High-precision filtering system

A filtration system, high-precision technology, applied in the direction of water/sewage multi-stage treatment, osmosis/dialysis water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of inability to reduce flushing wastewater discharge and low water utilization rate , The service life of the reverse osmosis membrane is not ideal, etc., to achieve a significant effect of water saving, prevent damage, and reduce the concentration of particulate matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

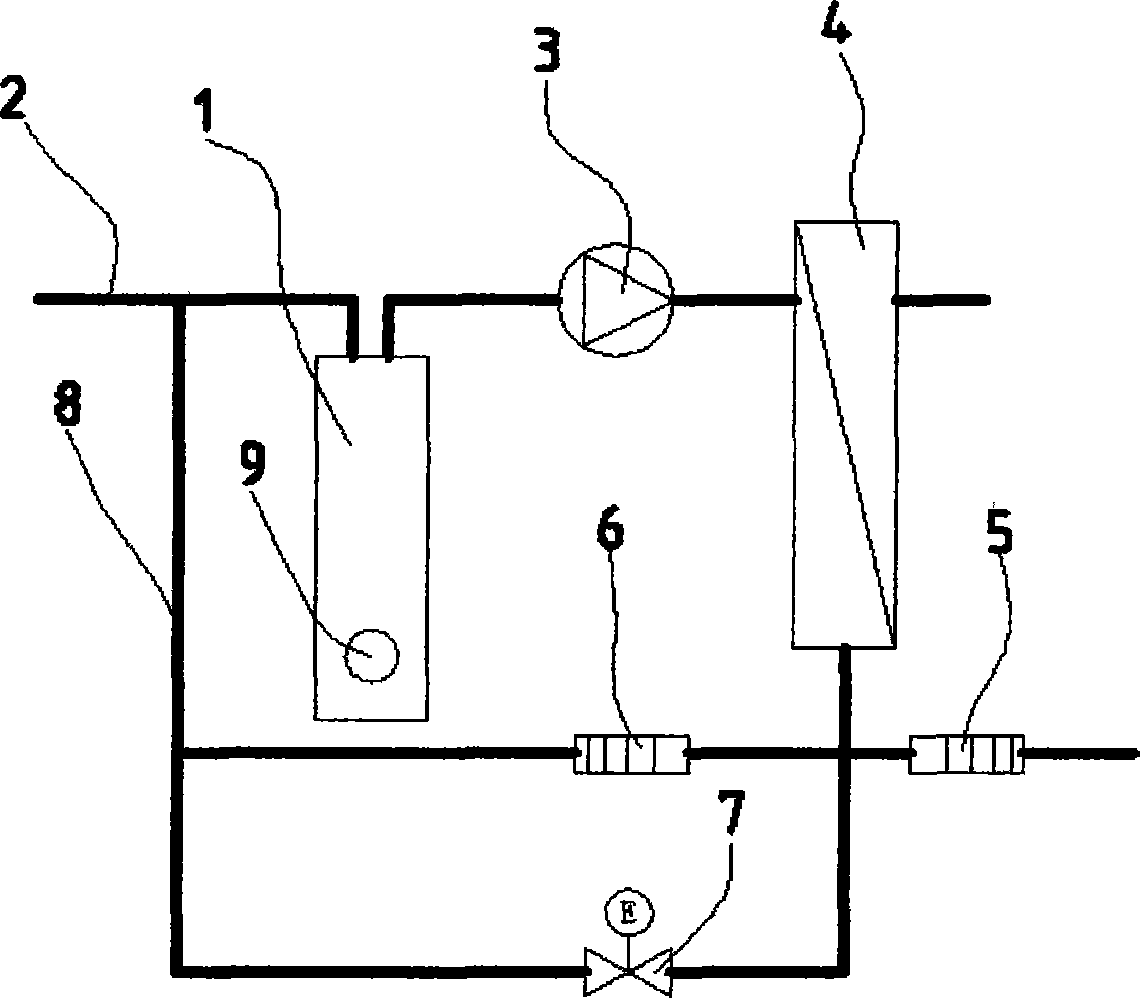

Embodiment 1

[0031] See figure 1, the high-precision filtration system of this embodiment includes a first pretreatment filter element 1, a water source pipe 2, a filter 4, a water pump 3, a flushing valve 7, a return pipe 8, a second throttling device 6 and a first throttling device 5; The filter 4 is provided with an inlet, an outlet and a concentrated water port, and a filter element is arranged in the filter 4, and the filter element is a reverse osmosis membrane, so the filter 4 is also a reverse osmosis processor, and the high-precision filter system of this embodiment is a reverse osmosis net Water machine; the water inlet end of the return pipe 8 is connected to the concentrated water port of the filter 4, and the water outlet end is connected to the inlet of the filter 4; the return pipe 8 is provided with a water pump 3, a first pretreatment filter element 1 and a second throttling device 6 , the water outlet of the water pump 3 is connected to the inlet of the filter 4, the wate...

Embodiment 2

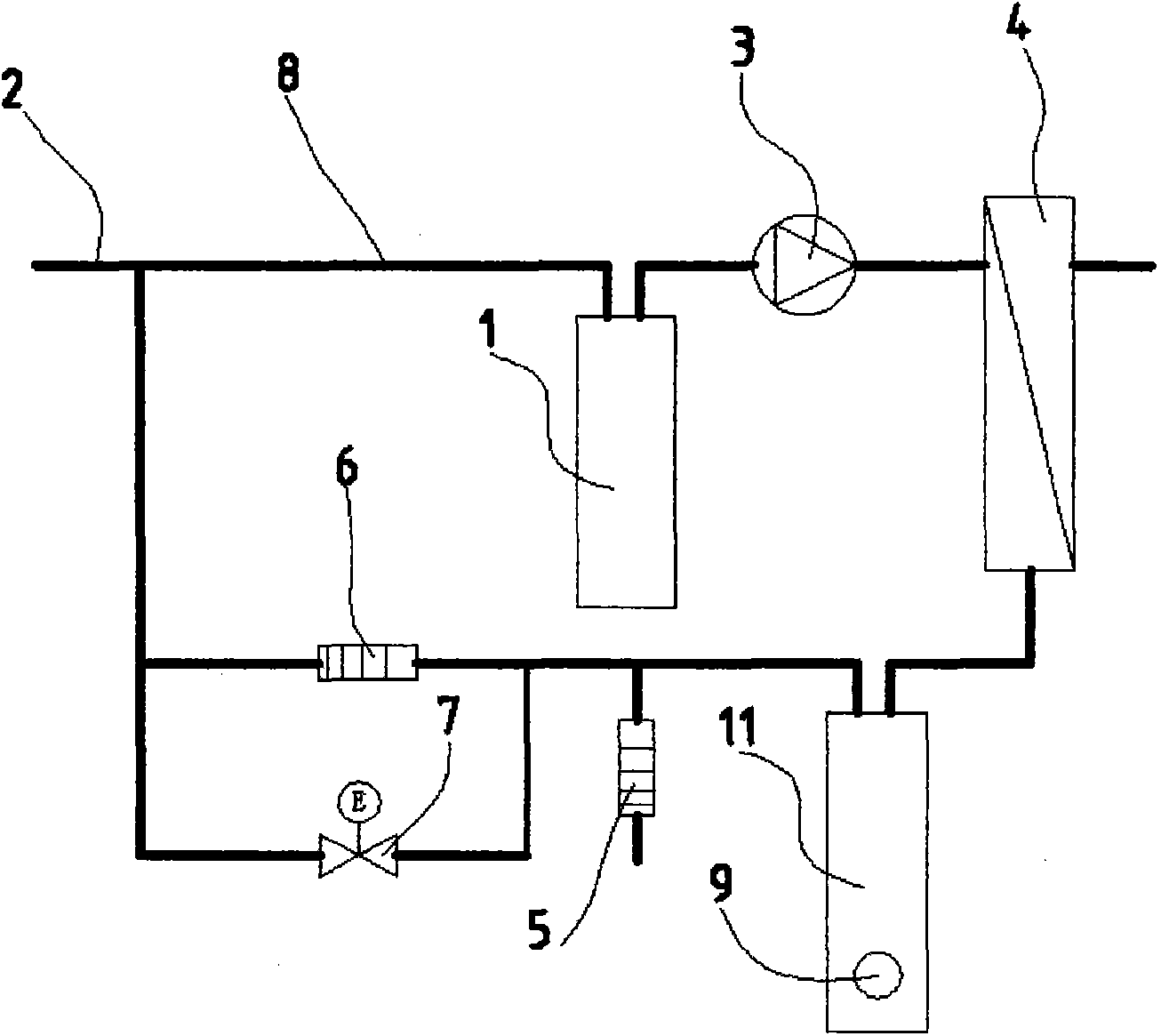

[0035] See figure 2 , this embodiment is basically the same as Embodiment 1, the difference is that this embodiment also includes a second pretreatment filter element 11, and the solid corrosion inhibitor 9 set in the first pretreatment filter element 1 is changed to the second pretreatment filter element 1 In the filter element 11, fiber filter material and / or activated carbon are also arranged in the second pretreatment filter element 11, and the second pretreatment filter element 11 is arranged in the return pipe 8; the water inlet of the second pretreatment filter element 11 communicates with the concentration of the filter 4 The water outlet, the water outlet of which communicates with the common water inlet of the first throttling device 5 , the second throttling device 6 and the flushing valve 7 .

[0036] The fiber filter material in the second pretreatment filter element 11 can effectively filter out the particles that may be carried in the concentrated water flowing...

Embodiment 3

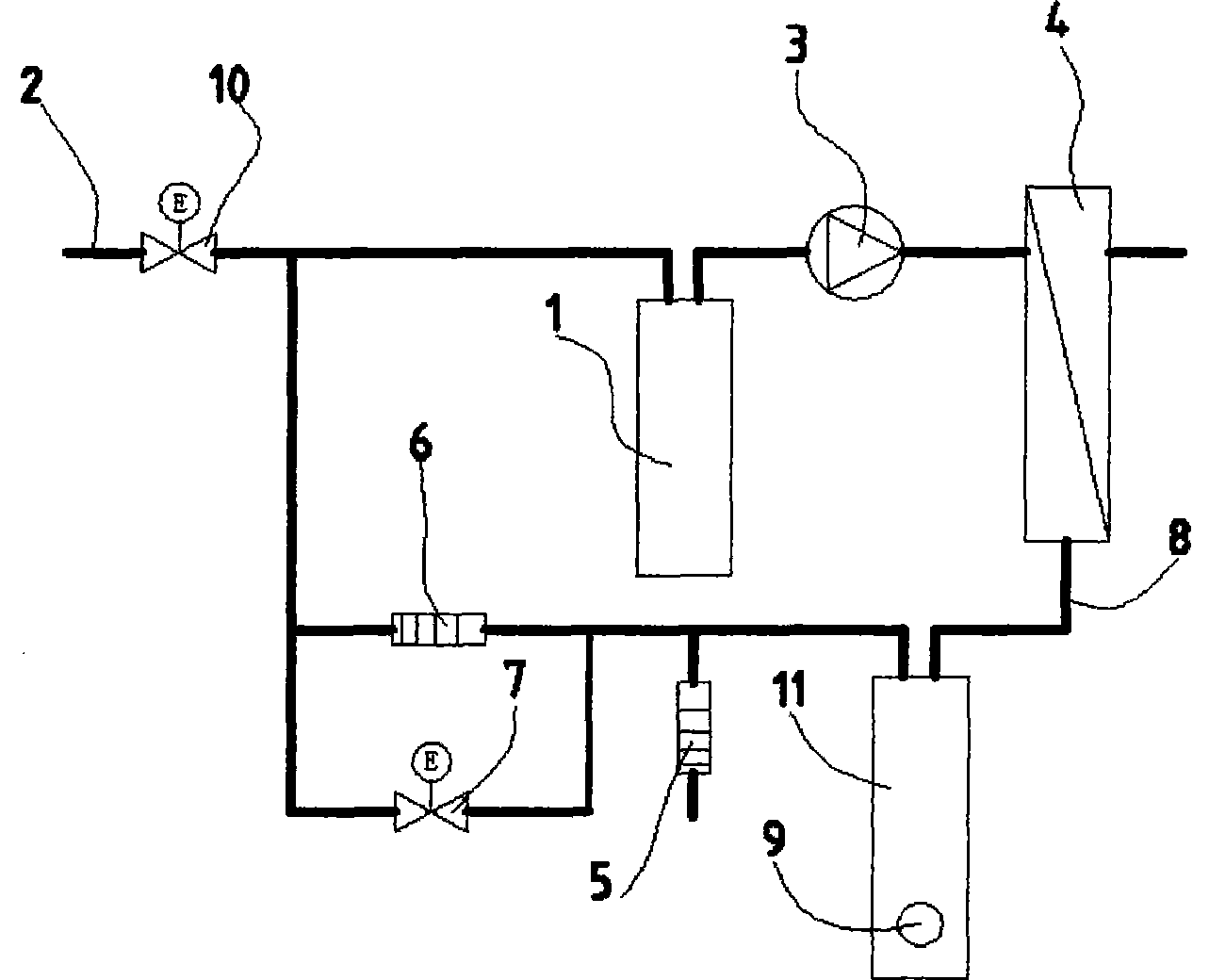

[0038] See image 3 , this embodiment is basically the same as Embodiment 2, the difference is that: a water inlet valve 10 is added in the water source pipe 2, the water inlet valve 10 is a normally closed valve, and the water inlet valve 10 is in a closed state when the water purifier is shut down. It is possible to prevent leakage of the throttling device 5 during shutdown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com