Vacuum deaeration refining process and equipment

A vacuum degassing and equipment technology, applied in the field of RH vacuum cycle degassing and refining, can solve the problems of difficult realization, inconvenient operation and maintenance, large investment, etc., and achieve the effect of increasing processing capacity and not being easy to splash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Such as Figure 4 As shown, the magnetic field generator is composed of an iron core 7 and a coil winding 8 , and the outside of the generator is wrapped by a casing 9 . The iron core 7 and the coil winding 8 can be made of planar ferromagnetic materials. The iron core 7 is made of silicon steel sheets and is divided into upper and lower layers. There are two D-shaped tubes 10 on both sides, forming four parallel water branches for cooling by water. Winding 8 is made of flat copper strip and is directly cooled by water. The housing 9 is made of double-layer non-magnetic stainless steel with water cooling in the middle. The inner cavity of the shell is filled with dry nitrogen with a pressure slightly higher than the atmospheric pressure to prevent water vapor from infiltrating and ensure the insulation of the copper tube winding.

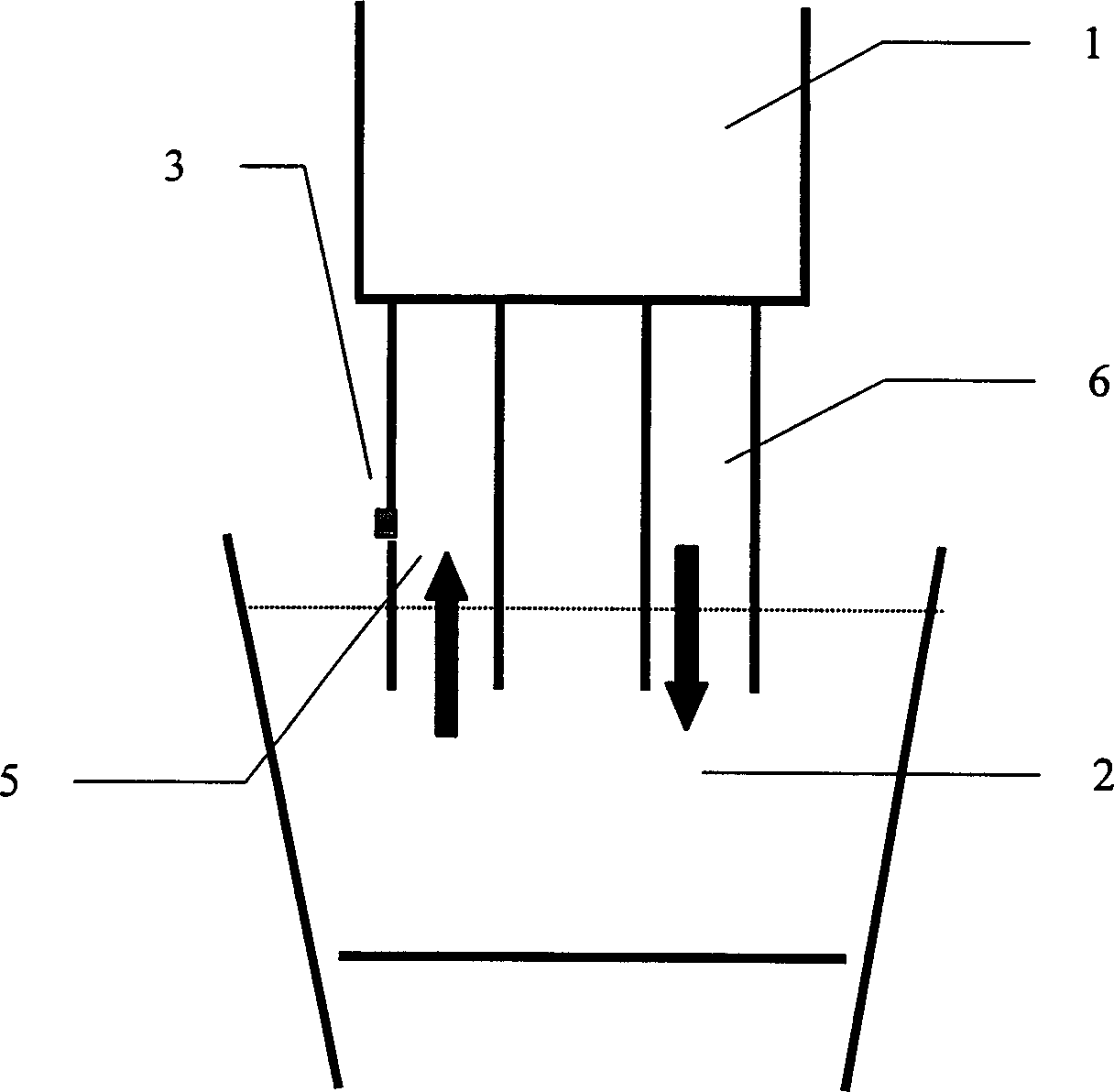

[0024] exist Figure 5 , 6 In and 7, the RH cycle degassing refining equipment consists of a vacuum chamber 1, a ladle 2, an argon chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com