Double-tower type anaerobic reactor capable of controlling quality of output water

An anaerobic reactor and tower-type technology, which is applied in the field of anaerobic reactors, can solve the problems of high investment, loss of granular sludge, uncontrollable and other problems, achieve maximum treatment efficiency, avoid long-term deposition, and increase the effect of dead sludge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings, but it is not intended to limit the protection scope of the present invention.

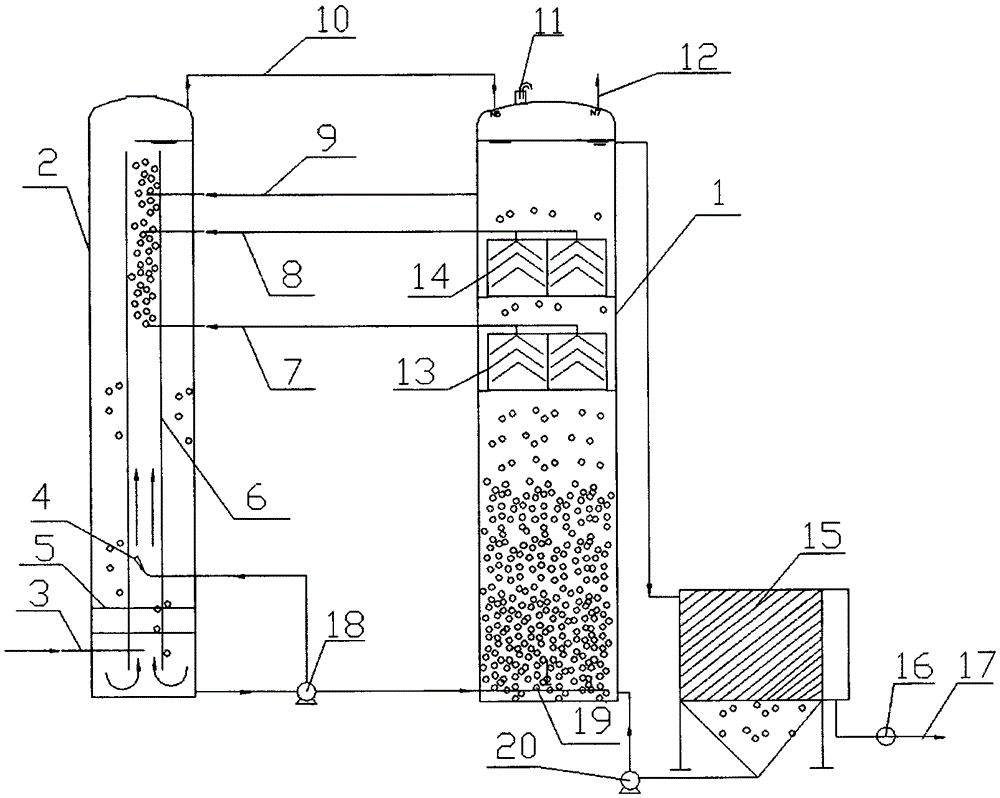

[0033] Such as figure 1 As shown, a double-tower anaerobic reactor with controllable effluent water quality includes main tank 1, auxiliary tank 2, water inlet 3, water injector 4, central tube support 5, central tube 6, and primary separator air pipe 7. Secondary separator air pipe 8, circulation pipe 9, biogas connecting pipe 10, pressure release device 11, biogas vent pipe 12, first-level three-phase separator 13, second-level three-phase separator 14, inclined tube sedimentation tank 15 , COD online detector 16, discharge pipe 17, circulating water pump, water distribution pipe 19, screw pump 20, the water inlet 3 is at the bottom of the central pipe 6, the upper part of the central pipe 6 is submerged in the water, and the lower part has a water inlet channel, and the central ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com