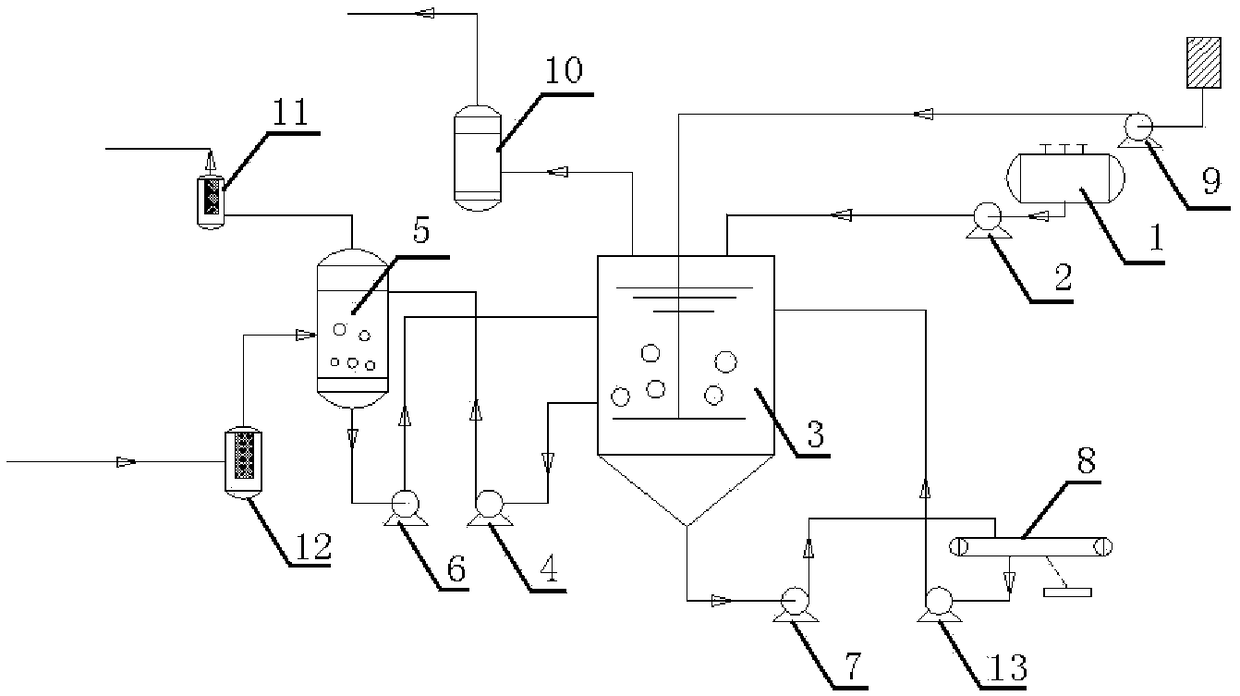

System and method used for removing hydrogen sulfide in oilfield associated gas and secondary gas

A hydrogen sulfide, oil field technology, applied in chemical instruments and methods, separation methods, sulfur preparation/purification, etc., can solve the problem of difficult disposal of waste desulfurizers, etc., and achieve the effect of preventing long-term deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

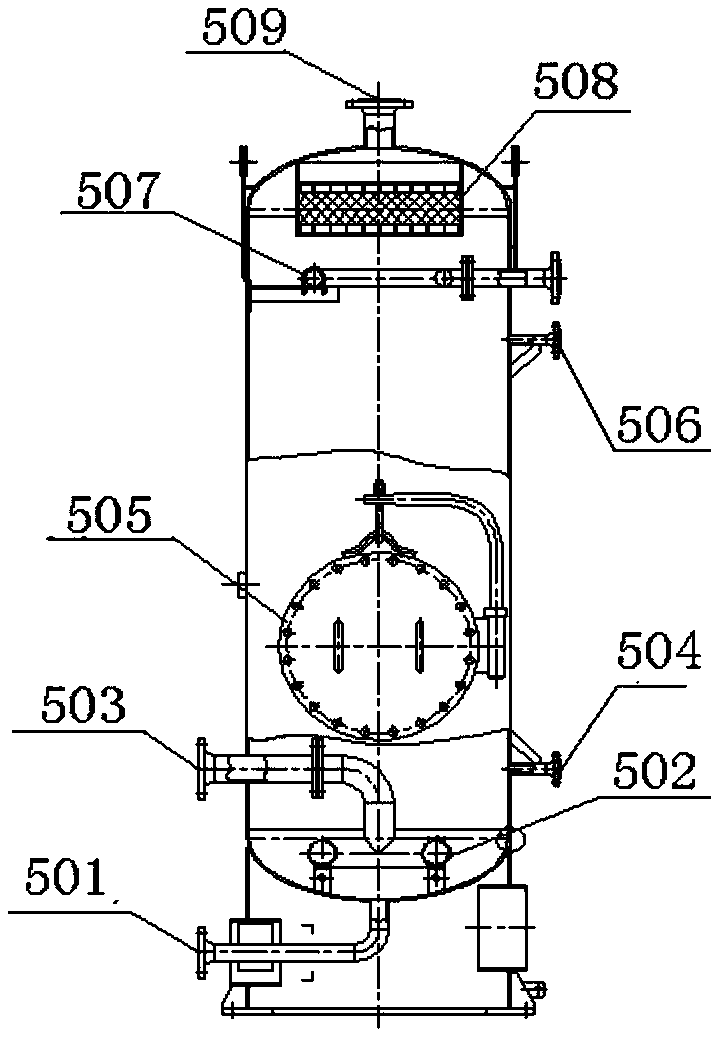

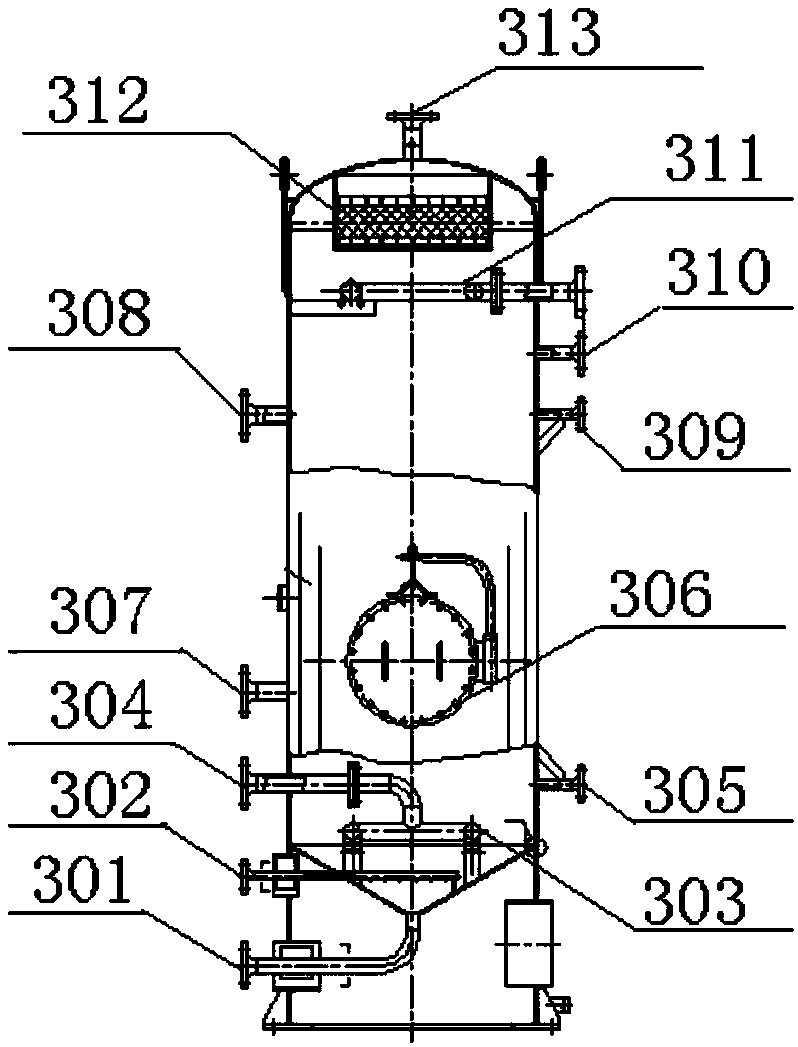

Method used

Image

Examples

Embodiment

[0062] The hydrogen sulfide removal system and method involved in the present invention have been practiced in Huanxiling Oil Production Plant of Liaohe Oilfield. Huanxiling Oil Production Plant Qi 40 block No. 30 station steam flooding secondary gas contains hydrogen sulfide concentration range of 0.15%-1.2%, carbon dioxide content> 80%, heavy hydrocarbon 0.8-1.5%, gas volume 260m 3 / d—5500m 3 / d; After the system and method for removing hydrogen sulfide of the present invention, H 2 The concentration of S is below 10ppm, which has great economic and environmental benefits.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com