Sulfur flocculation precipitator as well as preparation method and application thereof

A precipitant and flocculation technology, applied in the field of desulfurization, can solve the problem of small particle size of sulfur particles, reduce the generation of sulfur foam, ensure desulfurization efficiency, and achieve good aggregation and sedimentation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

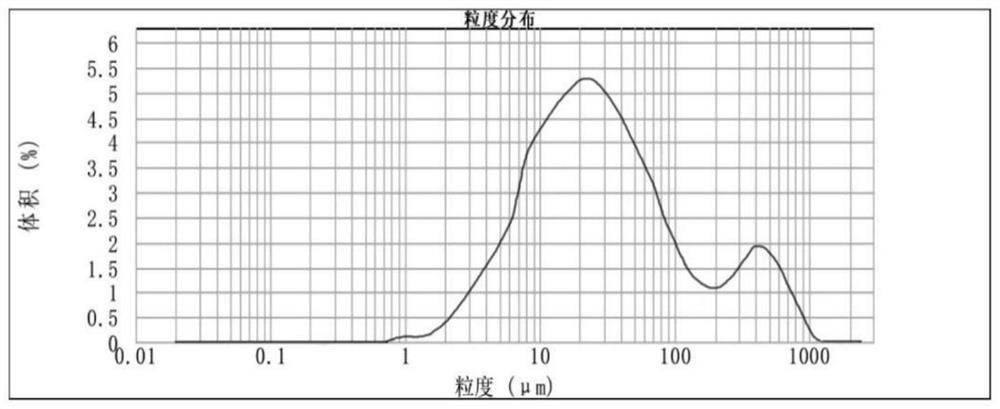

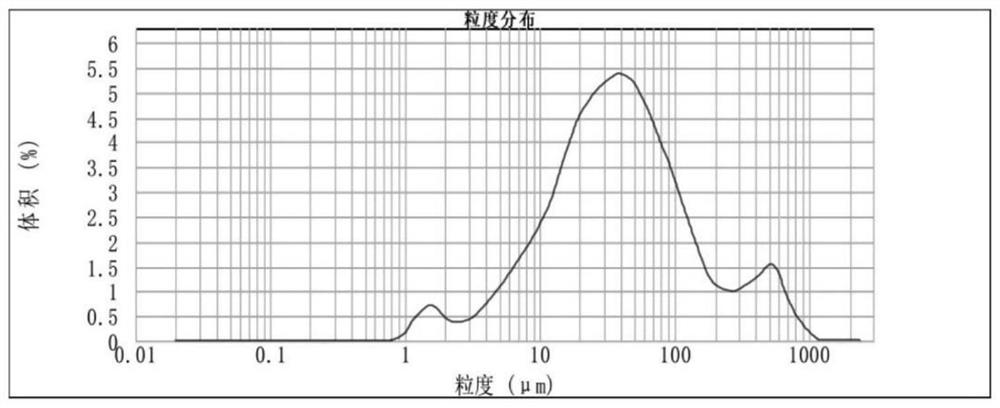

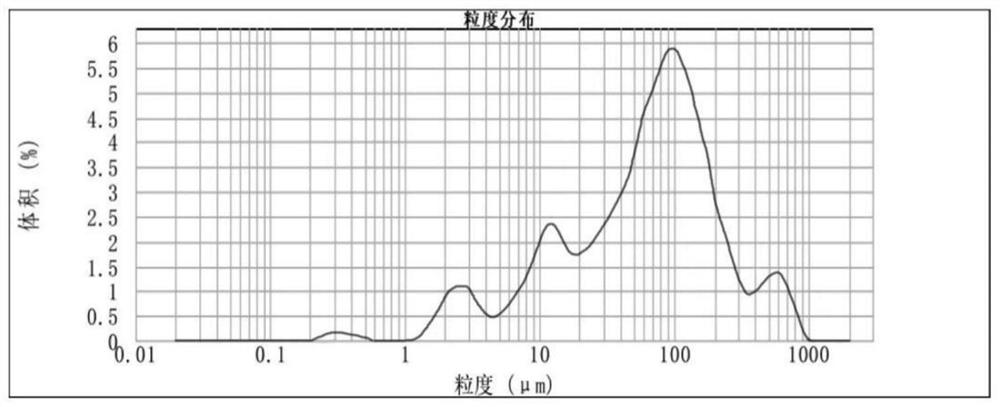

Image

Examples

preparation example Construction

[0033] The present invention further provides a method for preparing the sulfur flocculation precipitant described in the above scheme, comprising the following steps:

[0034] The glycolipid-type biosurfactant, Tween-type surfactant, low-carbon alcohol and water are mixed to obtain a sulfur flocculation precipitant.

[0035] In the present invention, the mixture is preferably: first the glycolipid biosurfactant and water mixed, and then sequentially added Tween type surfactant and low carbon alcohol.

[0036] The present invention has no special requirements for the specific operating method of the mixing, using a method well known to those skilled in the art, the various components can be mixed evenly, as specific as stirring.

[0037] The present invention further provides the application of the sulfur flocculation precipitant described in the above scheme in wet basic desulfurization.

[0038]In the present invention, the wet basic desulfurization preferably comprises complex...

Embodiment 1

[0041] Preparation of sulfur flocculation precipitant: the use of rhamnolipide, Tween-80, isopropanol and water to prepare sulfur flocculation precipitant, the preparation method is: the rhamnosin and water mixed, and then add Tween-80, and isopropanol, stirred and mixed to obtain sulfur flocculant precipitant. The dosage of each component is shown in Table 1.

[0042] Table 1 Composition and dosage of sulfur flocculant

[0043]

[0044]

Embodiment 2

[0055] Preparation of sulfur flocculation precipitant: the use of isopropanol, mannitol, Tween-60, and water to prepare sulfur flocculation precipitant, the preparation method is: first the mannose lipid and water mixed, and then Tween-60 and isopropanol are added one by one, stirred to form a uniform sulfur flocculant precipitant. The dosage of each component is shown in Table 3.

[0056] Table 3 Composition and dosage of sulfur flocculant precipitant

[0057] compose Dosage Manna glycolipids 90g Twain-60 10g isopropanol 5g water 895g

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com