Composite heat exchange type moving heat supply device

A heat-supply device and heat-exchange technology, applied in the field of composite heat-exchange mobile heat-supply devices, can solve the problems of reduced heating efficiency, long charging time, and increased circulation resistance of fluid working fluid, etc., to achieve increased circulation flow, high The heat storage density and the effect of increasing the direct contact heat transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

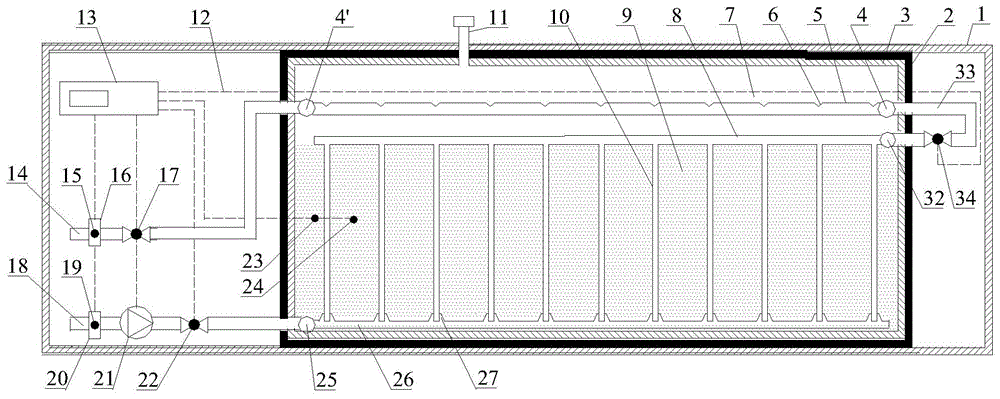

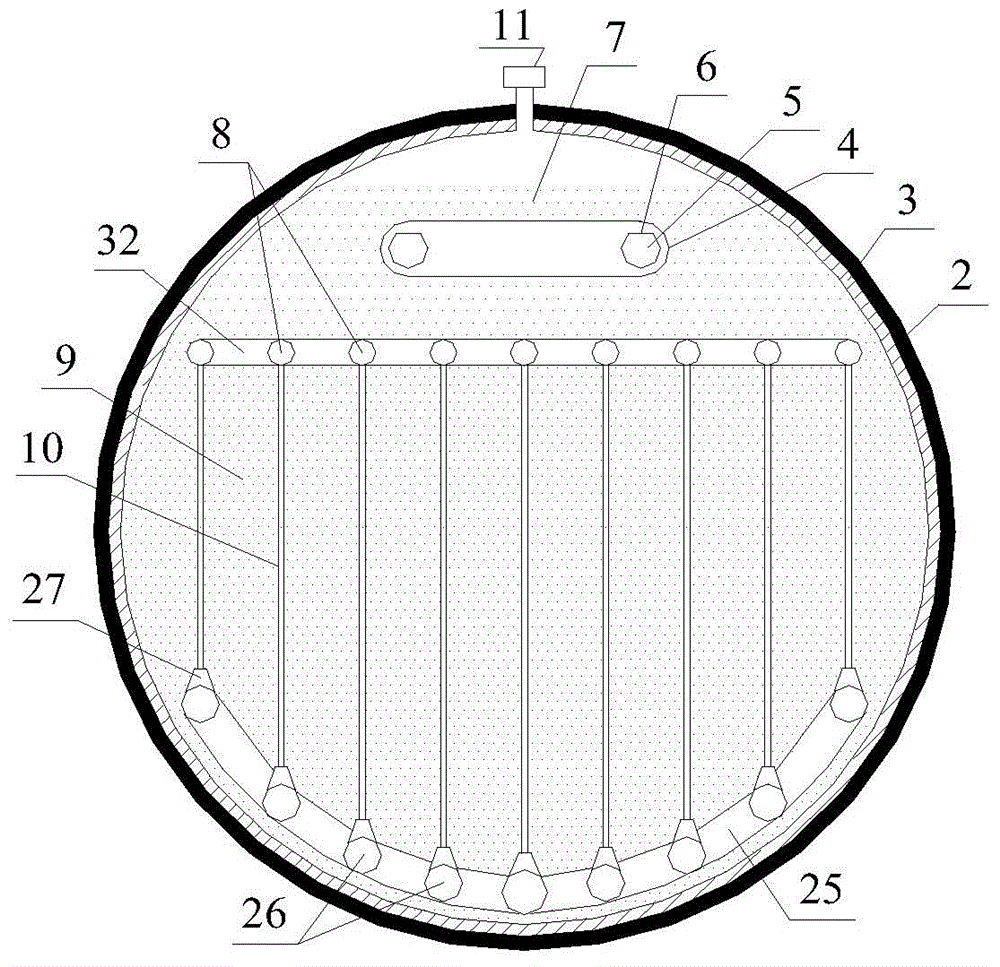

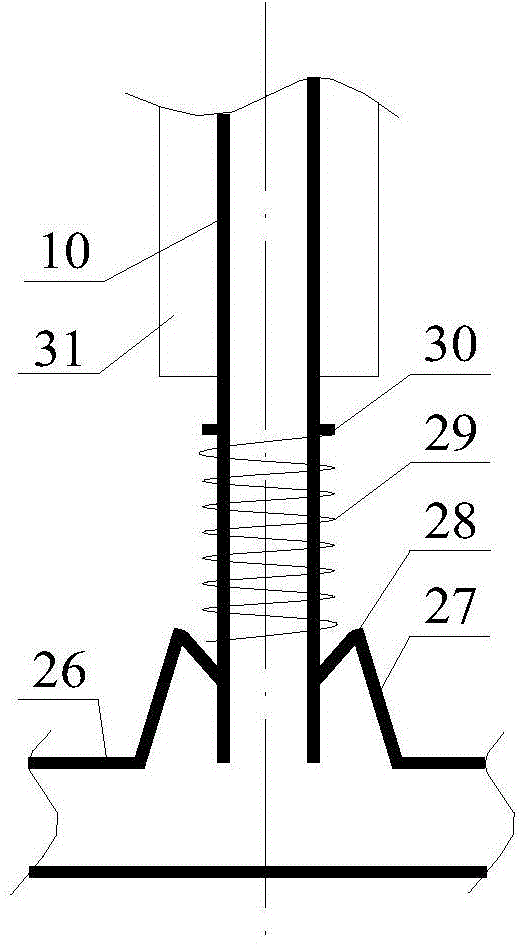

[0030] Such as figure 1 , figure 2As shown, the compound heat exchange type mobile heating device of the present invention includes an outer box body 1 and a heat storage tank 3 located in the outer box body 1, and the inlet dry pipe 18, the outlet dry pipe 14, and the external dry pipe drawn from the heat storage tank 3 33, and the automatic monitor 13 located in the outer casing 1. One end of the inlet dry pipe 18 and the outlet dry pipe 14 drawn from the heat storage tank is connected to the heat exchanger at the heat source end or the heat exchanger at the user end, the other end of the inlet dry pipe 18 is connected to the downlink pipe 25 in the heat storage tank, and the outlet dry pipe The other end of 14 is connected with the second porous pipe union 4 in the heat storage tank; one end of the external dry pipe 33 drawn from the heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com