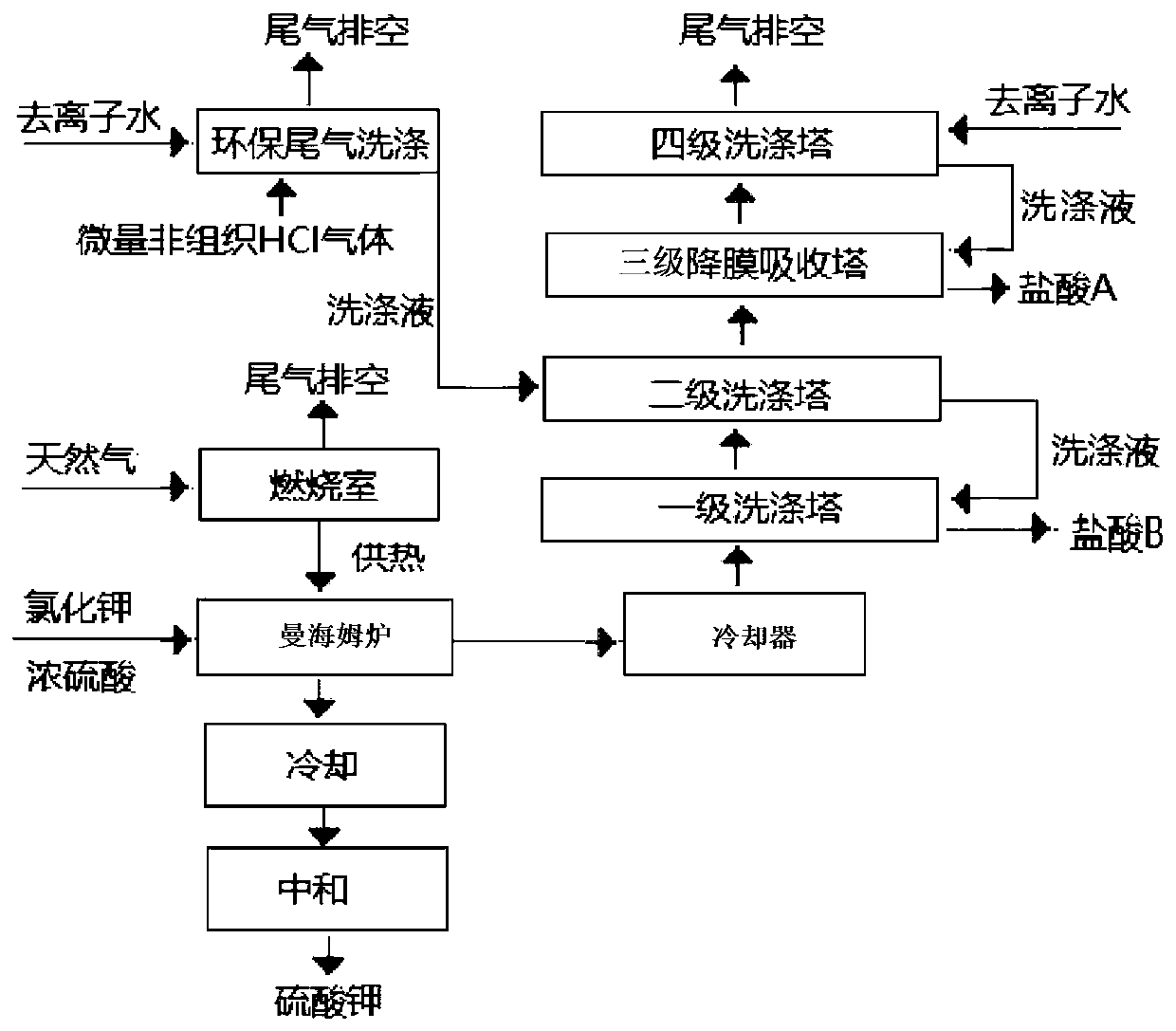

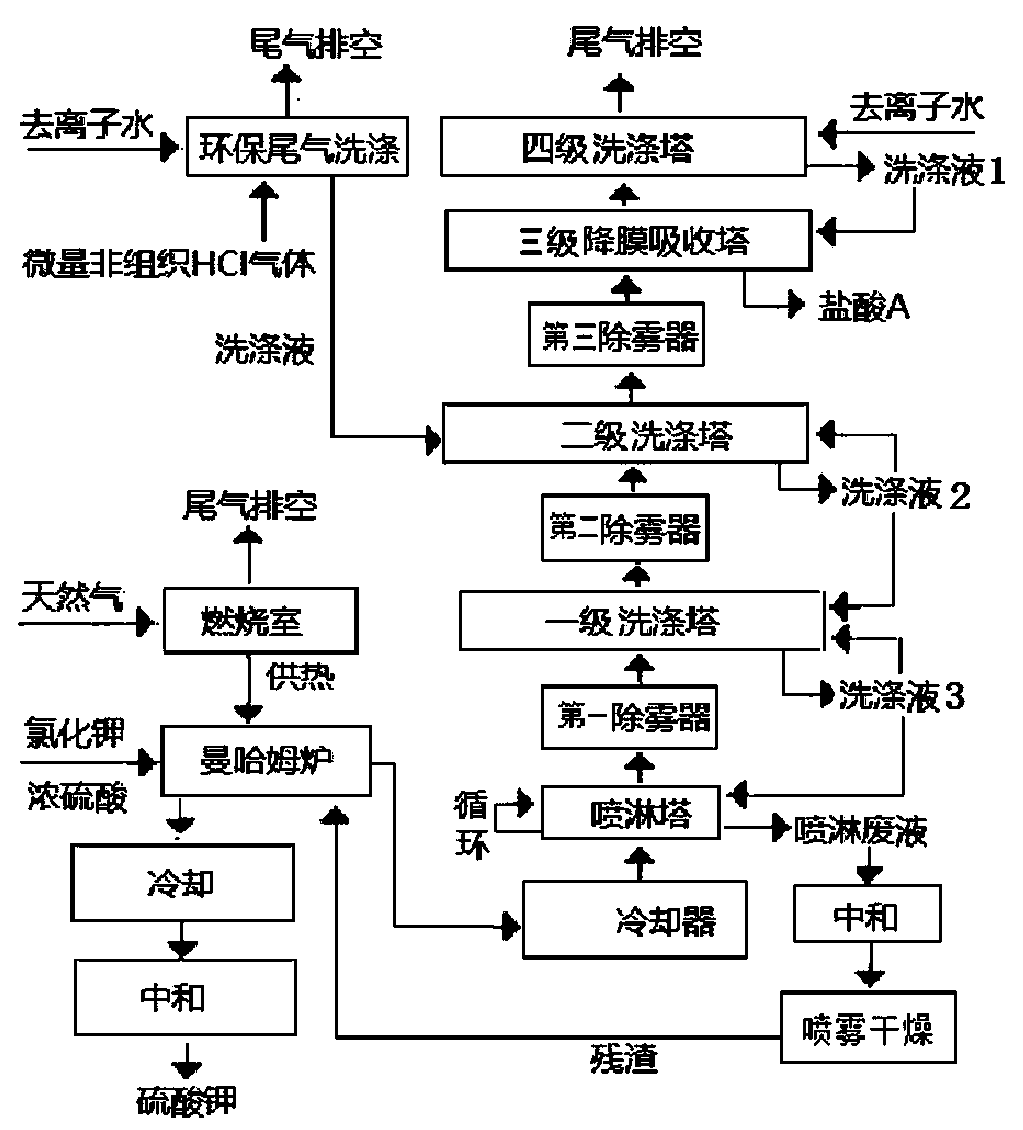

Method for preparing hydrochloric acid by utilizing hydrogen chloride gas in the process of producing potassium sulfate by Mannheim method

A Mannheim process, potassium sulfate technology, applied in chloride preparation, sulfate/bisulfate preparation, chlorine/hydrogen chloride, etc., can solve the problems of low quality, economic loss of enterprises, and high impurity content of hydrochloric acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The flow of deionized water for washing the gas in the four-stage scrubber is 14.8L / min, the internal circulation is 100L / min, and the output of hydrochloric acid A is 30.1 tons / day. The flow rate of deionized water for cleaning the environmentally friendly tail gas is 0.7L / min, and the output of mixed solids obtained from spraying waste liquid is 294kg / day.

[0042] The quality of detected hydrochloric acid A is shown in table 3 below:

[0043] project Sulfate (SO 4 2- ,%)

Fe 3+ (%)

HCl(%) color hydrochloric acid A 0.008 0.0005 32.1 colorless

[0044] table 3

[0045] The content of hydrogen chloride in the tail gas is: 5.17mg / m 3 , in line with environmental emission standards.

Embodiment 2

[0047] The flow of deionized water for washing the gas in the four-stage scrubber is 13.2L / min, the internal circulation is 115L / min, and the output of hydrochloric acid A is 28.0 tons / day. The flow rate of deionized water for cleaning the environmentally friendly tail gas is 2.6L / min, and the output of mixed solids obtained from spraying waste liquid is 299kg / day.

[0048] The hydrochloric acid quality after testing is shown in table 4 below:

[0049] project Sulfate (SO 4 2- ,%)

Fe 3+ (%)

HCl(%) color hydrochloric acid A 0.007 0.0005 32.6 colorless

[0050] Table 4

[0051] The content of hydrogen chloride in the tail gas is: 4.93mg / m 3 , in line with environmental emission standards.

Embodiment 3

[0053] The flow of deionized water for washing the gas in the four-stage scrubber is 14.8L / min, the internal circulation is 135L / min, and the output of hydrochloric acid A is 29.3 tons / day. The flow rate of deionized water for cleaning the environmentally friendly tail gas is 3.0L / min, and the output of mixed solids obtained from spraying waste liquid is 301kg / day.

[0054] The quality of detected hydrochloric acid A is shown in Table 5 below:

[0055] project Sulfate (SO42-,%) Fe3+(%) HCl(%) color hydrochloric acid A 0.007 0.0004 32.4 colorless

[0056] table 5

[0057] The content of hydrogen chloride in the tail gas is: 4.98mg / m 3 , in line with environmental emission standards.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com