Patents

Literature

91results about How to "Increase circulation flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Frequency conversion control method for heat pump water heater

The invention relates to a frequency conversion control method for a heat pump water heater. The frequency conversion control method for the heat pump water heater is characterized by comprising the following steps of: performing frequency conversion control on a compressor of the heat pump water heater; performing frequency conversion control on a throttle mechanism of the heat pump water heater; performing frequency conversion control on a defrosting mechanism of the heat pump water heater; and performing frequency conversion control on an exhaust temperature of the heat pump water heater. The frequency conversion control method for the heat pump water heater has the advantages of high heating speed, few start-stop times, small temperature fluctuation of a water tank and energy conservation. At a high ambient temperature, the frequency of the compressor can be reduced and the circulating flow quantity of a system can be reduced, so that the suction pressure is reduced and the stable operation of the compressor is guaranteed. At a low ambient temperature, the circulating flow quantity of the system is increased by increasing the frequency of the compressor and the opening degree of an electronic expansion valve, the exhaust temperature is reduced and the compression ratio is reduced, so that the compressor can operate stably. In the defrosting process, the defrosting time is greatly shortened by increasing the circulating flow quantity of the system; and the frost can be removed completely, without the problem that the frost is accumulated into ice.

Owner:JIANGSU TENESUN ELECTRICAL APPLIANCE

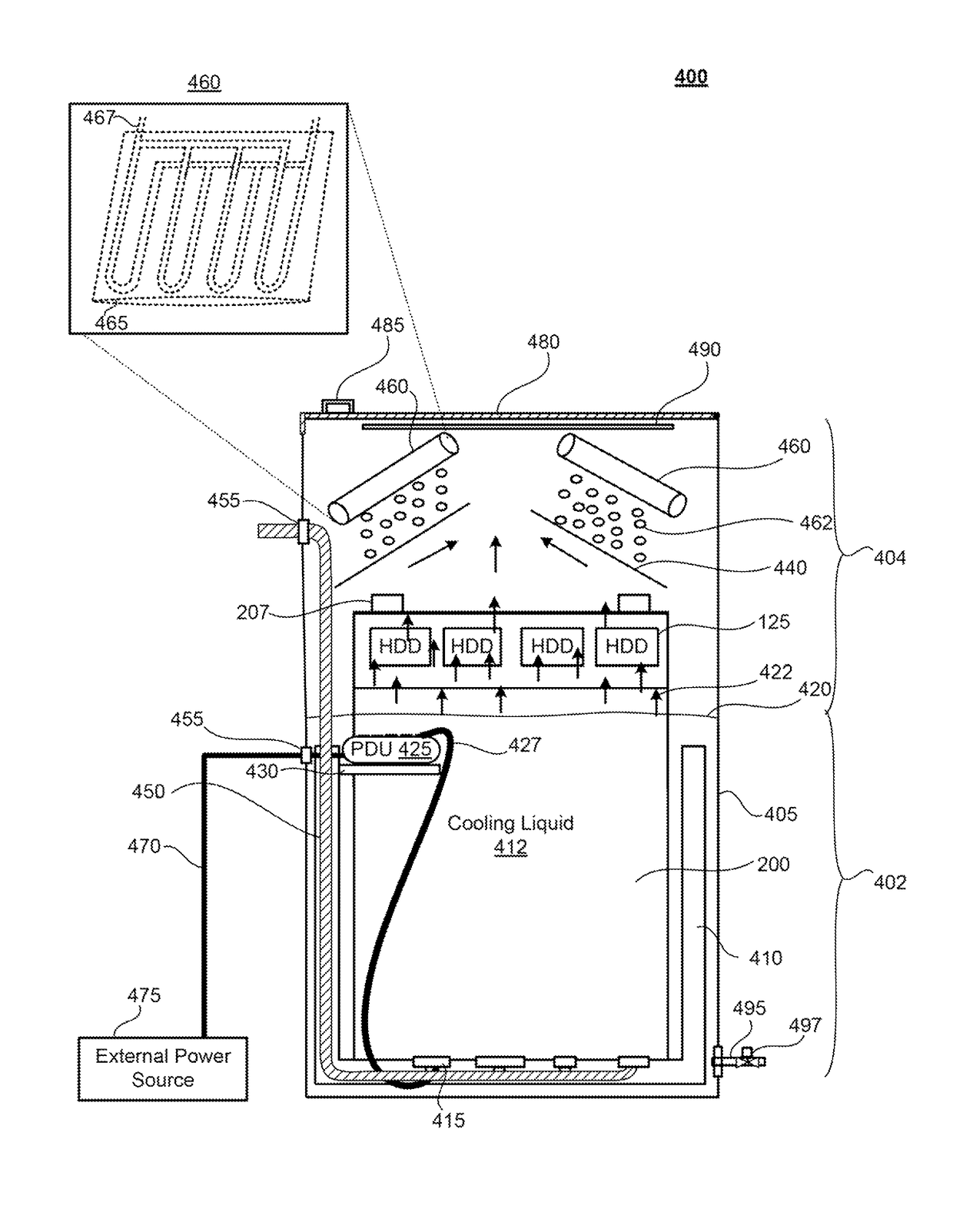

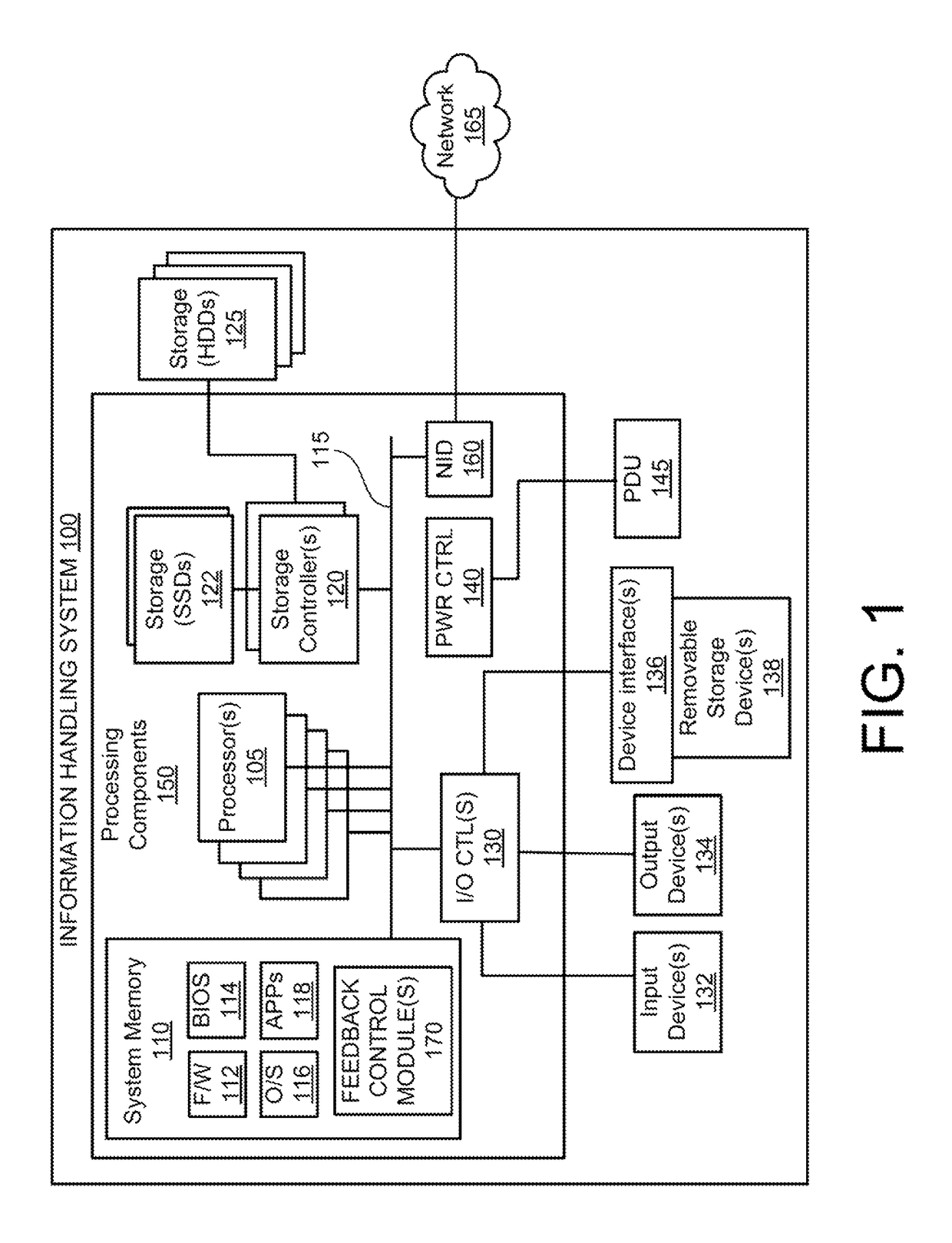

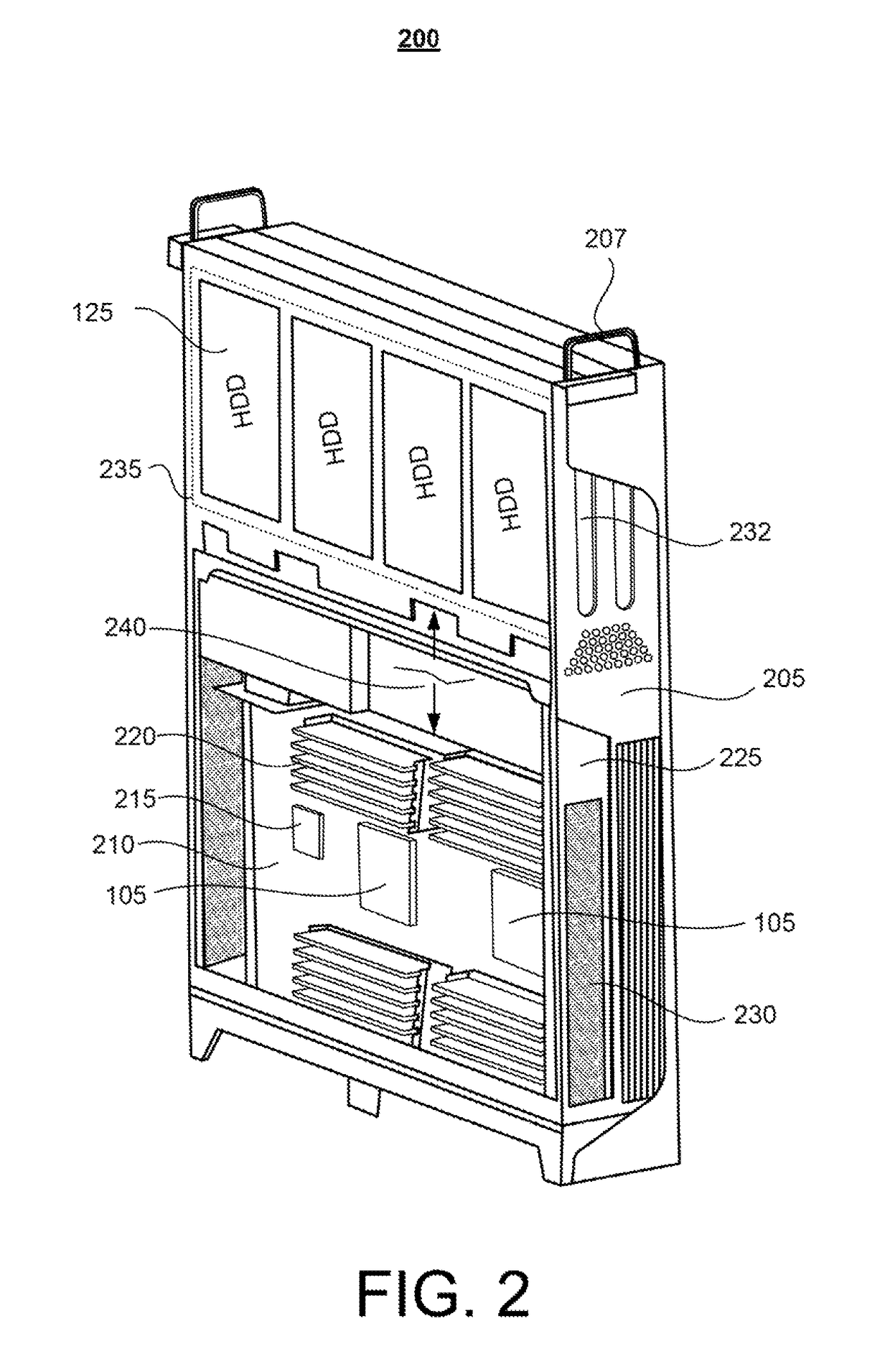

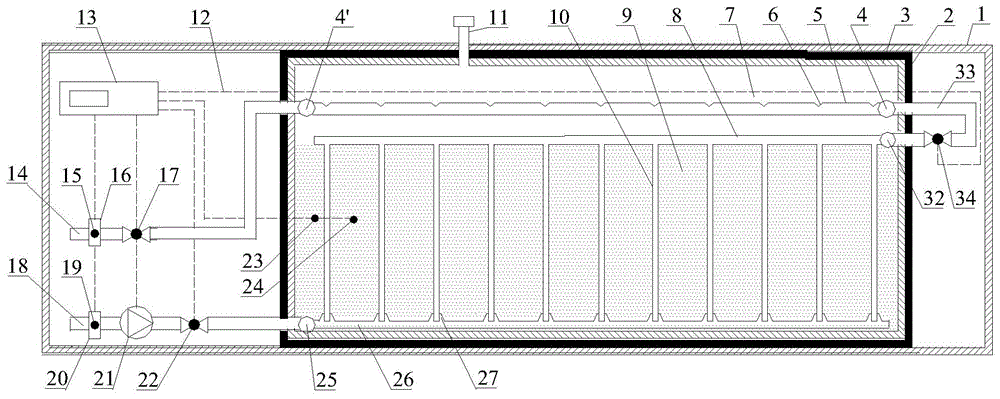

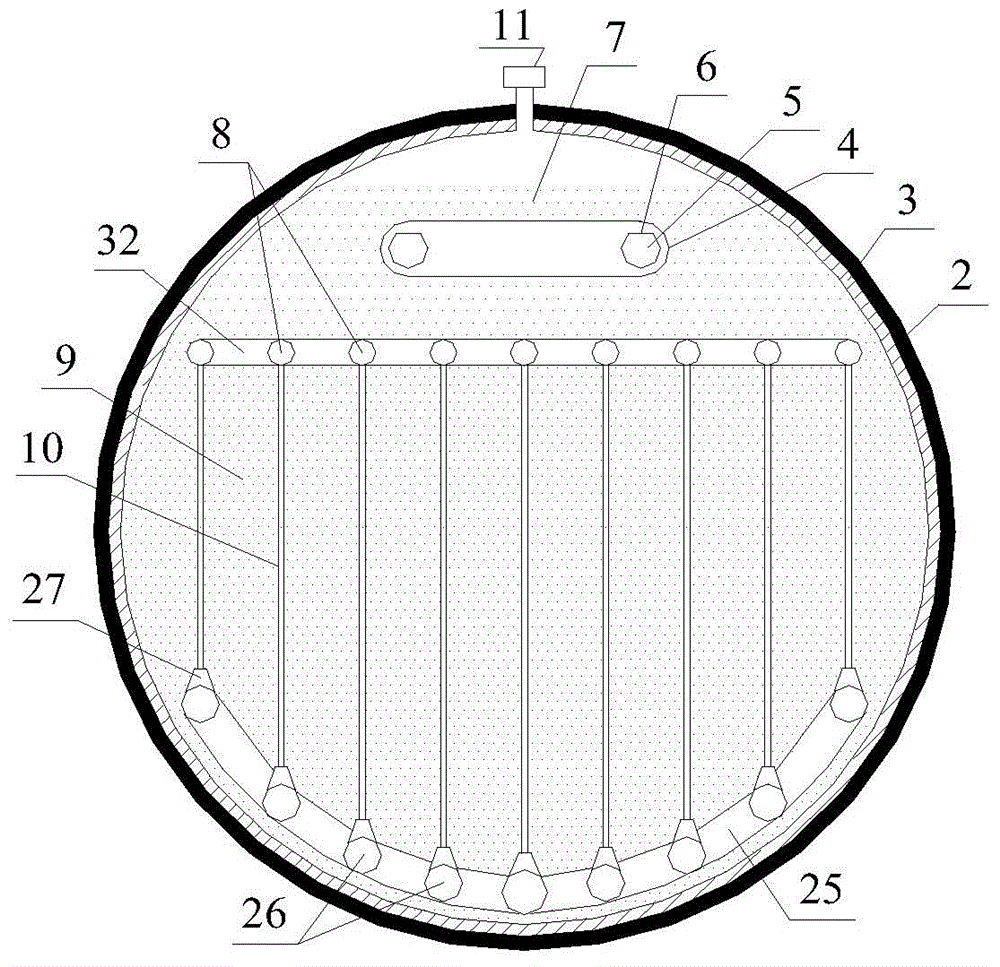

Stand alone immersion tank data center with contained cooling

ActiveUS9921622B2Increase surface areaHeat dissipationDigital data processing detailsCooling/ventilation/heating modificationsData centerCondenser (heat transfer)

A stand-alone immersion tank datacenter (SITDC) includes: a multi-phase heat transfer immersion cooling tank having external walls surrounding a tank volume within which a dielectric liquid is maintained and heated to a boiling point temperature; a plurality of servers having one or more processing and memory components submerged within the dielectric liquid for cooling of the one or more components via heat dissipation from the one or more components into the dielectric liquid when the one or more components are connected to an electric power supply; and a condenser located vertically above the plurality of servers and in a direct path of rising dielectric vapor created when the dielectric liquid absorbs sufficient heat from the one or more components to reach a boiling point temperature of the liquid. The condenser can be a passive heat exchanger, created by providing a heat conductive material as a top lid of the tank.

Owner:DELL PROD LP

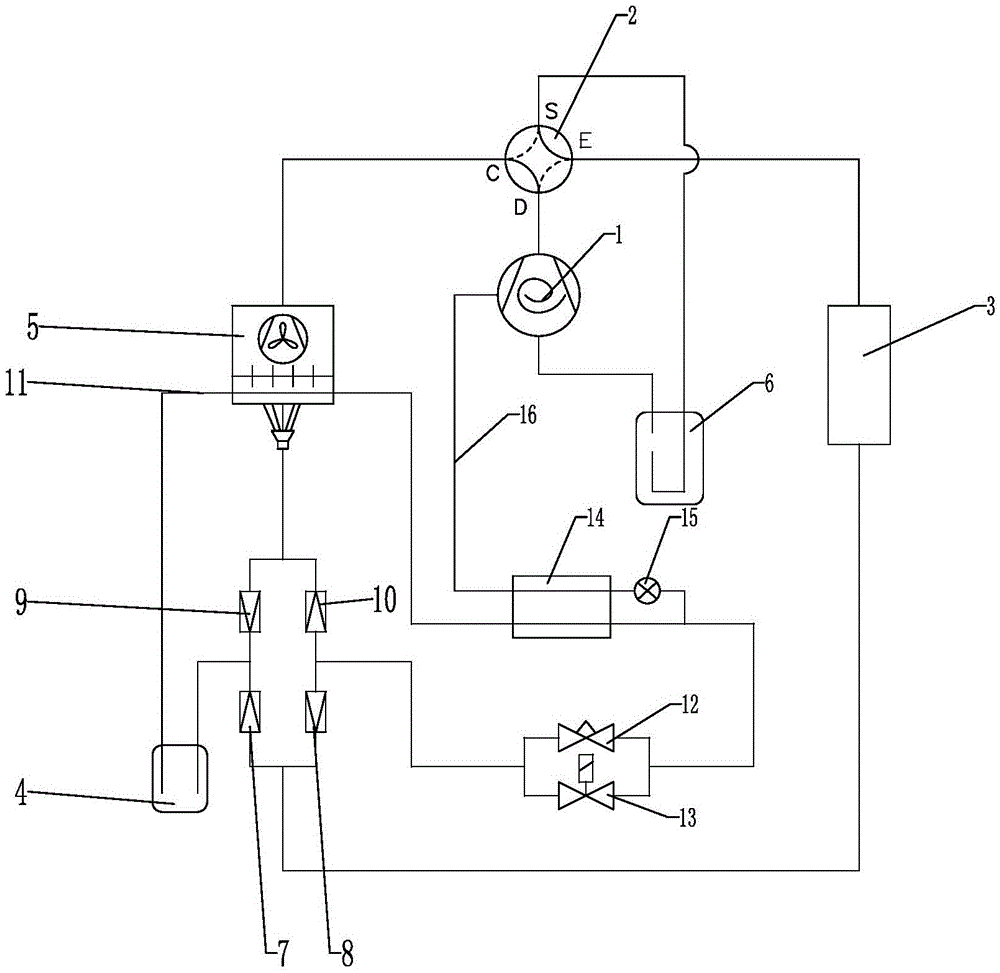

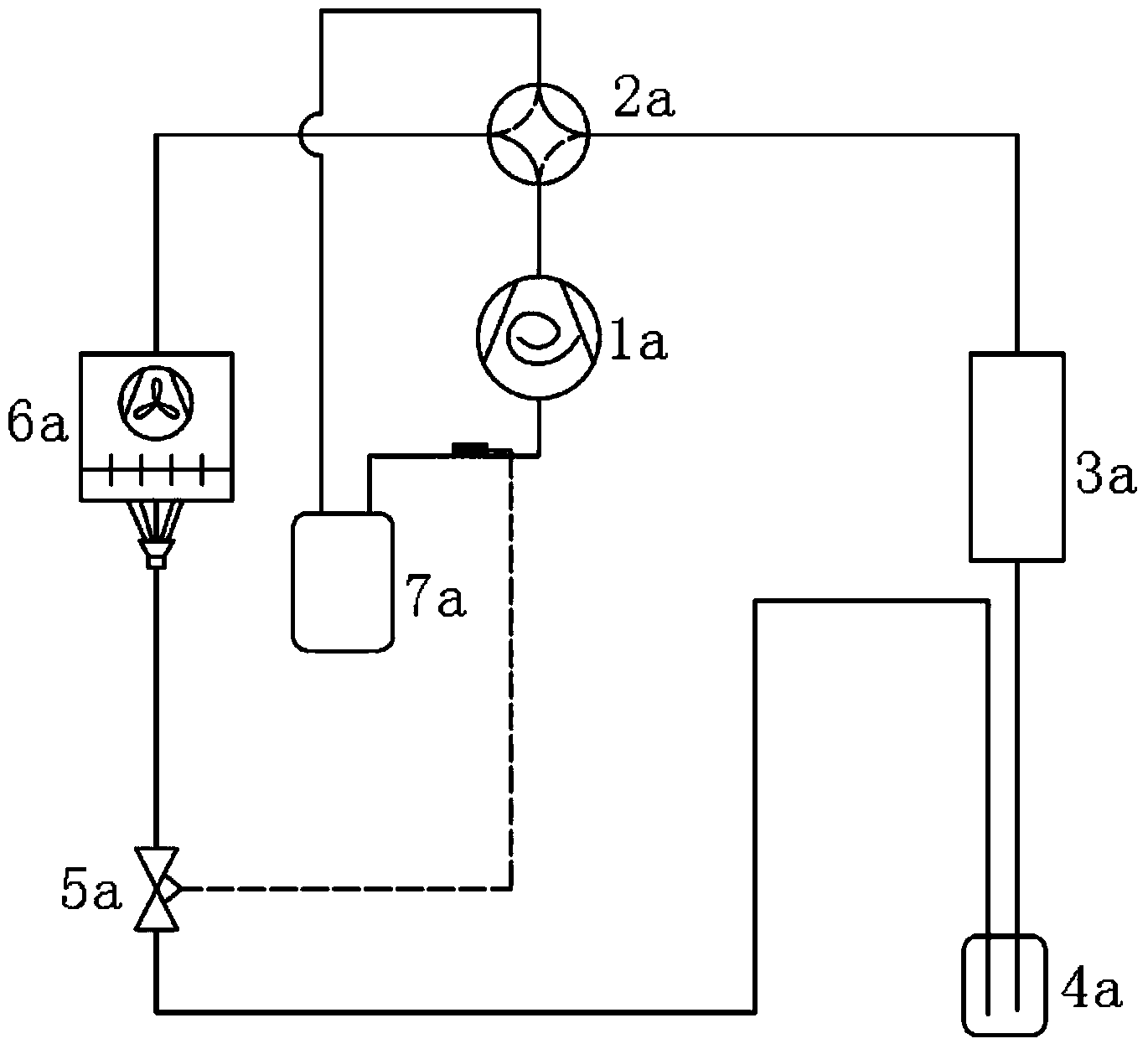

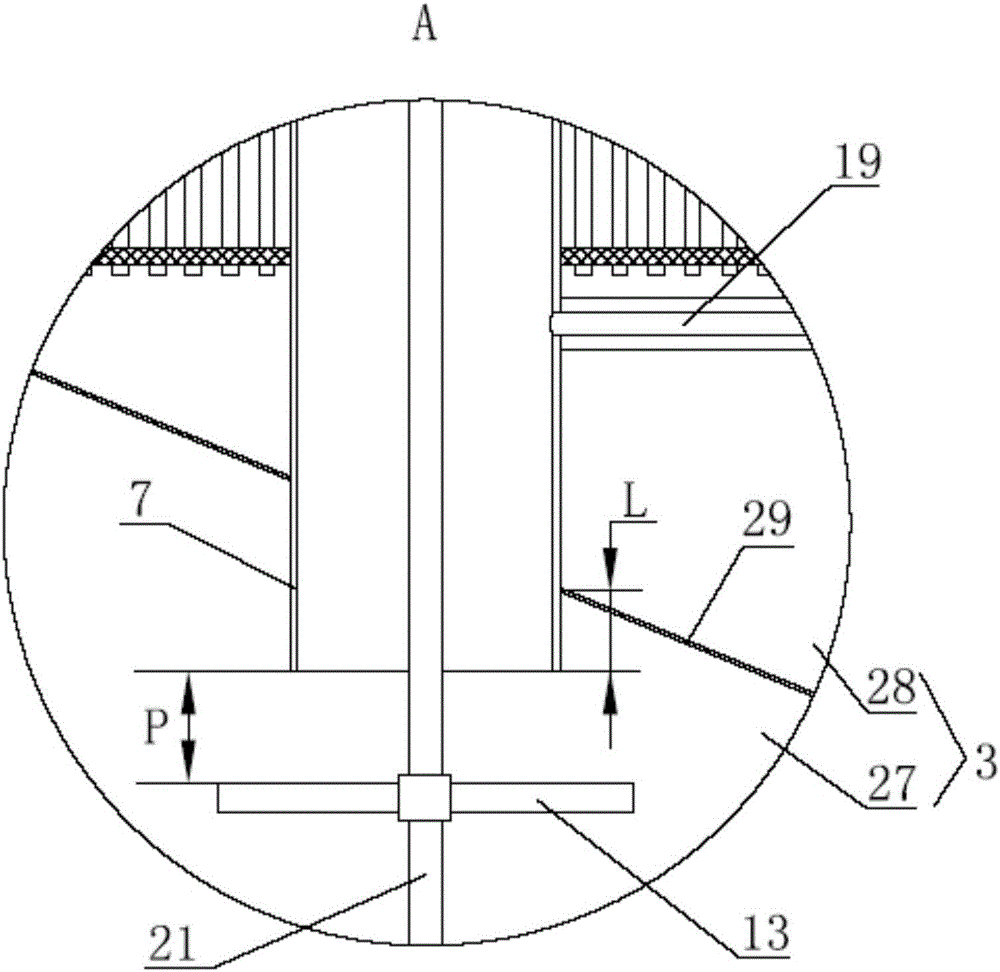

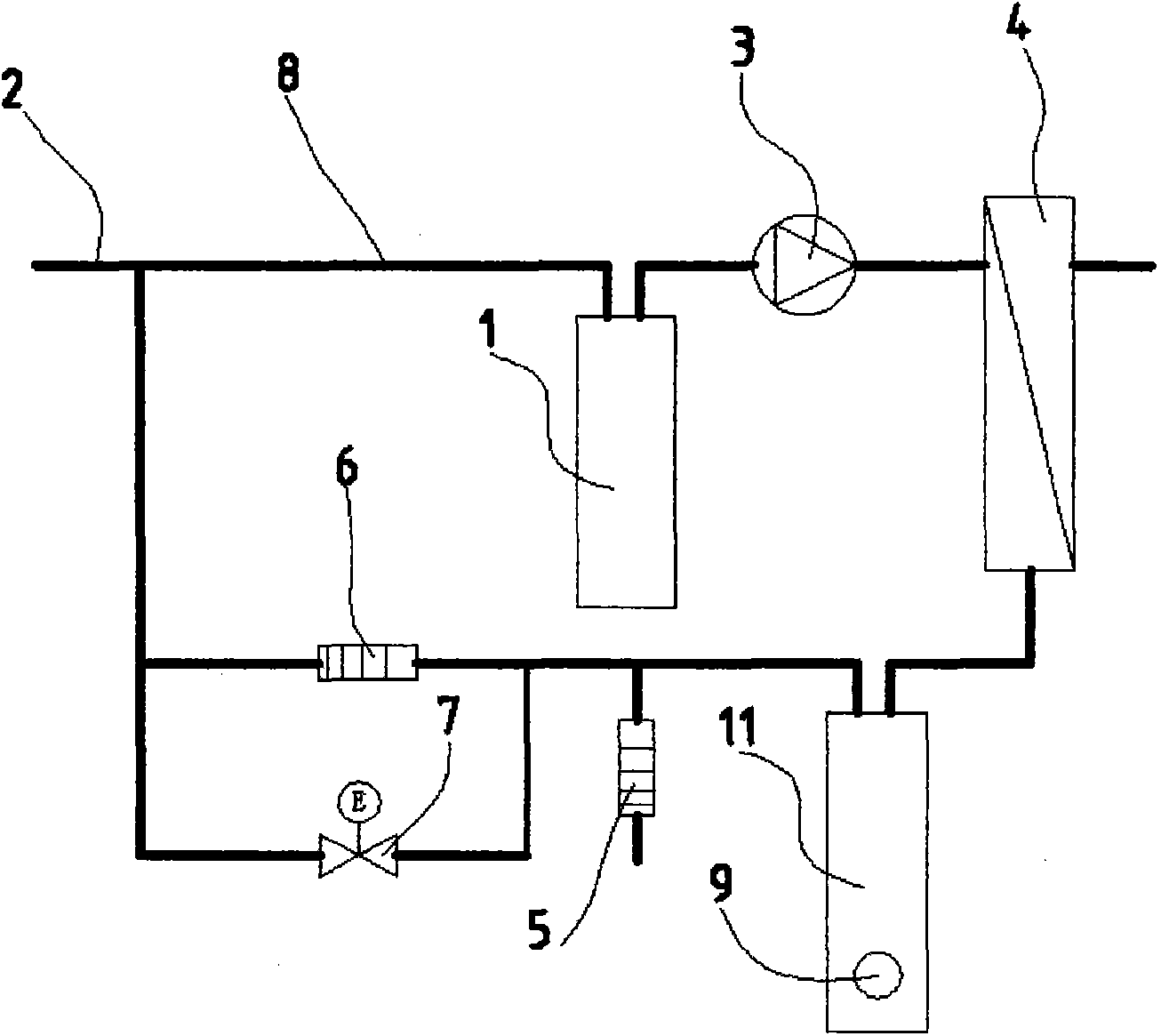

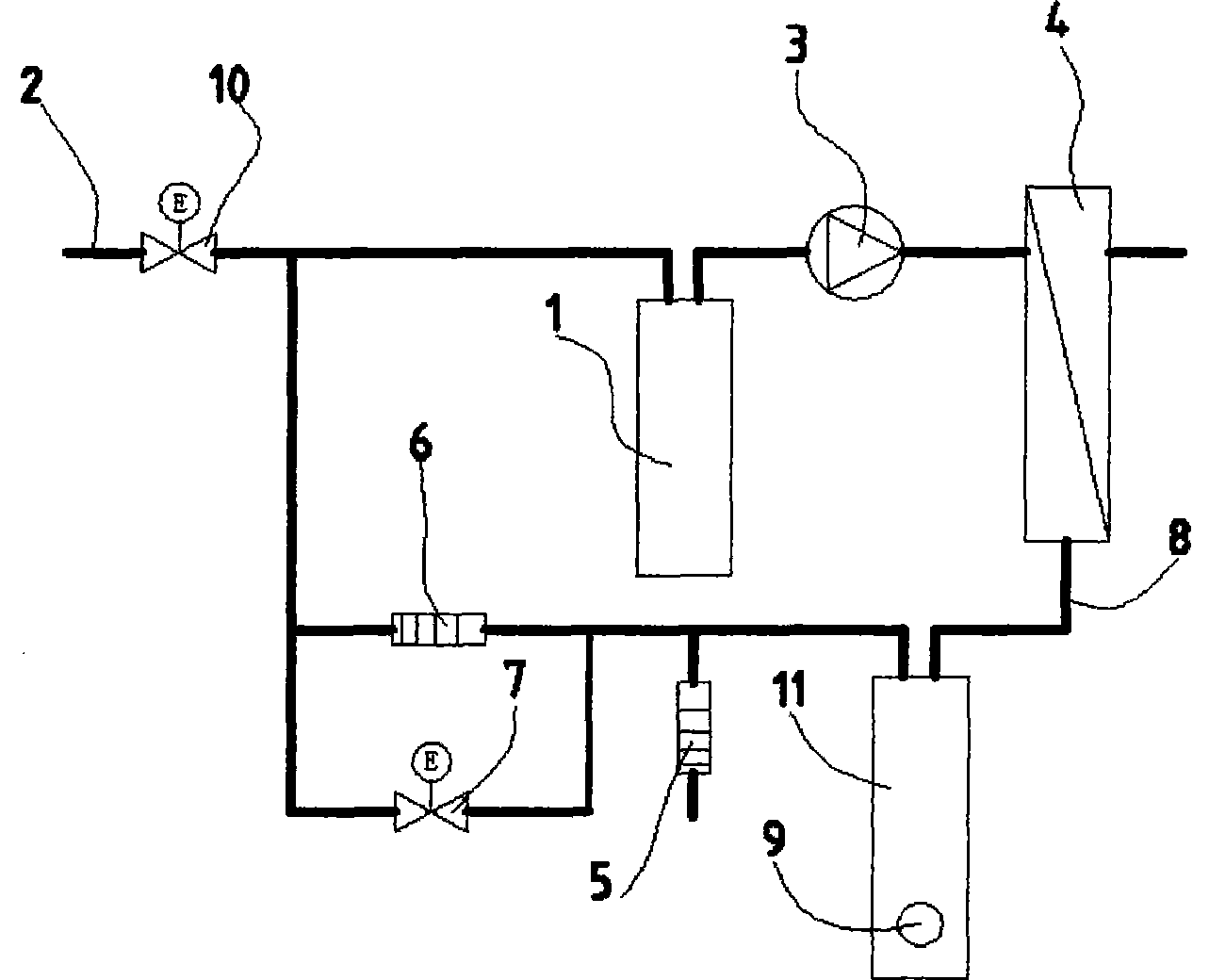

Low-environment-temperature air source heat pump system with undercooling loop

InactiveCN105157270AIncrease circulation flowIncrease subcoolingMechanical apparatusCorrosion preventionHigh humidityEngineering

The invention belongs to the technical field of air source heat pump systems, relates to an air source heat pump refrigerating system, in particular to a low-environment-temperature air source heat pump system with an undercooling loop. The low-environment-temperature air source heat pump system comprises a main loop, an auxiliary loop, the undercooling loop and a one-way valve assembly. A first outlet of an air-supplying enthalpy-adding compressor is connected with a first port of a four-way reversing valve. A second port of the four-way reversing valve is connected with a first port of an indoor heat exchanger. A second port of the indoor heat exchanger is connected with the inlet end of the one-way valve assembly. According to the low-environment-temperature air source heat pump system, the main loop, the auxiliary loop and the undercooling loop are combined in an optimization manner, so that the circular flow of the refrigerating system in the air source heat pump low-temperature environment is increased; high-temperature refrigerant is introduced into the bottom of an outdoor heat exchanger, so that the bottom temperature of the outdoor heat exchanger is always higher than zero in the low-temperature environment, the bottom of the heat exchanger will not freeze, condensate water and defrosting water of the outdoor heat exchanger can be discharged smoothly in winter, and the phenomenon that ice layers are accumulated, a unit cannot operate normally at the cold high-humidity environment is avoided.

Owner:WUXI TONGFANG ARTIFICIAL ENVIRONMENT

Heating and ventilating air-conditioning system and control method thereof

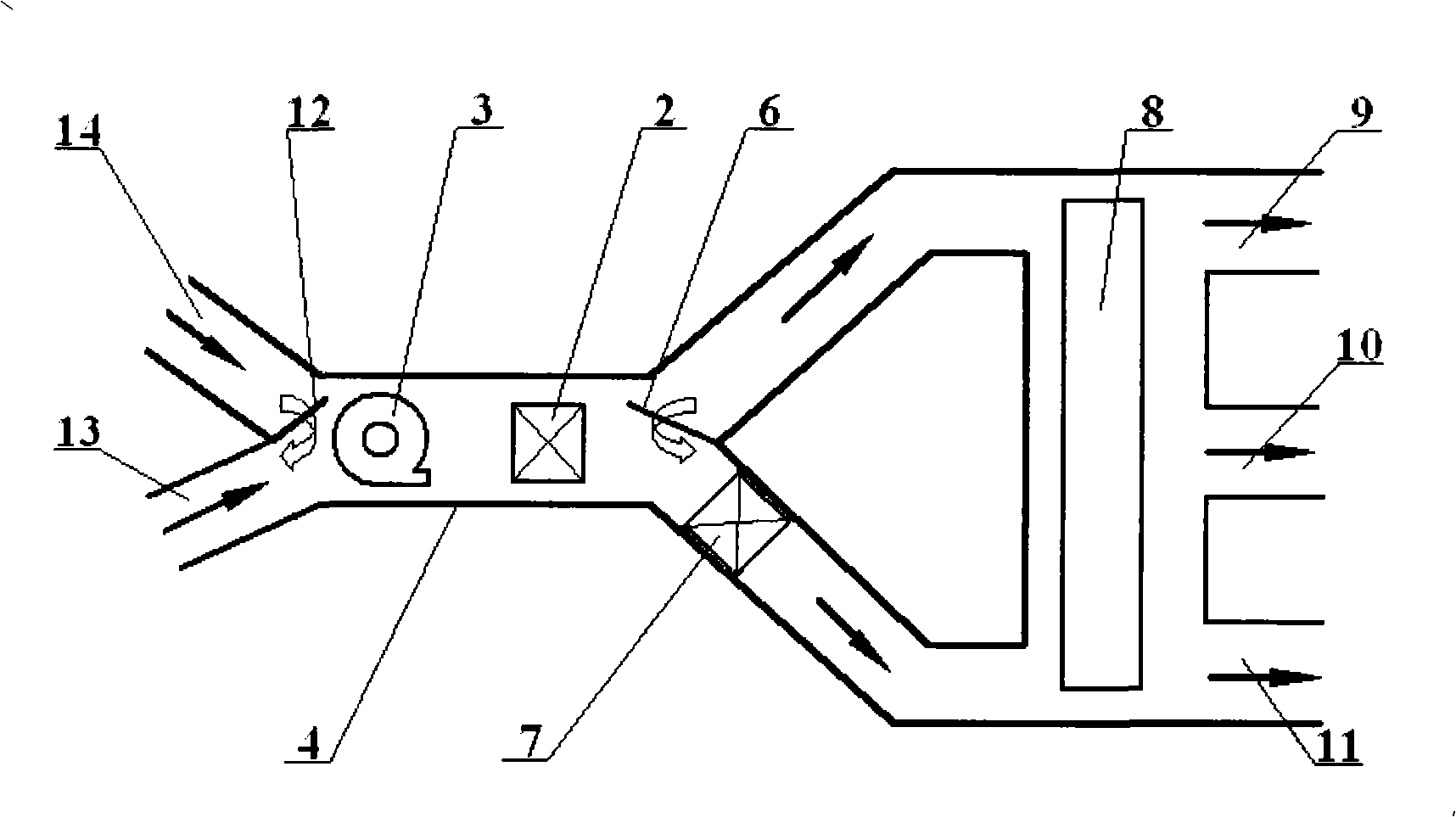

InactiveCN101259823AReduce pressure loss along the waySmall pressure lossAir-treating devicesVehicle heating/cooling devicesAir volumeAir conditioning

The invention discloses a heating ventilating air conditioning system. A blower (3), the core body of an evaporator (2) and a distribution case (1) are arranged on the air current channel of the heating ventilating air conditioning system and the core body of the evaporator (2) is arranged in an evaporator shell (4); a bypass gap (15) is arranged between the side surface of the core body of the evaporator (2) and the evaporator shell (4) and an evaporator bypass damper (5) which can be opened and closed is arranged on the bypass gap. When the evaporator bypass damper (5) is closed, the evaporator bypass damper can fully close the bypass gap (15). By adopting the technical scheme, the airflow passes through the bypass damper basically instead of the core body of the evaporator when the heating ventilating air conditioning system is in a ventilating mode or a heating mode, thus reducing the pressure loss of the airflow, increasing the air volume, reducing the noise and enhancing the inside driving comfort in case of the same blower power.

Owner:CHERY AUTOMOBILE CO LTD

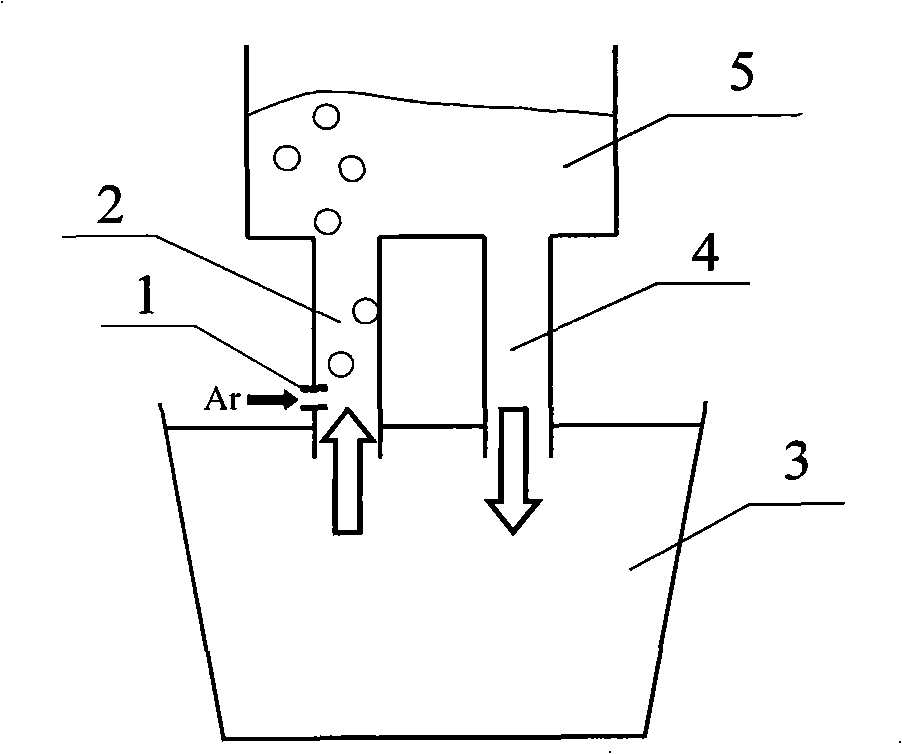

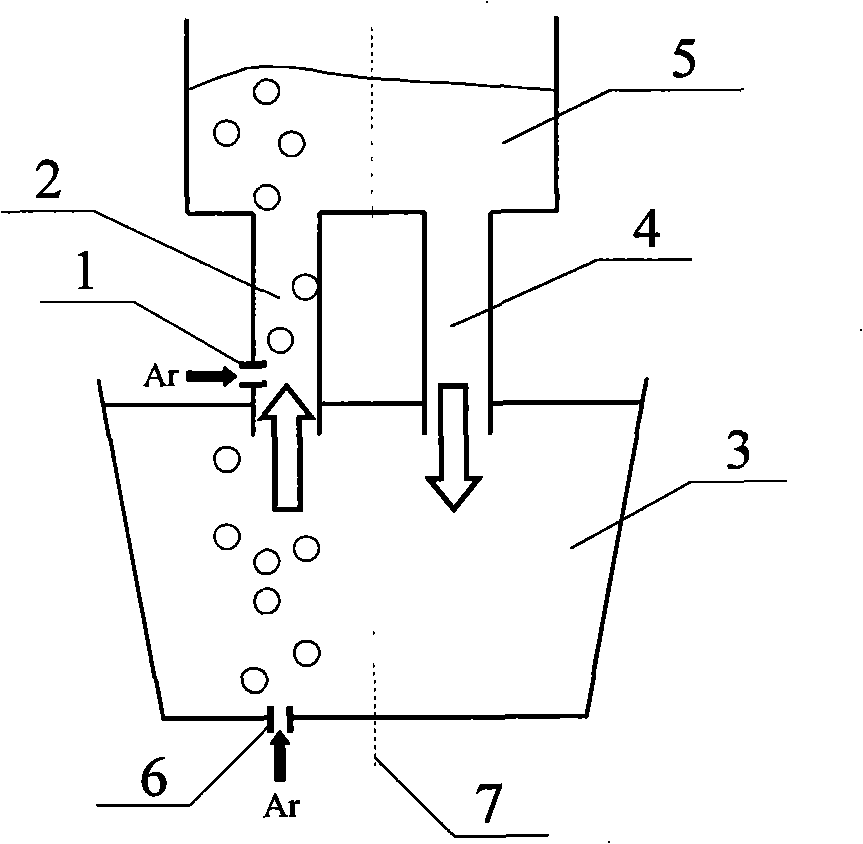

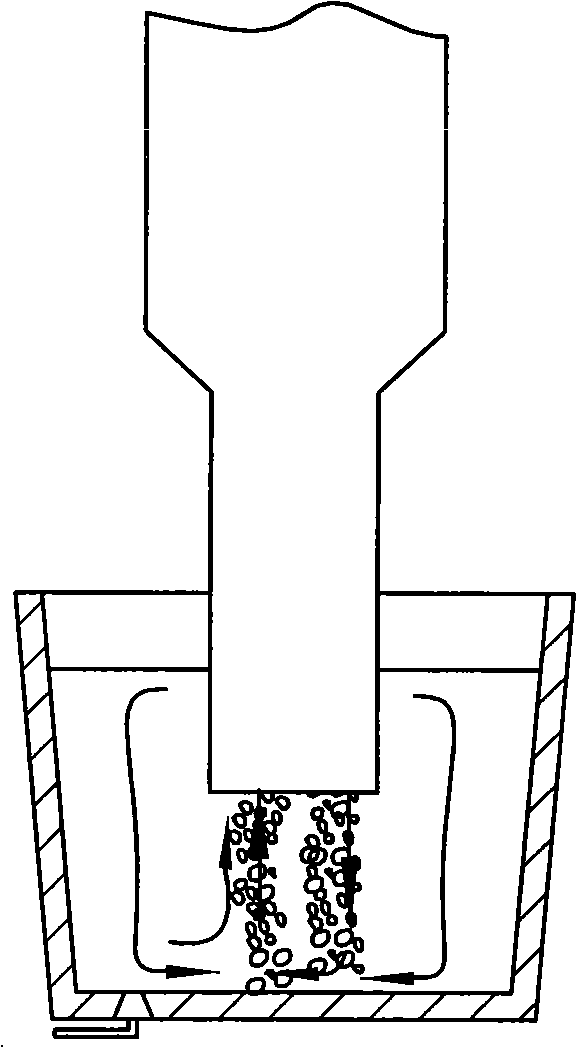

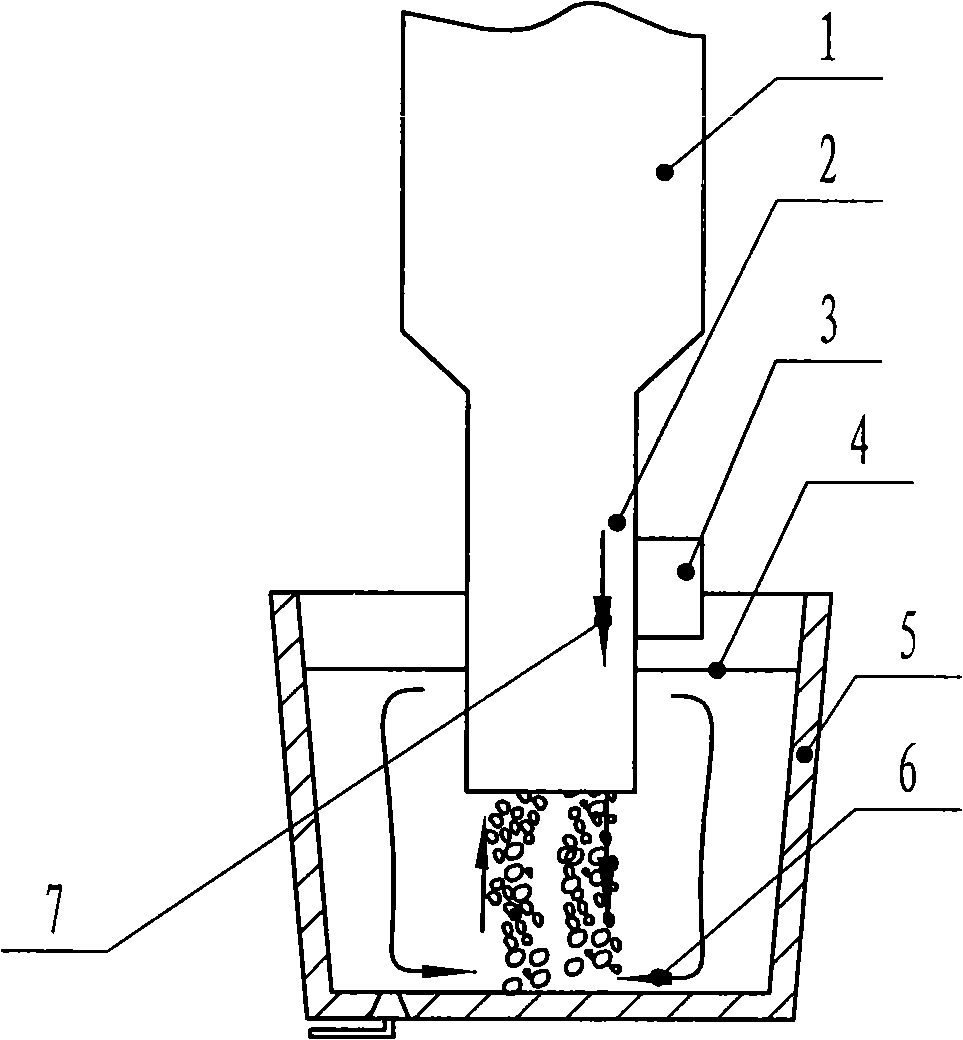

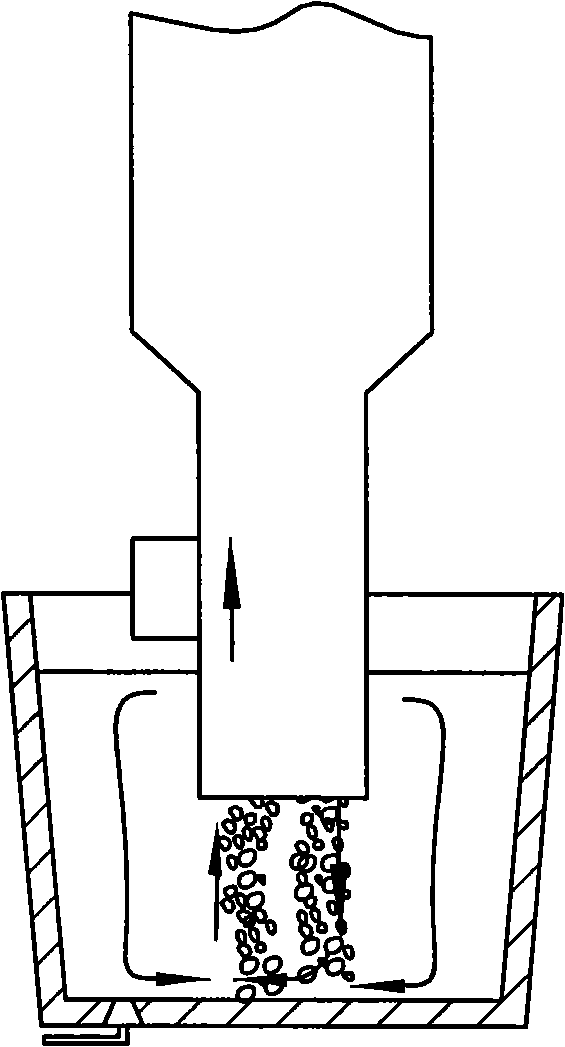

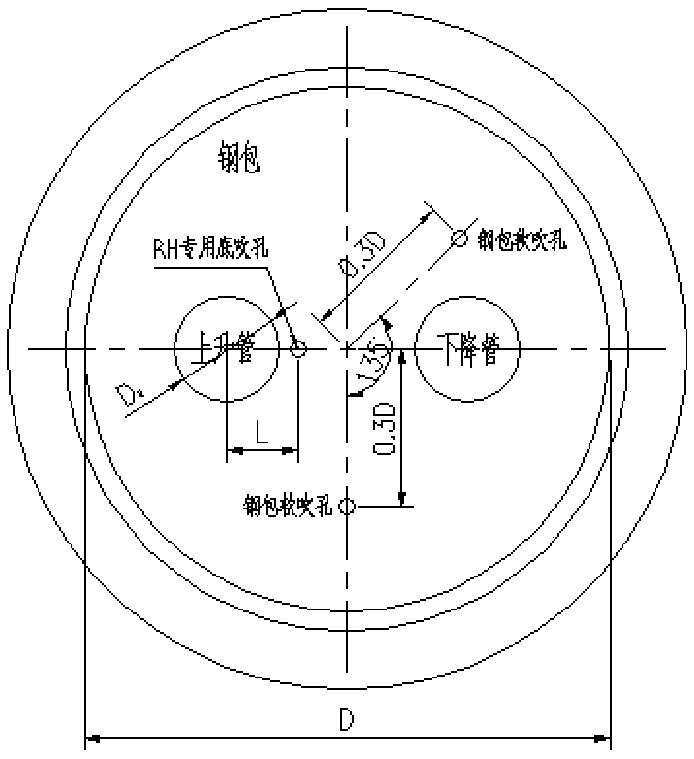

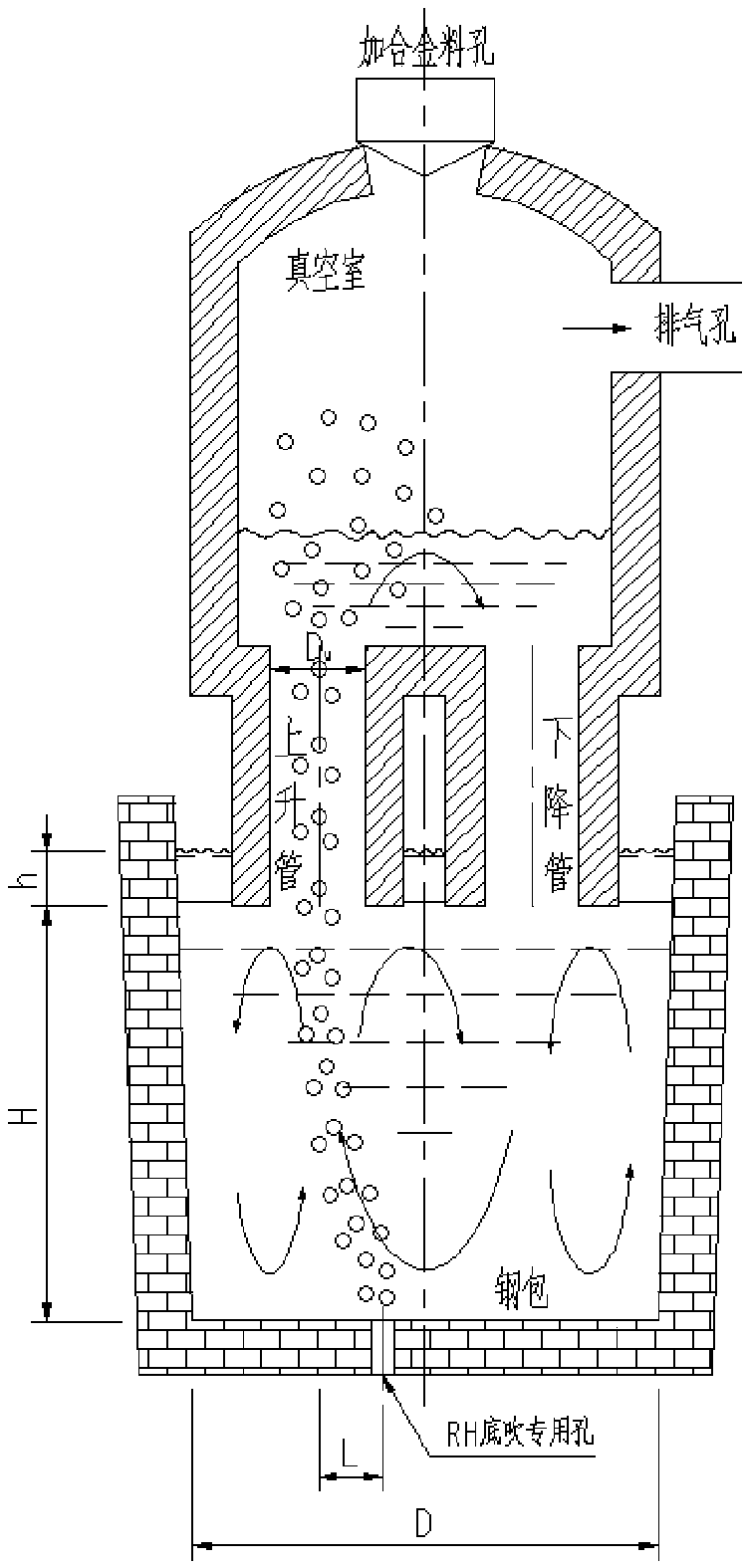

RH bottom blowing argon vacuum circulating degasser

The invention relates to an RH bottom argon blowing vacuum circulating degasser belonging to the technical field of metallurgy and comprising a steel ladle and a vacuum chamber, wherein the bottom wall of the steel ladle is provided with a nozzle or an air brick, and the nozzle or the air brick is connected with an argon blowing device and positioned at one side of the projection of an ascending tube of the vacuum chamber on the bottom wall of the steel ladle. The RH bottom argon blowing vacuum circulating degasser can effectively enhance the circular flow of the RH bottom argon blowing vacuum circulating degasser, increase the internal stirring of the RH vacuum circulating degassing steel ladle, shorten the blending time, accelerate the elimination of deoxidation type inclusions inside the RH vacuum circulating degassing steel ladle and enhance the degassing and the decarburization speed.

Owner:NORTHEASTERN UNIV

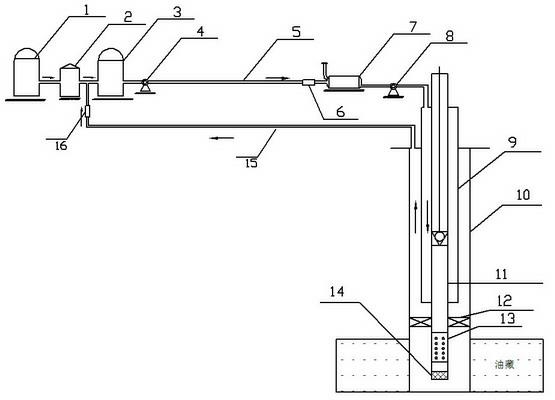

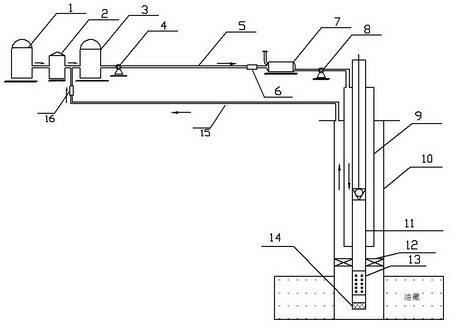

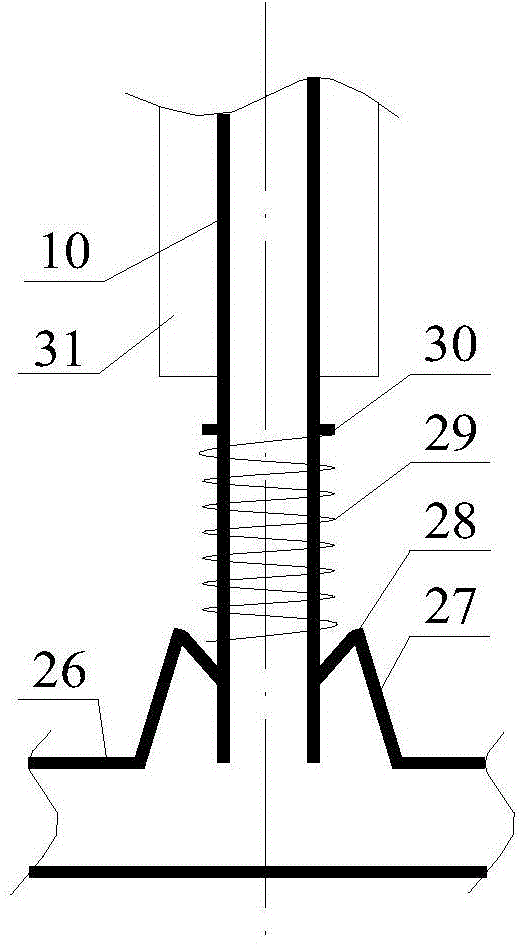

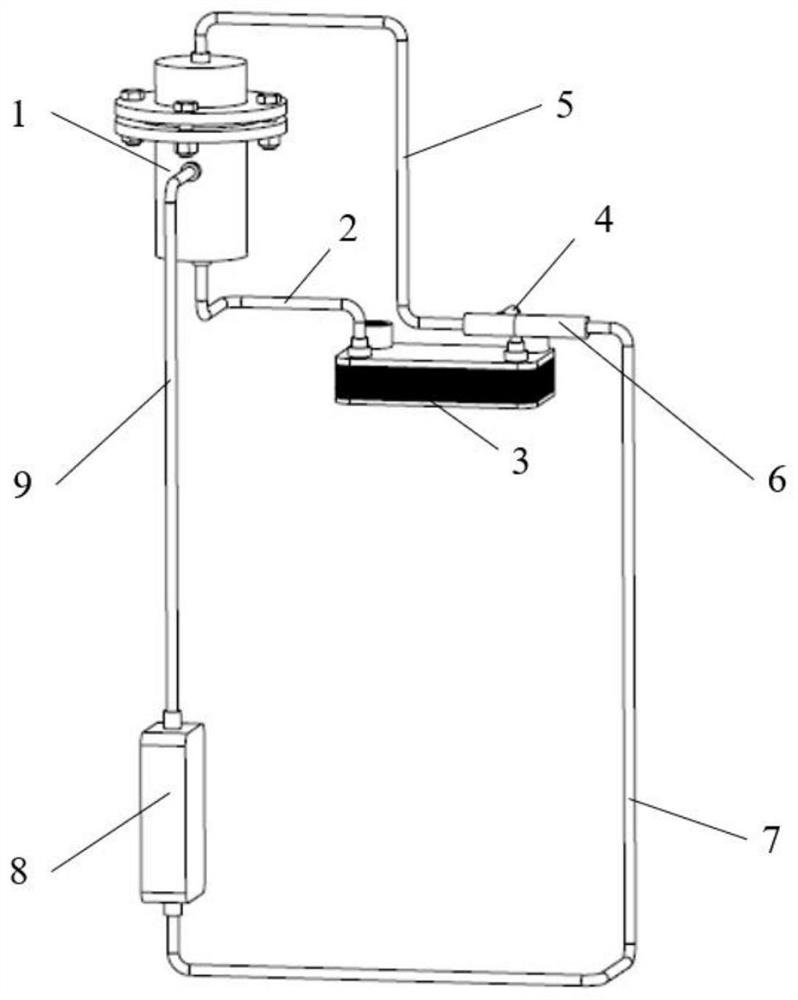

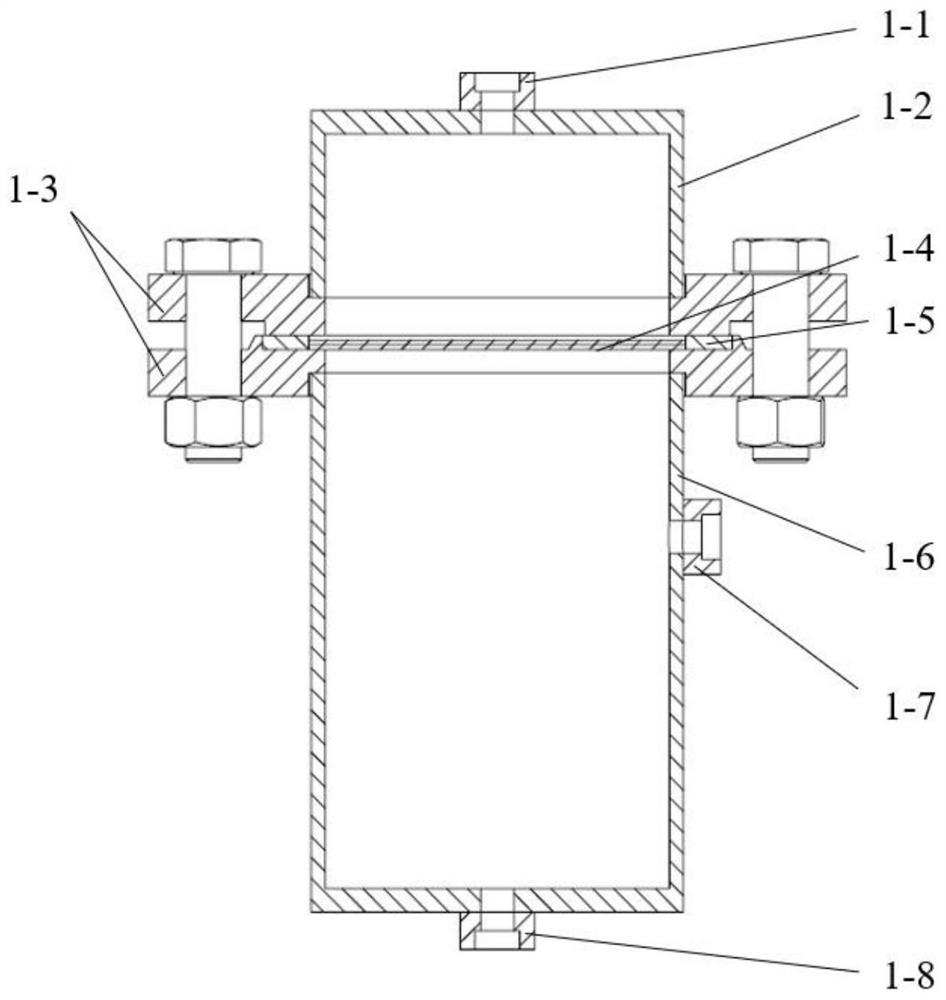

Hot water injection circulation viscosity reduction system for producing ultra-deep ultra-heavy oil and application method thereof

The invention relates to a hot water injection circulation viscosity reduction system for producing ultra-deep ultra-heavy oil and an application method thereof, belonging to the field of viscosity reduction production of heavy oil in an oilfield. The hot water injection circulation viscosity reduction system comprises a ground circulation system and an underground circulation viscosity reduction system, wherein the ground circulation system is formed by sequentially connecting a clear water tank, a water softening device, a softened water tank, a water supply pump, a magnetization device, a water jacket furnace and a water injection pump, which are arranged on a circulating injection pipeline, as well as a pressure relief valve on a circulating outflow pipeline; and the underground circulation system adopts a liquid injection and outflow pipeline constituted by a heat insulation oil pipe annulus, a sleeve annulus and a packer, as well as an inner-layer oil pipe, the packer, a sieve pipe and a screw plug to constitute an oil production pipeline. The hot water injection circulation viscosity reduction system according to the invention can reduce the viscosity of heavy oil, be conductive to production of the ultra-deep ultra-heavy oil and solve the problems of low effective pump efficiency, short pump inspection period of high energy consumption in a viscosity reduction process by light oil blending, and further has the advantages of low oil production cost, easiness in popularization and application and the like.

Owner:SOUTHWEST PETROLEUM UNIV

Variable-parameter liquid absorption core ultrathin heat pipe

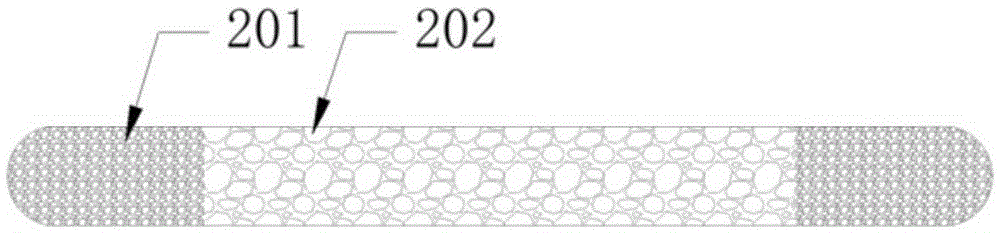

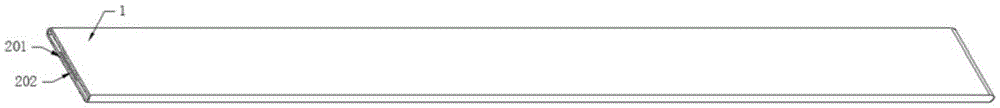

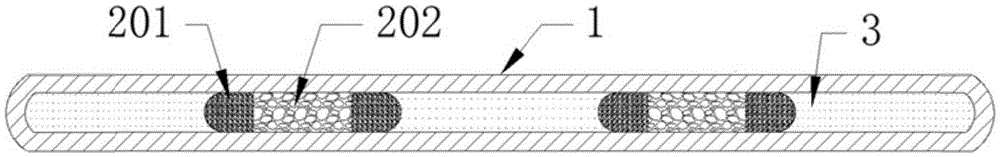

ActiveCN105403085AOptimizing the gas-liquid cycle processImprove performanceIndirect heat exchangersCondensation processPorosity

The invention provides a variable-parameter liquid absorption core ultrathin heat pipe. Small-bore and high-porosity structures (201) are adopted in the areas on the two sides, in the width direction, of a liquid absorption core (2). A large-bore and small-porosity structure (202) is adopted in the area in the middle, in the width direction, of the liquid absorption core (2). According to the small-bore and high-porosity structures (201) of the areas on the two sides of the liquid absorption core (2), when the heat pipe works, a gas-liquid interface area in the liquid absorption core can be enlarged, the flow of working media participating in the evaporation and condensation process is increased, and the capillary drive force of the area is improved; meanwhile, by means of the large-bore and small-porosity structure of the area in the middle, the amount of working medium liquid stored in the liquid absorption core is increased, the resistance for the working media flowing to the two sides of the liquid absorption core is lowered, and working medium liquid can be supplemented to the areas on the two sides more easily; and the circulating speed of gas-liquid working media is increased, and efficient running of the ultrathin heat pipe is achieved.

Owner:SHANGHAI LIZHENG SATELLITE APPL TECH CO LTD

Method for improving circular flow of single snorkel refining furnace

The invention relates to a method and a device for improving the circulating flow of a single-jet refining furnace. A steel ladle holding molten steel is arranged under a suction nozzle of the single-jet refining furnace; the suction nozzle of the single-jet refining furnace extends to the molten steel; the molten steel flows through a vacuum chamber by the suction nozzle; the device is characterized in that the periphery of the suction nozzle of the single-jet refining furnace is provided with at least one set of traveling wave magnetic field generators; a mounting position of the traveling wave magnetic field generator exceeds the molten steel level; the traveling wave magnetic field generator can produce an electromagnetic force consistent with the circulating direction of the molten steel; and the electromagnetic force and gas together drive the molten steel to circularly flow, thereby increasing the circulating flow of the molten steel. The periphery of the suction nozzle of the single-jet refining furnace is provided with the magnetic field generator; when the molten steel is refined, the magnetic field generator is started so as to generate the electromagnetic force consistent with the flowing direction of the molten steel close to the suction nozzle, thereby increasing the circulating flow of the molten steel and achieving the aims of shortening the refining treatment time and improving the refining treatment efficiency.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

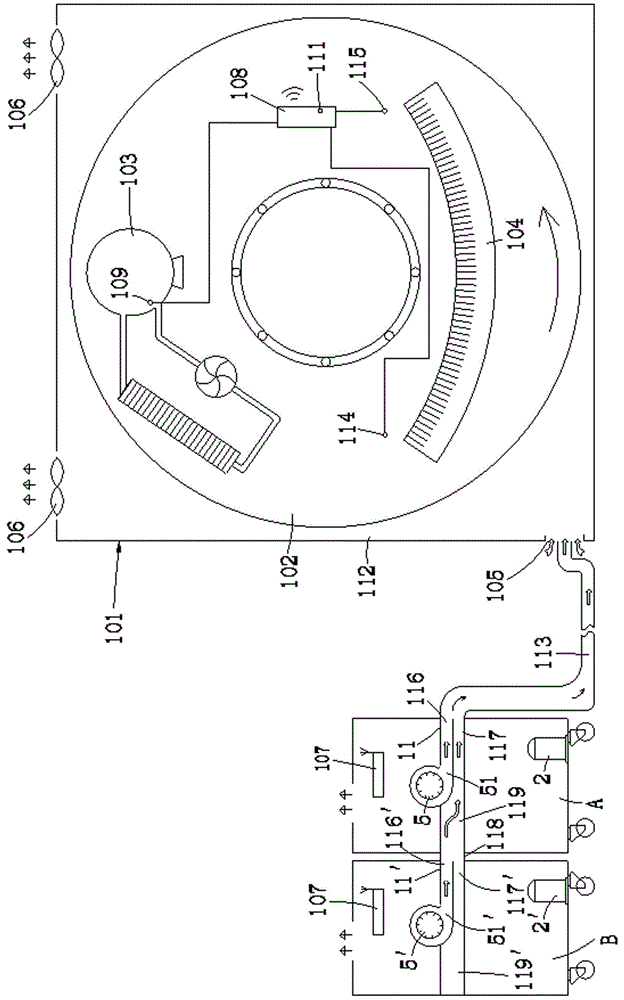

Air coolers, cooling system comprising air coolers and temperature regulating and balancing method for CT (Computed Tomography) scanning machine

InactiveCN104825184AImprove cooling efficiencyIncrease usage loadComputerised tomographsTomographyCold airComputing tomography

The invention relates to air coolers, a cooling system comprising the air coolers and a temperature regulating and balancing method for a CT (Computed Tomography) scanning machine. A plurality of negative pressure fans are arranged on the back side of a condenser of each air cooler in an array form; a condensation water tank is also arranged below the condenser; a water pump is arranged in the condensation water tank; a porous spraying pipe is arranged at the upper end of the condenser and is connected with the water pump through a pipeline; the cooling system comprises a CT scanning machine, two parallel air coolers, a receiving controller, a transmitting processor, a bulb tube temperature sensor, a condenser temperature sensor, a detector temperature sensor and a displacement sensor; a cold air outlet of the auxiliary air cooler is connected into the main air cooler through a connector and is connected with a cold air outlet of the main air cooler in parallel; the cold air outlet of the auxiliary air cooler and the cold air outlet of the main air cooler are jointly communicated with an air inlet of a rack through a cold air pipeline. According to the invention, no condensation water is stored in the air coolers, so that the energy efficiency of refrigeration is improved; the cooling system directly refrigerates a CT scanning rack, so that air temperatures of the CT bulb tube and a detector assembly in the scanning rack are reduced.

Owner:HANGZHOU SAMWAY IMAGE SCI & TECH CO LTD

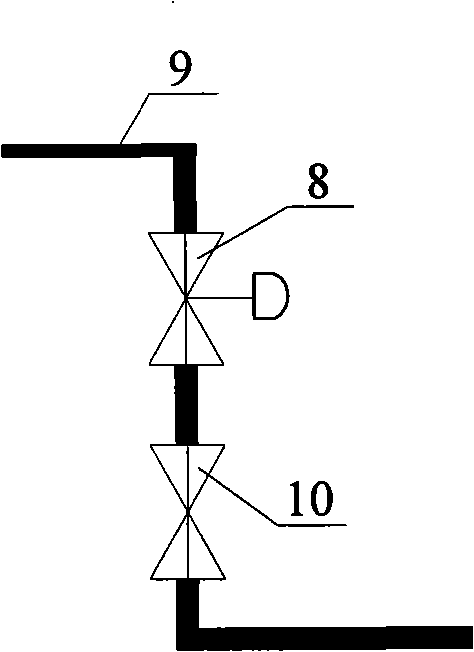

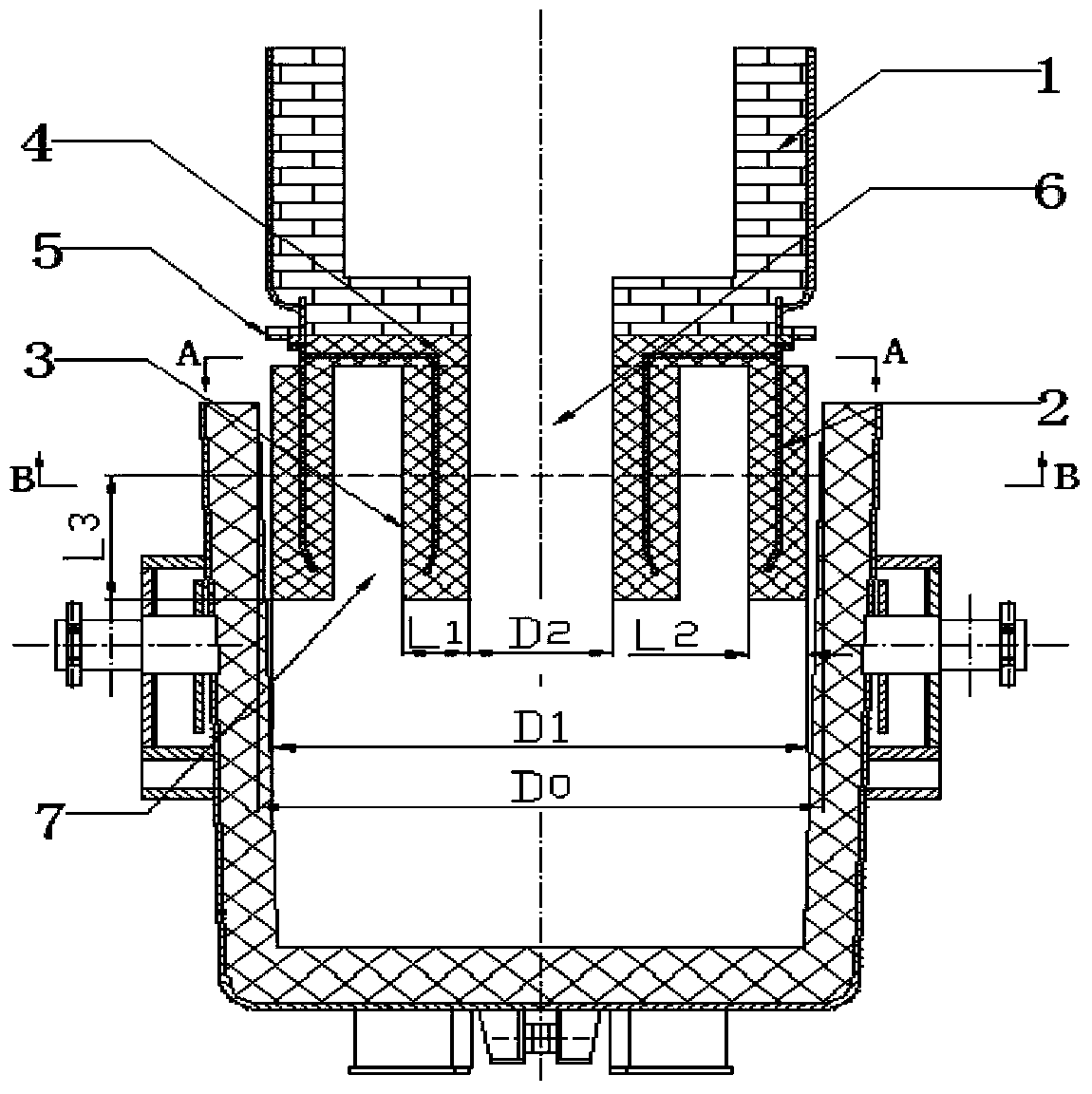

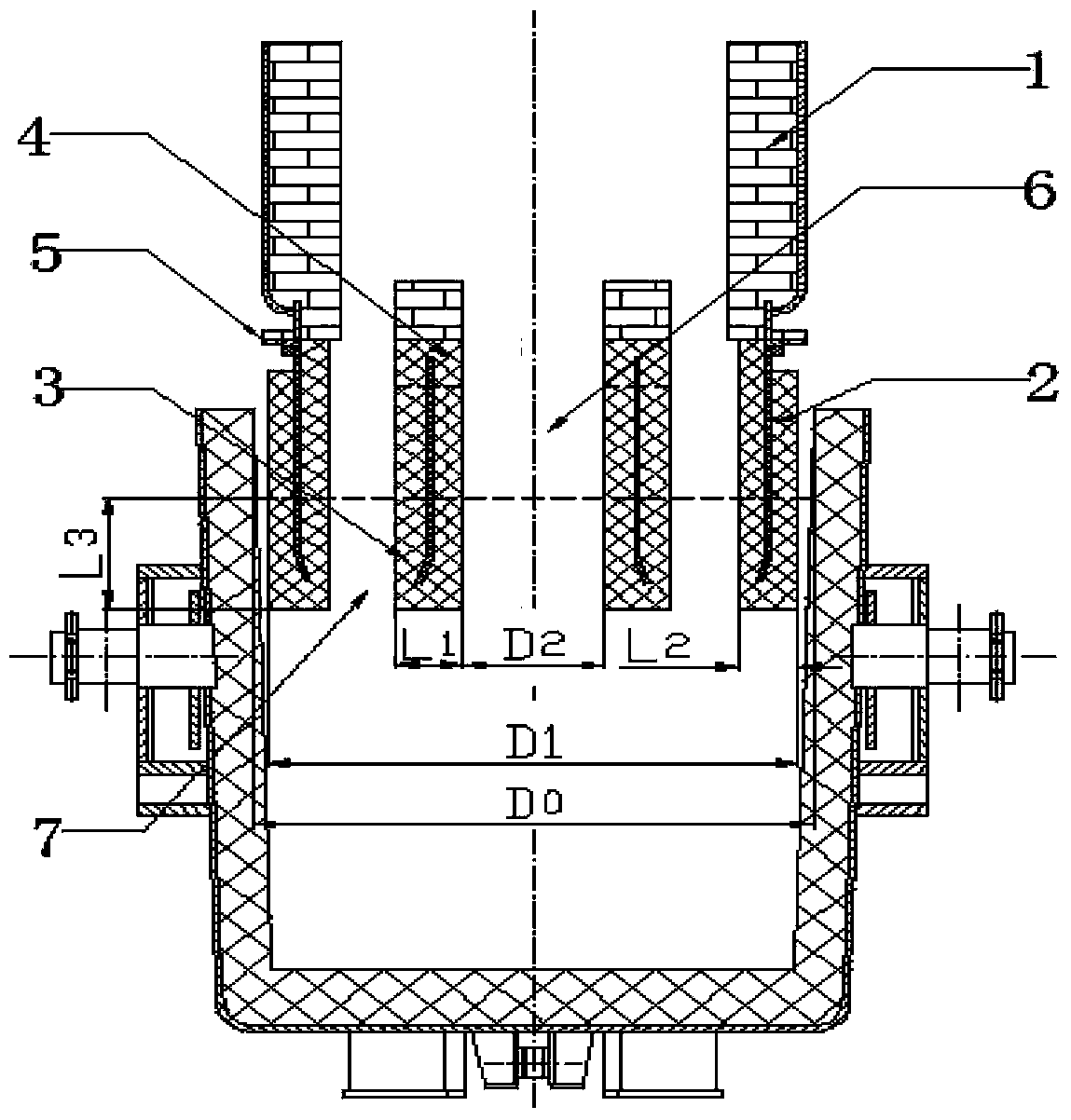

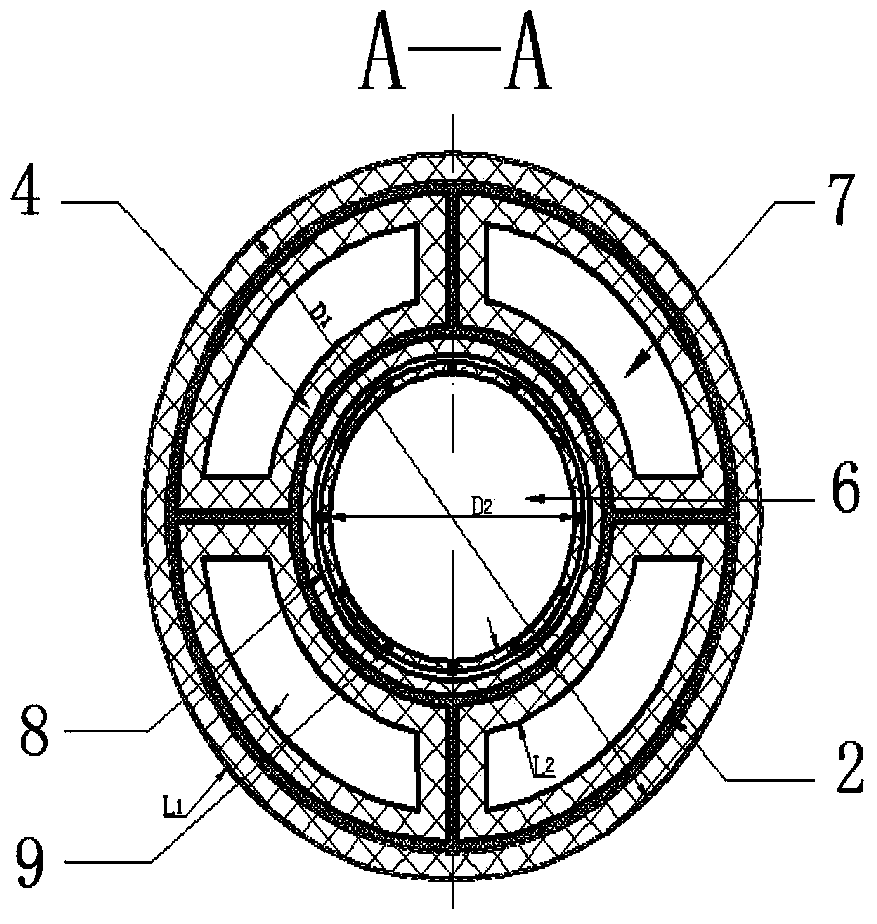

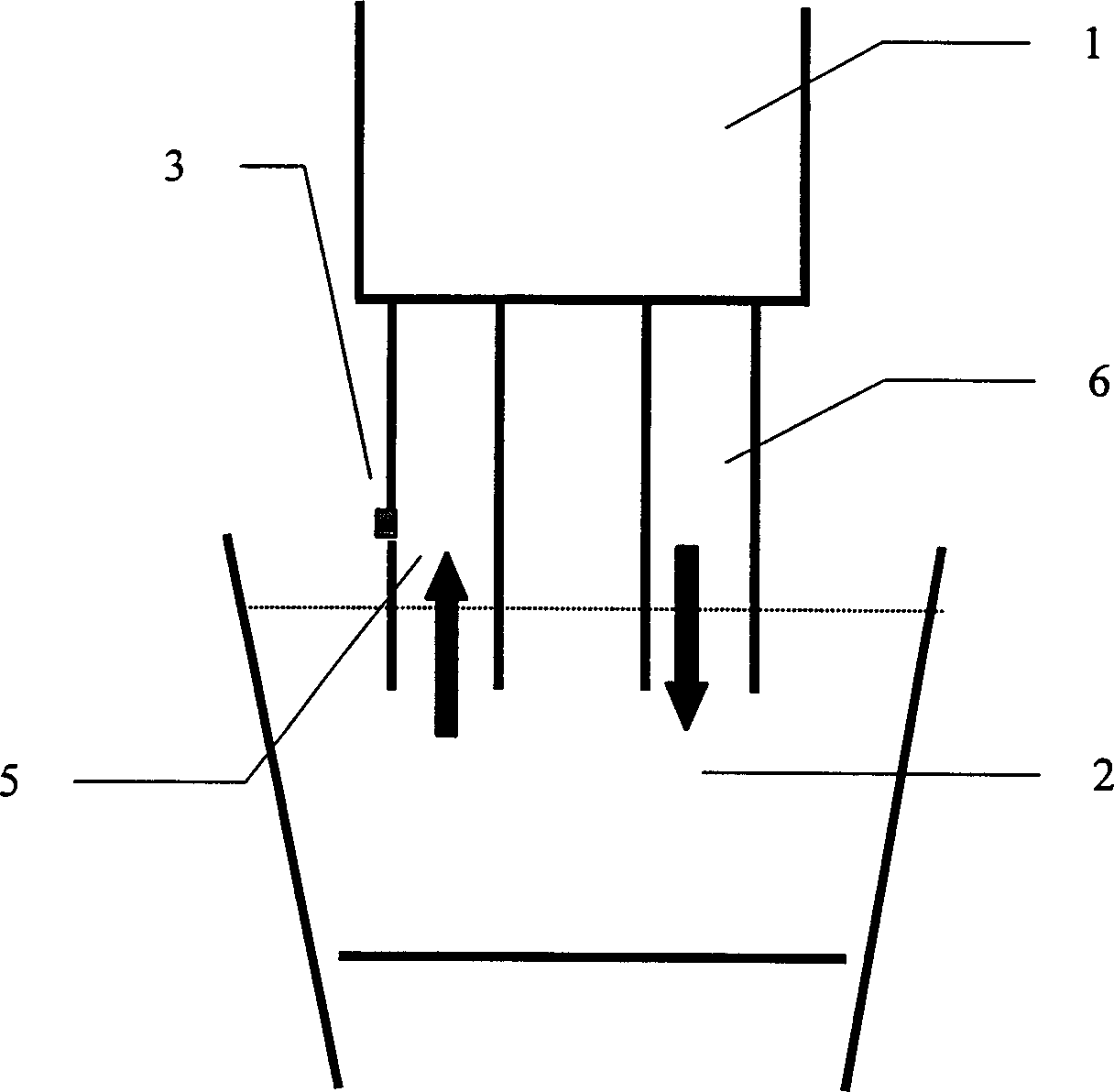

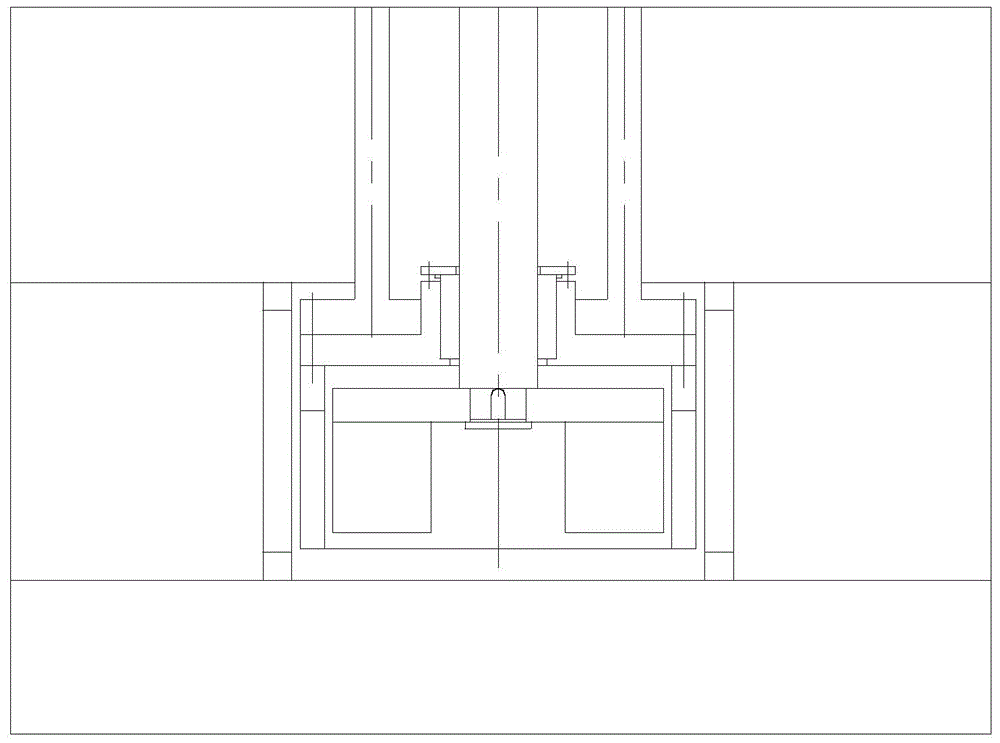

Sleeve type dip pipe for RH (Ruhrstahl Hereaeus) vacuum refining device

ActiveCN103866090AIncrease the circulation areaIncrease circulation flowArchitectural engineeringMolten steel

The invention discloses a sleeve type dip pipe for an RH (Ruhrstahl Hereaeus) vacuum refining device. The dip pipe mainly comprises an annular sleeve pipe, a circular-pipe-shaped partition wall, a cross beam and a flange plate, wherein the circular-pipe-shaped partition wall is coaxially arranged in the middle of the annular sleeve pipe; an inner circular pipe is formed on the inner side of the circular-pipe-shaped partition wall; an outer annular pipe is formed between the outer wall of the circular-pipe-shaped partition wall and the inner wall of the annular sleeve pipe on the outer side of the circular-pipe-shaped partition wall; the inner annular pipe and the outer annular pipe can be used as an ascending pipe and a descending pipe of the RH dip pipe respectively. As the space in the bottom of a vacuum chamber is fully utilized by the dip pipe with the structure to enlarge the circulation area of molten steel of the dip pipe, the circulation flow of an RH vacuum circulation degassing device can be remarkably increased.

Owner:NORTHEASTERN UNIV

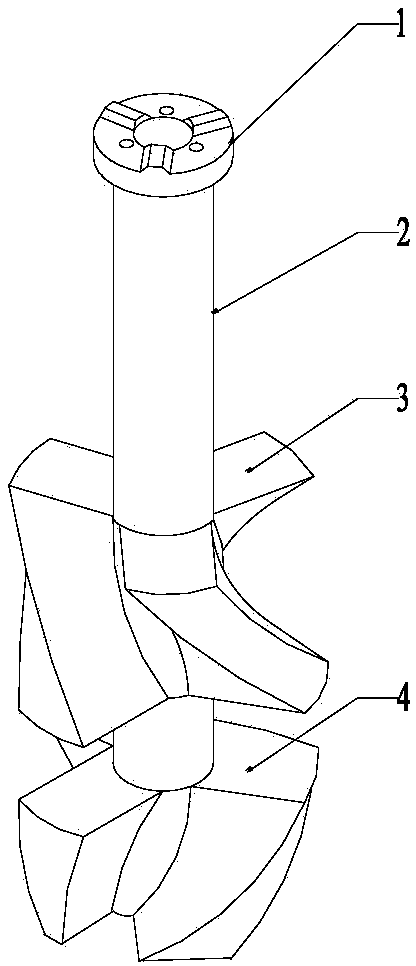

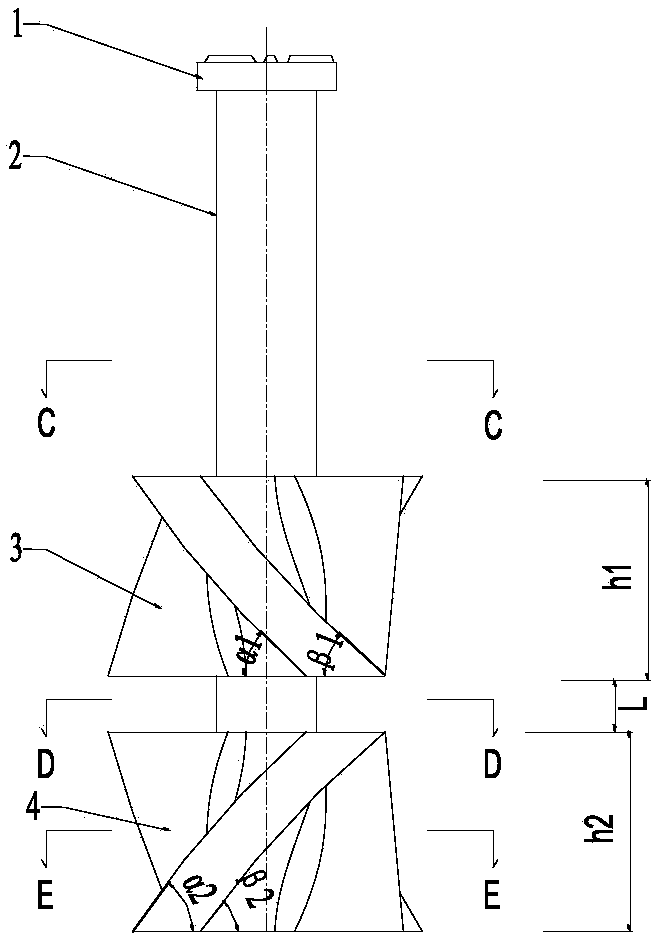

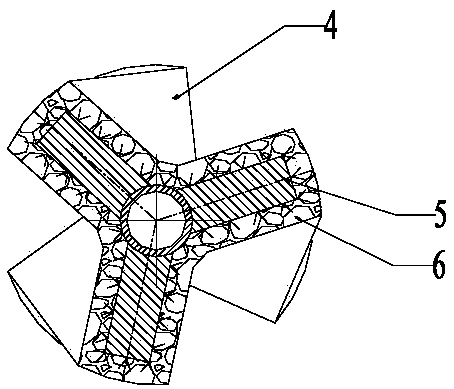

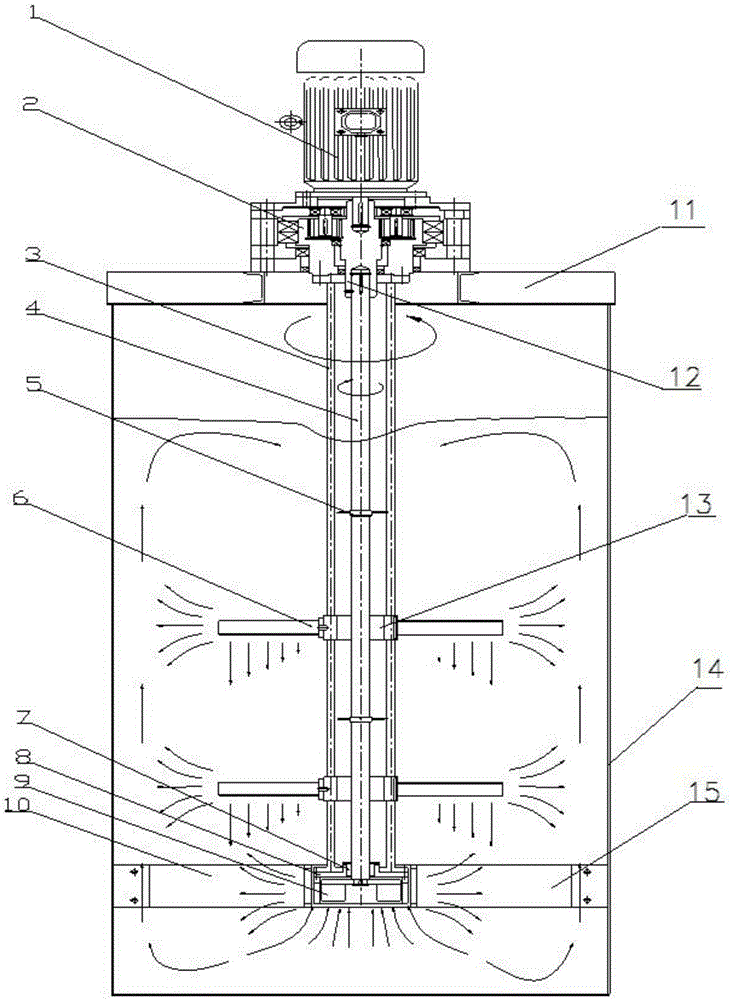

Molten iron full-domain stirring and desulfurization stirrer and using method thereof

The invention discloses a molten iron full-domain stirring and desulfurization stirrer. The stirrer comprises a stirring shaft, a stirrer connecting flange, upper-layer stirring blades and lower-layerstirring blades, each upper-layer stirring blade and each lower-layer stirring blade each comprises a stirring blade core and a stirring blade core fire-resistant pouring material lining, each upper-layer stirring blade is a left-rotated spiral blade rotating in the same direction as the stirring direction, each lower-layer stirring blade is a right-rotated spiral blade rotating in the directionopposite to the stirring direction, and the lower-layer stirring blades and the upper-layer stirring blades are arranged at the same circumferential angle in the circumferential direction of the stirring shaft or are arranged in a front-back equal-angle staggered angle mode. Through the double-layer stirring blade structure arranged up and down, the arrangement distance of the stirring blades in the length direction of the stirring shaft is greatly increased, the stirring depth and the effective stirring area of the stirrer on the molten iron in a molten iron ladle are expanded, stirring of the molten iron at the bottom of the molten iron ladle and stirring, mixing and mass transfer of the full-domain molten iron are remarkably enhanced, and the dynamic conditions of the full-domain molteniron stirring and desulfurization reaction are greatly improved.

Owner:武汉钢铁有限公司

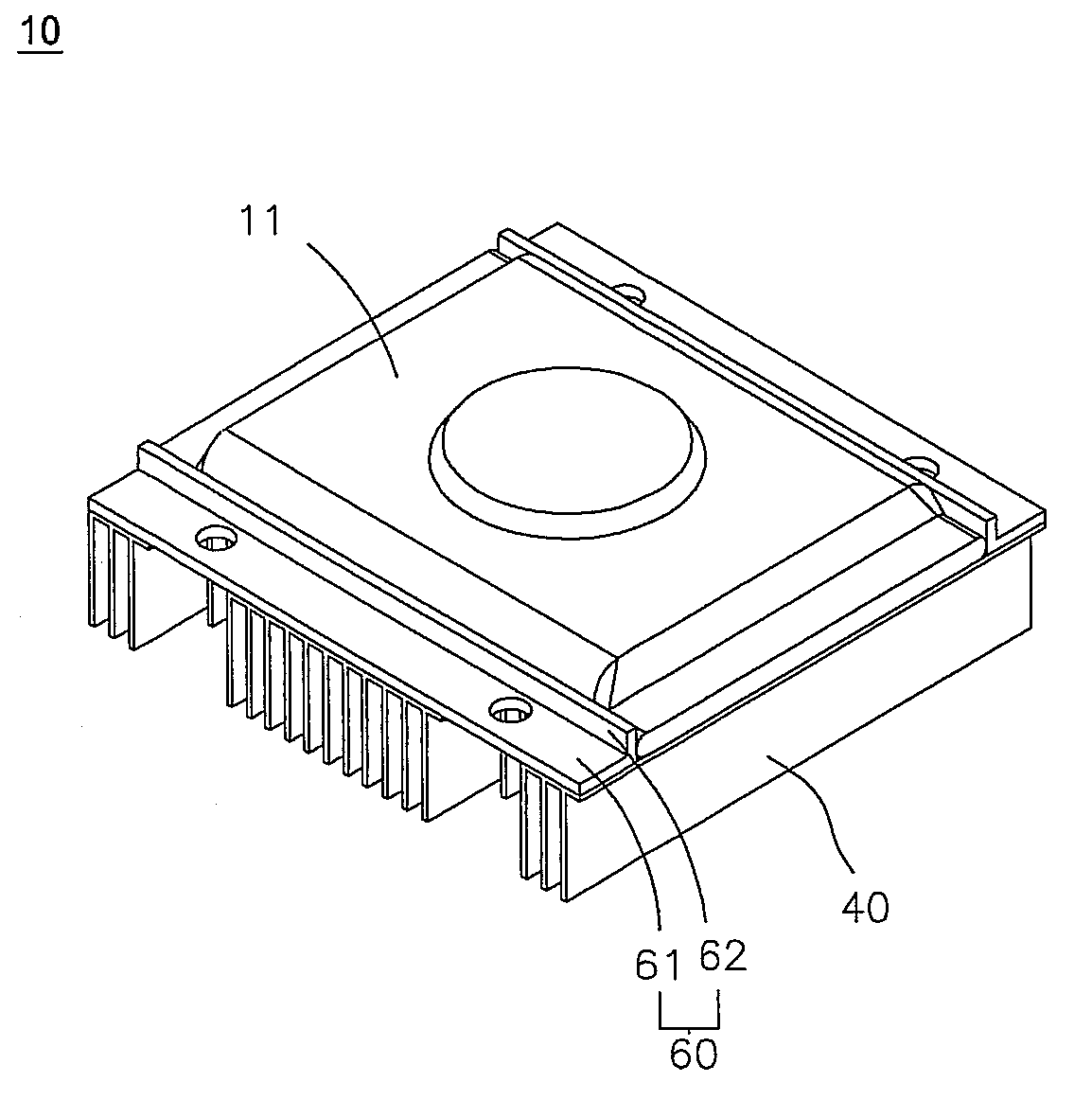

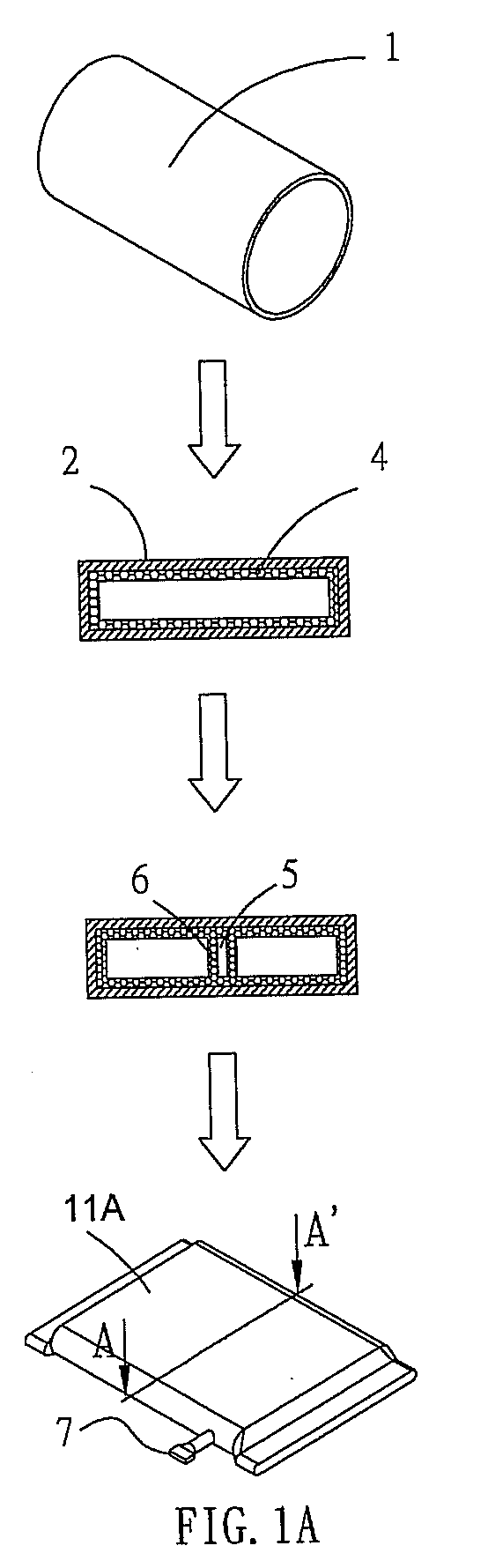

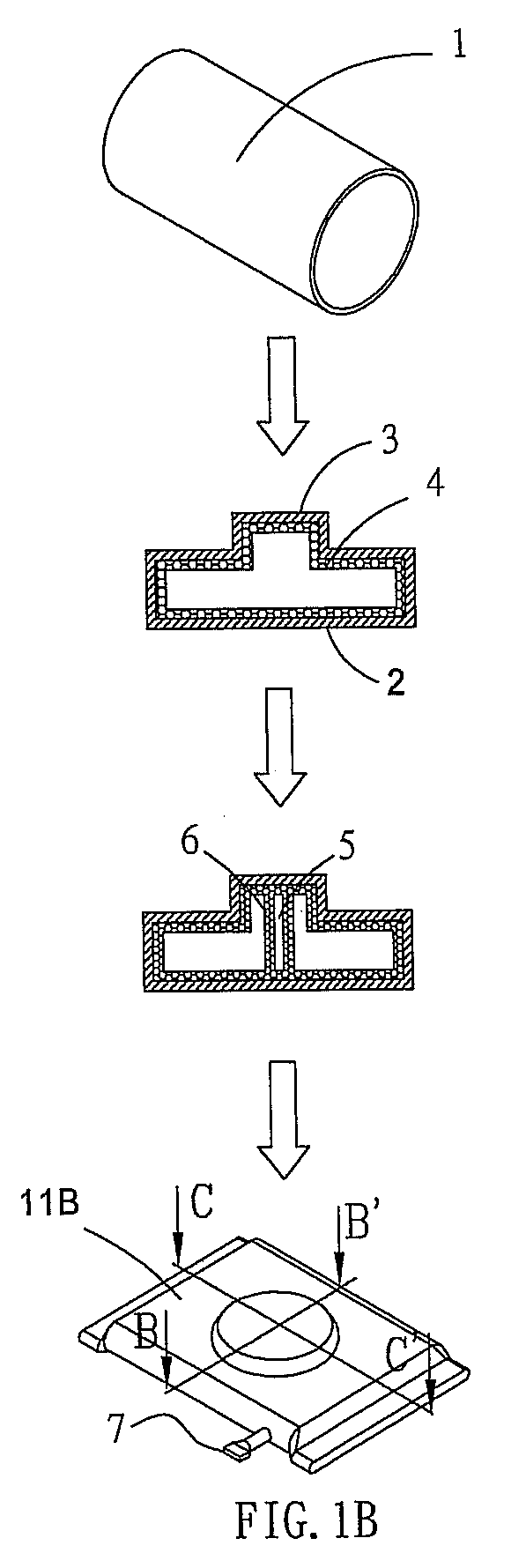

Dissipation module,flat heat column thereof and manufacturing method for flat heat column

InactiveUS20100051239A1Improve reliabilityLow costReinforcing meansIndirect heat exchangersWorking fluidComputer module

A manufacturing method for a flat heat column includes the steps of: providing a flat hollow tube, of which a first wick structure is disposed on the inner surface; providing at least one guiding device disposed within the flat heat tube for supporting the flat heat tube, wherein a second wick structure is disposed on the surface of the guiding device; connecting the first wick structure and the second wick structure for forming a continuous wick structure; and filling a working fluid and sealing both two ends of the flat hollow tube so as to form the flat heat column. A heat dissipation module and its flat heat column are also disclosed for applying to a heat element. The flat heat column can provide flowing path with optimum thermal conductive efficiency for the fluid therein.

Owner:DELTA ELECTRONICS INC

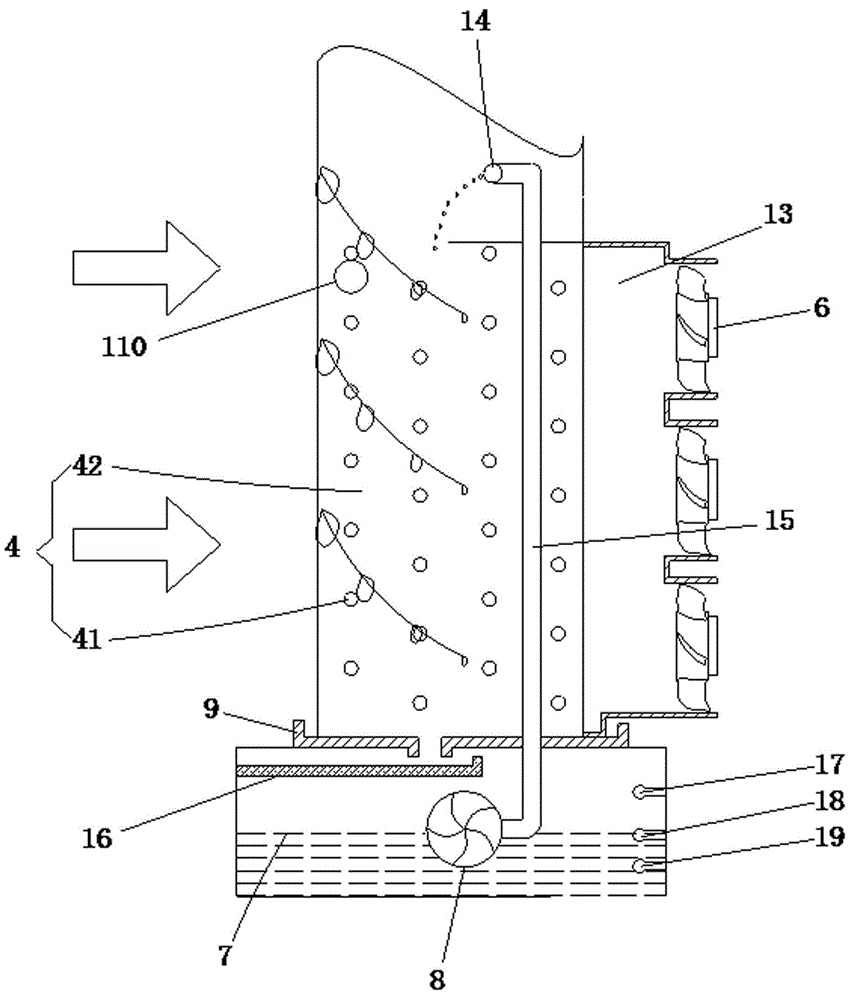

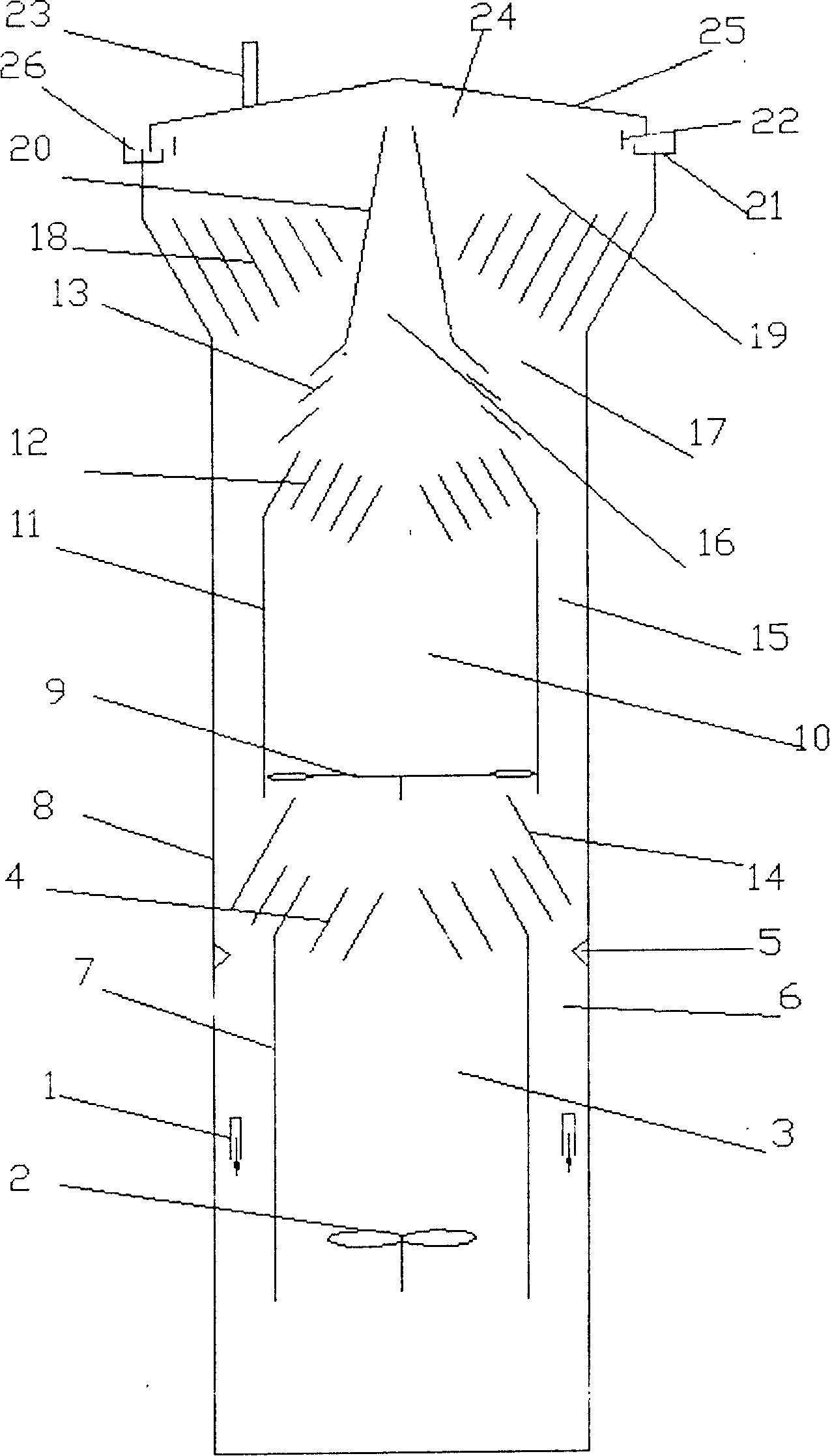

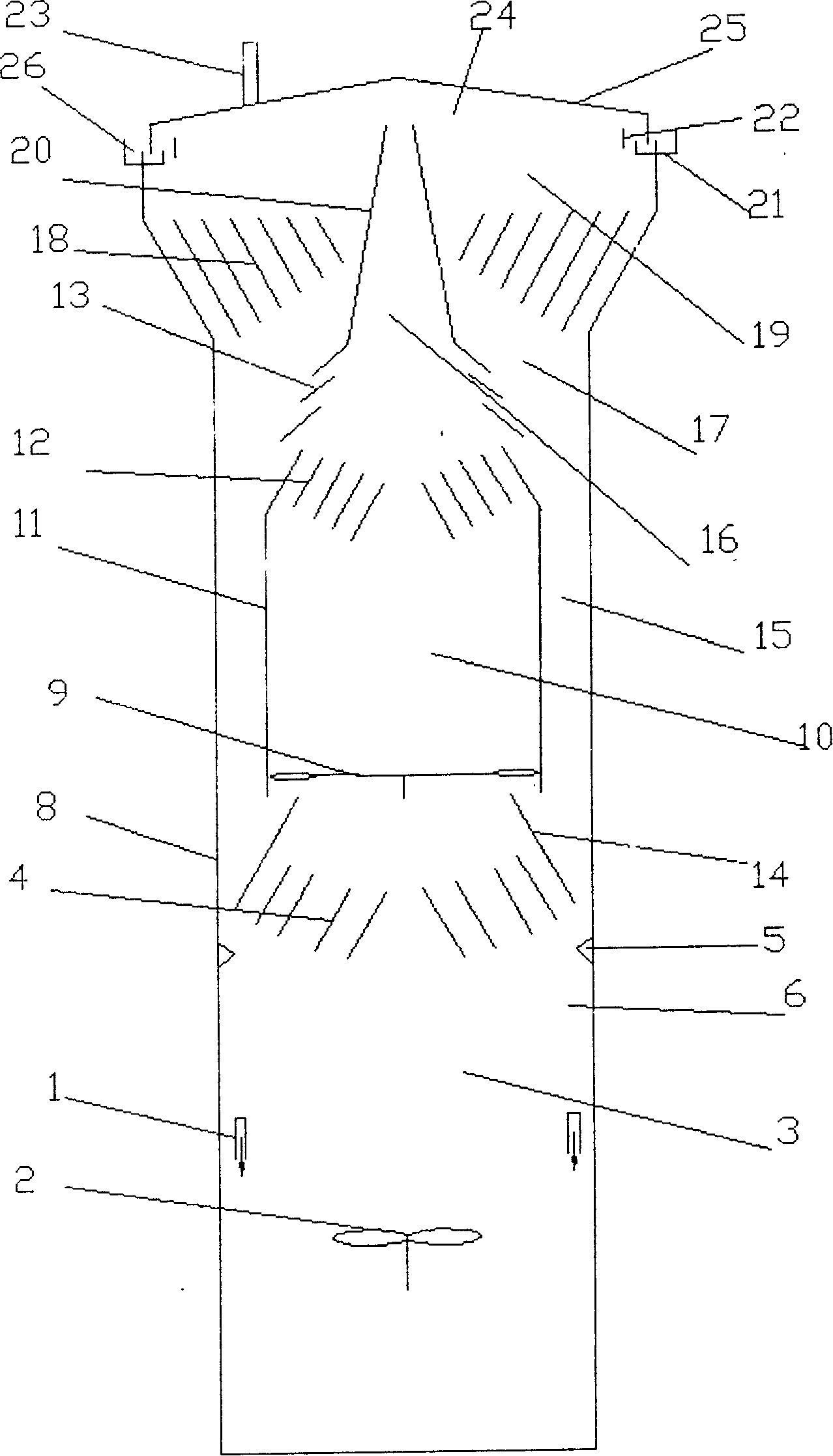

Diphase integrated multi-gradation internal circulation anaerobic bioreactor

InactiveCN101164915AThorough treatmentEasy to handleTreatment with anaerobic digestion processesHigh resistanceSmall footprint

This invention relates to a two-phase integrated, multi-layered and internal-circulation anaerobic biological reactor. It is composed of: an upper inner casing, a middle inner casing and alower inner casing, a 1st gas-liquid separation reflecting plate, a 2nd reflecting plate, a 1st gas-isolation guiding plate, a 2nd gas-isolation guiding plate, an upper agitator, a lower agitator, liquid distributor and solid-liquid separator. Due to the equipped multiple inner circulation it makes the liquid being of fluidization condition, the anaerobic reaction is better than that of prior art method. This invention has advantages of: low area occupation, high load rate, high resistance of shock load, high efficiency, stable treatment, convenient operation, low operation cost, full sealed system of reactor, no bad odour, quick starting, short period of establishment, being suitable for the treatment of waste-water, waste-matter and waste-sludge in size of large, medium or small scale.

Owner:林仁吉

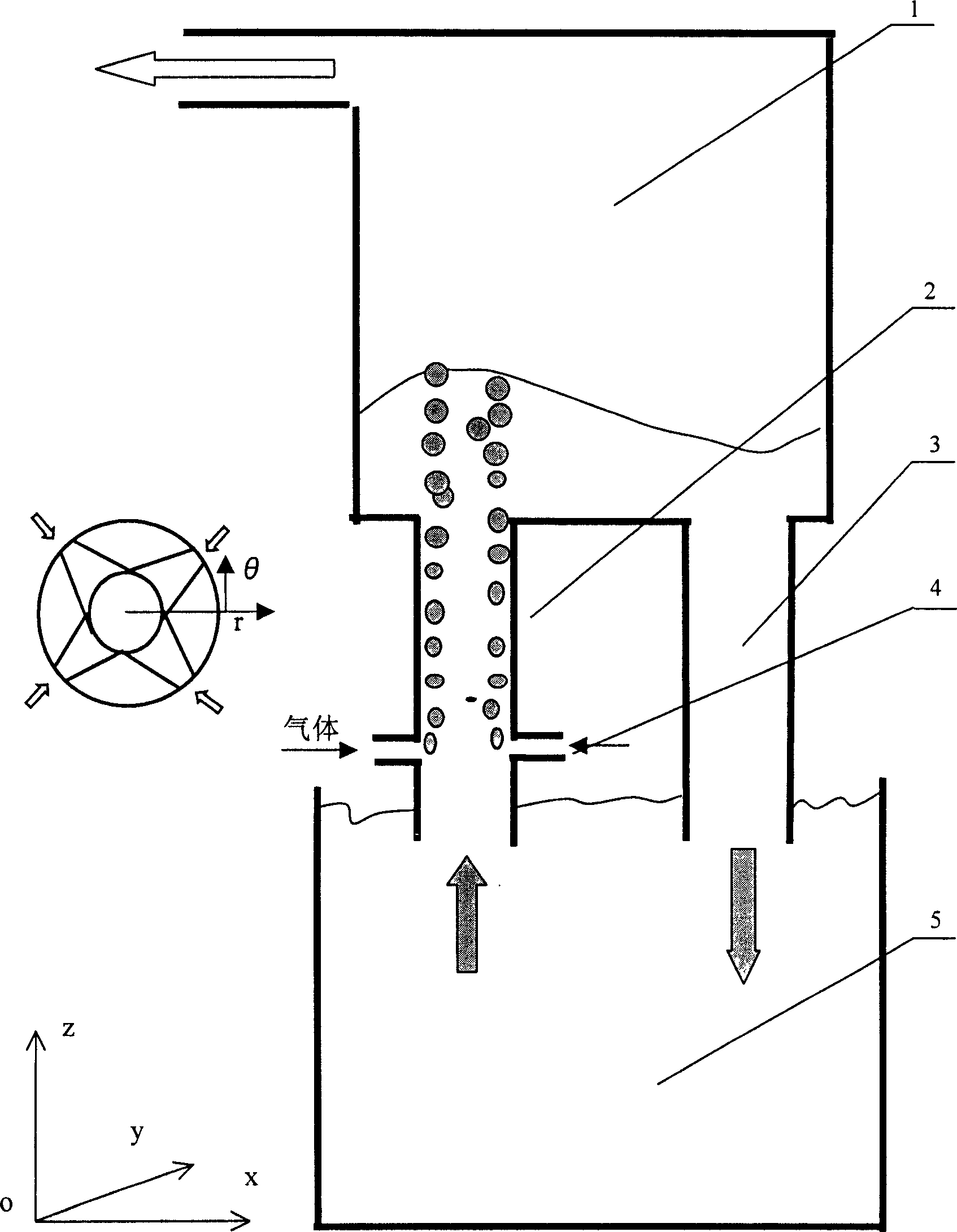

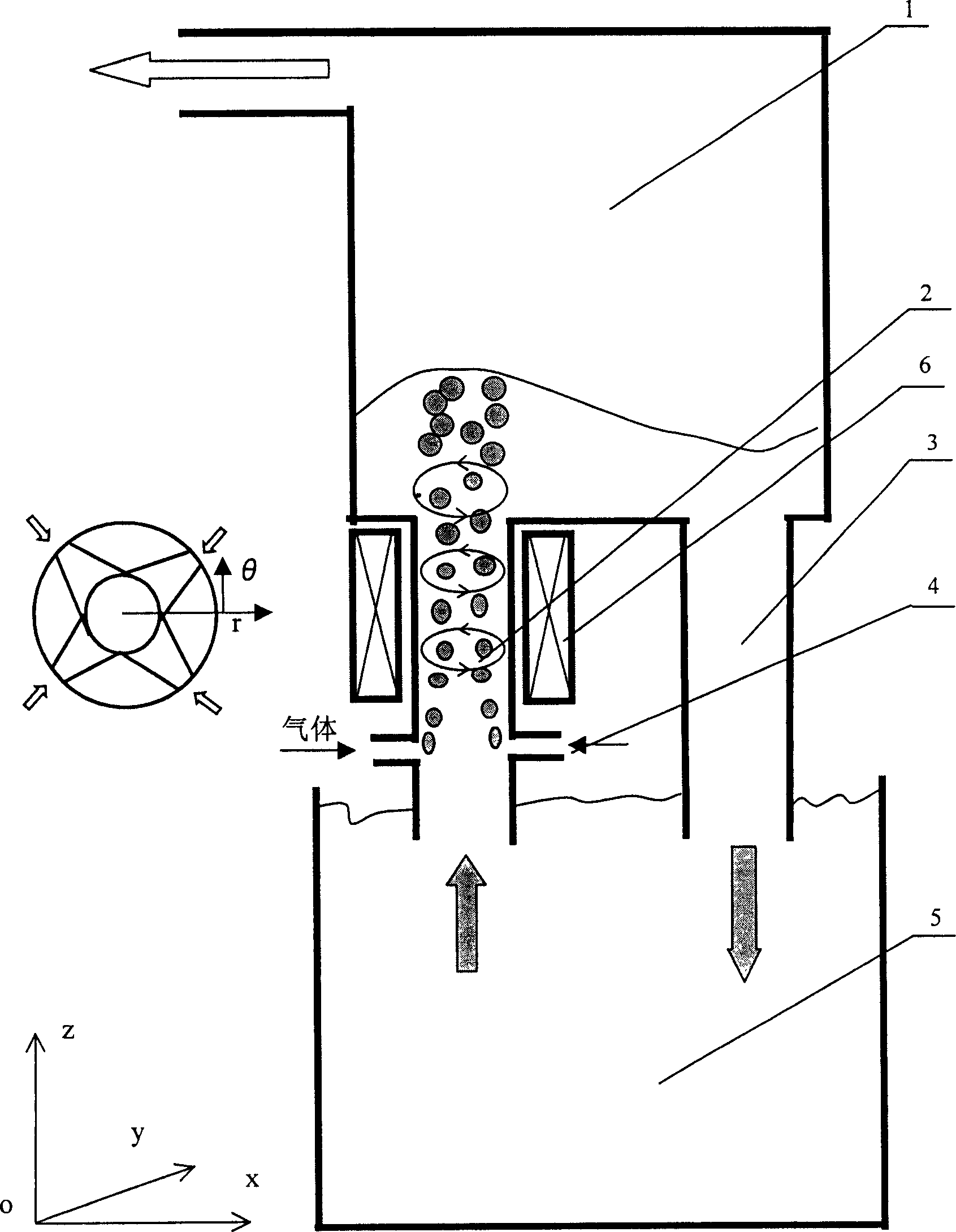

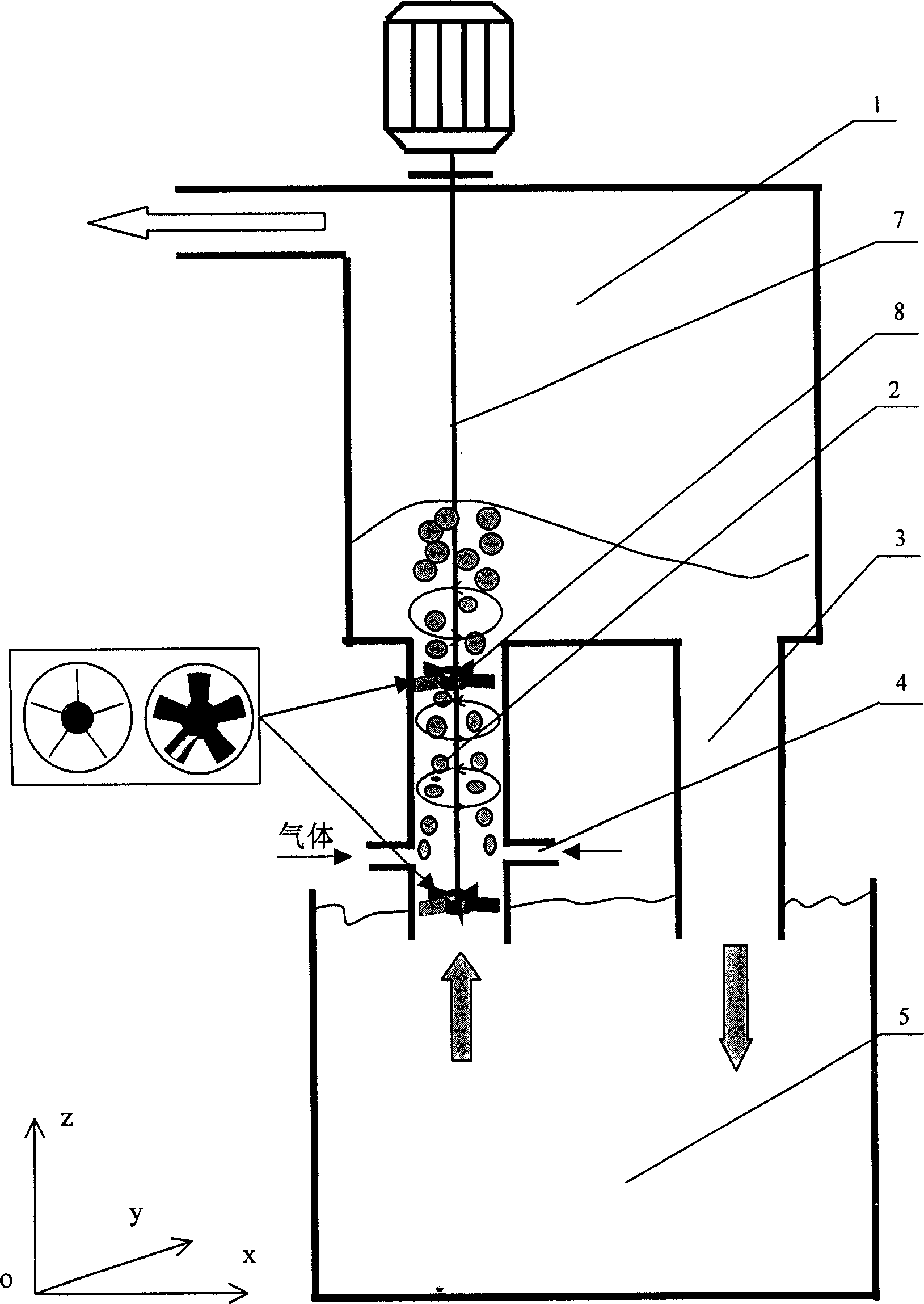

Improved circulation type molten steel vacuum refining method and device

An improved circulation-type vacuum refining method for molten steel includes such steps as sucking the molten steel upward from ladle to vacuum chamber via up-flow pipe while applying an external force to said molten steel to make it rotate in the up-flow pipe, blowing argon gas, and flowing back to the ladle via down-flow pipe. Its refining apparatus is composed of vacuum chamber, up-flow pipe, down-flow pipe, gas nozzle and molten steel stirrer.

Owner:NORTHEASTERN UNIV

Vacuum deaeration refining process and equipment

The present invention provides one kind of vacuum deaeration refining process and equipment. Soaking pipes in the bottom of the vacuum chamber are inserted into molten steel inside the molten steel container, driving gas is introduced into the ascending soaking pipe and the molten steel flows from the molten steel container, through the ascending soaking pipe, the vacuum chamber and the descending soaking pipe before returning to the molten steel container circular. The present invention features that there is magnetic field generator installed outside at least one soaking pipe to produce electromagnetic force in the same direction to that of the circular molten steel and this results in increased circulating molten steel amount and high refining efficiency.

Owner:BAOSHAN IRON & STEEL CO LTD +1

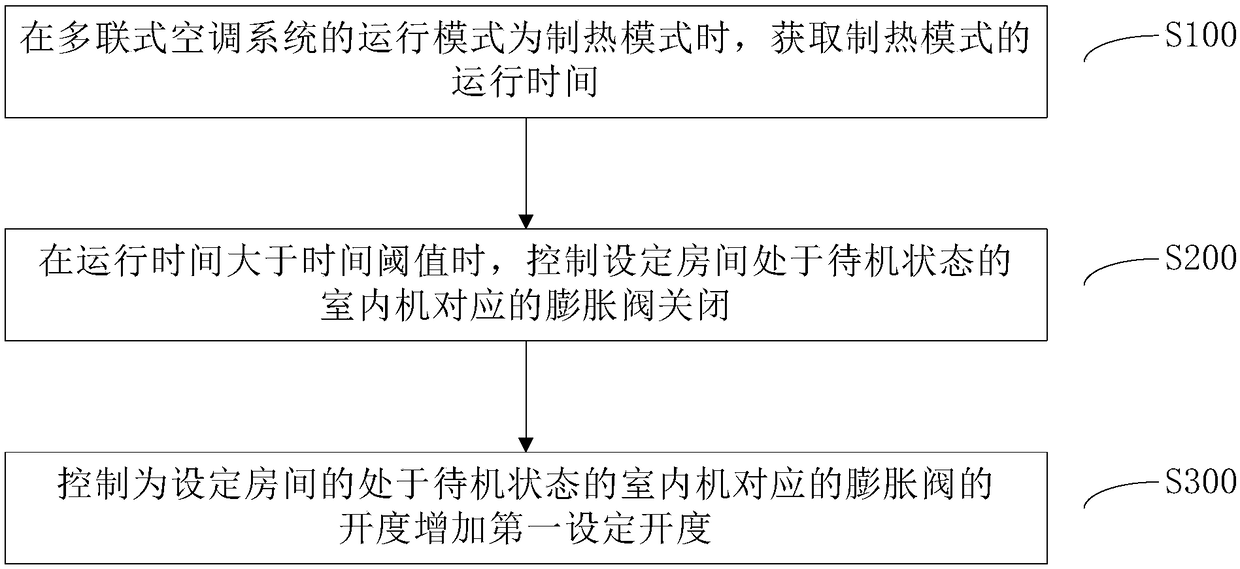

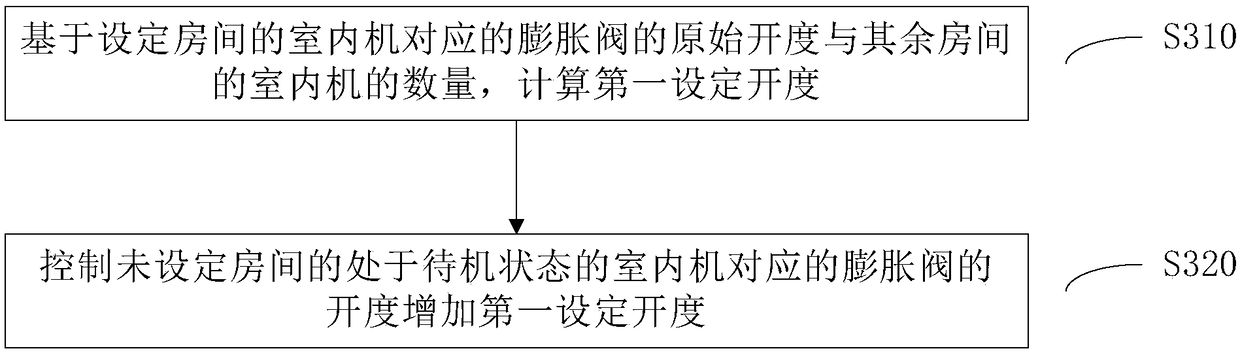

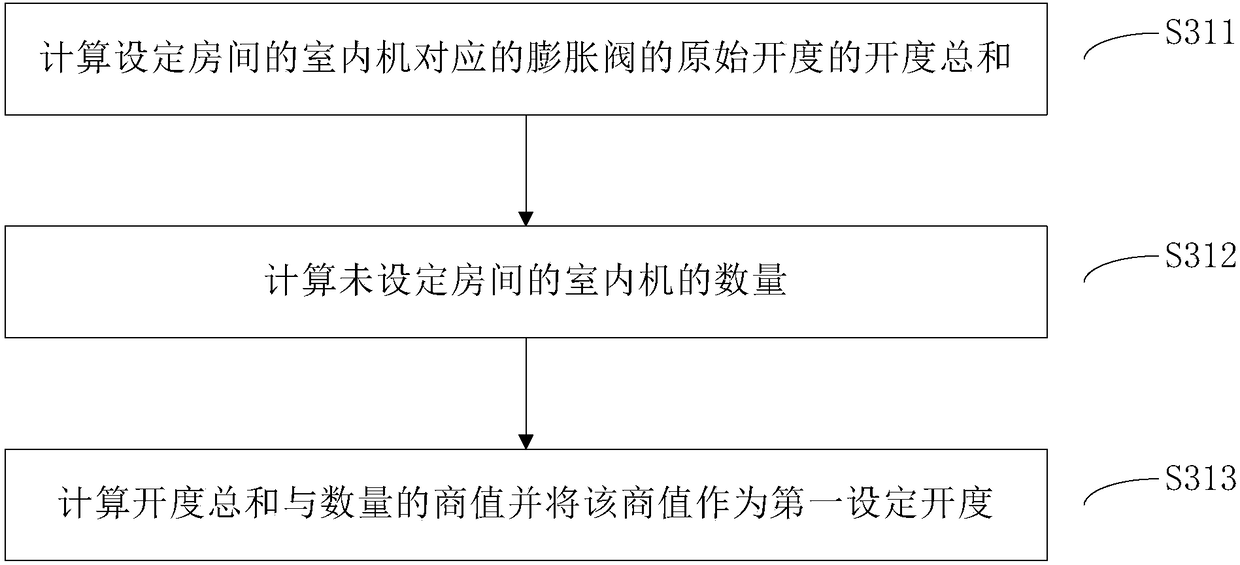

Noise control method and controller of multi-connected air conditioner system

ActiveCN108195047ACancel noiseReduce noiseMechanical apparatusNoise suppressionElectronic expansion valveNoise control

The invention relates to the technical field of air conditioners, in particular to a noise control method and a controller of a multi-connected air conditioner system, and aims to solve the problems that according to an existing technical scheme which is characterized in that replacement of a large-diameter electronic expansion valve is adopted to solve the problem of the high standby noise of a heating indoor unit, the effect is poor, and the cost is high. The noise control method of the multi-connected air conditioner system comprises the following steps that when the running mode of the multi-connected air conditioner system is a heating mode, the running time of the heating mode is acquired; and when the value of the running time is larger than a time threshold value, an expansion valve corresponding to an indoor unit which is located in a set room and in a standby state is controlled to be closed. By the adoption of the noise control method and the controller of the multi-connected air conditioner system, due to the fact that the expansion valve corresponding to the indoor unit in the set room is controlled to be completely closed, noise control can be conducted over the set room, the noise generated by the indoor unit of the room is completely eliminated, and the user experience is greatly improved.

Owner:QINGDAO HAIER AIR CONDITIONING ELECTRONICS CO LTD +1

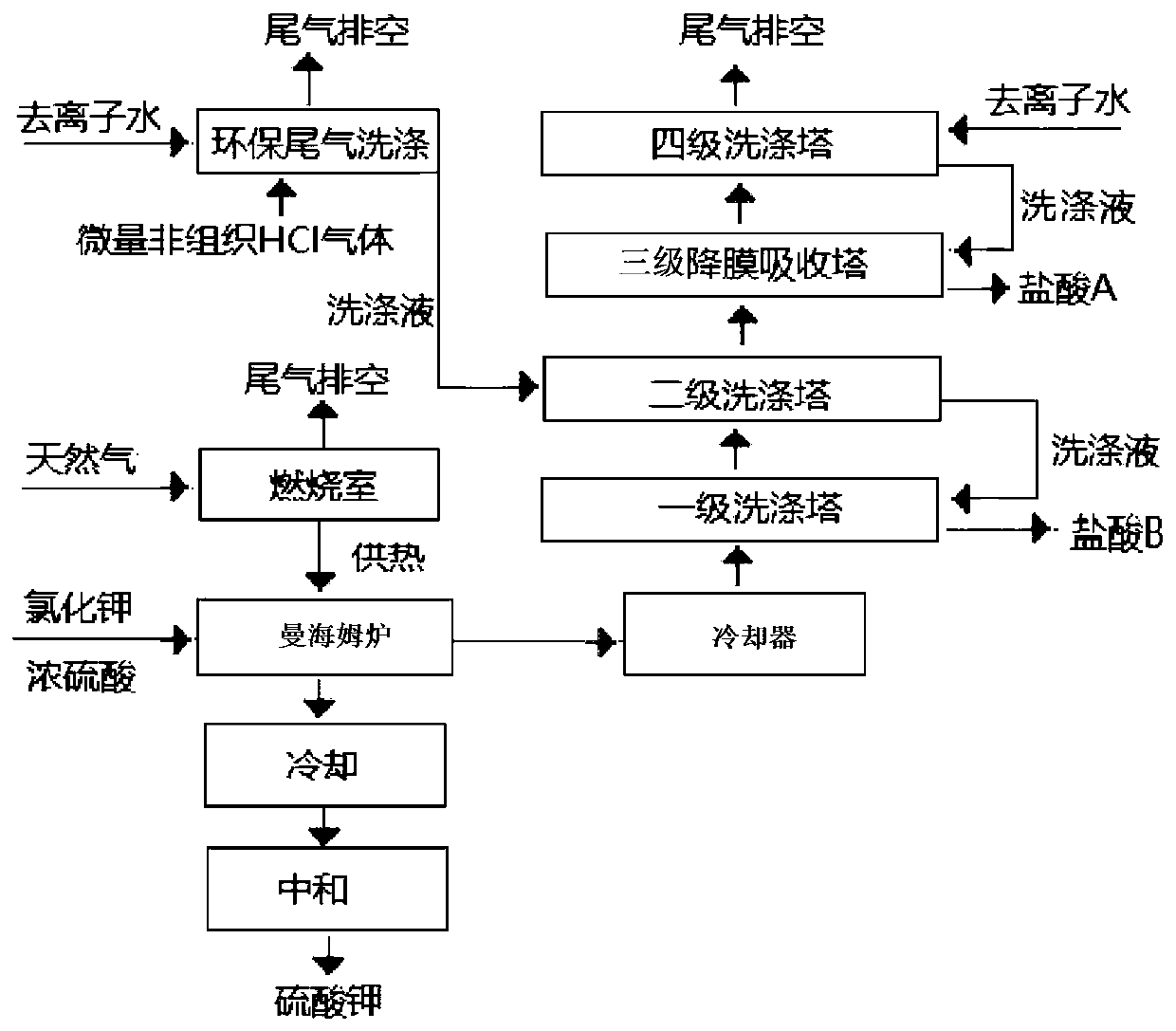

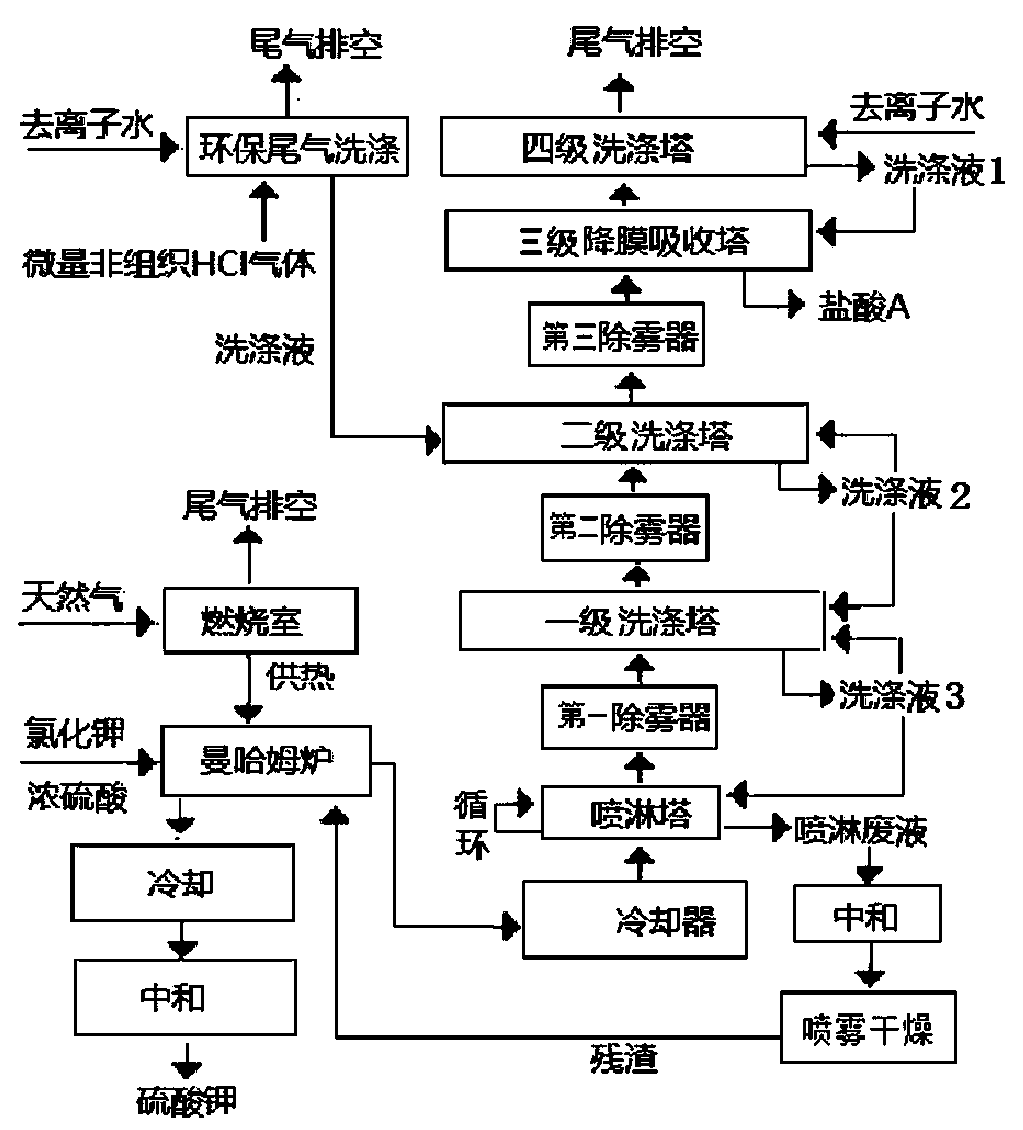

Method for preparing hydrochloric acid by utilizing hydrogen chloride gas in the process of producing potassium sulfate by Mannheim method

ActiveCN110092352AAvoid it happening againAvoid compromising qualityChlorine/hydrogen-chloride purificationSulfate/bisulfate preparationIonExhaust gas

The invention discloses a method for preparing hydrochloric acid by using hydrogen chloride gas in the process of producing potassium sulfate by a Mannheim method. After being cooled, the gas generated in a Mannheim furnace enters a spray tower for spray washing, and then enters a primary washing tower, a second defogger, a secondary washing tower, a third defogger, a third-stage falling film absorption tower and a fourth-stage washing tower in sequence after defogging treatment by a first defogger for continuous washing and emptying; a washing liquid 1 obtained by washing and absorbing the gas in the fourth-stage washing tower with deionized water enters the third-stage falling film absorption tower for washing and absorption to obtain hydrochloric acid A; environment-friendly tail gas iswashed by deionized water, a washing liquid sequentially enters the secondary washing tower, the primary washing tower and the spraying tower to wash the gas out of the Mannheim furnace, the sprayingwashing liquid in the spraying tower is discharged after reaching a certain concentration and neutralized by a KOH solution to obtain a potassium sulfate and potassium chloride mixed solution, and the mixed solution enters the Mannheim furnace after spray drying to produce potassium sulfate. The process is simple, and the obtained hydrochloric acid has high purity.

Owner:CHINA THREE GORGES UNIV +1

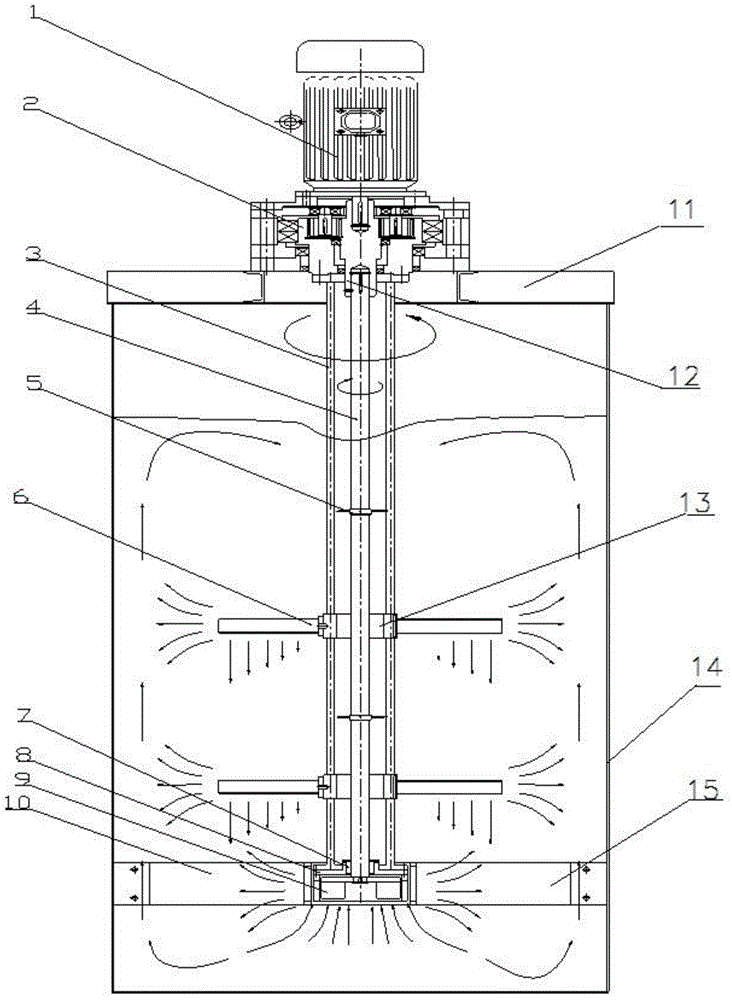

High-efficiency and high-shearing emulsifying machine

ActiveCN103908911AIncreased shear and circulation flowIncrease shear forceRotary stirring mixersMixing methodsShear forceElectric motor

The invention provides a high-efficiency and high-shearing emulsifying machine. The high-efficiency and high-shearing emulsifying machine comprises a motor, a dual output shaft gearbox, a central stirring paddle, an external stirring paddle and an emulsification tank, wherein the emulsification tank is in a cylindrical structure; a cover plate is arranged at the top of the emulsification tank; the dual output shaft gearbox is arranged on the upper side of the center of the cover plate; the motor is connected to the top end of the dual output shaft gearbox; the dual output shaft gearbox is transmitted by adopting two stages of gears which are internally and externally meshed or planetary gears; a central input shaft and an external output shaft are arranged in the dual output shaft gearbox; the lower ends of the central stirring shaft and the external stirring shaft penetrate through the cover plate and stretch into the emulsification tank; the central stirring paddle is mounted on the central stirring shaft; the external stirring paddle is mounted on the external stirring shaft through a fixed hoop; the lower ends of the central stirring shaft and the external stirring shaft are mounted on a bottom bracket. By adopting a two-rotor emulsification head with relative positive and negative rotation and a plurality layers of stirring paddles with unlimited diameters, the shearing force and the circulation flow are exponentially increased.

Owner:ANHUI SONGYU ENG TECH EQUIP

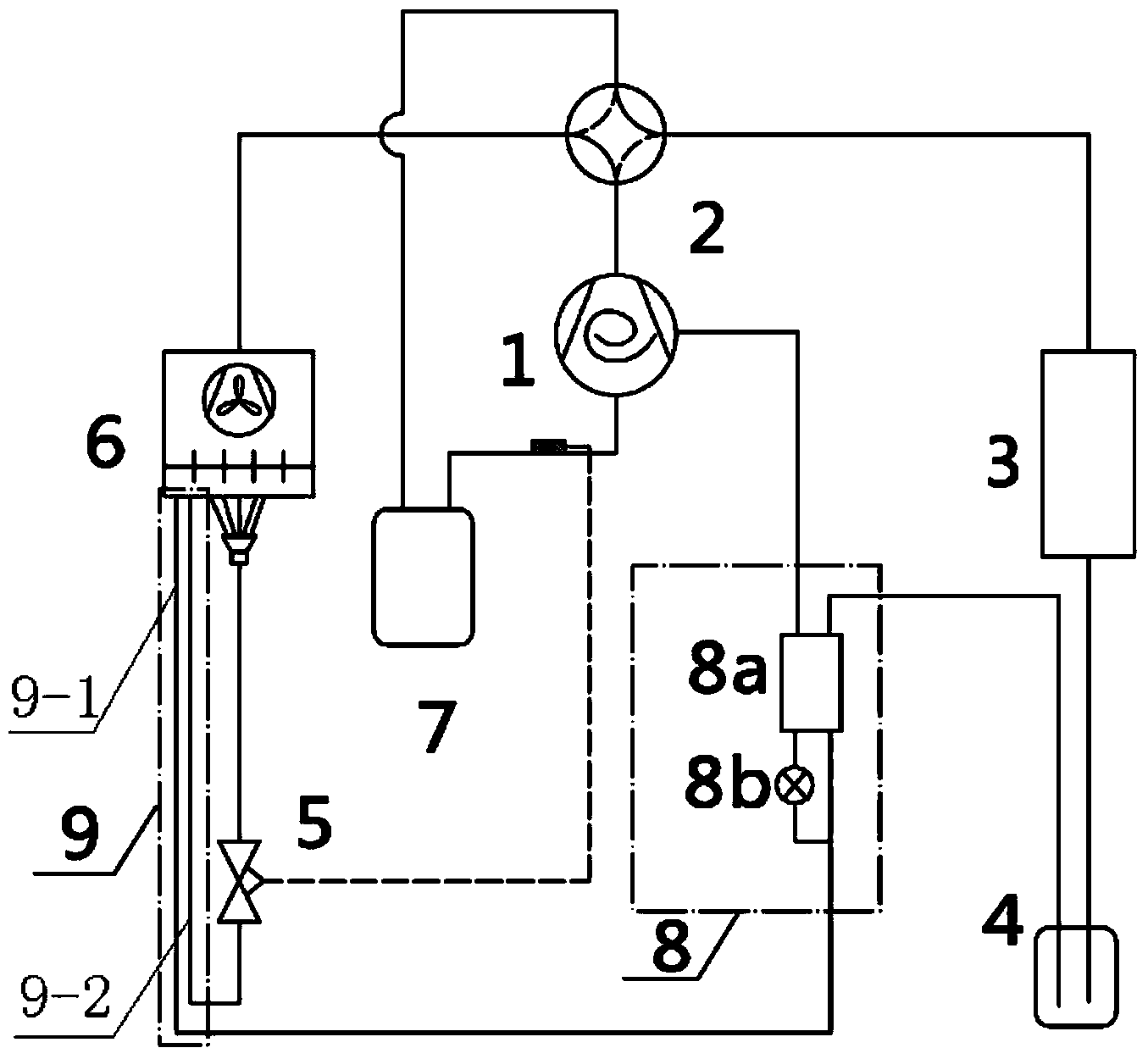

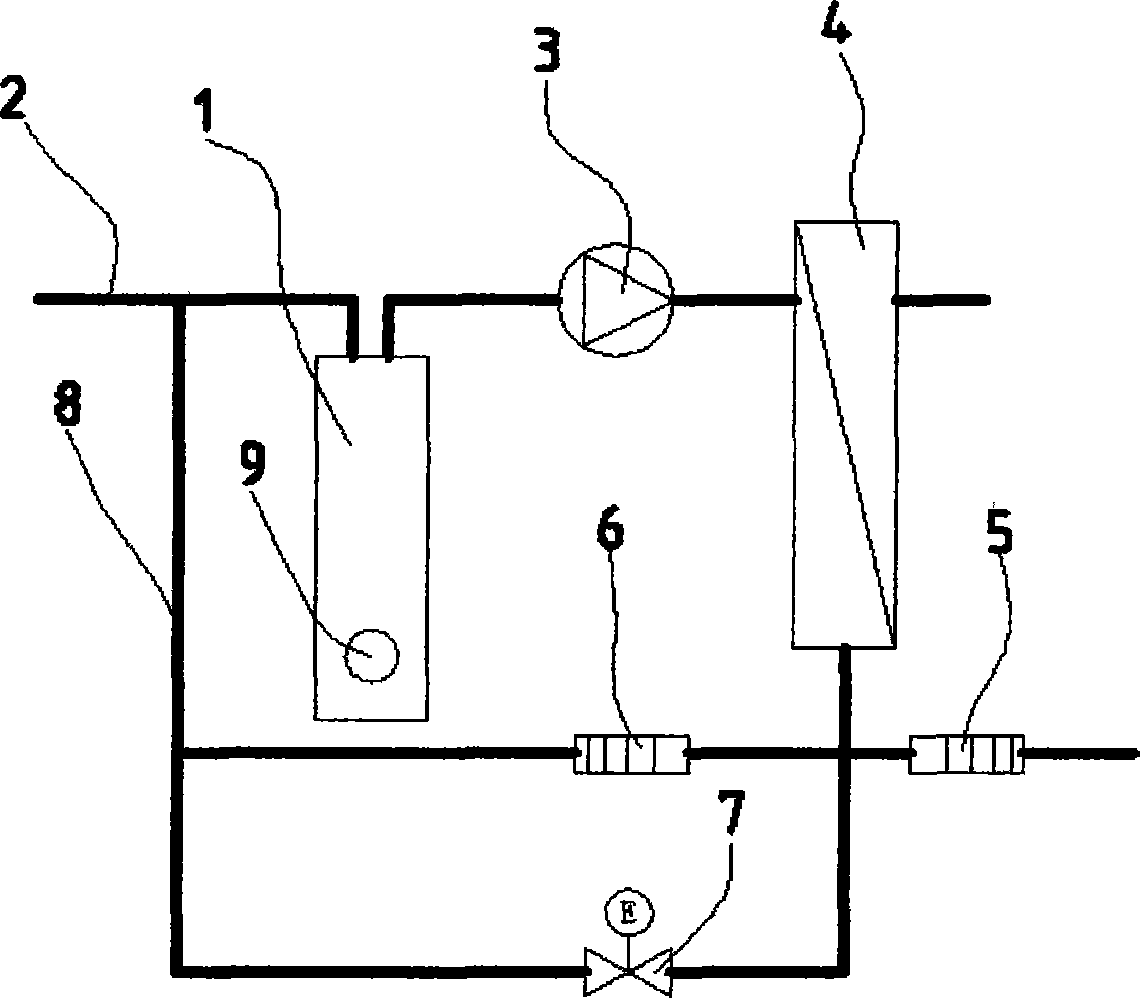

Low-environmental-temperature air source heat pump refrigerating system with heat pipe loop

ActiveCN103528267AIncrease circulation flowGuaranteed uptimeMechanical apparatusFluid circulation arrangementRecuperatorEngineering

The invention relates to a low-environmental-temperature air source heat pump refrigerating system with a heat pipe loop. The low-environmental-temperature air source heat pump refrigerating system comprises a compressor, an indoor heat exchanger, an outdoor heat exchanger and a liquid storage device. The compressor is connected with a four-way reversing valve, the four-way reversing valve is respectively connected with the indoor heat exchanger and the outdoor heat exchanger, the indoor heat exchanger is connected with the liquid storage device, and the outdoor heat exchanger is connected with a heating power expansion valve. The low-environmental-temperature air source heat pump refrigerating system is characterized in that an air supply loop and the heat pipe loop are arranged between the indoor heat exchanger and the outdoor heat exchanger, an economizer and an electronic expansion valve are arranged on the air supply loop, a first inlet of the economizer is connected with the liquid storage device, a first outlet of the economizer is respectively connected with the electronic expansion valve and the heat pipe loop, the heat pipe loop comprises a first pipe and a second pipe, the first pipe is connected with the economizer and the bottom of the outdoor heat exchanger, and the second pipe is connected with the bottom of the outdoor heat exchanger and the heating power expansion valve. According to the low-environmental-temperature air source heat pump refrigerating system, the heating capacity attenuation rate in a low-temperature environment can be restrained, and the phenomenon that the outdoor heat exchanger is frozen in the low-temperature and high-humidity environment is avoided.

Owner:WUXI TONGFANG ARTIFICIAL ENVIRONMENT

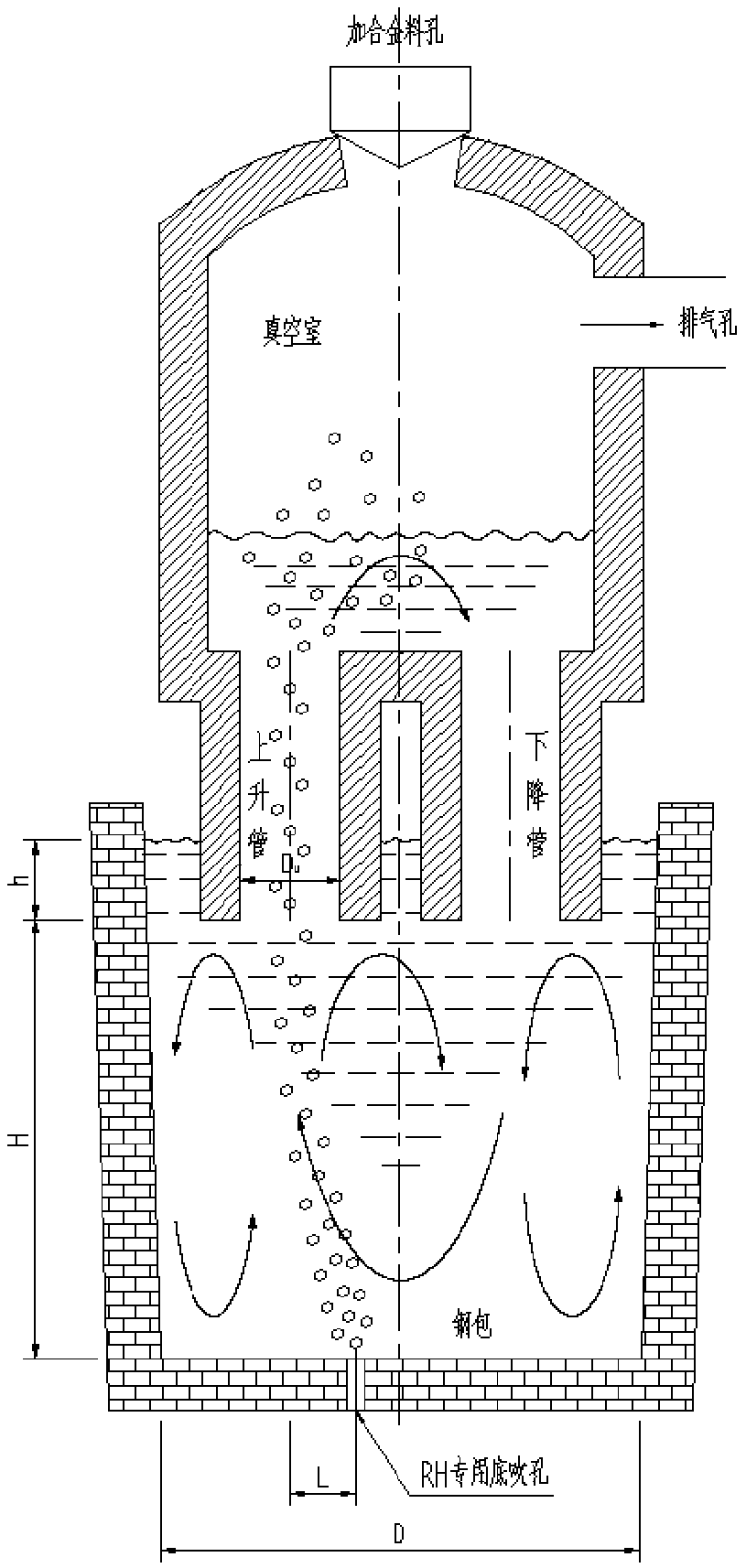

Method for increasing molten steel circulating flow quantity in RH refining process

The invention provides a method for increasing the molten steel circulating flow quantity in the RH refining process and belongs to the technical field of molten steel refining. According to the method for increasing the molten steel circulating flow quantity in the RH refining process, a process procedure of converter / electric furnace-refining RH-continuous casting is adopted to produce high-quality pure steel, in the RH refining process, by means of utilization of an existing steel ladle argon bottom blowing system, argon is blown into the bottom of a steel ladle, argon bubbles blown in thebottom move along with a molten steel flow field, molten steel is lifted to enter an RH dipping pipe ascending pipe, coordinated control between steel ladle argon bottom blowing and dipping pipe inside gas lifting is realized, so that adverse effects in actual production that the air blowing hole position of an RH dipping pipe cannot be remolded and the lifting gas flow quantity is too large to blow through the molten steel inside the dipping pipe to reduce the lifting driving force instead are overcome, and the purpose of increasing the steel circulating flow quantity in the RH refining process is finally achieved. The method for increasing the molten steel circulating flow quantity in the RH refining process has the advantages of being simple and reliable, high in operability and convenient to realize, the RH circulating flow quantity is increased, the decarbonization efficiency is high, the refining time is obviously shortened, and the molten steel purity is improved.

Owner:CENT IRON & STEEL RES INST

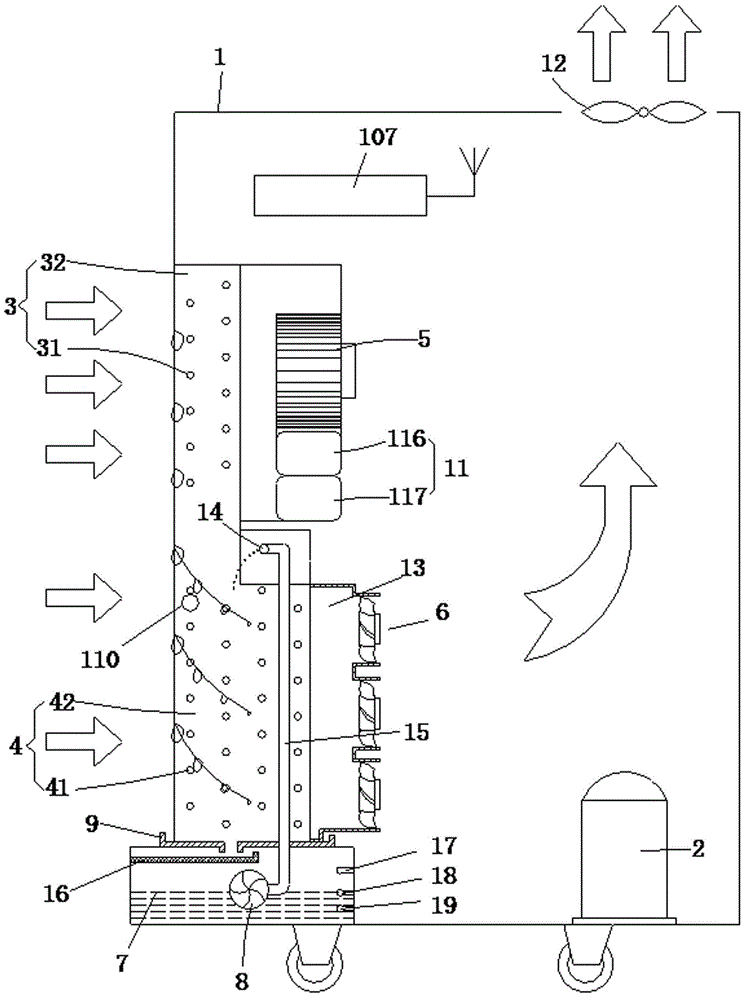

Composite heat exchange type moving heat supply device

InactiveCN104964336AIncrease circulation flowIncrease the areaLighting and heating apparatusSpace heating and ventilation detailsEngineeringHeat storage material

The invention discloses a composite heat exchange type moving heat supply device which comprises an outer box, a heat storage tank located in the outer box, an inlet main pipe, an outlet main pipe, an external main pipe and an automatic controller. The inlet main pipe, the outlet main pipe and the external main pipe are led from the heat storage tank, and the automatic controller is located in the outer box. A heat exchange pipe is vertically buried in a phase-change heat storage material in the heat storage tank. The upper end of the heat exchange pipe is perpendicularly connected with an inlet branch pipe, and the lower end of the heat exchange pipe is inserted in a nozzle of the inlet branch pipe. The nozzle is sealed through a nozzle cap under the elasticity of a spring. A porous pipe is arranged in a fluid working medium in the heat storage tank. During heat charging, the high-temperature fluid working medium enters the heat exchange pipe to conduct indirect contact heat exchange circulation with the phase-change heat storage material, a fluid channel is formed in the solid phase-change heat storage material, and then the fluid working medium is controlled to be sprayed into the fluid channel from the nozzle to conduct direct contact heat exchange circulation with the phase-change heat storage material. During heat supply, an automatic controller adjusts the flow of direct contact heat exchange circulation by monitoring a sensor and controlling the opening degree of an electric valve, and therefore the heat supply temperature is controlled.

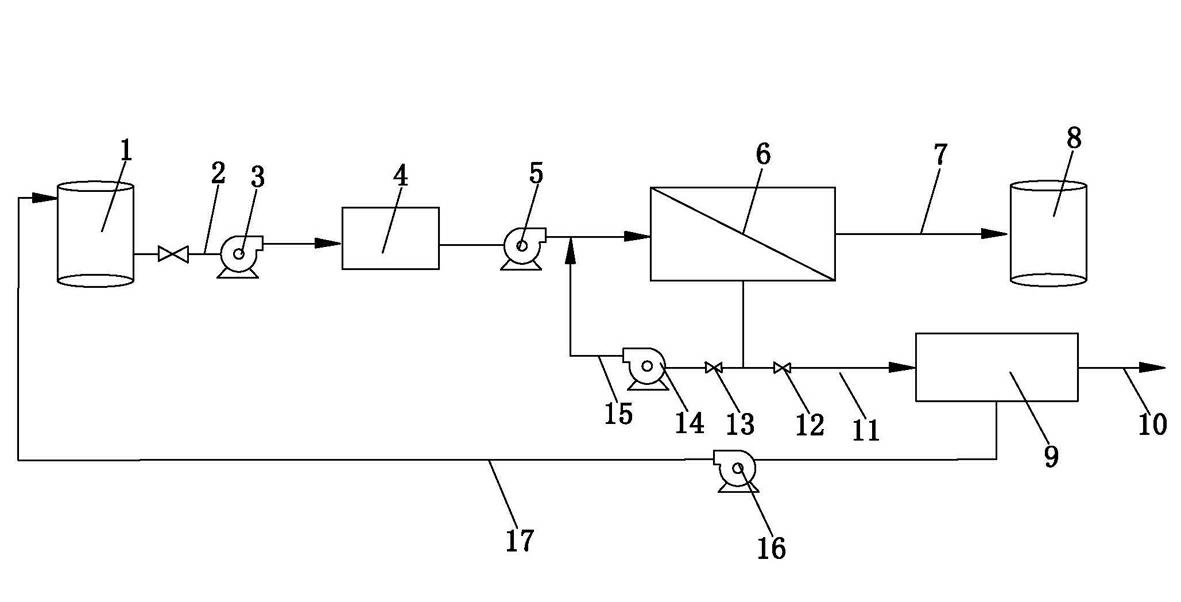

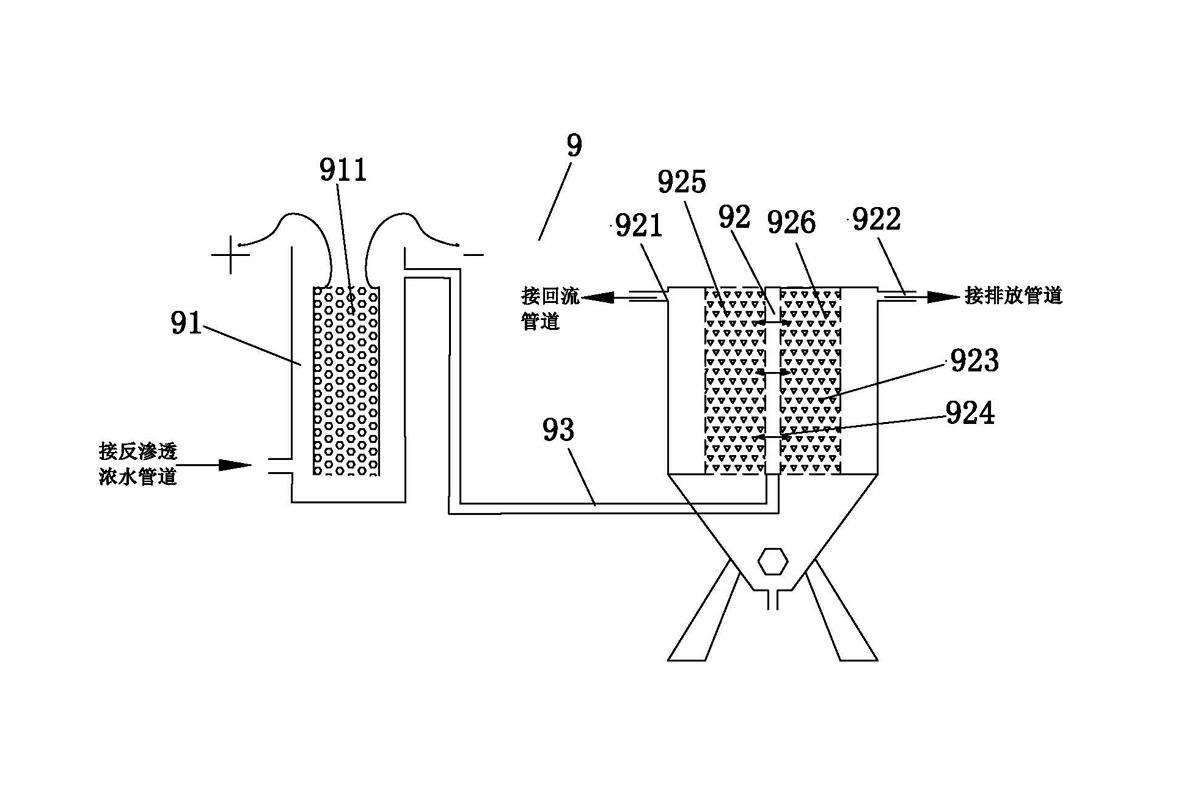

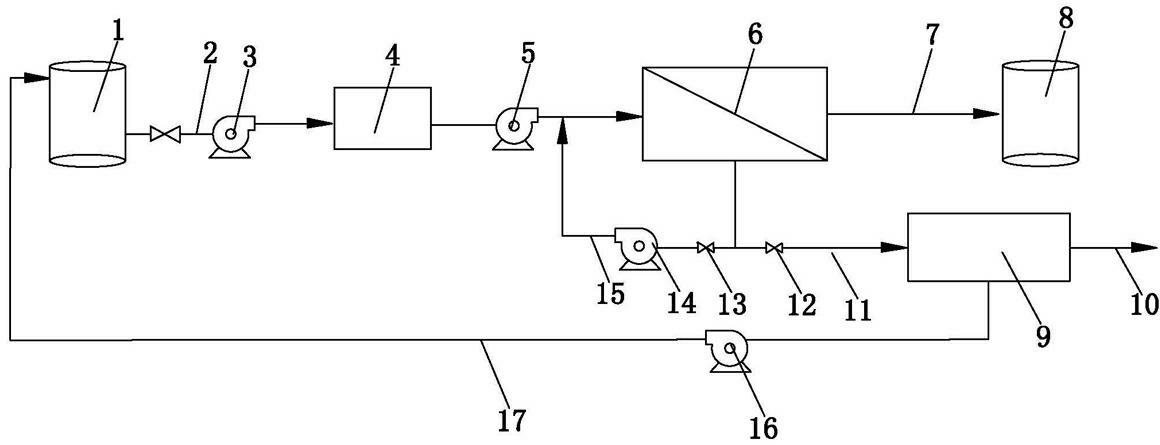

Recycled water recycling equipment and process

ActiveCN102219321AAnti-pollutionHigh recovery rateMultistage water/sewage treatmentReverse osmosisHigh pressure

The invention discloses recycled water recycling equipment and a recycled water recycling process. The recycled water recycling equipment comprises a raw water tank, a raw water pump, a pretreatment system, a high-pressure pump and a reverse osmosis membrane component which are connected with one another sequentially through a water inlet pipeline, wherein a dialyzate outlet of the reverse osmosis membrane component is connected with a water generating tank through a water generating pipeline. The recycled water recycling equipment is characterized in that: a concentrated liquid outlet of the reverse osmosis membrane component is connected with a valve and a circulating pump through a concentrated pipeline and then is connected with a pipeline behind the high-pressure pump; the concentrated liquid outlet of the reverse osmosis membrane component is connected with a valve and a three-dimensional electric catalyst system through a pipeline; one outlet of the three-dimensional electric catalyst system is connected with a delivery pump through a backflow pipeline and then is connected with a raw material tank; and the other outlet of the three-dimensional electric catalyst system is connected with a drainage pipeline. The equipment and the process have the two-level circulation characteristic and have the advantages that: the recovery ratio is high; pollution is resisted; concentrated water can be directly drained after being treated, and the like; the whole process is used for treating recycled water; and the water recovery ratio is over 90 percent.

Owner:VISBE XIAMEN ENVIRONMENT TECH CO LTD

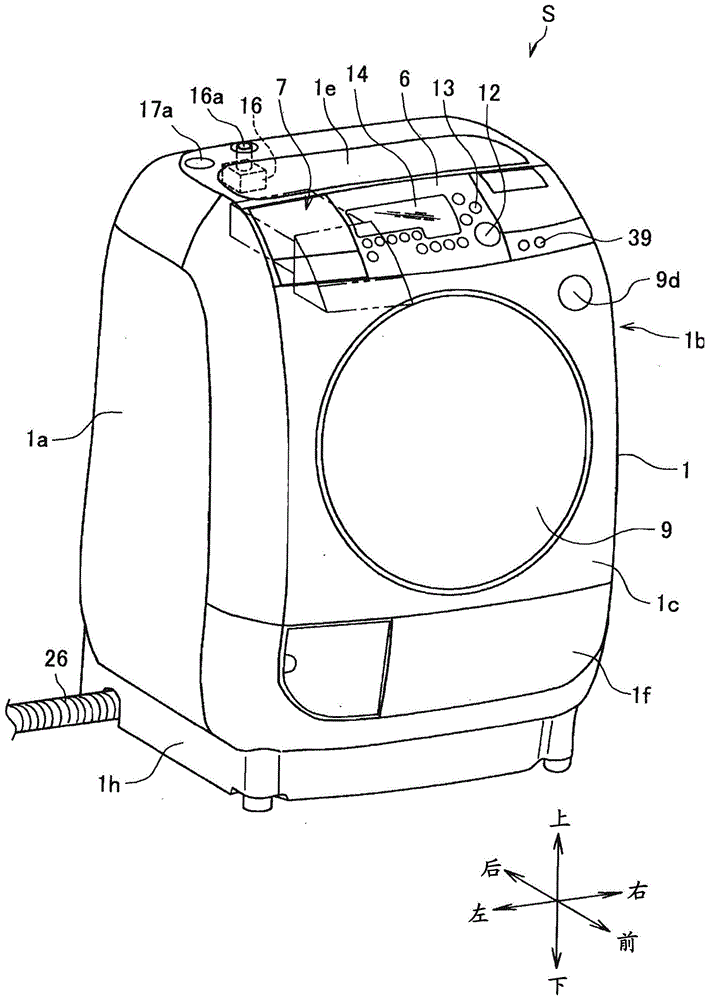

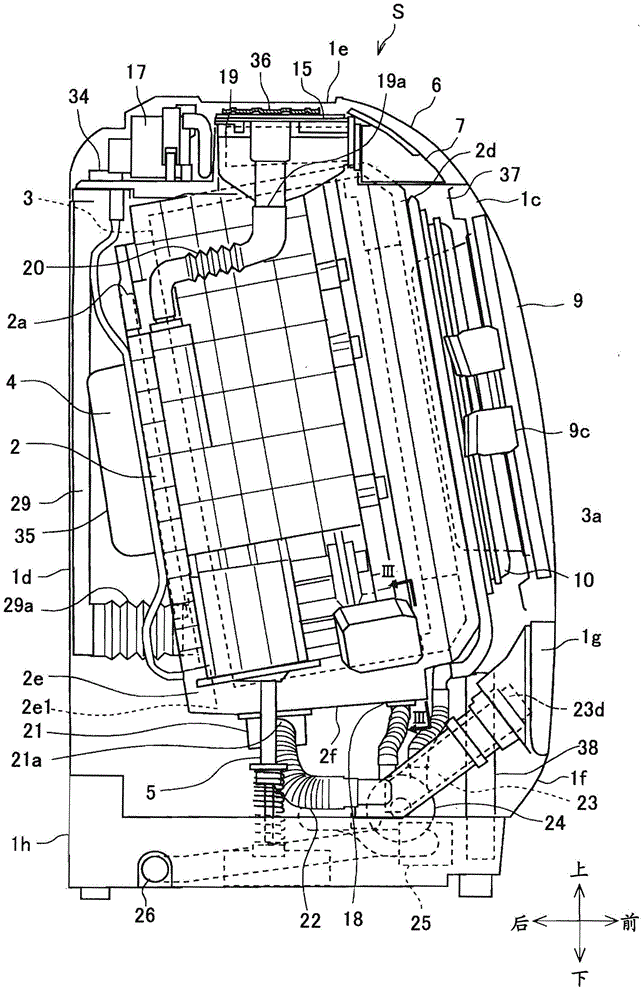

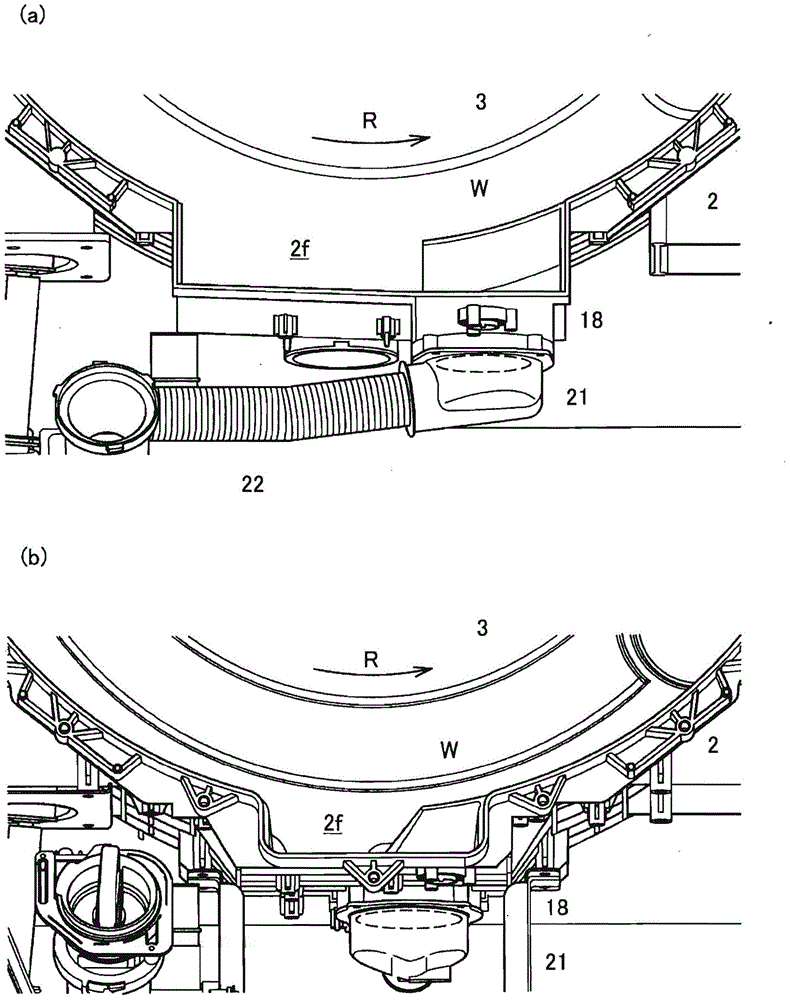

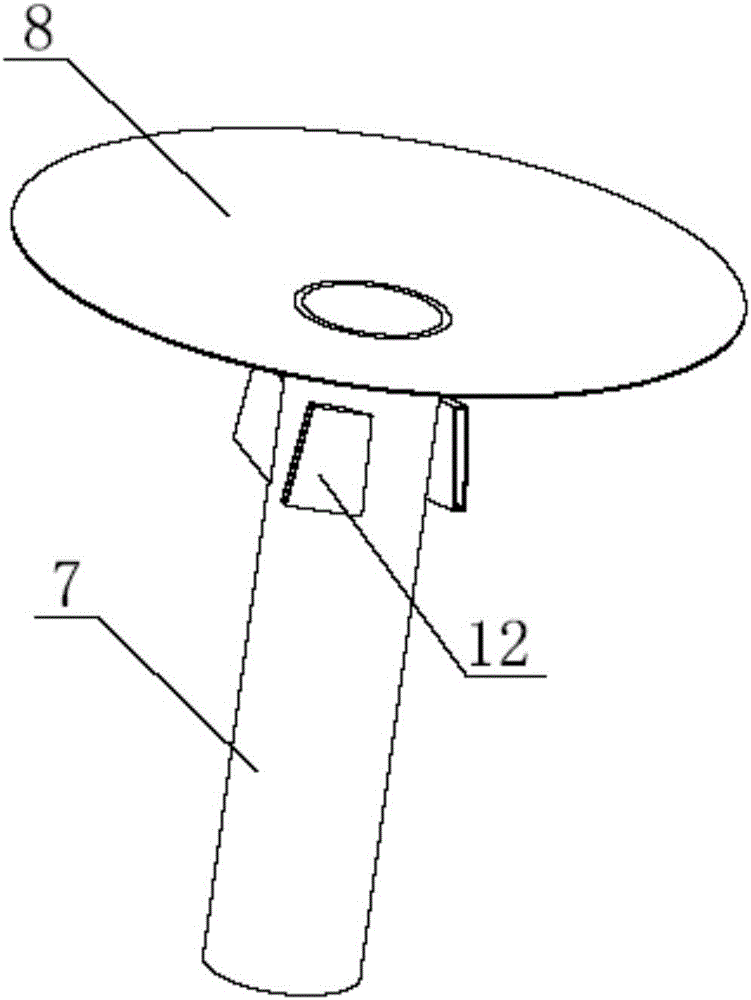

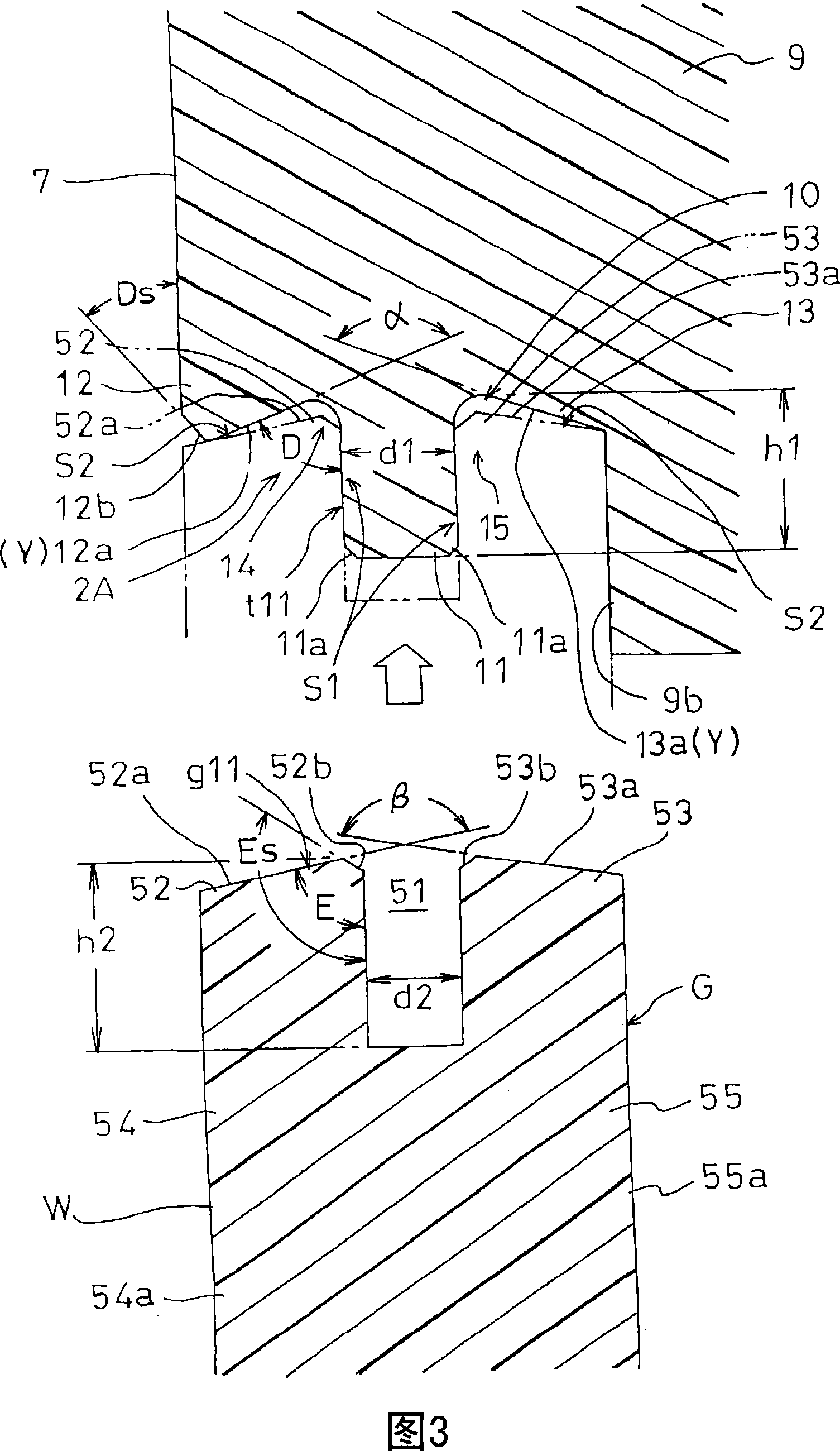

Drum type washing machine

ActiveCN104452170AAchieve serenityIncrease circulation flowOther washing machinesWashing machine with receptaclesLow noiseImpeller

The invention provides a drum type washing machine capable of ensuring relatively large circular flow and realizing lower noise. A circulating pump of the drum type washing machine provided by the invention has an impeller (46) which rotates in a way of sending out water from an outer groove into a drum when watering towards the inside of the drum, the impeller (46) has blades (46a) formed by a plurality of plate bodies arranged around a rotating shaft and radially configured, each blade (46a) bends from the rotating shaft side towards a radiation direction, and bending surfaces protrudes towards a rotation direction (r) of the impeller (46).

Owner:HITACHI APPLIANCES INC

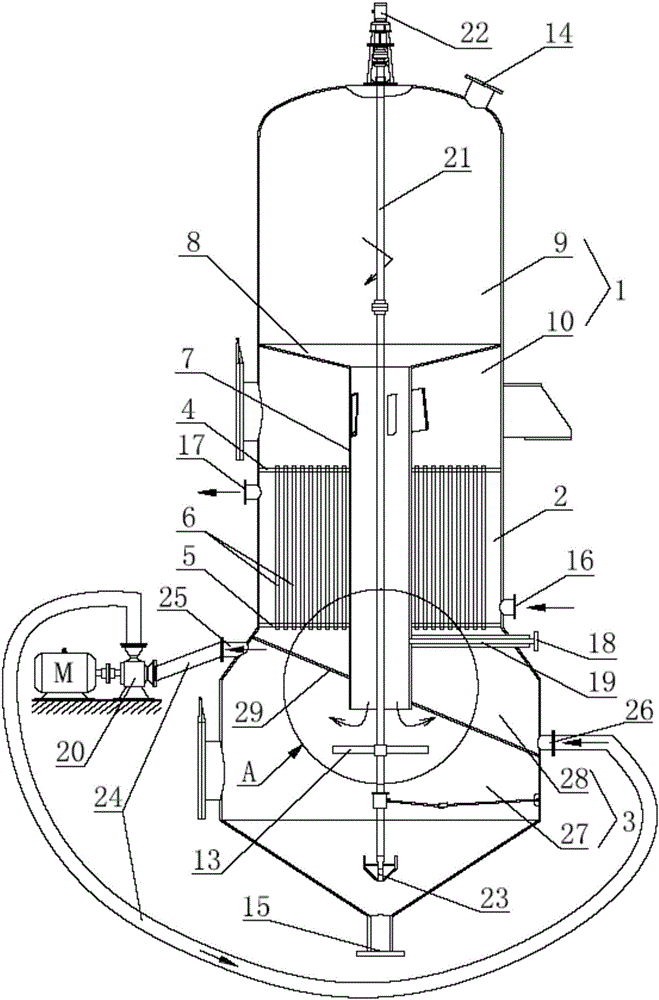

Crystallizer

ActiveCN106422400ASimple equipment structureLow flow resistanceSolution crystallizationCrystallization by component evaporationEngineeringStreamflow

The invention discloses a crystallizer, belongs to the field of crystallizing equipment, and provides a crystallizer, which aims at effectively improving liquid circulation rate in the crystallizing equipment and further improving crystallizing efficiency. The crystallizer comprises an upper chamber, a heat exchange cavity, a crystallizing chamber, a flow guide pipe and an oblique plate, wherein the upper cavity, the heat exchange chamber and the crystallizing chamber are sequentially connected from top to bottom; the flow guide pipe penetrates through the heat exchange chamber; the oblique plate is used for separating the crystallizing chamber into an upper circulation cavity and a lower crystallizing cavity; the lowest part of the circulation cavity is provided with a circulation liquid inlet which is communicated with the circulation cavity, and the highest part of the crystallizing cavity is provided with a circulation liquid outlet which is communicated with the crystallizing cavity; the circulation liquid inlet and the circulation liquid outlet are communicated through a circulation pipeline, and a circulation pump is arranged on the circulation pipeline. The crystallizer has the advantages that forced circulation power is provided for the whole crystallizer through the circulation pump, thus the higher liquid circulation rate and the larger circulation flow rate in the crystallizer are guaranteed, and the crystallizing efficiency of the whole crystallizer is guaranteed.

Owner:四川思特瑞锂业有限公司

High-precision filtering system

InactiveCN103435176AAvoid easy cloggingNot easy to damageWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentWater savingWater source

The invention discloses a high-precision filtering system. The high-precision filtering system comprises a water source pipe, a preprocessing filter element, a water pump, a flushing valve, a return pipe, a filter, a first throttling device and a second throttling device, wherein the filter is provided with an inlet, an outlet and a concentration water port, and the filter is internally provided with a high precision filtering element; the water inlet end of the return pipe is communicated with the concentration water port of the filter, and the water outlet end of the return pipe is communicated the inlet of the filter; the return pipe is provided with the water pump, the preprocessing filter element and the second throttling device, the water outlet of the water pump is communicated with the inlet of the filter, and the inlet of the second throttling device is communicated with the concentration water port of the filter; the water inlet and the water outlet of the flushing valve are respectively communicated with the water inlet and the water outlet of the second throttling device; the water inlet of the first throttling device is communicated with the return pipe, the water outlet of the first throttling device is evacuated, and the water source pipe connected with a water source is communicated to the return pipe. The high-precision filtering system provided by the invention has the advantages that the flushing valve with the evacuating water outlet is not arranged, thus almost all flushing water is recycled, so that the water-saving effect is obvious.

Owner:黄瑞中

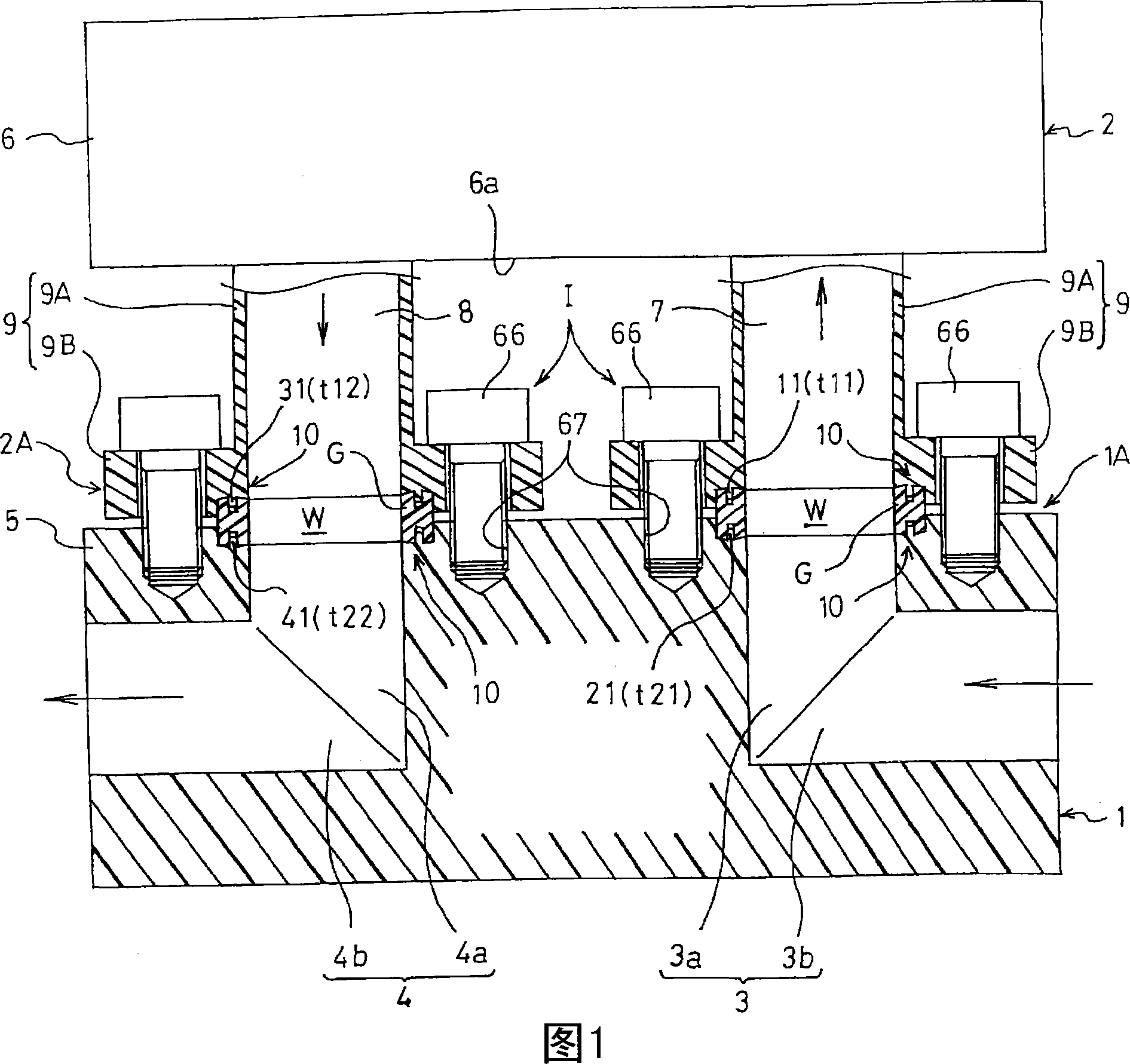

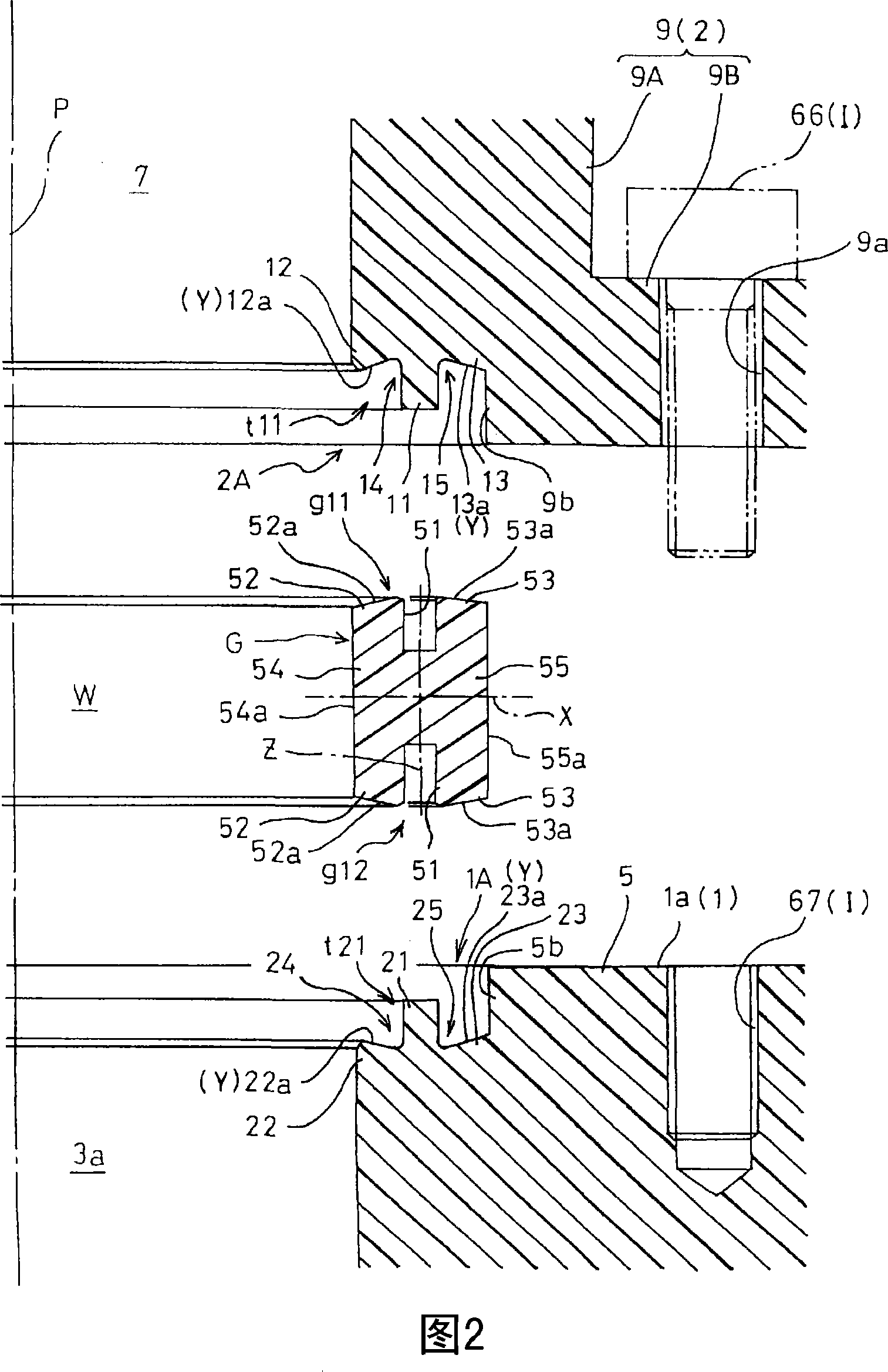

Connection structure of integrated panel and fluid device

InactiveCN101223395AStop the leakImprove sealingFlanged jointsJoints with sealing surfacesEngineeringGasket

A connection structure of a stack panel to a fluid device capable of maintaining excellent sealability without almost performing further tightening and improving assemblability. The stack panel (1) is communicably connected to a valve (2) through an annular gasket (G) in such a state that a single cylindrical fluid passage (3, 7) is sealed. Annular projections (11) and (21) are formed at first and second fluid inlet and outlet parts (1A) and (2A), and the gasket (G) is formed of a fluororesin and comprises a pair of annular grooves (51) and (51) formed in the outer diameter portion of a fluid route (W) to be fitted to the annular projections (11) and (21). The stack panel (1) and the valve (2) are pulled to each other and the annular projections (11) and (21) of the first and second fluid inlet and outlet parts (1A) and (2A) are fitted to the annular grooves (51) of the gasket (G) to form a fitted seal part. The connection structure further comprises a maintaining means (I) for maintaining the connected state of the stack panel to the valve.

Owner:NIPPON PILLAR PACKING CO LTD

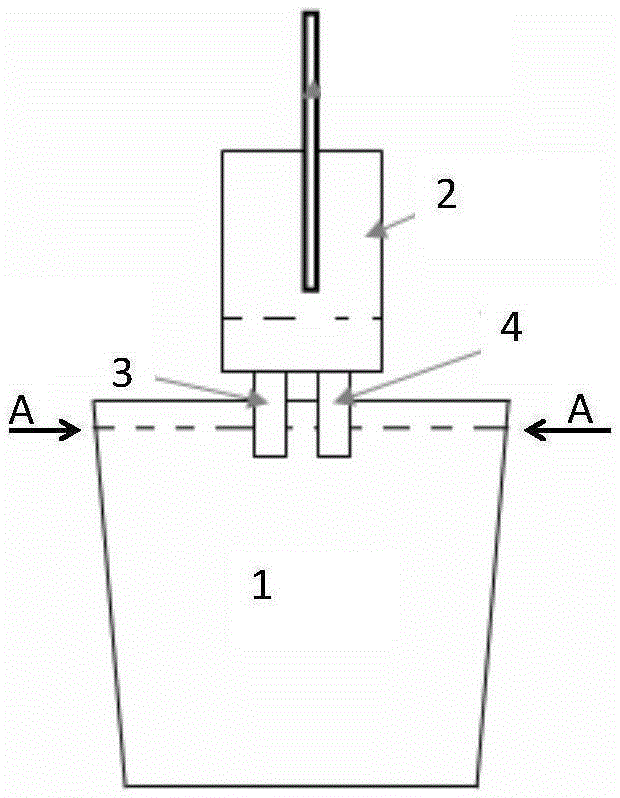

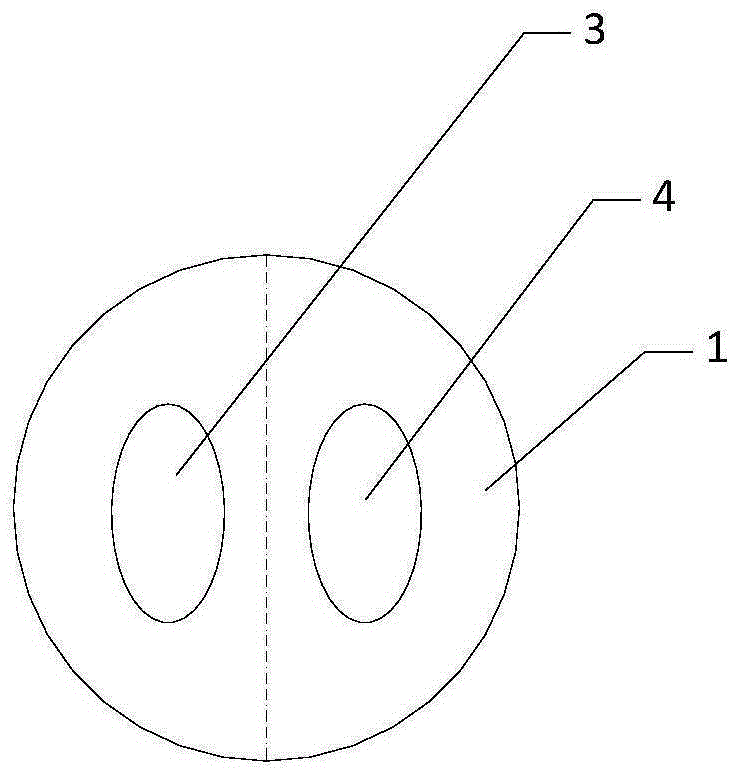

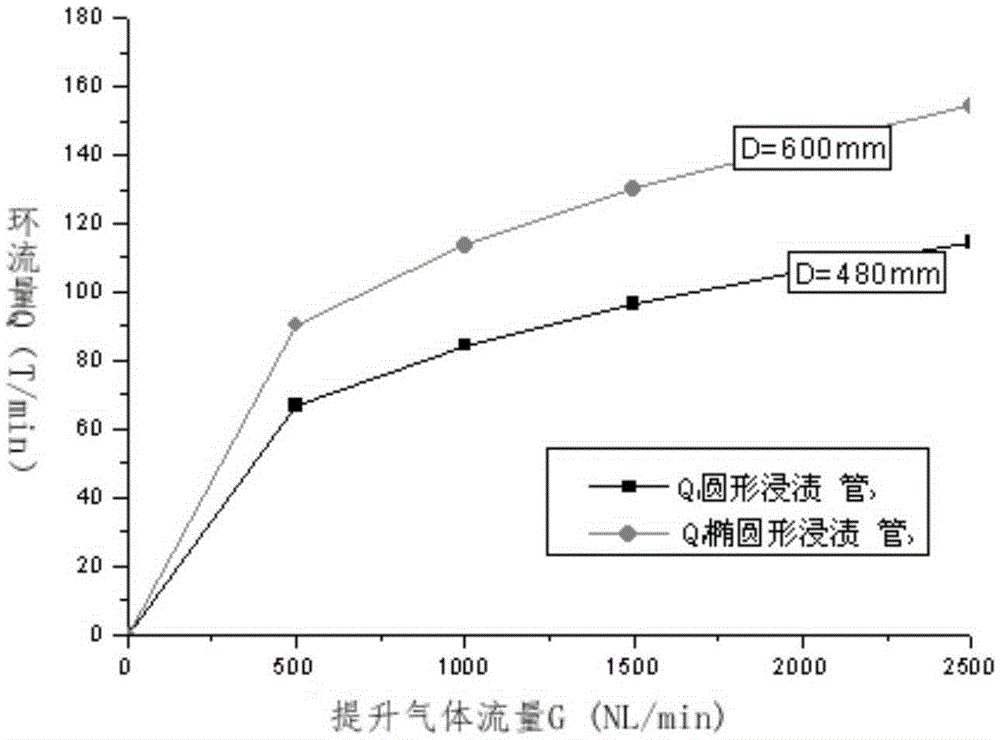

RH refining device

InactiveCN105256106AIncrease circulation flowImprove decarbonization efficiencyMaterials scienceMolten steel

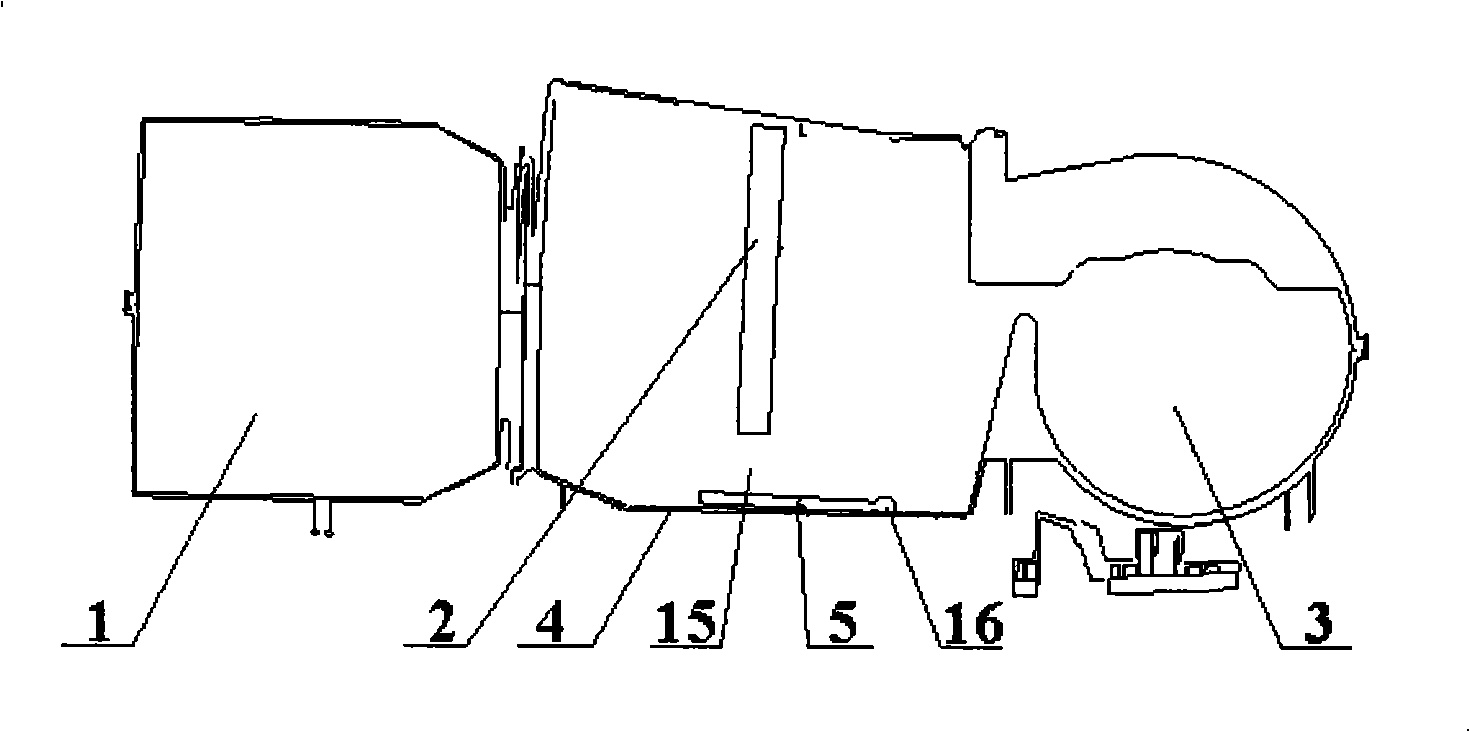

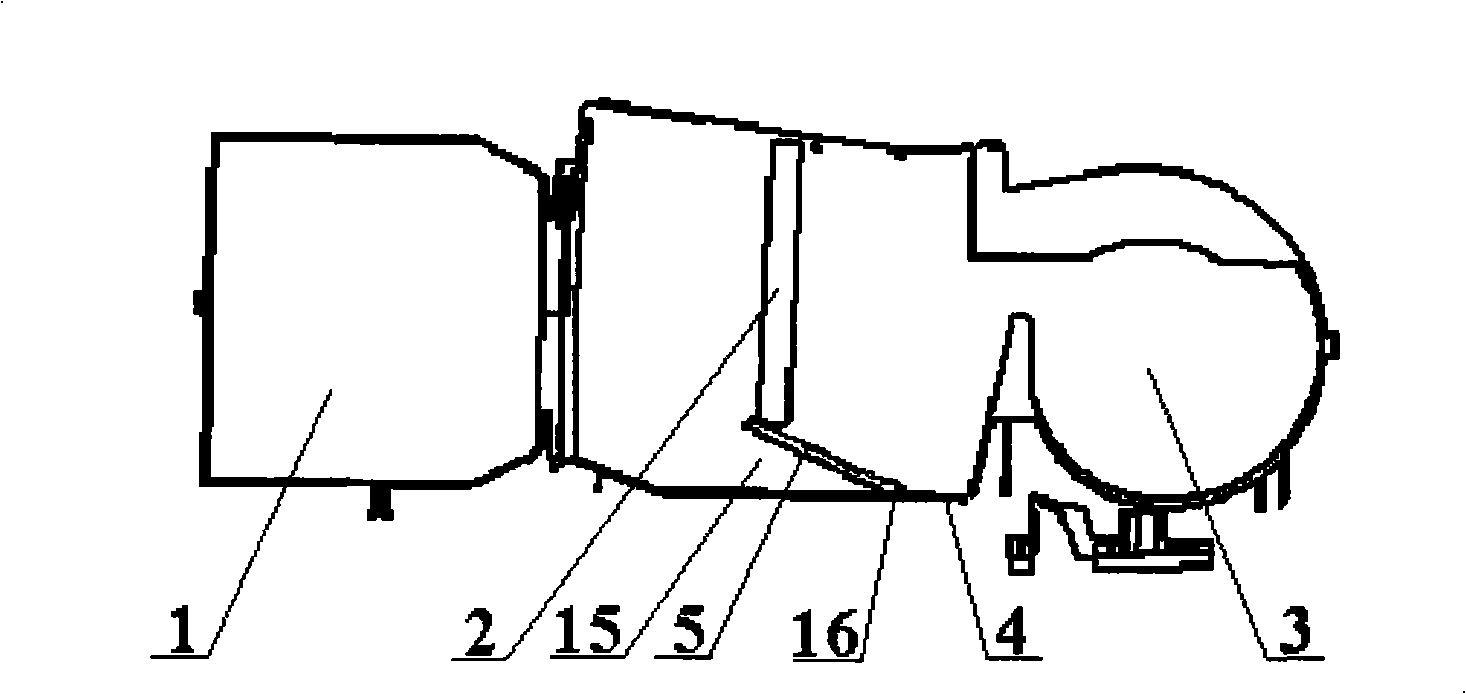

The invention discloses a RH refining device which comprises a steel ladle (1) and a vacuum slot (2), wherein the steel ladle (1) and the vacuum slot (2) communicate through an ascending impregnation tube (3) and a descending impregnation tube (4) which are parallel; and cross sections of the ascending impregnation tube (3) and the descending impregnation tube (4) are oval. According to the device, by changing the shapes of the sections of the impregnation tubes, equivalent diameters of the RH impregnation tubes are increased, so that the problem that loop flow of molten steel is difficult to increase is radically solved.

Owner:SHANDONG IRON & STEEL CO LTD

High Shear Emulsifier

ActiveCN103908911BIncrease shear forceIncrease circulation flowRotary stirring mixersMixing methodsGear drivePulp and paper industry

The invention provides a high-efficiency and high-shearing emulsifying machine. The high-efficiency and high-shearing emulsifying machine comprises a motor, a dual output shaft gearbox, a central stirring paddle, an external stirring paddle and an emulsification tank, wherein the emulsification tank is in a cylindrical structure; a cover plate is arranged at the top of the emulsification tank; the dual output shaft gearbox is arranged on the upper side of the center of the cover plate; the motor is connected to the top end of the dual output shaft gearbox; the dual output shaft gearbox is transmitted by adopting two stages of gears which are internally and externally meshed or planetary gears; a central input shaft and an external output shaft are arranged in the dual output shaft gearbox; the lower ends of the central stirring shaft and the external stirring shaft penetrate through the cover plate and stretch into the emulsification tank; the central stirring paddle is mounted on the central stirring shaft; the external stirring paddle is mounted on the external stirring shaft through a fixed hoop; the lower ends of the central stirring shaft and the external stirring shaft are mounted on a bottom bracket. By adopting a two-rotor emulsification head with relative positive and negative rotation and a plurality layers of stirring paddles with unlimited diameters, the shearing force and the circulation flow are exponentially increased.

Owner:ANHUI SONGYU ENG TECH EQUIP

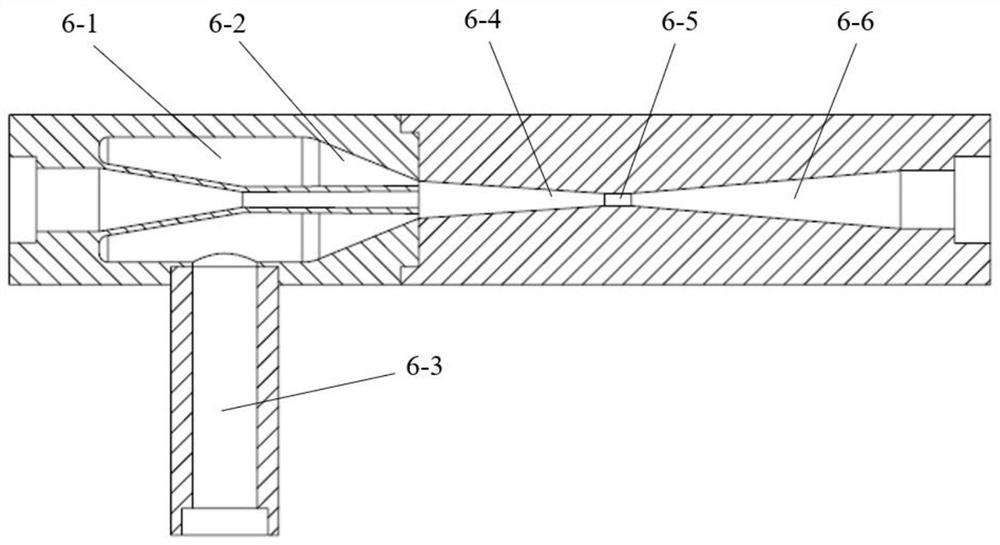

Self-driven thermosyphon loop heat dissipation device coupled with gas-liquid two-phase flow jet pump

ActiveCN113357946AImprove cooling effectGuaranteed uptimeIndirect heat exchangersCooling/ventilation/heating modificationsVapor–liquid separatorThermosipho

A self-driven thermosyphon loop heat dissipation device coupled with a gas-liquid two-phase flow jet pump comprises a gas-liquid separator, a cooler, the gas-liquid two-phase flow jet pump and an evaporator which are sequentially connected to form a loop, wherein a liquid outlet of the gas-liquid separator is connected with an inlet of the cooler through a first liquid section; an outlet of the cooler is connected with a liquid inlet of the gas-liquid two-phase flow jet pump through a second liquid section, a steam outlet of the gas-liquid separator is connected with a steam inlet of the gas-liquid two-phase flow jet pump through a first steam section, and an outlet of the gas-liquid two-phase flow jet pump is connected with an inlet of the evaporator through a third liquid section; an outlet of the evaporator is connected with an inlet of the gas-liquid separator through a second steam section; and the vertical height of the gas-liquid separator is larger than the position of the cooler and the position of the gas-liquid two-phase flow jet pump, the vertical height of the cooler and the vertical height of the gas-liquid two-phase flow jet pump are larger than the position of the evaporator, and the evaporator is vertically arranged. According to the self-driven thermosyphon loop heat dissipation device, a flowing pressure head in a loop can be remarkably improved, so that the heat dissipation capacity of the thermosyphon loop is enhanced, operation is more stable, and noise generated in the working process is small.

Owner:SHANGHAI JIAO TONG UNIV

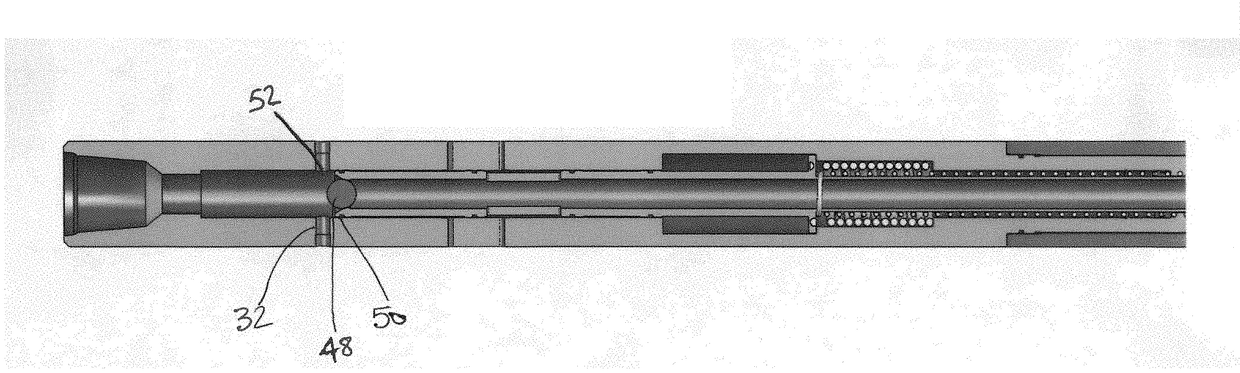

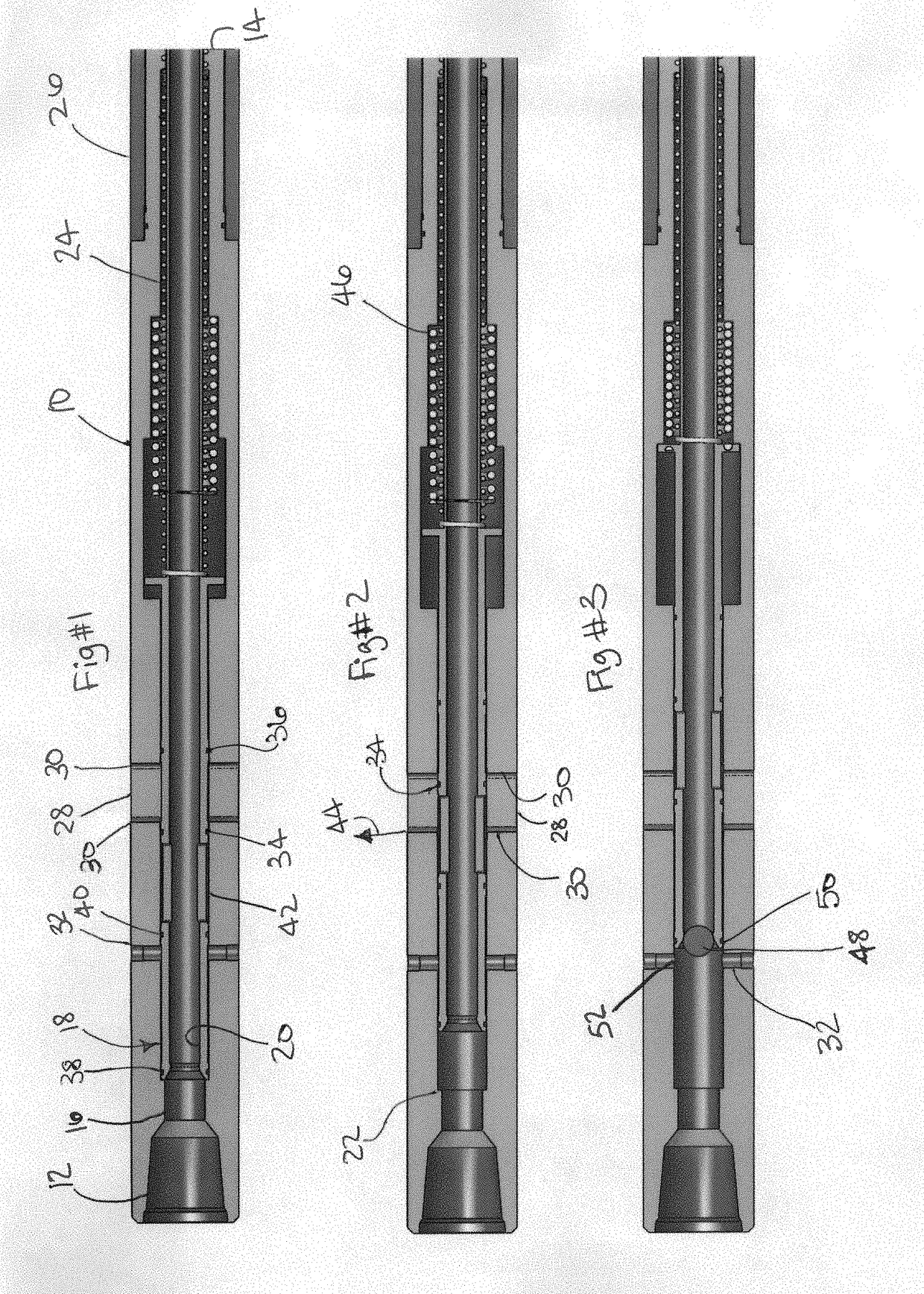

Variable Circulation Rate Sub for Delivering a Predetermined Straight through Flow

A housing is integrated into a tubing string having a straight through passage and a lateral wall exist. Inside the passage is a flow responsive member with an applied preload force. Flow corresponding to a predetermined differential pressure in the housing will not move the valve member so all flow will go straight through in a downhole direction. As flow increases, the preload bias is overcome to align the passage through the housing and openings in the valve member with wall openings. As flow into the housing increases, more lateral wall opening area is aligned with the passage to increase circulation flow while holding through flow downhole constant. Dropping a ball on the valve member blocks through flow and allows opening of total bypass passages. The ball can be removed by blowing it through the seat or otherwise failing or disintegrating it.

Owner:BAKER HUGHES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com