Hot water injection circulation viscosity reduction system for producing ultra-deep ultra-heavy oil and application method thereof

A hot water circulation and circulation system technology, which is applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., can solve the problems of shortened pump inspection period, lower sales price, heavy oil pumping, etc. The effect of application, short pump inspection period and low oil production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

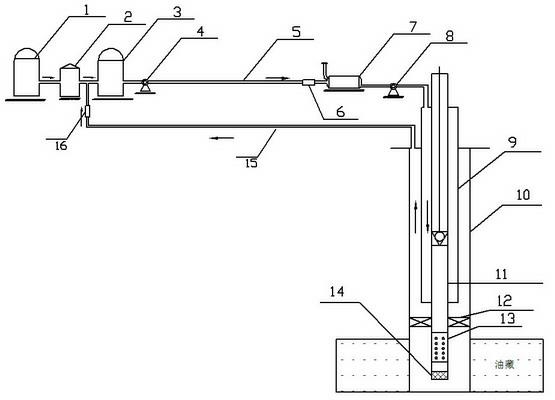

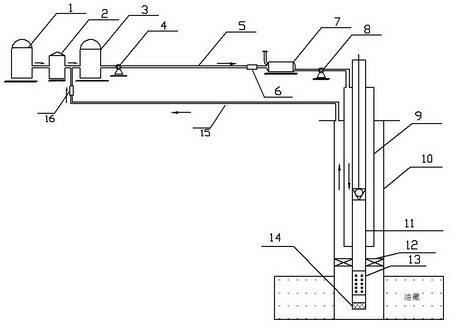

[0019] Such as figure 1 As shown, a hot water injection circulation viscosity reduction system for ultra-deep and ultra-heavy oil production in the present invention includes a surface circulation system and an underground circulation viscosity reduction system. The surface circulation system includes a clear water tank 1, a softening water device 2, a softening water Tank 3, water supply pump 4, magnetization device 6, water jacket furnace 7, water injection pump 8, pressure relief valve 16, circulation injection pipeline 5, circulation outflow pipeline 15; the downhole circulation system includes heat insulating oil pipe 9, casing pipe 10, Inner tubing 11, packer 12, screen 13, plug 14.

[0020] The surface circulation system consists of a clear water tank 1 on the circulation injection pipeline 5, a softened water device 2, a softened water tank 3, a water supply pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com