Method for increasing molten steel circulating flow quantity in RH refining process

A refining process and circulating flow technology, which is applied in the field of molten steel refining technology, can solve the problems of shortening RH refining time and difficulty in circulating flow, and achieve the effects of improving RH decarburization efficiency, increasing circulating flow, and prolonging the time of lifting action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

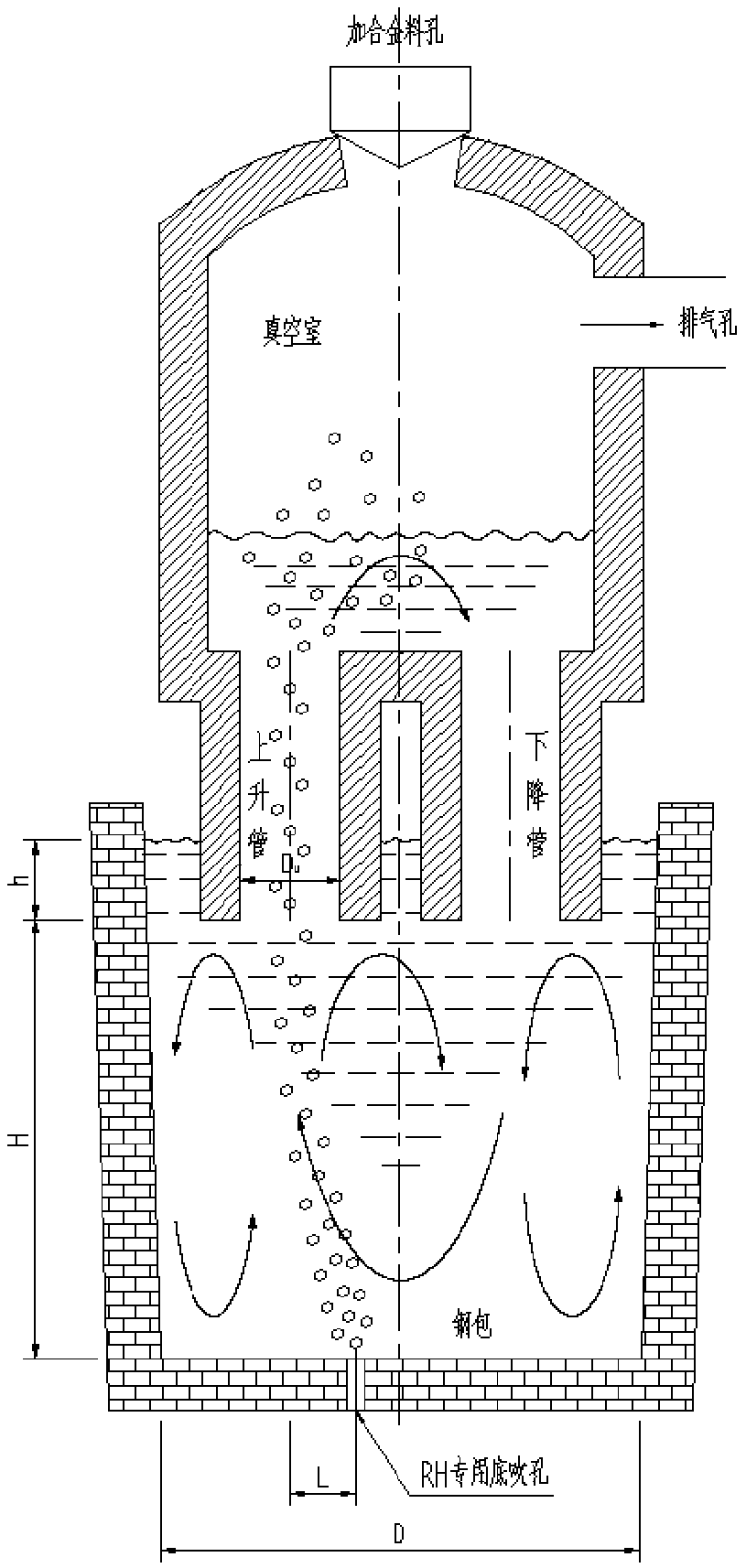

[0024] For the production of ultra-low carbon IF steel in a converter-RH-CC process flow, this method is used for RH refining process. The specific implementation process is as follows:

[0025] (1) After the converter smelting is completed and the ladle enters the RH refining station, connect the blowing pipe to the pre-set ladle bottom blowing hole for the circulation flow of the RH refining process, and connect the ladle bottom argon blowing system for use;

[0026](2) Insert the pre-vacuum RH dipping tube under the liquid steel surface, and the RH dipping tube is immersed at a depth of 600mm; then vacuumize, the pressure of the vacuum chamber is controlled at 67Pa, and the riser of the RH dipping tube is adjusted to increase the gas flow rate to a stable value of 3000NL / min;

[0027] (3) Open the bottom blowing argon control valve, adjust the pressure and flow rate of the bottom blowing argon to be stable, and the ladle bottom blowing hole used for the circulation flow in ...

Embodiment 2

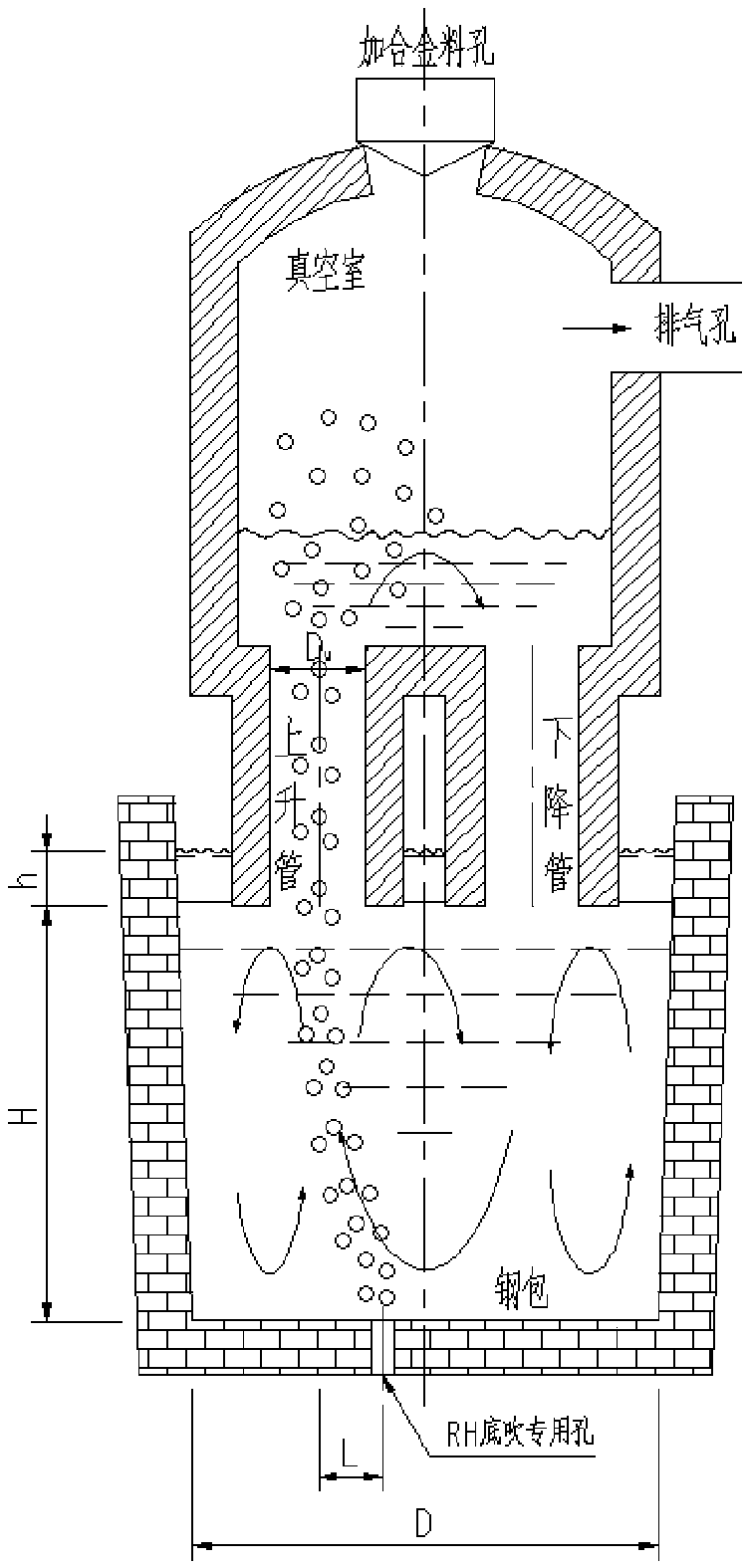

[0037] For the production of high-carbon bearing steel in a converter-LF-RH-CC process flow of a factory, the RH refining process of this method is used for processing. The specific implementation process is as follows:

[0038] (1) After the LF refining is completed and the ladle enters the RH refining station, connect the blowing pipe to the pre-set ladle bottom blowing hole for the circulating flow of the RH refining process, and connect the ladle bottom argon blowing system for standby;

[0039] (2) Insert the pre-vacuum RH dipping tube under the liquid steel surface, and the RH dipping tube is immersed at a depth of 400mm; then vacuumize, the pressure of the vacuum chamber is controlled at 100Pa, and the riser of the RH dipping tube is adjusted to increase the gas flow rate to a stable value of 1500NL / min;

[0040] (3) Open the bottom blowing argon control valve, adjust the pressure and flow rate of the bottom blowing argon to be stable, and use the bottom center line of ...

Embodiment 3

[0050] For iron and steel smelting processes using RH as a refining means to produce silicon steel, home appliance panels and other steel types, the refining method of increasing the circulating flow rate of RH molten steel in this embodiment is also applicable. Due to different steel types and RH equipment parameters, the control conditions of RH vacuum pressure, lifting gas flow, ladle bottom blowing gas flow and ladle treatment after refining are also different during the RH refining process.

[0051] It is worth noting that, in addition to the above-mentioned steel types, the present invention is not limited to the steel types in the above-mentioned embodiments, and is also applicable to other types of steel types that adopt the RH refining process in the production process.

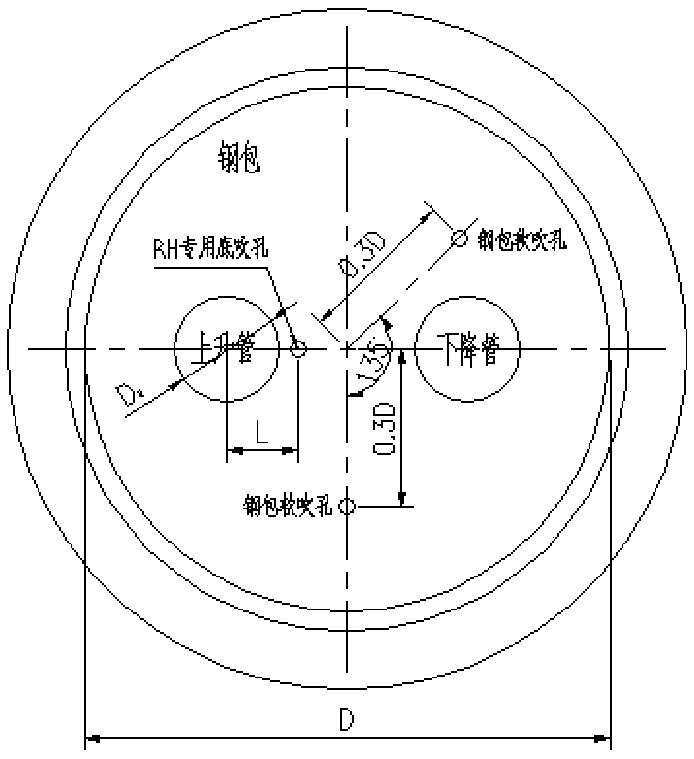

[0052] It should be noted that the single hole position parameter L and the lifting gas flow rate Q1 and the bottom blowing gas flow rate Q1 are provided in the present invention. 2 Relational formul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com