Variable Circulation Rate Sub for Delivering a Predetermined Straight through Flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

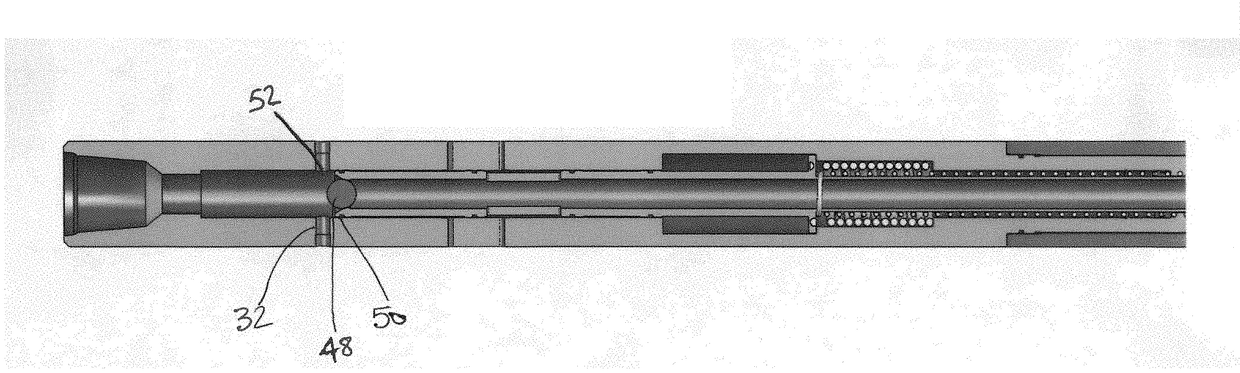

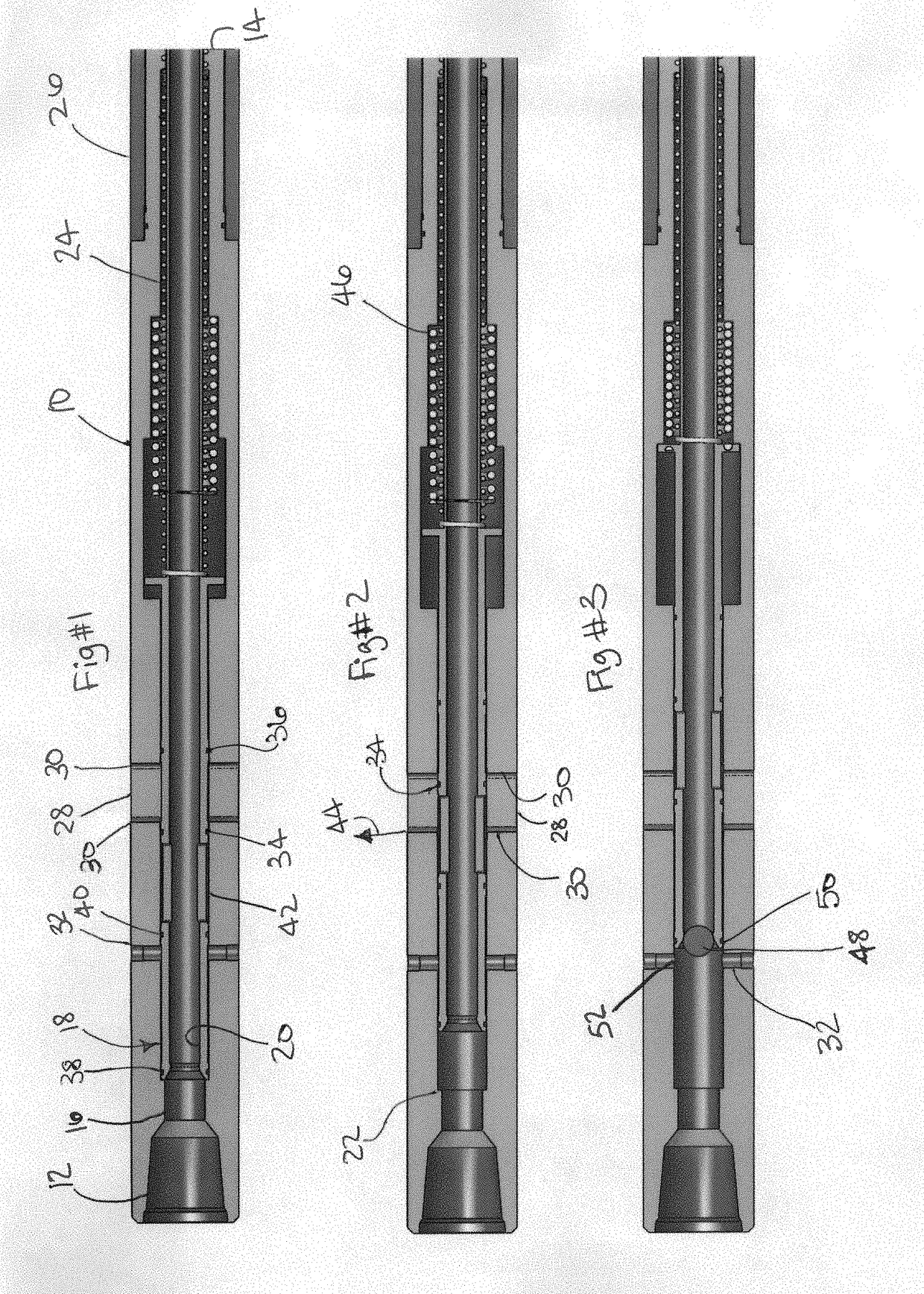

[0008]Referring to FIG. 1, a housing 10 with an uphole connection 12 to a tubular string that is not shown. A downhole end 14 can be connected to a bottom hole assembly for drilling that is also not shown. For a number of reasons, the bottom hole assembly that is not shown needs a predetermined flow rate out the downhole end 14. Flow coming into uphole end 12 enters passage 16 where a valve member 18 is located that has flow path 20 therethrough that aligns with passage 16. Housing 10 has an internal shoulder 22 that acts as an uphole travel stop for the valve member 18 under the bias of a stored force. In this case, the preferred mode for the force is a coiled spring 24. Sleeve 26 schematically illustrates a device that can be used to change the preload on spring 24 which has the effect of changing the amount of flow coming into uphole end 12 that will go straight through to downhole end 14 without being circulated through openings 28, 30 or 32. In the FIG. 1 position openings 28 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com