed by taking element sulphur as electrode active center and conductive polymer polythiophene with excellent in-situ chemical oxidation polymerization conductivity as shell. The concrete preparation method comprises adding anhydrous chloroform in element sulphur and anhydrous ferric chloride, mixing uniformly, putting into a controllable low temperature reaction kettle, and slowly adding monomer thiophene by adopting in-situ chemical oxidation polymerization process to clad polythiophene on the surface of sulphur granules to form the composite product with uniform granules. The composite anode material prepared by the inventive method has high electrochemical activity, and the battery packed by the material has large discharge specific volume and long cycle life, thus having advantage in new system of large volume energy storage battery.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

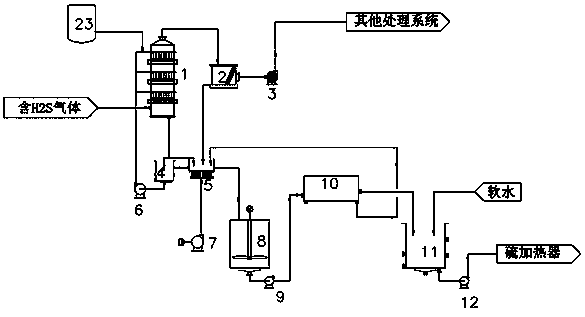

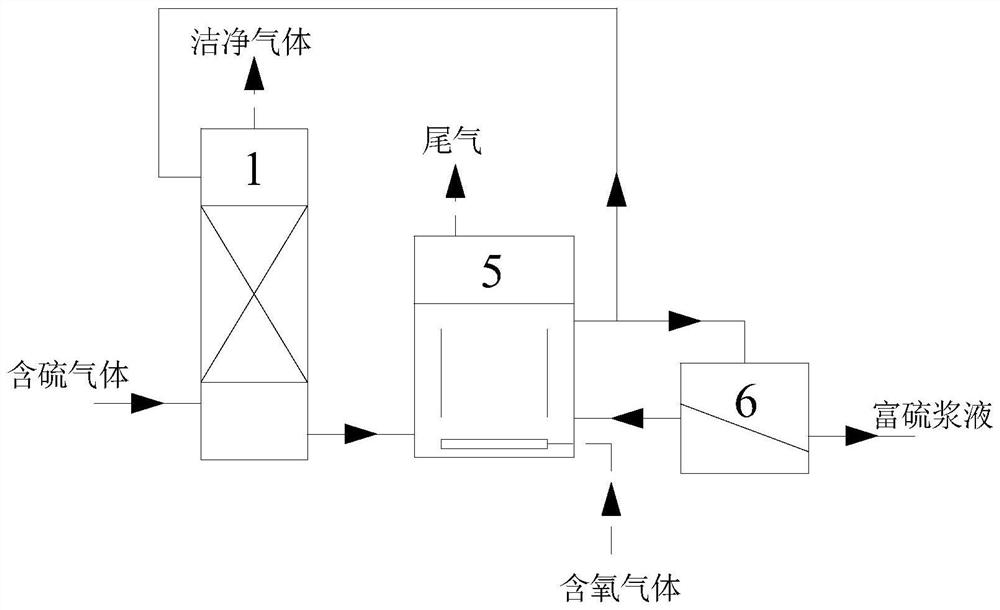

Regenerative and integrative hydrogen sulfide liquid phase oxidation absorption method of sulphur separation/desulfuration solution

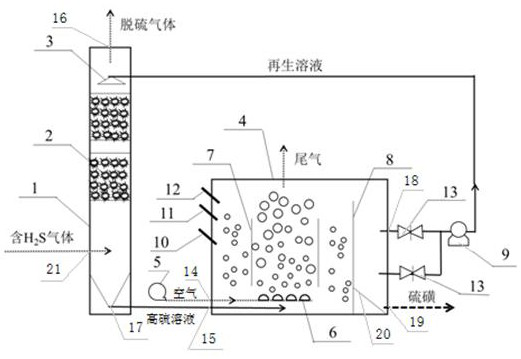

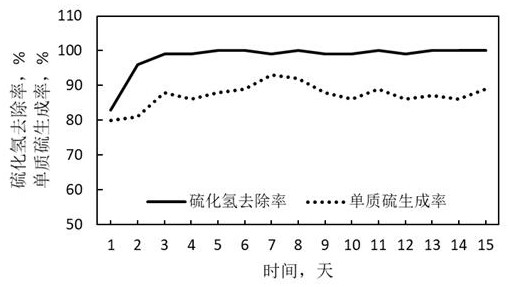

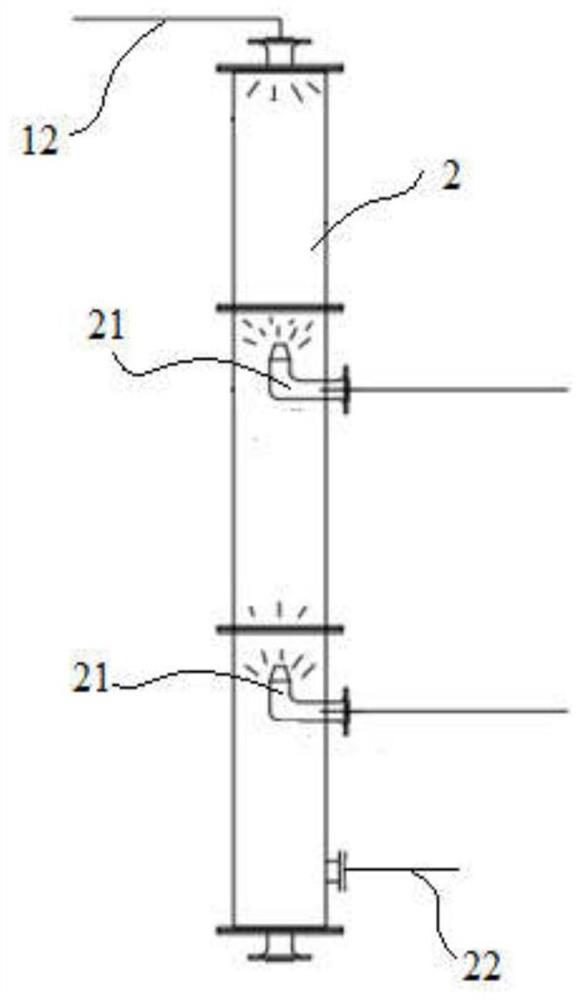

ActiveCN101870884AImprove separation efficiencyImprove gas-liquid mass transfer coefficientRefining with oxygen compoundsReaction rateSelf-absorption

The invention relates to a regenerative and integrative hydrogen sulfide liquid phase oxidation absorption method of sulphur separation / desulfuration solution, comprising a regeneration-separation tower composed of a bubbling reaction section, an air liquid separation section and a foam collection section. Desulfuration solution used for absorbing H2S flows out of a self-absorption tower and enters into the regeneration-separation tower, and then is oxidized and regenerated by a catalyst at the bubbling reaction section so as to enrich sulphur granules on a bubble interface; at the air liquidseparation section, the regeneration / desulfuration solution is separated from foams and is returned to an absorption tower for recycling, and sulphur is carried to the foam collection section by foams and is recovered by collecting foams; 0.008-0.012g of surfactant is added when per desulfuration solution containing 1g of sulphur enters into the tower; air dose introduced in the desulfuration solution containing 1g of sulphur is no less than 34L, and empty tower gas velocity is 0.8-2.5cm / s; and the sulphur granule separation rate and regenerative reaction rate are high, the energy consumptionand catalyst consumption are low, and the method can be applicable to the process of absorbing H2S gas in medium-size sulphur throughputs.

Owner:PETROCHINA CO LTD +1

Method regarding wood chips as carbon source and for removing nitrate in underground water by using solid-phase heterotrophy and sulfur autotrophic integrated denitrification

InactiveCN102923854ASolve the problem that still needs to add liquid carbon sourceWater contaminantsTreatment with anaerobic digestion processesCelluloseBiofilm

The invention discloses a method for removing nitrate in underground water by using solid-phase heterotrophy and sulfur autotrophic integrated denitrification. A hybrid anaerobic baffled reactor (HABR) is used, wood chips and sulfur serve as reaction substrates and biofilm carriers in two-stage separating chambers of the HABR, the heterotrophic and autotrophic denitrification is integrated through a portioning structure of the HABR and a flow pushing state, wood chips serve as the carbon source and biofilm carriers in separating chambers in which wood chips are filled, the solid-phase denitrification is achieved under the cooperating action of cellulose degrading bacterium and heterotrophic denitrifying bacterium, alkalinity is provided for sequent sulfur autotrophic denitrification, and sulfur autotrophic denitrification bacterium inside a biofilm attached to sulfur particle surfaces can increase the nitrate removing load further in separating chambers in which sulfur particles are filled. A heterotrophic and autotrophic integrated denitrification process is developed, and a new method for disposing nitrate in underground water is provided.

Owner:SHENYANG JIANZHU UNIVERSITY

System and method used for removing hydrogen sulfide in oilfield associated gas and secondary gas

PendingCN108722161APrevent long-term depositionGood processing effectGas treatmentDispersed particle separationOil fieldProduct gas

The invention belongs to the field of oil field tail gas treatment, and relates to a system and a method used for removing hydrogen sulfide in oilfield associated gas and secondary gas. According to the system, a double path mode is adopted, one path is adopted for absorption, and one path is adopted for oxidation regeneration. The numbers of absorbing towers and regeneration towers can be designed based on-site practical situations. Compared with other conventional technology, the system and the method possesses following advantages: the safety is better, environment protection is achieved, raw materials are saved, the effect is stable, the separated gas is capable of reaching discharging requirements, rapid sulphur enriching is realized, the enriched sulphur particles are large, blocks are large, the purity is high, and the utilization value is high.

Owner:PANJIN DAOBOER PETROLEUM NEW TECH DEV +1

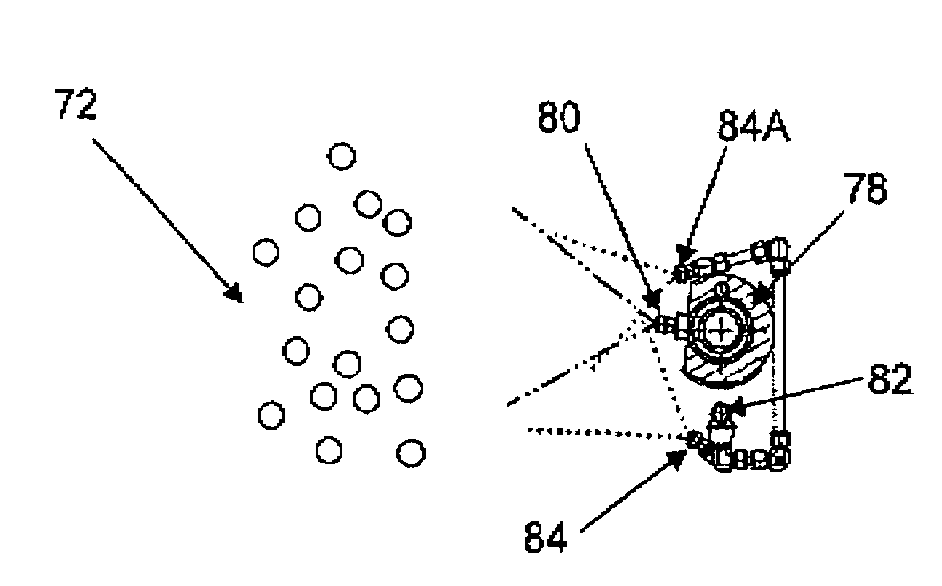

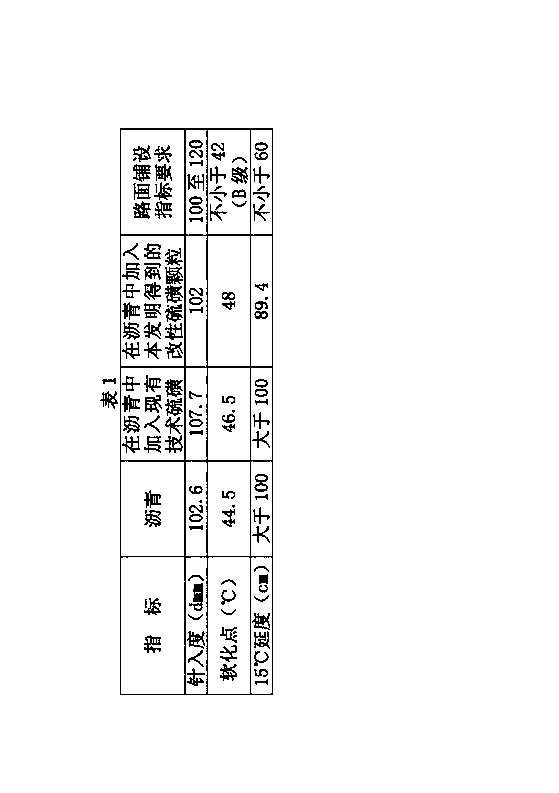

Sulphur pellet comprising H2S-suppressant

The invention provides a sulphur pellet comprising at least one H2S-suppressant, comprising in the range of from 60 to 100 wt % elemental sulphur, based on the total weight of the pellet. The invention further provides a process for the manufacture of sulphur pellets comprising at least one H2S-suppressant, comprising the steps of:(a) mixing elemental sulphur, one or more H2S-suppressants and optionally a filler in a mixing unit to obtain a mixture;(b) shaping and / or palletizing the mixture obtained in step (a) in a palletizing unit to obtain H2S-suppressant-comprising sulphur pellets.The invention further provides a process for the manufacture of a sulphur-comprising asphalt paving mixture comprising the steps of:(i) preheating bitumen at a temperature of between 140 and 180° C.;(ii) preheating aggregate at a temperature of between 140 and 180° C.;(iii) mixing the hot bitumen with the hot aggregate in a mixing unit,wherein sulphur pellets comprising H2S-suppressant according to the invention are added in at least one of the steps (i), (ii) or (iii).The invention also provides the use of a sulphur-comprising asphalt paving mixture comprising H2S-suppressant in the paving of roads.

Owner:SHELL OIL CO

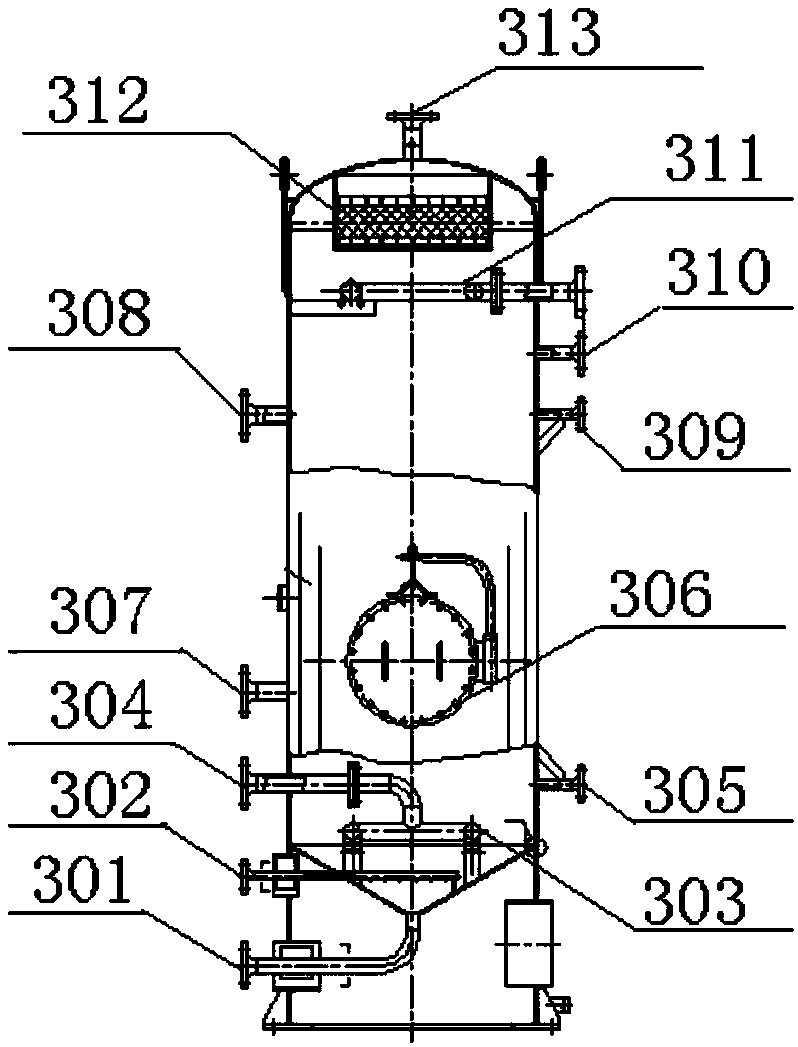

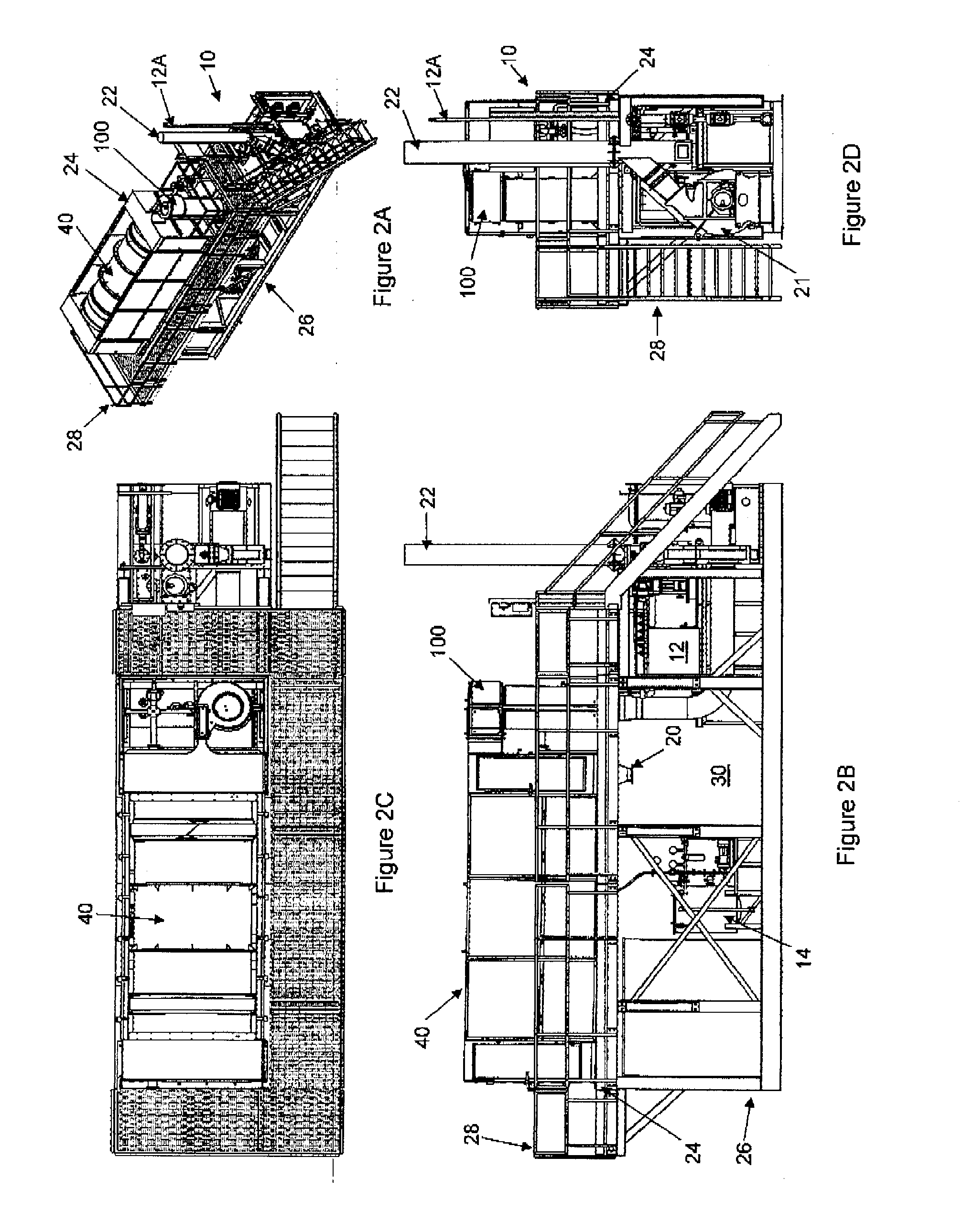

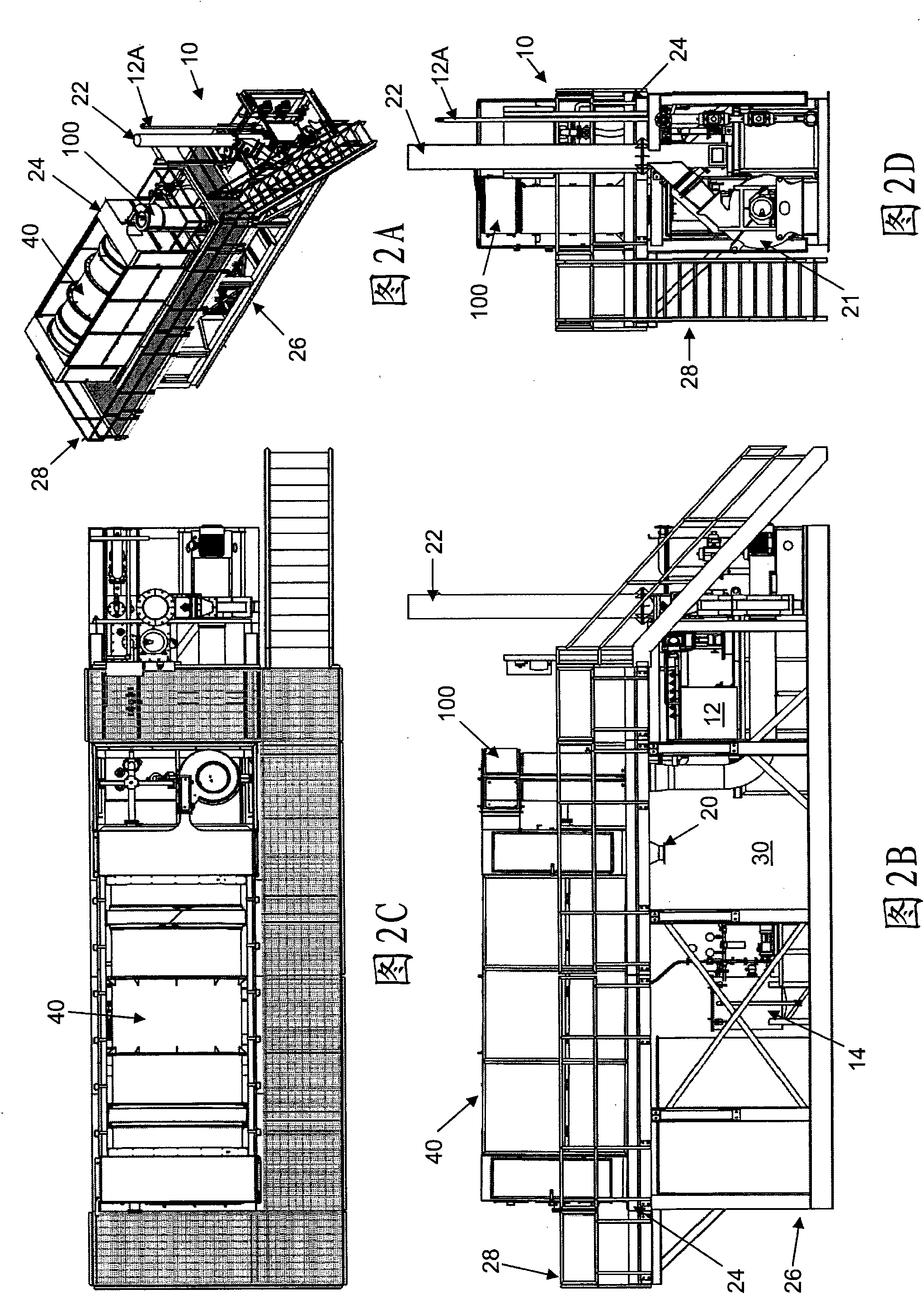

Sulphur Granulation Apparatus and Process

A portable apparatus for producing sulphur granules includes a granulator with a rotatable drum having distinct zones for seed generation and product growth. The seed generation zone has an intense water spray pattern for each sulphur spray nozzle with intersecting water sprays to solidify molten sulphur and create seeds. The growth zone has a moderate, non-intersecting water spray pattern to allow sulphur nozzles to coat and grow a curtain of seeds into granules. The granulator's exhaust air is filtered either by a heated cyclone separator to recapture residual sulphur particles and moisture before venting, and / or by a granular air filter which uses the produced granules to filter the granulator's exhaust air. A two piece collar enhances maintenance of the granulator's drive system.

Owner:ENERSUL

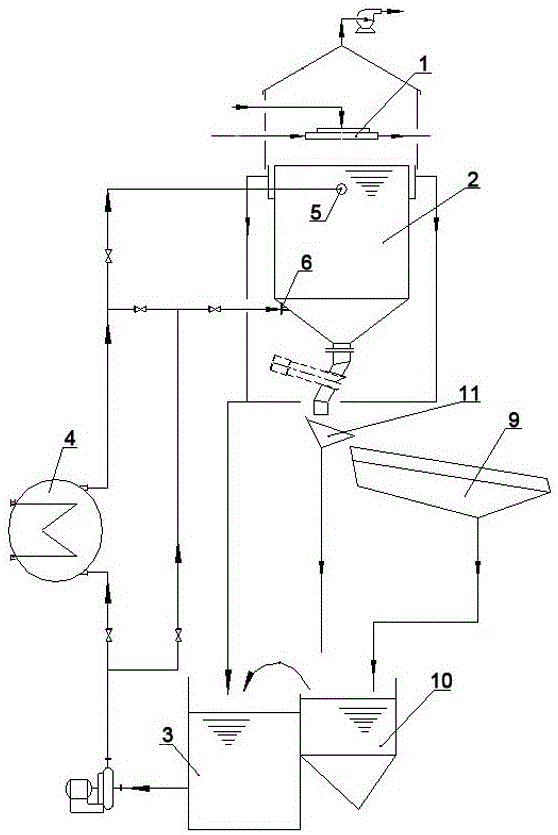

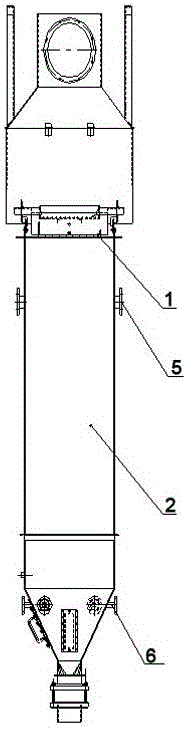

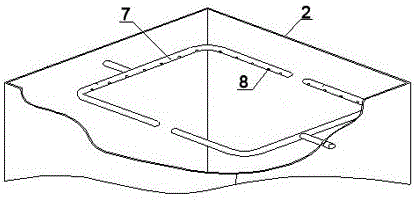

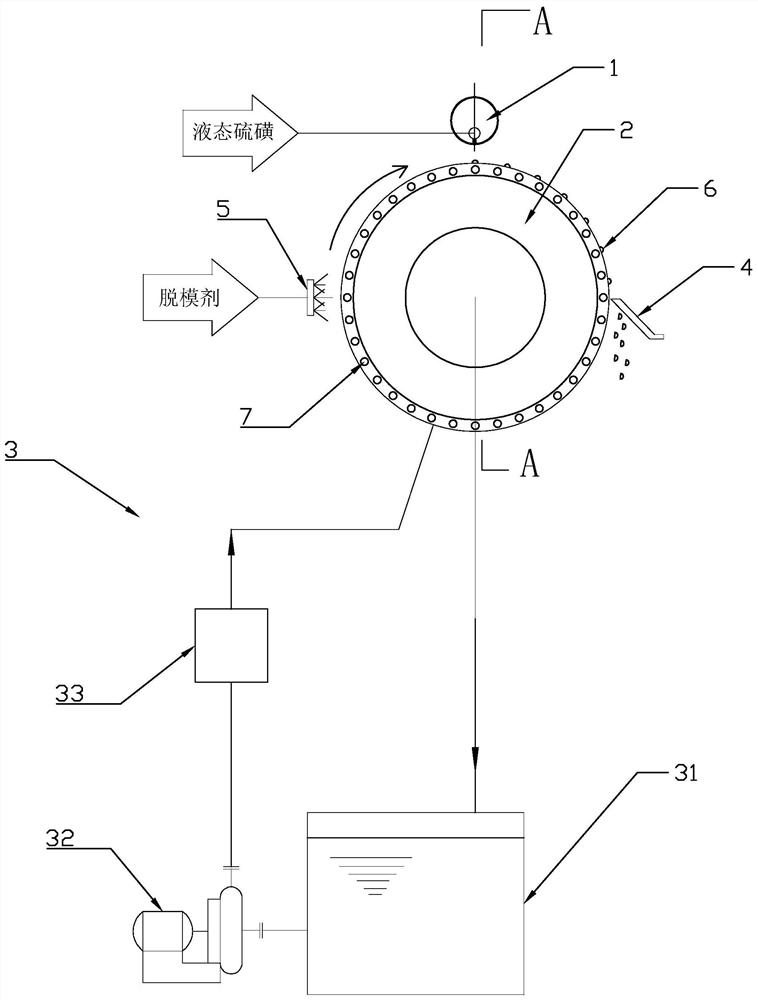

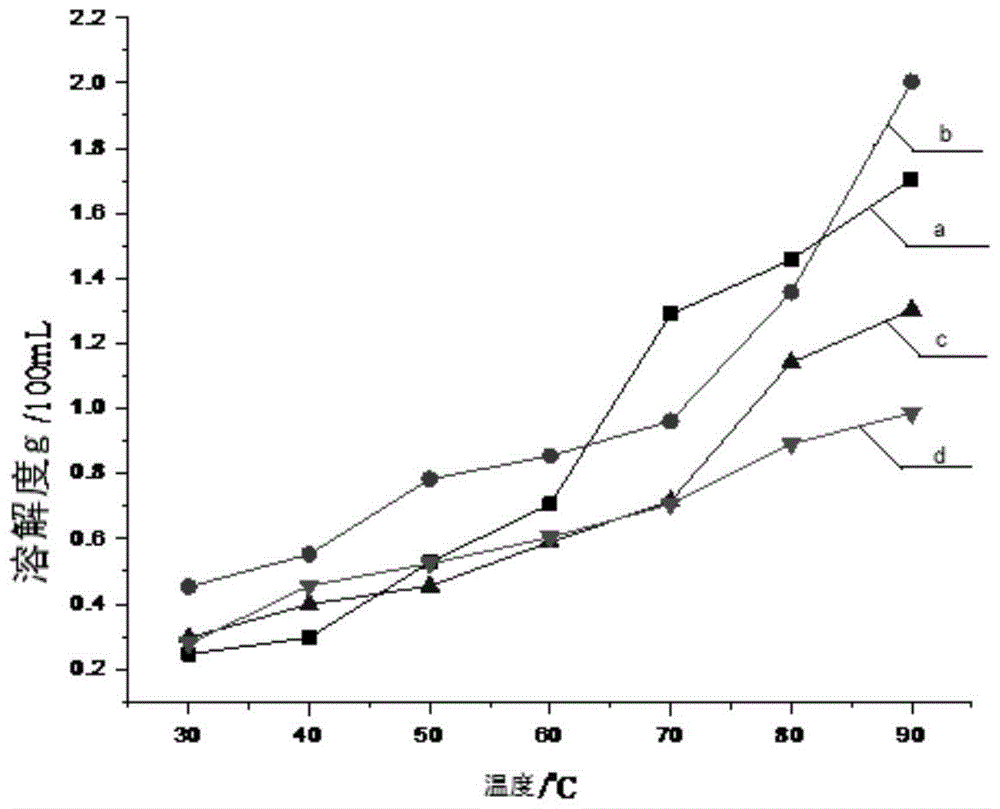

Wet forming equipment for sulphur and forming technology thereof

ActiveCN105129740AEasy to dehydrateEasy to operateSulfur preparation/purificationHeat transmissionProcess engineering

The invention relates to wet forming equipment for sulphur and a forming technology thereof. An upper cooling water inlet and a lower cooling water inlet are formed in a forming tank, two branches of a water outlet of a hot water tank are connected to a hot water inlet of a heat exchanger and the lower cooling water inlet of the forming tank respectively, and two branches of a cold water outlet of the heat exchanger are connected to the lower cooling water inlet and the upper cooling water inlet of the forming tank respectively; a steam coil pipe is arranged at the bottom of a forming disc in a buckling mode, an indirect heat transmission mode is changed into a direct heat transmission mode, therefore, the heat preservation measures are more stable, and the steam usage amount can be decreased; an arc-shaped static screen is arranged between the forming tank and a vibrating-dewatering screen, the dewatering load of the vibrating-dewatering screen is reduced, therefore, the moisture content of sulphur particles screened out of the vibrating-dewatering screen is reduced, and the production efficiency is improved. According to the wet forming technology for the sulphur, the operability, adjustability and controllability of the sulphur production process are improved, and therefore not only can the resource cost be saved, but also the production efficiency and the regularity of the sulphur particles can be improved.

Owner:LUOYANG JIANGUANG SPECIAL EQUIP

Modified sulfur granules and preparation method and application thereof

InactiveCN103275498AEnhanced inhibitory effectRaw materials are easy to getBuilding insulationsSulfur granulesPhysical chemistry

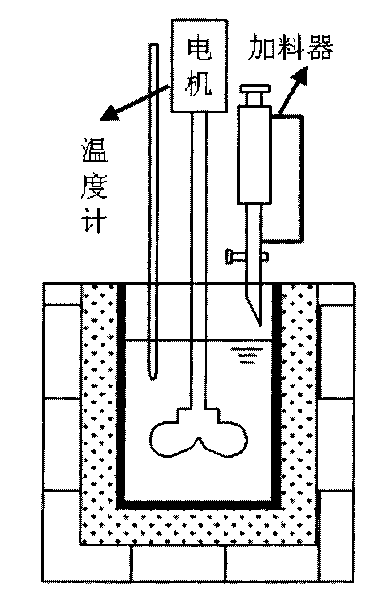

The invention relates to the technical field of sulfur, and in particular relates to modified sulfur granules and a preparation method and application thereof. The modified sulfur granules comprise the following raw materials in parts by weight: 80-100 parts of sulfur and 1-10 parts of hydrogen sulfide inhibitor. The modified sulfur granules are prepared by the following steps of: adding the sulfur and hydrogen sulfide inhibitor of the required amount into a reaction container and uniformly mixing; heating the uniformly mixed sulfur and hydrogen sulfide inhibitor in an oil bath at 130-140 DEG C; and after the sulfur and hydrogen sulfide inhibitor are molten, reacting for 25-35 minutes until the product has a bright ash black color. According to the sulfur granules provided by the invention, after the heating reaction of the sulfur and hydrogen sulfide inhibitor in the oil bath, the mixture after the reaction is poured into cold water and then filtered to obtain the modified sulfur granules. The sulfur granules provided by the invention have the characteristics that the raw materials are easily available, the physical and chemical properties are stable, the sulfur granules are convenient to store and transport, and the hydrogen sulfide inhibition effect is good in combination with asphalt; and moreover, the production cost is reduced, and the production efficiency is improved.

Owner:XINJIANG UNIVERSITY

Sulfur particle flocculating agent applicable to iron-based desulfurizing solution

InactiveCN105194911AReduce sulfur particulate contentEasy to separateDispersed particle separationSulfur preparation/purificationFlocculationPhysical chemistry

The invention discloses a sulfur particle flocculating agent applicable to iron-based desulfurizing solution. The sulfur particle flocculating agent is composed of a flocculation initiating agent, a flocculation coagulating agent and a flocculation settling agent. By addition of the sulfur particle flocculating agent into complex iron desulfurizing solution, sulfur particles generated in a desulfurizing process can be flocculated and settled in a settling tank spontaneously, and consequently the sulfur particles can be separated out to prevent tower blockage and realize reclaiming of by-product sulfur.

Owner:ZHONGBEI UNIV

Process for making a composite granule with rock phosphate, sulfur, and humic acid

ActiveUS11136275B2Phosphatic fertiliser granulation/pelletisationOrganic fertilisersSulfur granulesPhosphate

Owner:HUMIC GROWTH SOLUTIONS LLC

Method and device for preparing sulfur by recovering hydrogen sulfide gas from viscose waste gas

The invention discloses a method and a device for preparing sulfur by recovering hydrogen sulfide gas from viscose waste gas. The method comprises the following steps: preparing a washing solution from ethylenediamine tetraacetic acid, triethanolamine, ferrous sulfate, sodium carbonate and water; pumping the washing solution into an H2S washing tower for spraying, introducing viscose waste gas through the bottom of the washing tower and realizing full contact of the waste gas with the washing solution in a countercurrent mode, and absorbing hydrogen sulfide gas in the viscose waste gas by thewashing solution; conveying enriched elemental sulfur containing liquid flowing out of the bottom of the washing tower into a centrifugal machine; conveying concentrated sulfur slurry separated by thecentrifugal machine into a sulfur recovery device; heating sulfur to 135 DEG C in the sulfur recovery device and thenmelting into liquid sulfur, conveying pure sulfur liquid into a sulfur granulator,separating into small liquid drops and cooling to 50 DEG C for solidification to obtain sulfur particles. The method has the beneficial effects that hydrogen sulfide is selectively treated, a large amount of detergent is not consumed, heating and pressurizing are not needed, and the hydrogen sulfide gas can be recycled from the viscose waste gas to prepare sulfur.

Owner:博拉经纬纤维有限公司

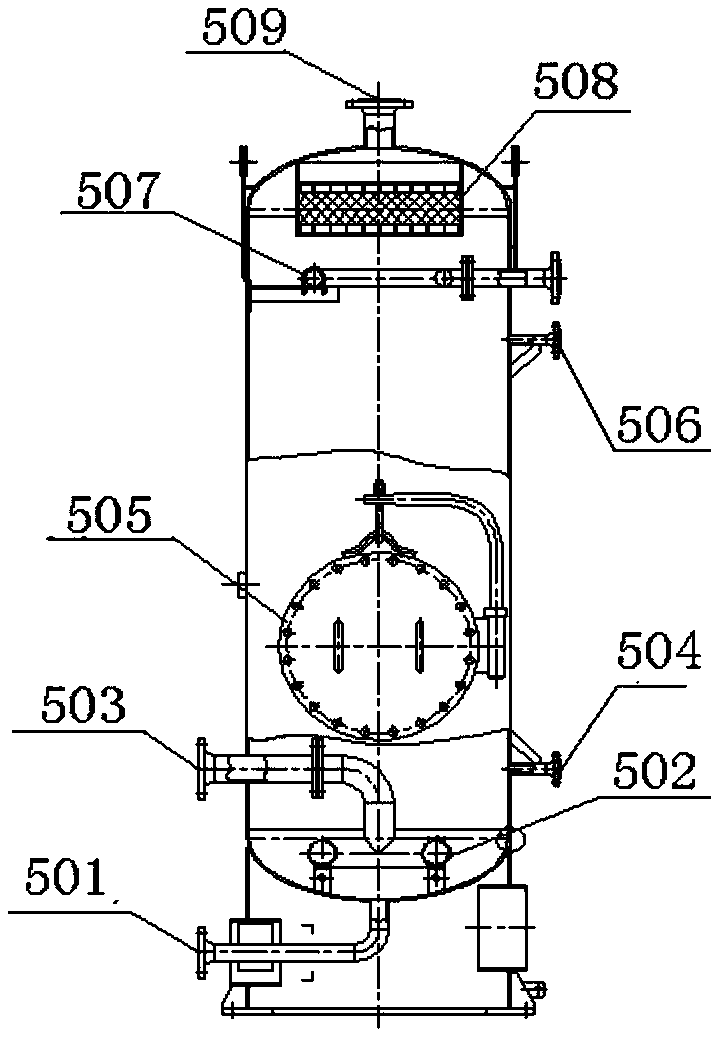

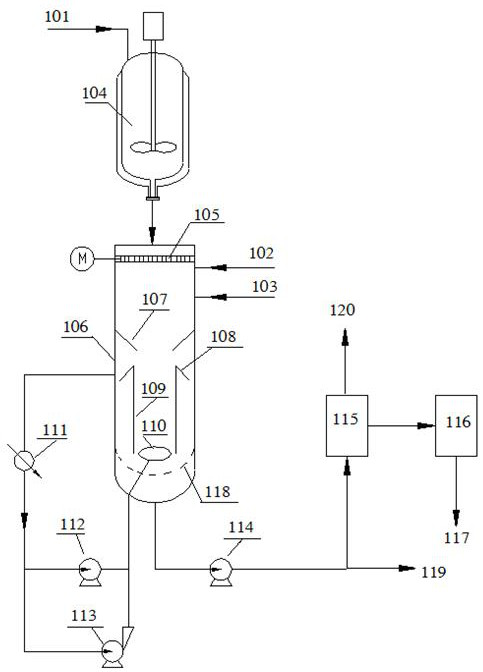

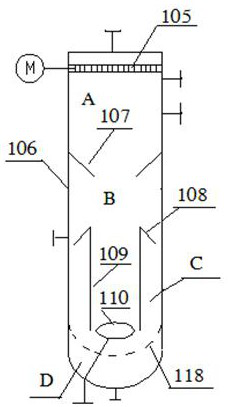

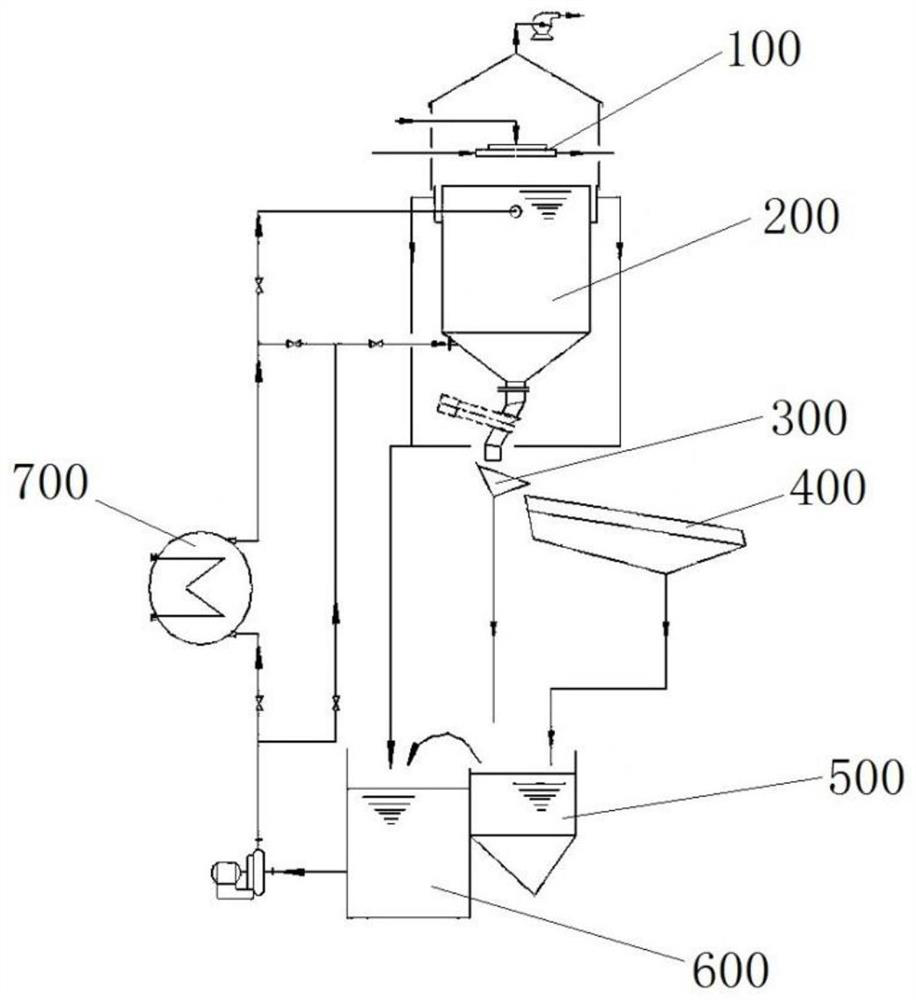

High performance insoluble sulfur production system and method

PendingCN113120870ASolve transportation difficultiesSolving Sulfur-Clogged PipelinesChemical industrySulfur preparation/purificationProcess engineeringSulphur granules

The invention discloses an insoluble sulfur production system and method. The production system comprises a polymerization kettle, a quench tower, a washing filter and a dryer, a discharge port of the polymerization kettle communicates with a feed port of the quench tower through a pipeline, a discharge port of the quench tower communicates with a feed port of the washing filter through a discharge pump through a pipeline, and a discharge port of the washing filter is connected with a feed port of the dryer through a pipeline. According to the production system disclosed by the invention, granulation, curing, extraction and crushing processes are integrated, continuous quenching, curing and the like of the polymerized sulfur are realized, and the technological process is simplified. According to the method, the operation process is shortened, the purity, thermal stability and yield of the product are ensured, the blockage of a sulfur particle system is avoided, and the production process has the characteristics of safety, reliability, simple equipment and operation, low operation cost, obvious energy-saving effect and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Complex iron desulfurizer as well as preparation method and application thereof

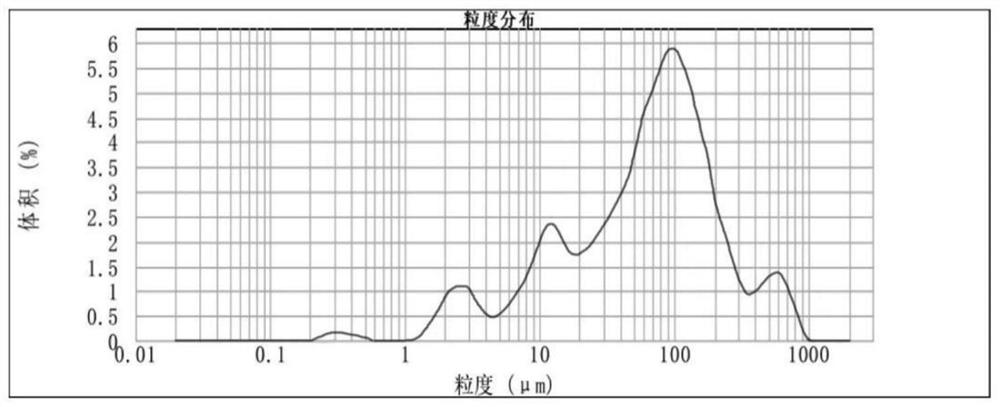

PendingCN112973404AHigh sulfur capacityLess secondary saltDispersed particle separationGas contaminants removalIron saltsPolyaspartic acid

The invention relates to the technical field of desulfurization, and particularly discloses a complex iron desulfurizer as well as a preparation method and application thereof. The complex iron desulfurizer comprises, by weight, 0.4 to 1 part of a soluble iron salt, 2 to 10 parts of iminodisuccinate, 2 to 10 parts of polyaspartate, 10 to 15 parts of a hydrogen sulfide absorbent, 1 to 5 parts of a corrosion inhibitor and 900 to 1100 parts of water. The preparation method of the complex iron desulfurizer comprises the following steps: adding the soluble iron salt into water for dissolving according to the weight part ratio, then sequentially adding the iminodisuccinate, the polyaspartate, the corrosion inhibitor and the hydrogen sulfide absorbent, and adjusting the pH value to 8-9 to obtain the complex iron desulfurizer. The complex iron desulfurizer provided by the invention has the advantages of high sulfur capacity, low secondary salt generation amount and no temperature influence, and the generated sulfur particles have the advantages of high purity, large particle size and easiness in separation, and have relatively high application value.

Owner:河北络合科技有限公司

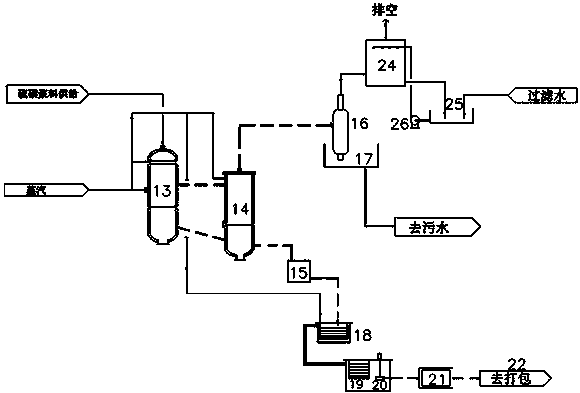

Insoluble sulfur production system and production method

ActiveCN113120869ASolve clogged pipesSolve key problems such as equipmentChemical industryChemical liquid solidificationEngineeringProcess engineering

The invention discloses an insoluble sulfur production system and a production method. The production system comprises a polymerization kettle, a quench tower, a washing filter and a dryer, a discharge port of the polymerization kettle communicates with a feed port of the quench tower through a pipeline, a discharge port of the quench tower communicates with a feed port of the washing filter through a discharge pump through a pipeline, and a discharge port of the washing filter is connected with a feed port of the dryer through a pipeline. According to the production system disclosed by the invention, granulation, curing, extraction and crushing processes are integrated, continuous quenching, curing and the like of the polymerized sulfur are realized, and the technological process is simplified. According to the method, the operation process is shortened, the purity, thermal stability and yield of the product are ensured, the blockage of a sulfur particle system is avoided, and the production process has the characteristics of safety, reliability, simple equipment and operation, low operation cost, obvious energy-saving effect and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Sulfur flocculation precipitator as well as preparation method and application thereof

ActiveCN114470885AThe preparation method is simple and easyEasy to operateDispersed particle separationSulfur preparation/purificationFlocculationAlcohol

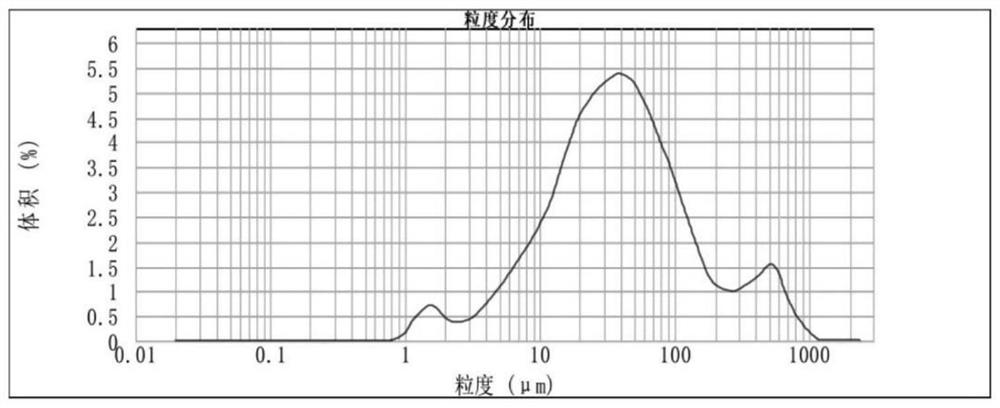

The invention relates to the technical field of desulfurization, and provides a sulfur flocculation precipitator as well as a preparation method and application thereof. The sulfur flocculation precipitator provided by the invention is prepared from the following components in percentage by mass: 6 to 12 percent of glycolipid type biological surfactant, 0 to 1.5 percent of Tween type surfactant, 0.1 to 1 percent of low-carbon alcohol and the balance of water. The sulfur flocculation precipitator provided by the invention is good in wettability and strong in bridge bond action, and the relatively high wettability can change the hydrophobicity of sulfur, so that the sulfur forms a wetted body, and the adhesion is reduced; the good bridge bond effect can promote the wetted sulfur to rapidly agglomerate, hydrophilic large-particle sulfur is formed, and sulfur sedimentation is accelerated, so that sulfur adhesion and blockage are effectively prevented. Results of the embodiment show that by adopting the sulfur flocculation precipitator obtained by the invention, sulfur particles can be quickly gathered and precipitated, the precipitation time is as low as 18s, and the particle size of the generated sulfur particles is as high as 150mu m.

Owner:CHINA PETROCHEMICAL CORP +2

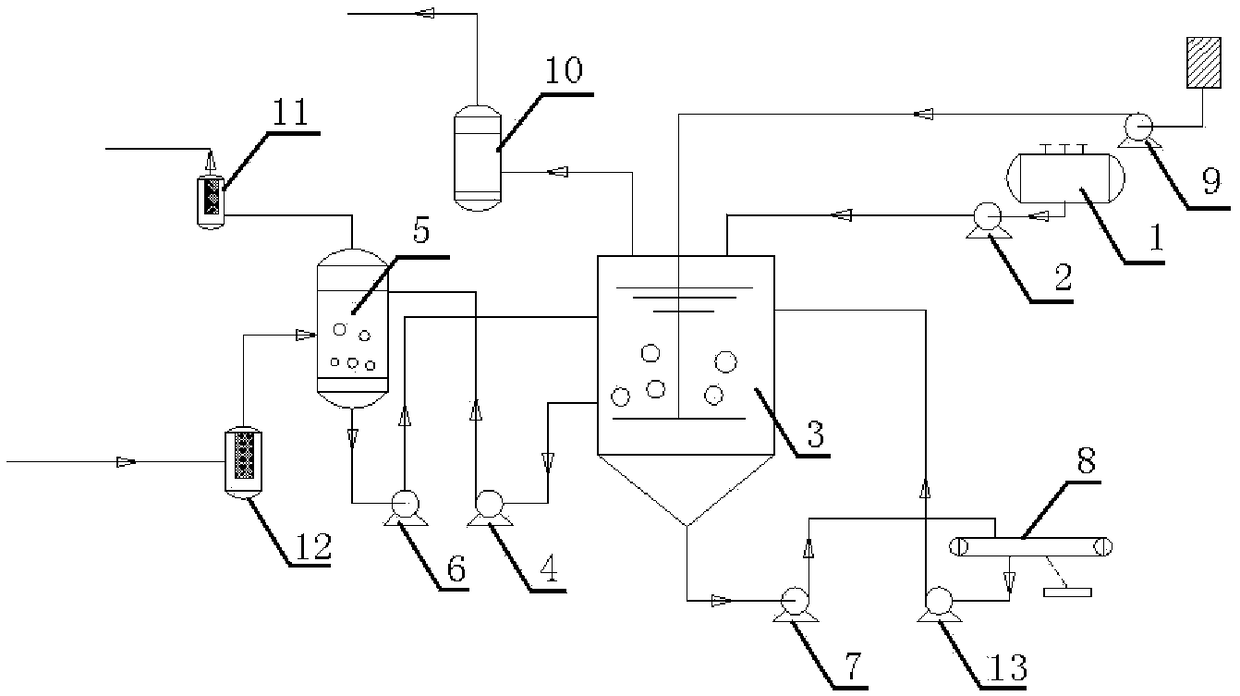

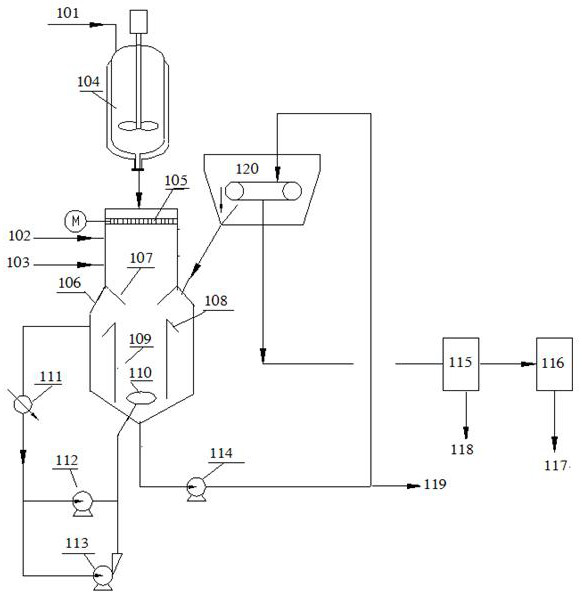

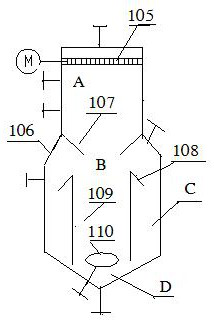

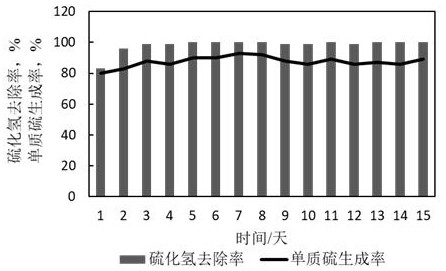

Biological desulfurization integrated system and method for hydrogen sulfide-containing gas

PendingCN112495162ASmall footprintReduce construction costsBioreactor/fermenter combinationsBiological substance pretreatmentsMicroorganismBiological oxidation

The invention relates to a biological desulfurization integrated system and method for hydrogen sulfide-containing gas, the biological desulfurization integrated system comprises an absorption tower and a biological sulfur oxide separation integrated device, the bottom end of the absorption tower is connected with the lower end of the biological sulfur oxide separation integrated device, and the middle end of the biological sulfur oxide separation integrated device is connected with the top end of the absorption tower; in the reaction process, hydrogen sulfide is absorbed by alkali liquor in the absorption tower to form hydrosulfide, a high-sulfur solution containing the hydrosulfide enters the biological oxidation sulfur separation integrated unit, the hydrosulfide is firstly oxidized into sulfur by microorganisms, and after sulfur particles are subjected to sedimentation and gravity separation, a regenerated solution returns to the absorption tower to restart absorption circulation;according to the invention, the biological oxidation process and the sulfur sedimentation process are integrated in one reactor, so that the occupied area of equipment is remarkably reduced, the operation difficulty is reduced, and the risk that air enters treated gas is reduced; and the system is simple in structure, convenient to process and beneficial to amplification.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +2

Preparation method of composite anode material for lithium element sulphur secondary battery

The invention comprises a preparation method of composite anode material for lithium element sulphur secondary battery, belonging to the field of chemical energy storage battery. The composite material is formed by taking element sulphur as electrode active center and conductive polymer polythiophene with excellent in-situ chemical oxidation polymerization conductivity as shell. The concrete preparation method comprises adding anhydrous chloroform in element sulphur and anhydrous ferric chloride, mixing uniformly, putting into a controllable low temperature reaction kettle, and slowly adding monomer thiophene by adopting in-situ chemical oxidation polymerization process to clad polythiophene on the surface of sulphur granules to form the composite product with uniform granules. The composite anode material prepared by the inventive method has high electrochemical activity, and the battery packed by the material has large discharge specific volume and long cycle life, thus having advantage in new system of large volume energy storage battery.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Separation and extraction method for sulfur powder in water during preparation of insoluble sulfur

PendingCN110697659AEasy to separateContinuous key production processSulfur preparation/purificationSolid solvent extractionPhysical chemistrySlurry

The invention provides a separation and extraction method for sulfur powder in water during preparation of insoluble sulfur. The method is characterized by comprising the following steps: pumping slurry formed by water and crude insoluble sulfur powder into a separation tank by using a pump, wherein an extraction solvent is added into the separation tank, settling sulfur particles to enter the solvent, pumping a mixture of the solvent and the sulfur particles into the upper part of an extraction tower by using a pump, pumping the solvent to the lower part of the extraction tower by using a pump, allowing the solvent flowing out from the top of the extraction tower to return to the separation tank, performing evaporation on part of the solvent to recover the solvent to obtain soluble sulfur, adding a stabilizer into insoluble sulfur and a solvent flowing out from the bottom of the extraction tower, performing filtration, and performing evaporation to recover the solvent and obtain the purified insoluble sulfur.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

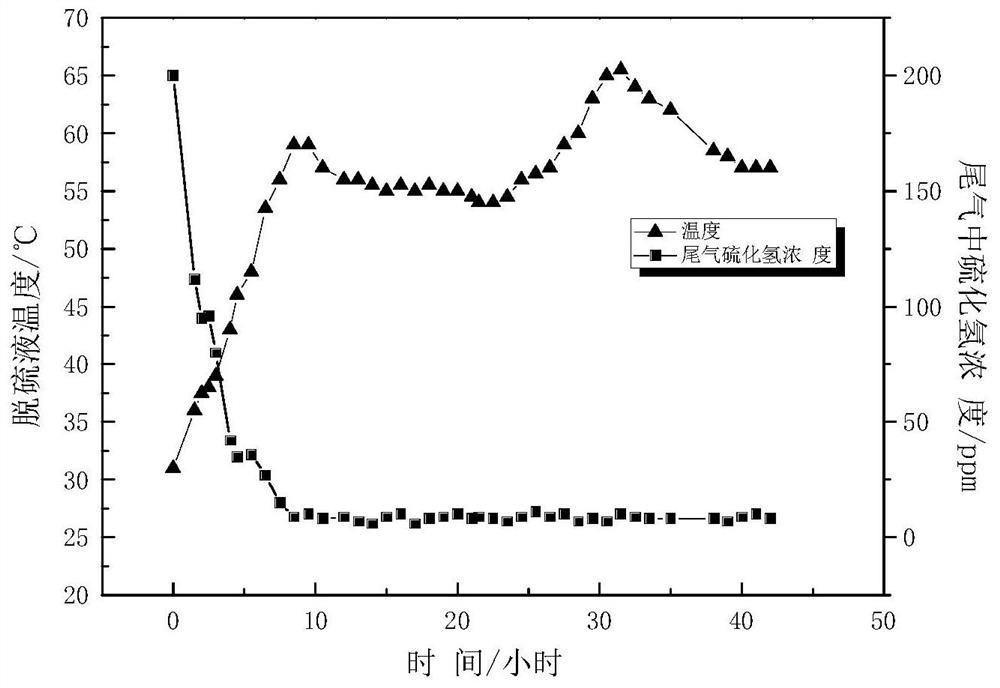

Wet oxidation desulfurization system for Claus hydrogenation tail gas, and desulfurizationmethod thereof

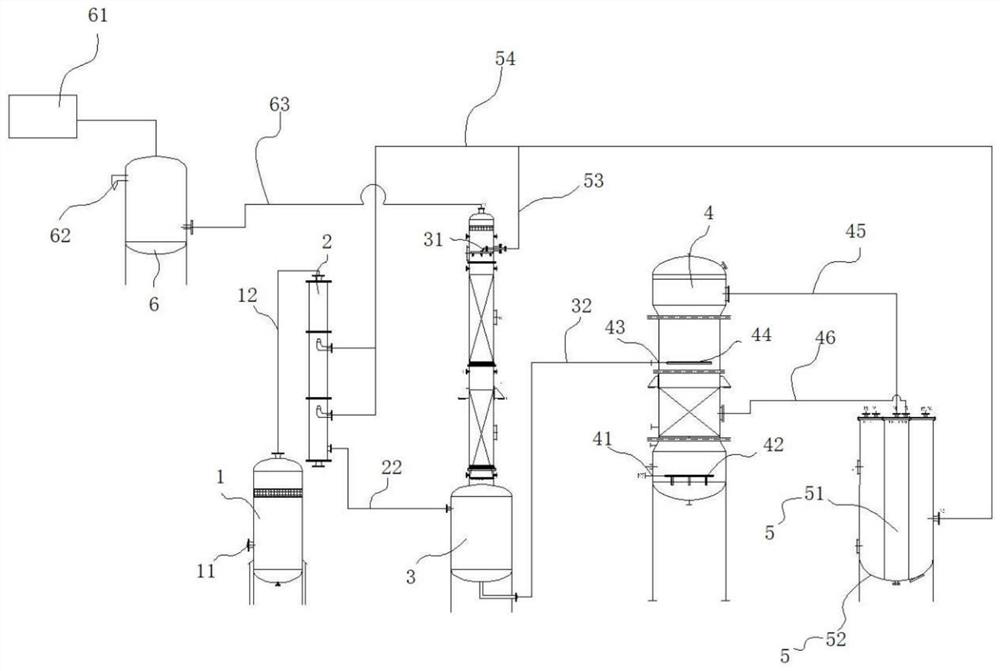

PendingCN113041825AAchieve recyclingAchieve separationDispersed particle separationSulfur preparation/purificationBuffer tankPhysical chemistry

The invention discloses a wet oxidation desulfurization system for Claus hydrogenation tail gas, and relates to the technical field of industrial tail gas desulfurization. The system comprises a buffer tank, a booster fan, a dynamic wave washer, an absorption tower, a regeneration tower, a settling tank, a washing tank and a filter bag centrifuge. The invention also provides a desulfurization method adopting the organic phase iron-based ionic liquid desulfurization system. The desulfurization system disclosed by the invention has the beneficial effects that the desulfurization system disclosed by the invention can realize wet-process oxidation desulfurization of Claus hydrogenation tail gas, meanwhile, desulfurization liquid cyclic regeneration and sulfur separation are realized, through a dynamic wave-absorption tower-washing tank three-step treatment process, the desulfurization efficiency of hydrogen sulfide reaches 99.9% or above, the pH of a desulfurization system and the morphology of sulfur particles do not need to be regulated and controlled in the desulfurization process, and secondary pollution is avoided.

Owner:BEIJING UNIV OF CHEM TECH +1

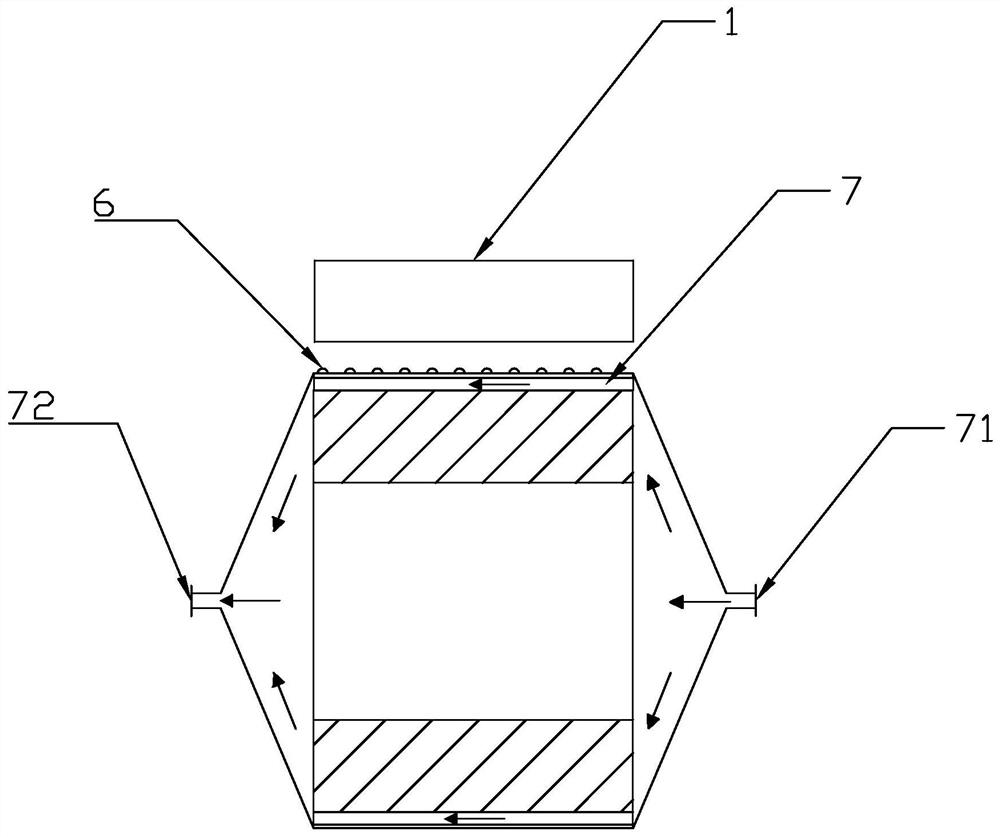

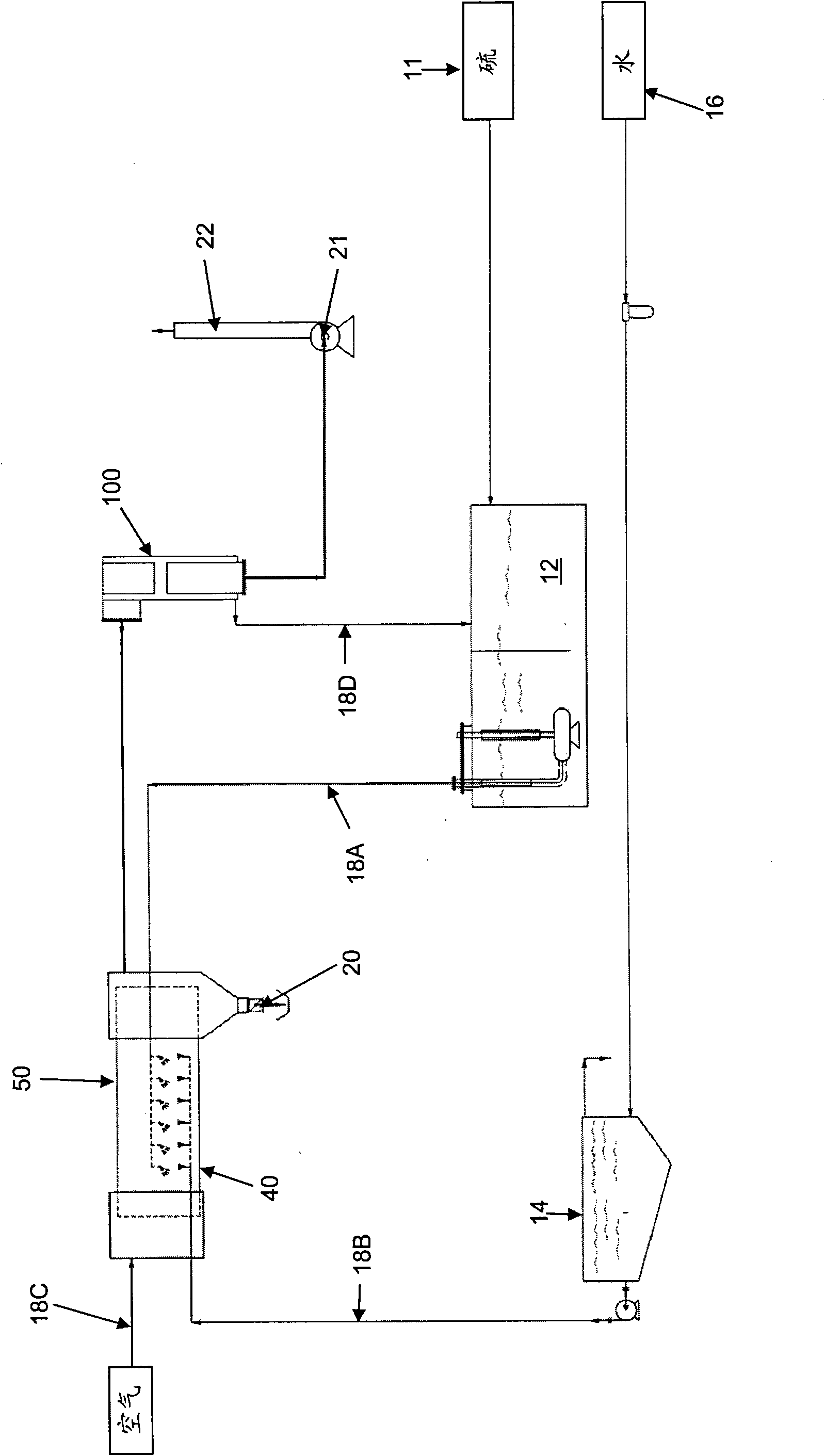

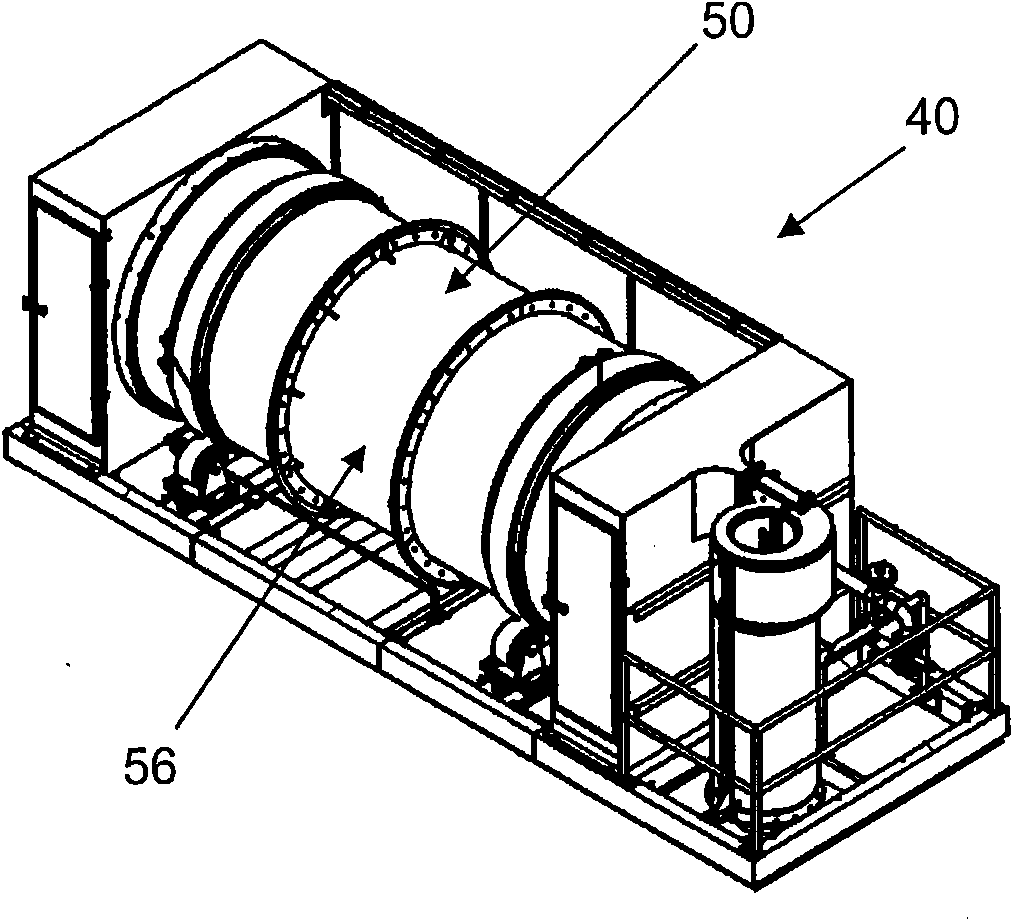

Complete equipment and method for drum sulfur granulation with cooling flow channel

PendingCN111939836AReduce moisture contentImprove heat transfer efficiencyGranulation in rotating drumsSulfur preparation/purificationThermodynamicsEngineering

The invention provides complete equipment and a method for drum sulfur granulation with a cooling flow channel. The complete equipment comprises a liquid sulfur distributor, a cooling granulation drum, a cooling water circulation system and a scraper, wherein the liquid sulfur distributor can distribute and drop liquid sulfur produced by an upstream device to the outer surface of the cooling granulation drum; the cooling granulation drum can rotate around a central shaft, the outer surface of the cooling granulation drum can be used for cooling liquid sulfur to form sulfur particles, and a cooling flow channel is arranged in the cooling granulation drum and can be used for cooling the outer surface; the cooling water circulation system is in circulation communication with the cooling flowchannel and can provide cooling water for the cooling flow channel; and the scraper is in scraping connection with the outer surface of the cooling granulation drum and can be used for scraping sulfurparticles on the outer surface of the cooling granulation drum. The outer surface of the cooling granulation drum is adopted for sulfur granulation, and the interior of the cooling granulation drum communicates with the cooling water system, so sulfur is not in direct contact with cooling water, and the water content of a product is low.

Owner:CHINA HUANQIU CONTRACTING & ENG CO LTD

Non-agglomerated slow release fertilizer containing sulfur, phosphorous and ammonium and preparation method thereof

The present invention relates to the technical field of slow release fertilizers, in particular to a non-agglomerated slow release fertilizer containing sulfur, phosphorous and ammonium and a preparation method thereof. According to the method provided by the present invention, after sulfur particles and water containing dispersant are mixed and are subjected to ultrasonic treatment, a thickener and a moisturizer are added in the mixture, the ultrasonic treatment is performed again to enable the dispersant, the moisturizer and the thickener to be filled among the sulfur particles, then the mixture is ground by a grinding mill, so that hydrophilicity modification treatment is performed on the sulfur particles, the content of the sulfur in the aqueous solution is high, an explosion accident caused by dust accumulation can not occur, and production safety is improved; the prepared sulfur-covered slurry is sprayed on surfaces of diammonium phosphate particles containing 18% of nitrogen and 46% of phosphorous so as to ensure that the thickness of a sulfur layer on the surface of the prepared slow release fertilizer containing sulfur, phosphorous and ammonium is 0.1-0.3 times of the diameters of the particles; and in the slow release fertilizer containing sulfur, phosphorous and ammonium, the sulfur content is 8-12%, the nitrogen content is 15-17% and the phosphorous content is 41-43%. Quality of the slow release fertilizer containing sulfur, phosphorous and ammonium is improved.

Owner:GUIZHOU KAILIN GRP CO LTD

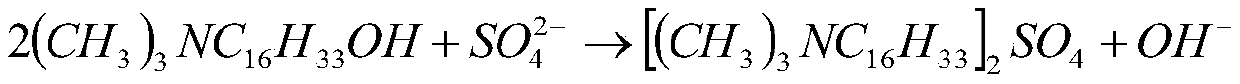

Composite desulfurizing agent

InactiveCN111265984AIncrease iron contentHigh sulfur capacityDispersed particle separationAluminium chlorideSulfate radicals

The invention discloses a composite desulfurizing agent and belongs to the technical field of gas purification. The composite desulfurizing agent comprises an iron-containing complex, an alkaline substance, a settling agent, a stabilizer, hydroquinone and water, wherein the iron ion concentration is 0.5-20 g / L and pH value is 7-8.5; the settling agent is a mixture of polyacrylamide, sodium polyacrylate, polyaluminium chloride and hexadecyl trimethyl ammonium hydroxide; according to the invention, the iron ion content is high, the sulfur capacity is high, the generated secondary salt amount issmall, sulfate ions can be removed along with sulfur, so that the situation that the desulfurization performance is reduced due to excessive accumulation of the sulfate ions in the solution is avoided, and therefore the performance is stable, secondary pollution is avoided, and generated sulfur particles settle fast and are convenient to separate.

Owner:SICHUAN XIYOUZHICHENG PETROLEUM TECH CO LTD

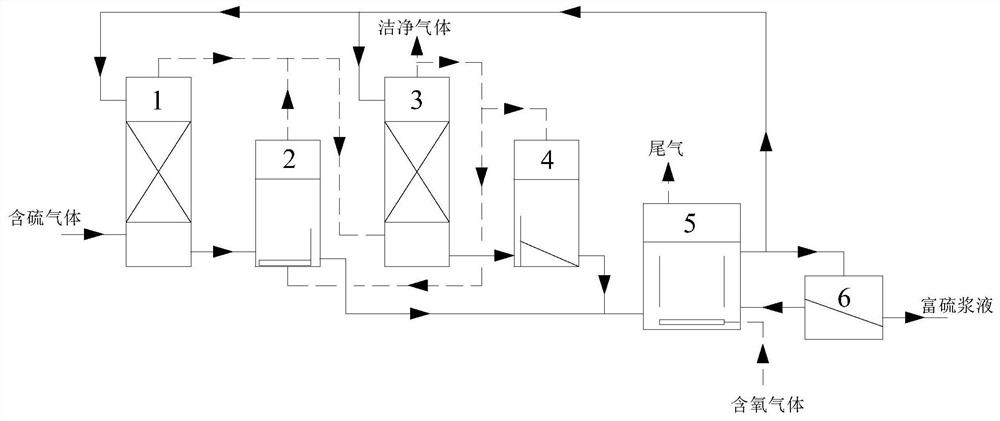

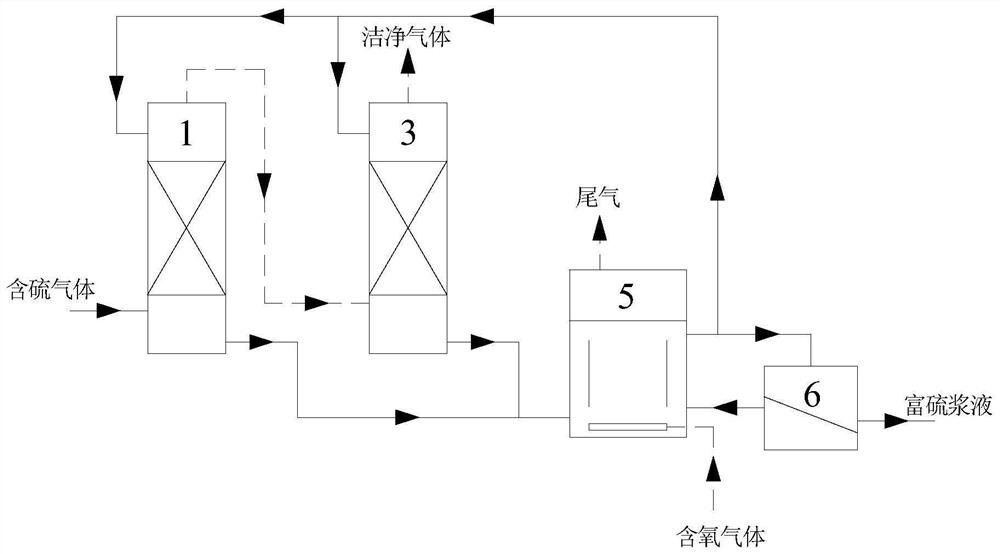

Sulfur-containing gas desulfurization device system and method

ActiveCN112892202AReduce inhibitionReduce demandGas treatmentDispersed particle separationMicroorganismSulfide

The invention provides a sulfur-containing gas desulfurization device system and method. The device system comprises a biological purification device, a deep adsorption device, a tail gas removal device, an anaerobic conversion device, a biological regeneration device and a sulfur collection device. According to the device system, due to the arrangement of the tail gas removal device and the anaerobic conversion device, and organic sulfur in sulfur-containing gas reacts with sulfur particles to generate sulfide; then the sulfide is mixed with effluent of the deep adsorption tower and enters the biological regeneration tower, and the HS- is oxidized by sulfur oxidizing microorganisms under the oxygen-enriched condition to generate elemental sulfur, and the elemental sulfur is recycled. Compared with a traditional method, the method has the advantages that by adding an organic sulfur conversion process, inhibition of organic sulfur on the biological desulfurization process is effectively reduced, absorption of desulfurization bacteria on HS- and selection of HS- oxidation pathways are enhanced, formation of S2O3 < 2-> and SO4 < 2-> in the treatment process is reduced, and the generation rate of elemental sulfur is increased; the method has excellent economic benefits and application prospects.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Sulphur granulation apparatus and process

Owner:ENERSUL

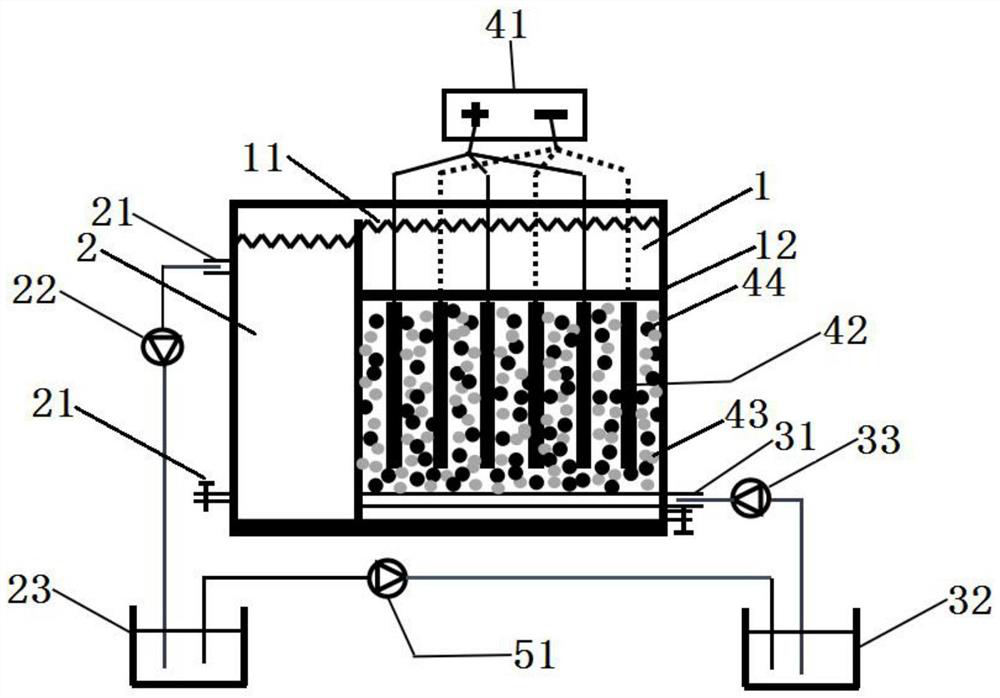

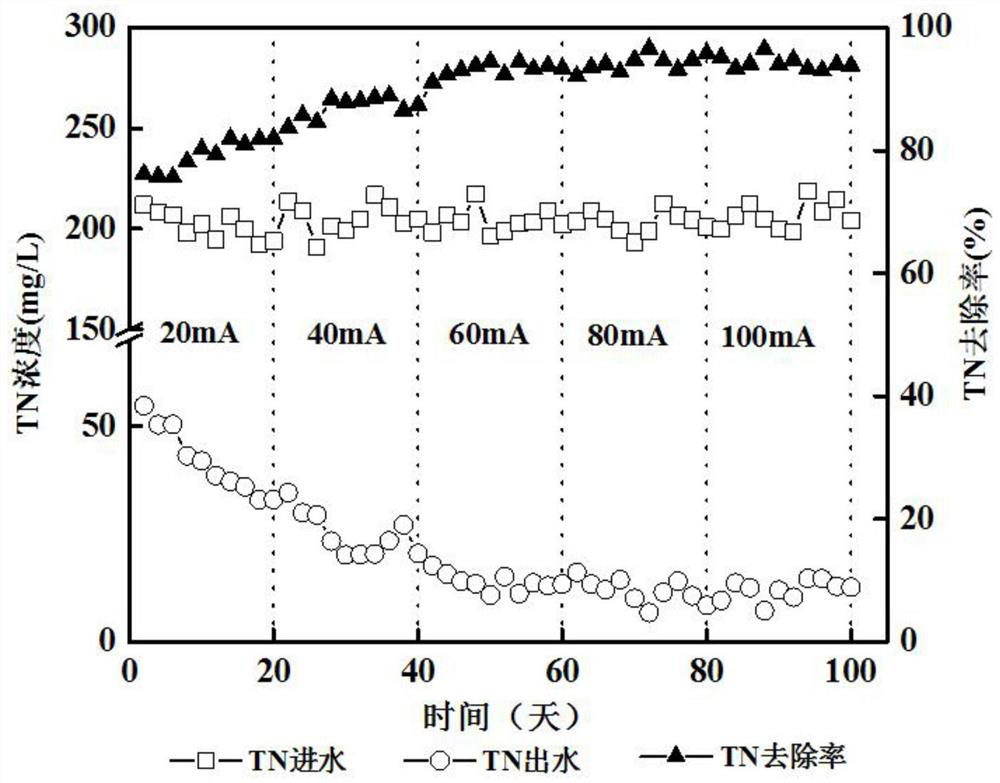

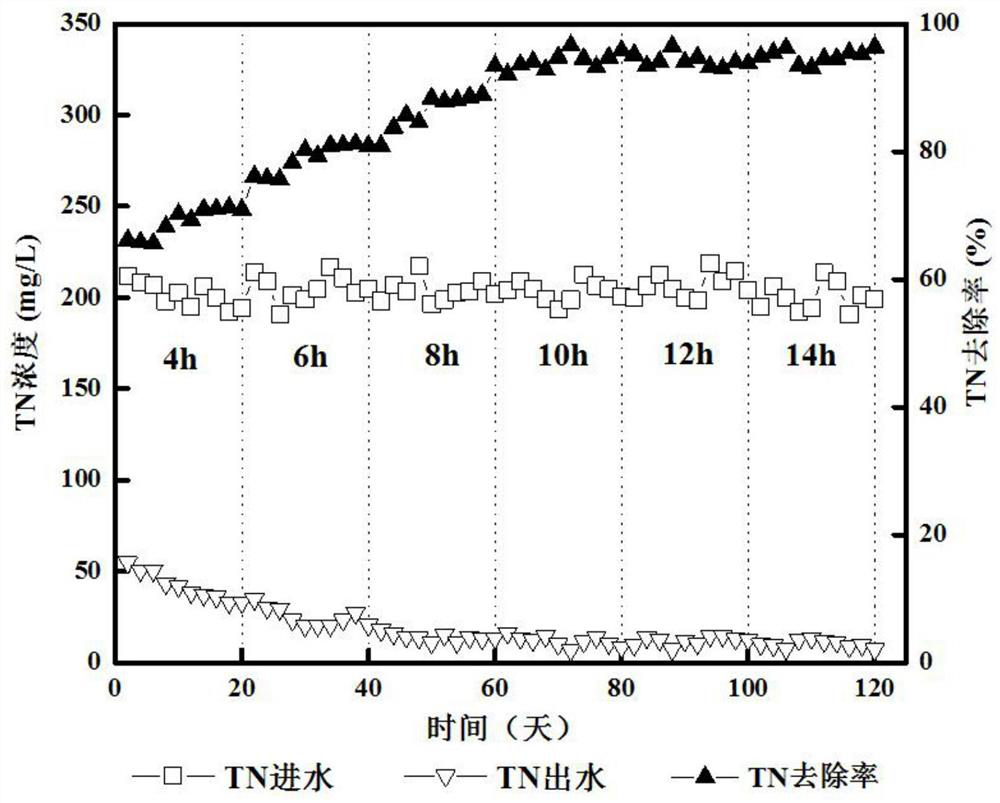

Device and method for deeply denitrifying landfill leachate through electrochemical coupling sulfur autotrophic denitrification system

PendingCN113716680AReduce outputGuaranteed denitrification activityTreatment by combined electrochemical biological processesWater contaminantsElectron donorSludge

The invention belongs to the technical field of biological sewage treatment, and particularly relates to a device and method for deeply denitrifying landfill leachate through an electrochemical coupling sulfur autotrophic denitrification system, the electrochemical coupling sulfur autotrophic denitrification system is adopted, the process operation is simple, the operation is convenient, and the stability is high; the device and method are used for deeply denitrifying the landfill leachate, an external carbon source is not needed, the sludge yield is low, the denitrification efficiency is high, and a subsequent residual sludge treatment process is not needed; in the sulfur autotrophic denitrification process, as elemental sulfur is adopted as an electron donor, the pH does not need to be adjusted, and the denitrification activity of microorganisms is well guaranteed; in the operation process, a large number of functional microorganisms can be enriched on the surfaces of the sulfur particles, the carbon particles and the electrode plates, so that sulfur autotrophic denitrification on the surfaces of the sulfur particles can be coupled with hydrogen autotrophic denitrification performed on the microorganisms on the surfaces of the cathode plates and the carbon particles, and the denitrification effect is further enhanced; the deep denitrification of the low-carbon-nitrogen-ratio landfill leachate is realized.

Owner:SUN YAT SEN UNIV

Modified sulfur particles and its preparation method and application

InactiveCN103275498BEnhanced inhibitory effectRaw materials are easy to getBuilding insulationsSulfur granulesPhysical chemistry

The invention relates to the technical field of sulfur, and relates to a modified sulfur granule and its preparation method and application; the raw material of the modified sulfur granule contains 80 to 100 parts of sulfur and 1 to 10 parts of hydrogen sulfide inhibitor in parts by weight; The modified sulfur granules are obtained according to the following steps: in the first step, add the required amount of sulfur and hydrogen sulfide inhibitor into the reaction vessel and mix them uniformly, then place the uniformly mixed sulfur and hydrogen sulfide inhibitor at 130°C to Heating in an oil bath at 140°C, the sulfur and hydrogen sulfide inhibitors are melted and reacted for 25 to 35 minutes before turning into bright gray black. In the present invention, sulfur and hydrogen sulfide inhibitors are heated and reacted in an oil bath, and the reacted mixture is poured into cold water and filtered to obtain modified sulfur particles; the present invention has the advantages of easy-to-obtain raw materials, stable physical and chemical properties, convenient storage and transportation, and The combination of asphalt and hydrogen sulfide has a good suppression effect, which reduces the production cost and improves the production efficiency.

Owner:XINJIANG UNIVERSITY

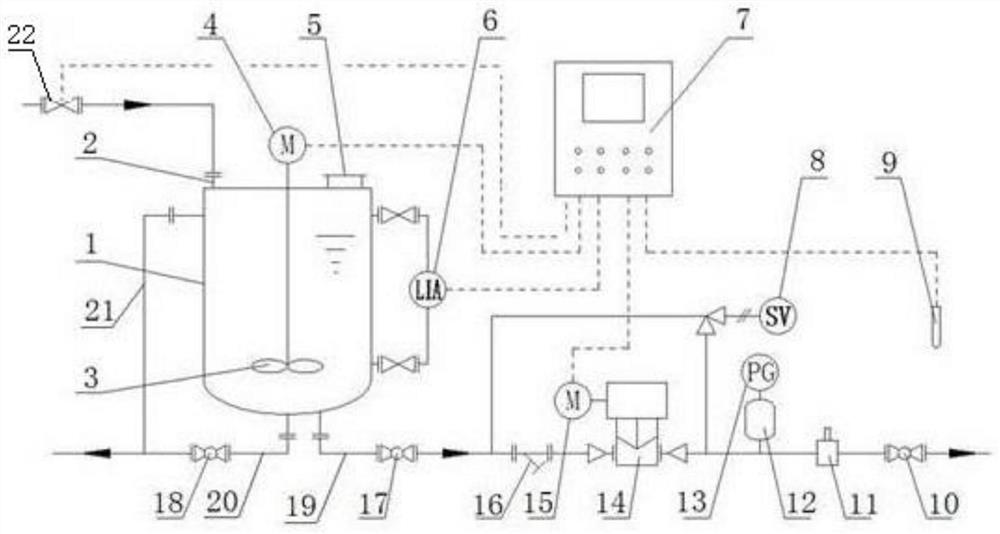

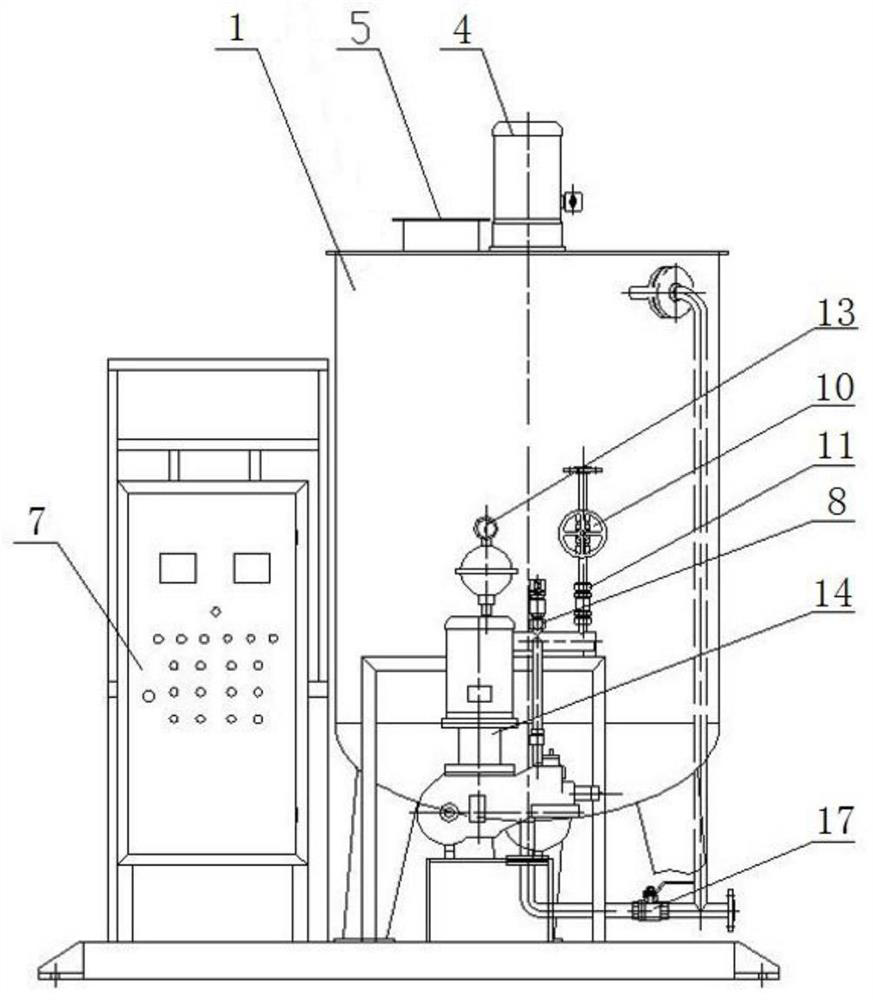

Sulfur wet forming system

PendingCN113800477AAvoid corrosionExtended service lifeSulfur preparation/purificationLiquid storage tankProcess engineering

The invention relates to the field of sulfur wet forming, in particular to a sulfur wet forming system which comprises a water tank used for containing process water, a liquid storage tank used for storing alkali liquor, a pH detector used for detecting the pH value of process water in the water tank, a liquid injection pipeline connected to the liquid storage tank and a controller. The liquid injection pipeline is used for injecting the alkali liquor in the liquid storage tank into the water tank, and is provided with a metering pump. The controller is used for controlling the metering pump to be opened or closed according to a detection value of the pH detector. According to the sulfur wet forming system, the pH value of process water is always kept in a proper range in the production process, equipment and pipelines are prevented from being corroded, the service life of the sulfur wet forming system is prolonged, and the forming quality of sulfur particles is improved.

Owner:CHINA PETROLEUM & CHEM CORP +2

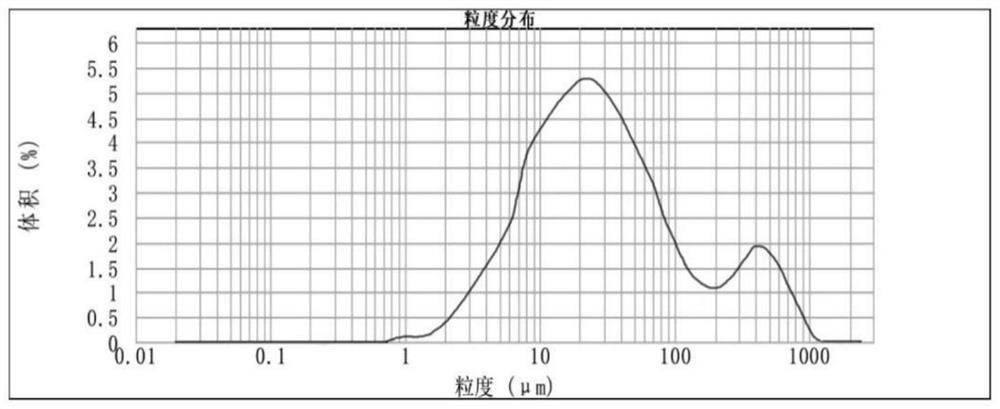

A kind of separating agent and method for separating sulfur from sulfur-containing system

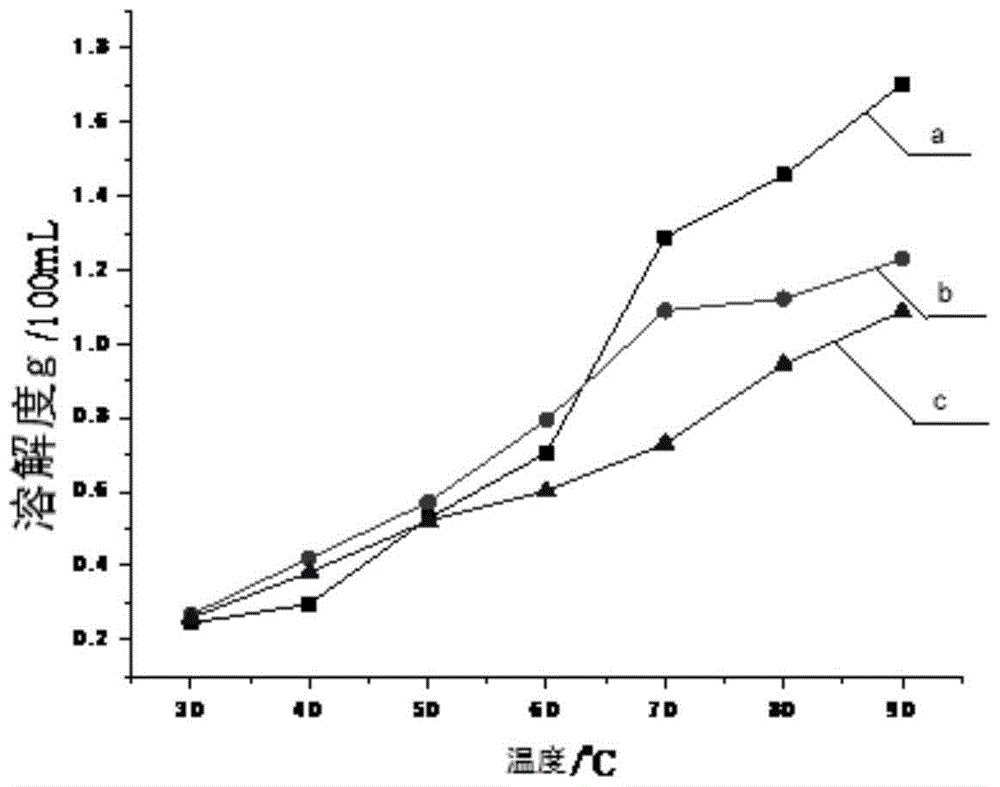

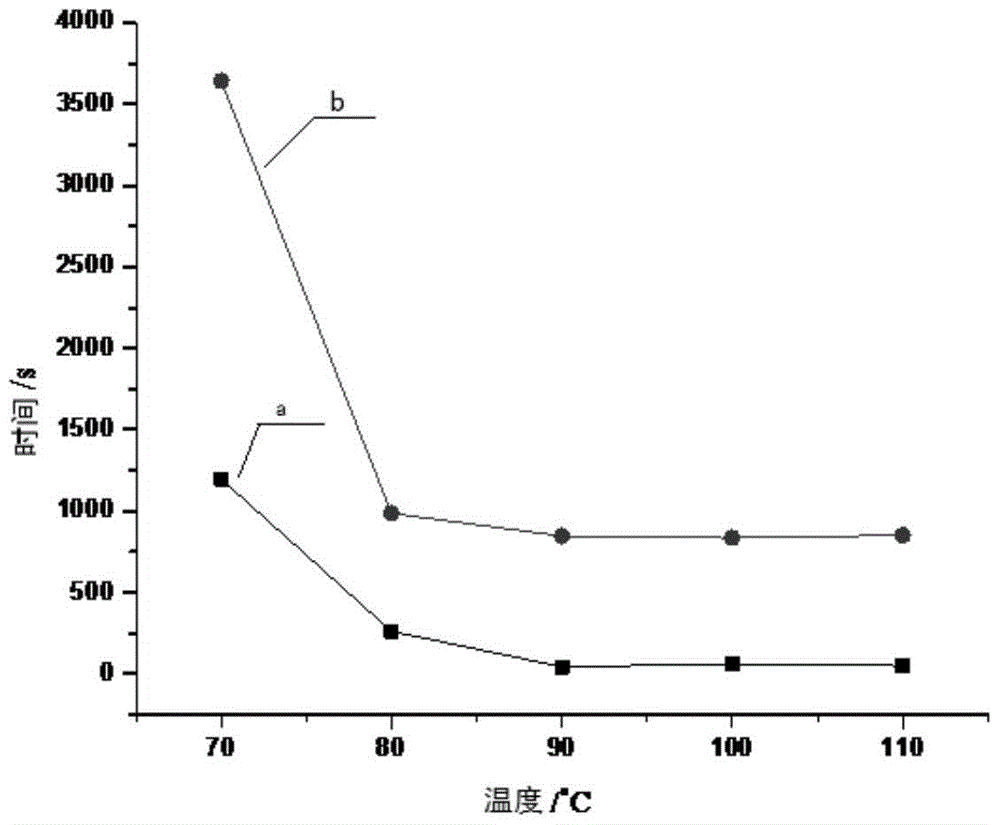

ActiveCN105084319BEasy to prepareNo pollutionSulfur preparation/purificationBulk chemical productionSulfur productActive agent

The invention discloses a method for separating sulfur from a sulfur-containing system. The method comprises that a composition containing a Fe-based ionic liquid, a solvent and a surfactant is employed, the composition promotes agglomeration of sulfur simple substance in a sulfur-containing system, and therefore small-particle sulfur generated in a sulfur-containing system rapidly grows into a sulfur particle with relatively large particle size at a relatively low temperature, and the sulfur product generated in the desulphurization technology is easy for sedimentation and recovery, and is prevented from depositing on a reactor wall or blocking a pipe. Also, investment reutilization is realized and economic benefit is increased.

Owner:BEIJING UNIV OF CHEM TECH

Assistant bag for promoting uniform dissolution of nickel anode in electroplating and using method of assistant bag

ActiveCN112410830ASolve the problem of insufficient solubilityDissolve evenlyProcess efficiency improvementActive agentBall mill

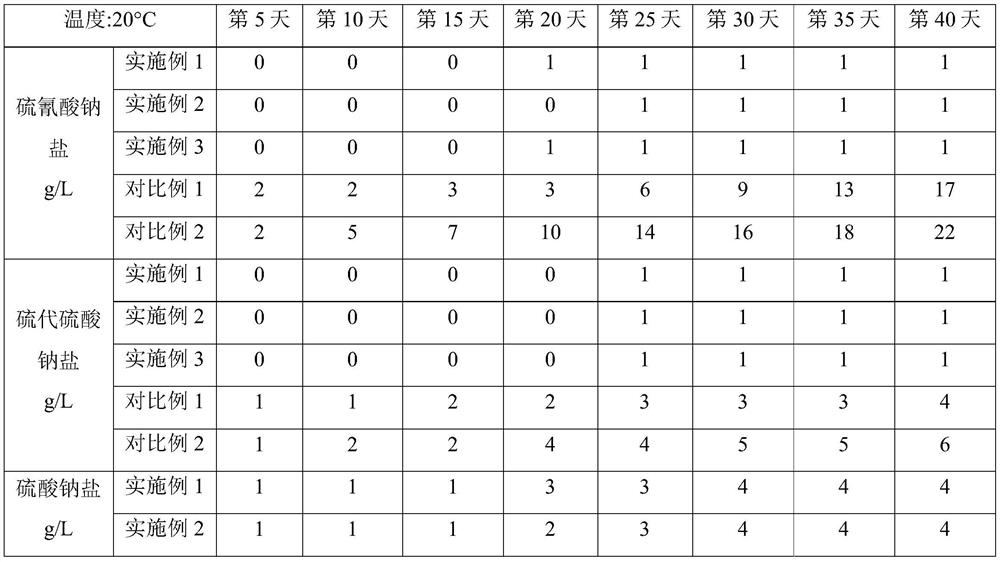

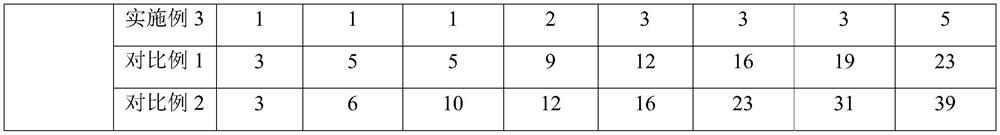

The invention relates to an assistant bag for promoting uniform dissolution of a nickel anode in electroplating and a using method of the assistant bag. The assistant bag comprises a permeable bag andmodified sulfur particles arranged in the permeable bag, wherein the particle sizes of the modified sulfur particles are 30-200 nm, the modified sulfur particles are prepared by grinding high-puritysulfur, a modifier which is 0.01%-10% of the mass of the sulfur and a ball milling medium which is 5-8 times of the mass of the sulfur on a ball mill under nitrogen protection, and the modifier is oneor more anionic surfactants containing sulfonic acid groups. Through use of the assistant bag, passivation of a nickel anode in Watt nickel electroplating can be effectively inhibited, surface dissolution is promoted to be uniform, formation of residues is remarkably reduced, and maintenance of a bath solution and the quality of a coating cannot be remarkably affected. The assistant bag is simplein using method and has a wide application prospect in the nickel electroplating industry.

Owner:JINCHUAN GROUP LIMITED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com