Patents

Literature

37results about How to "Not prone to splashing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

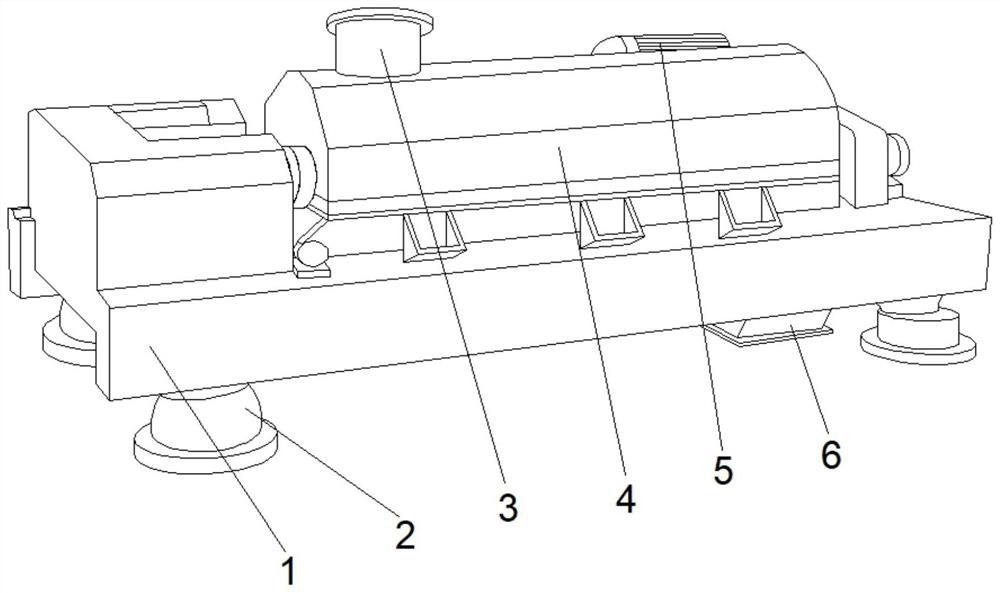

Vacuum deaeration refining process and equipment

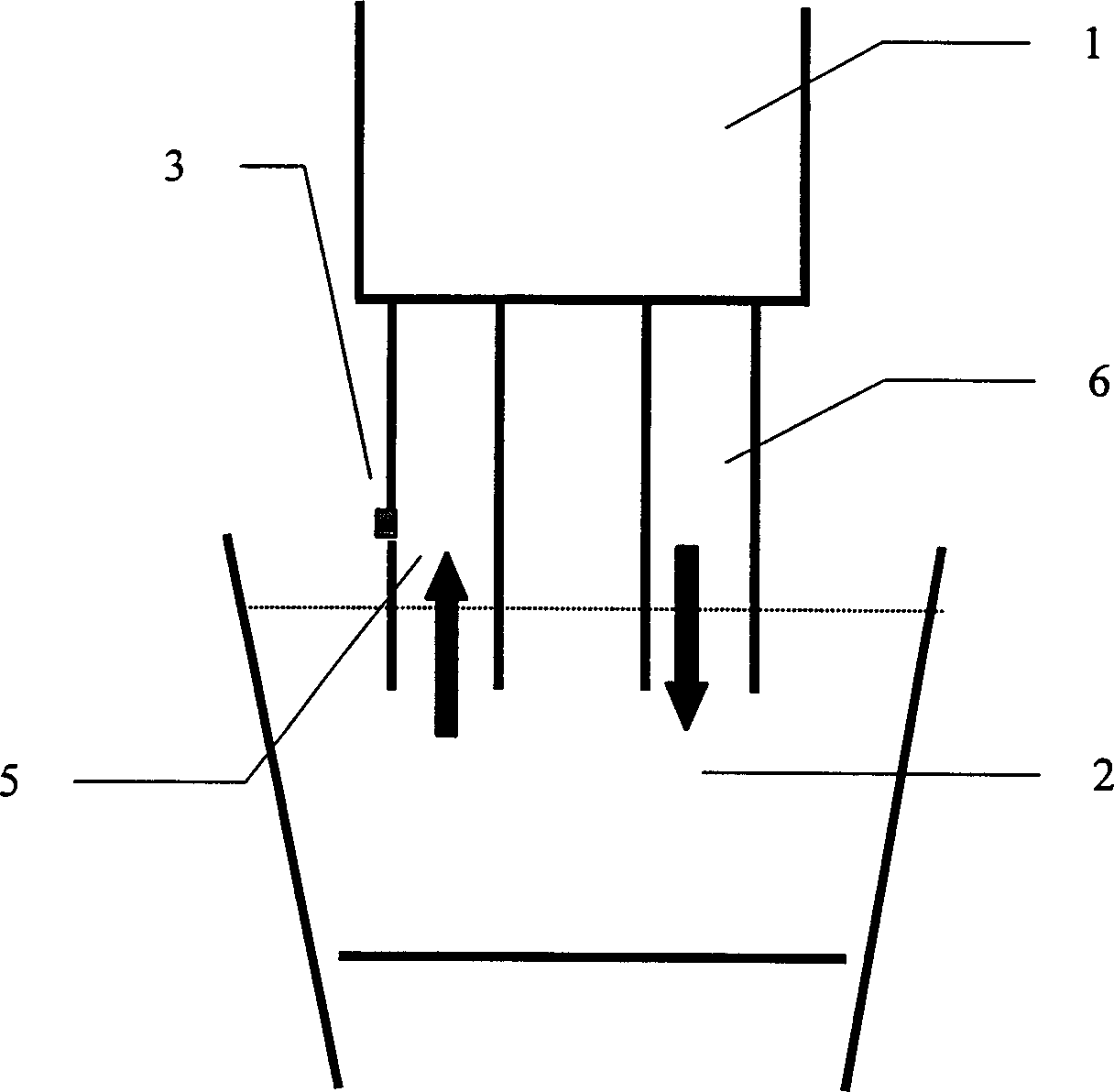

The present invention provides one kind of vacuum deaeration refining process and equipment. Soaking pipes in the bottom of the vacuum chamber are inserted into molten steel inside the molten steel container, driving gas is introduced into the ascending soaking pipe and the molten steel flows from the molten steel container, through the ascending soaking pipe, the vacuum chamber and the descending soaking pipe before returning to the molten steel container circular. The present invention features that there is magnetic field generator installed outside at least one soaking pipe to produce electromagnetic force in the same direction to that of the circular molten steel and this results in increased circulating molten steel amount and high refining efficiency.

Owner:BAOSHAN IRON & STEEL CO LTD +1

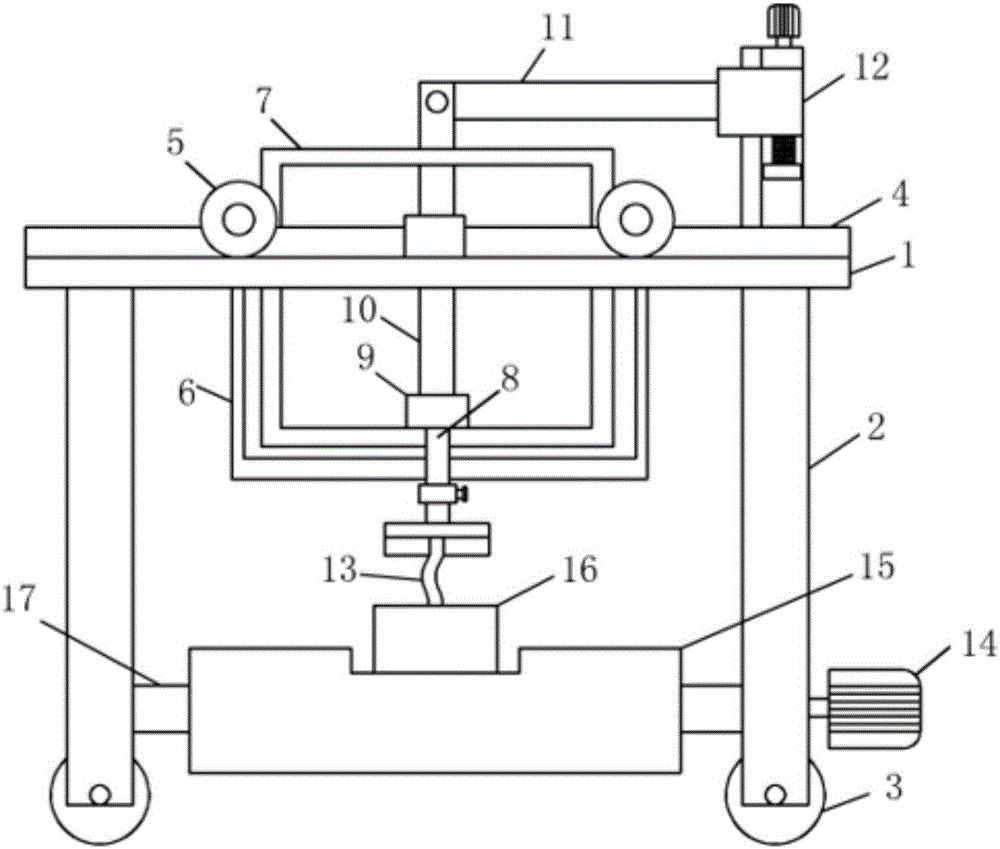

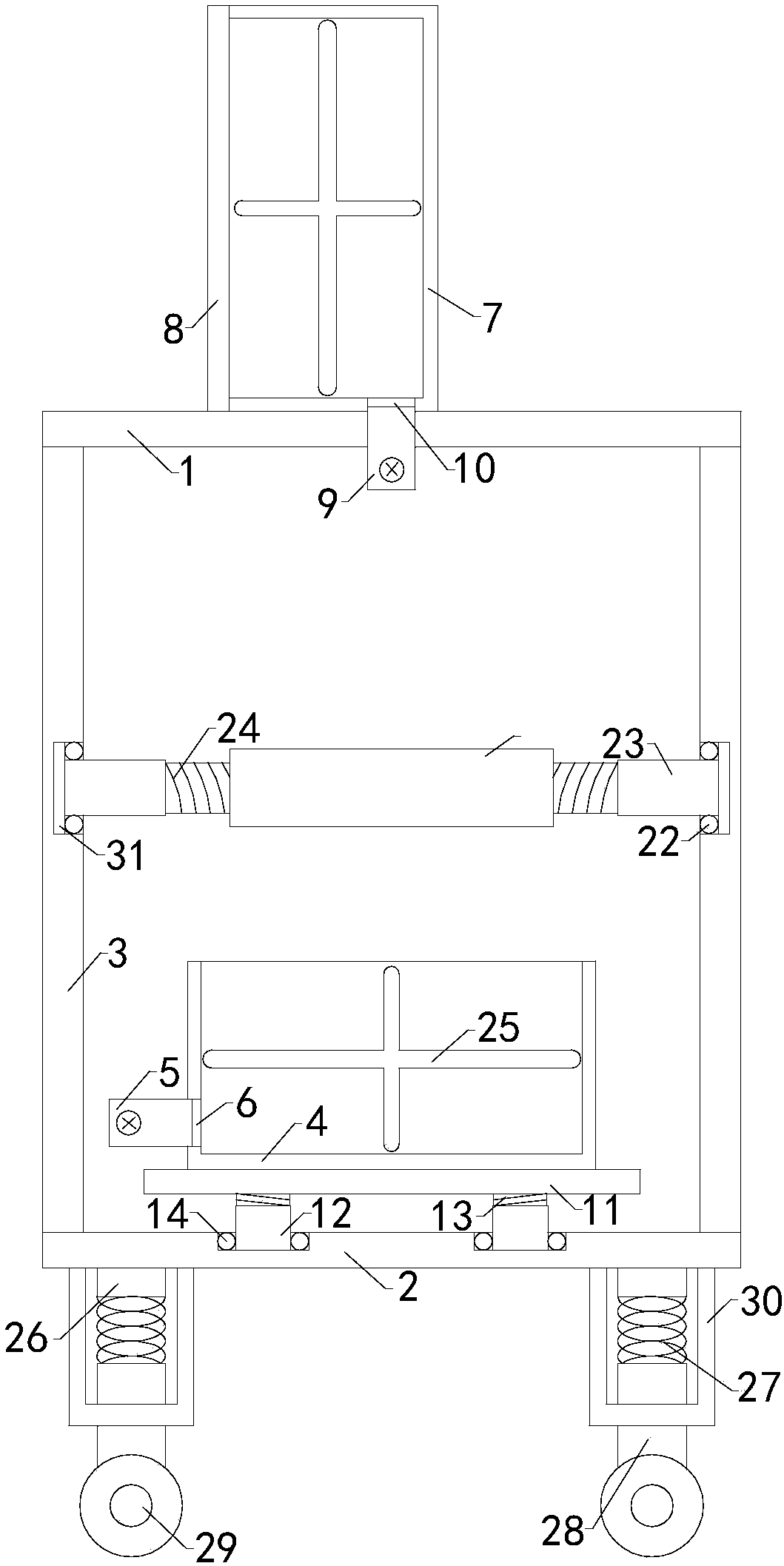

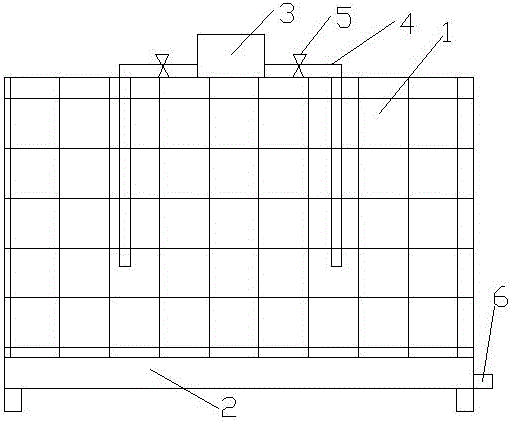

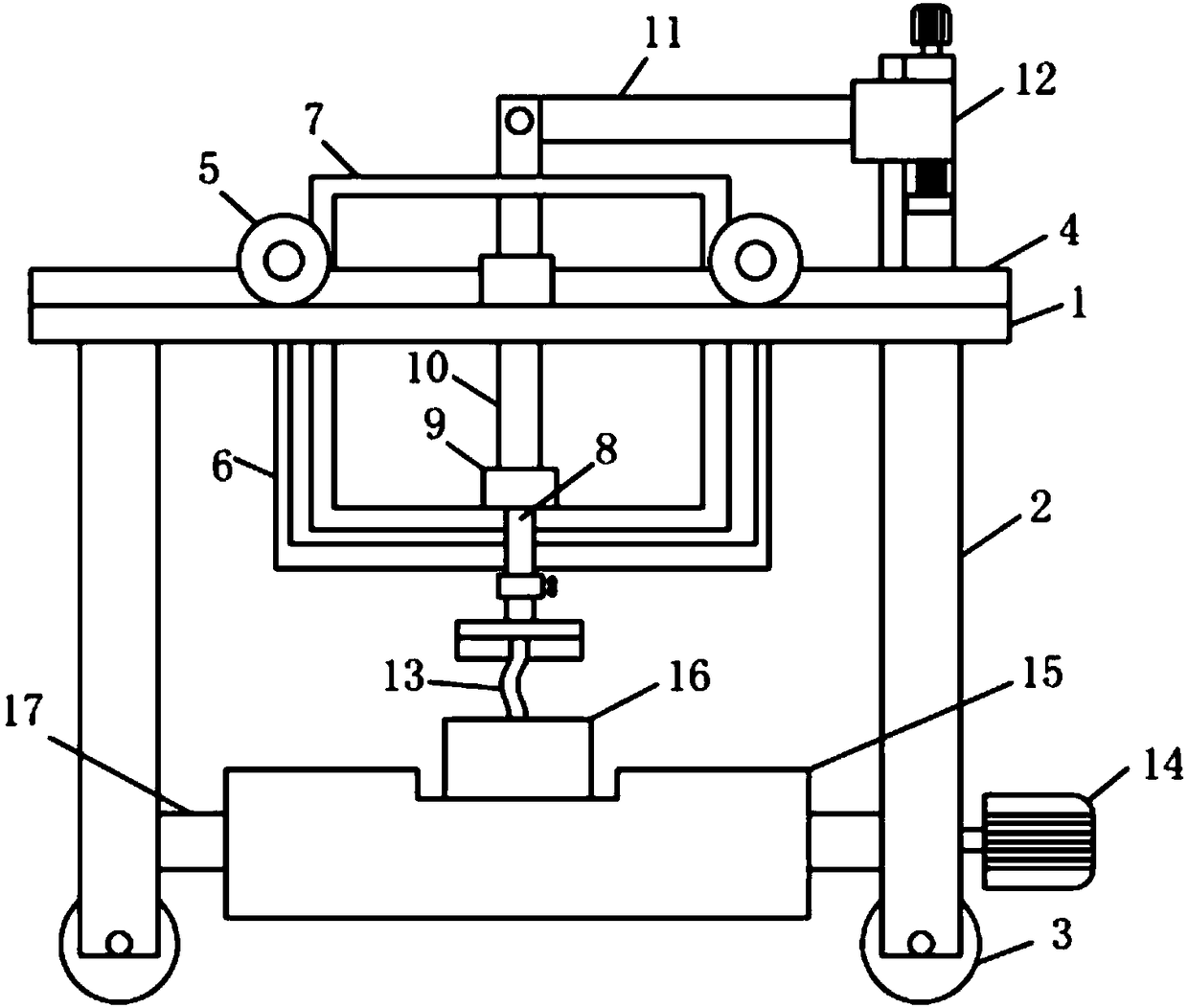

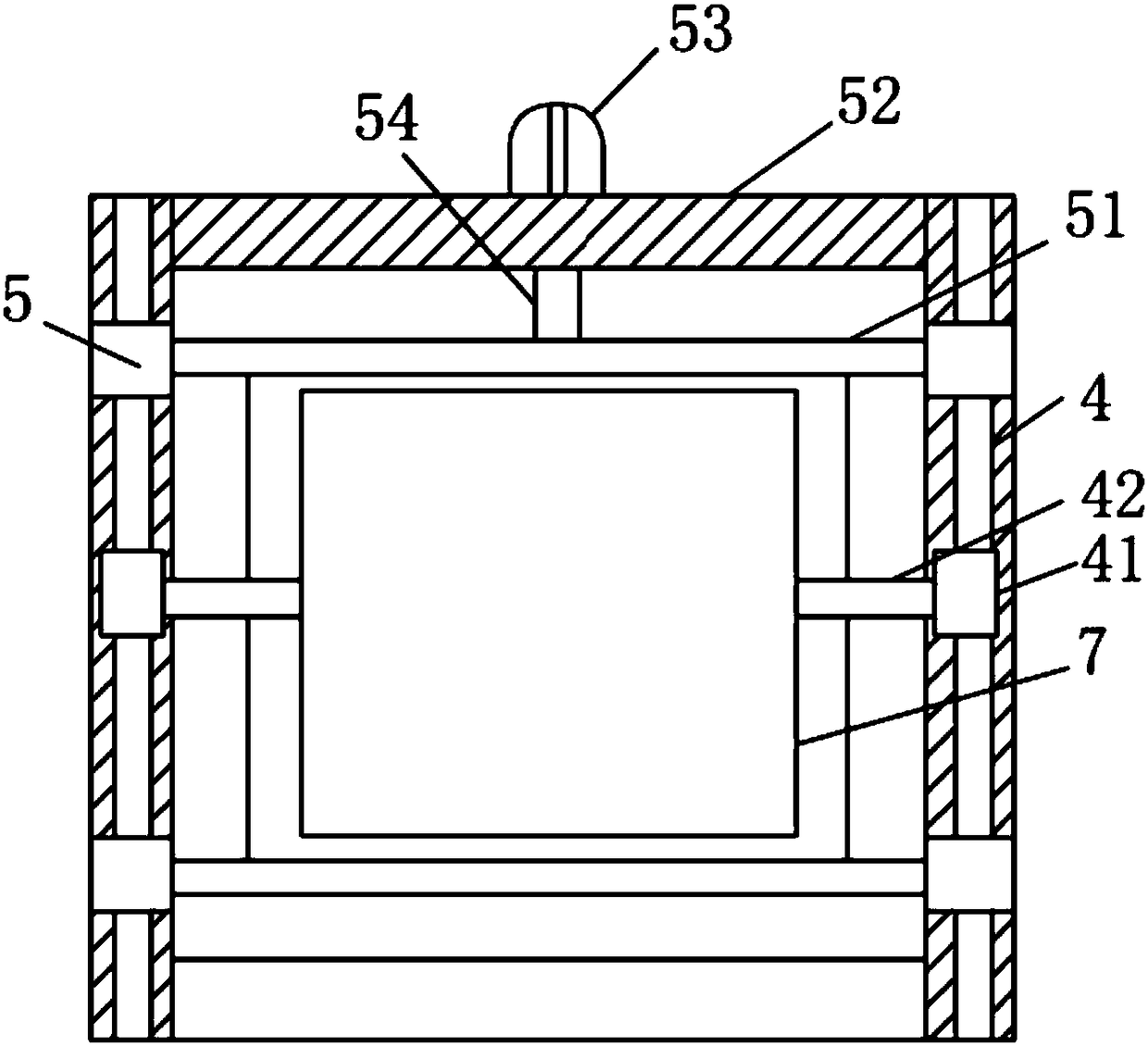

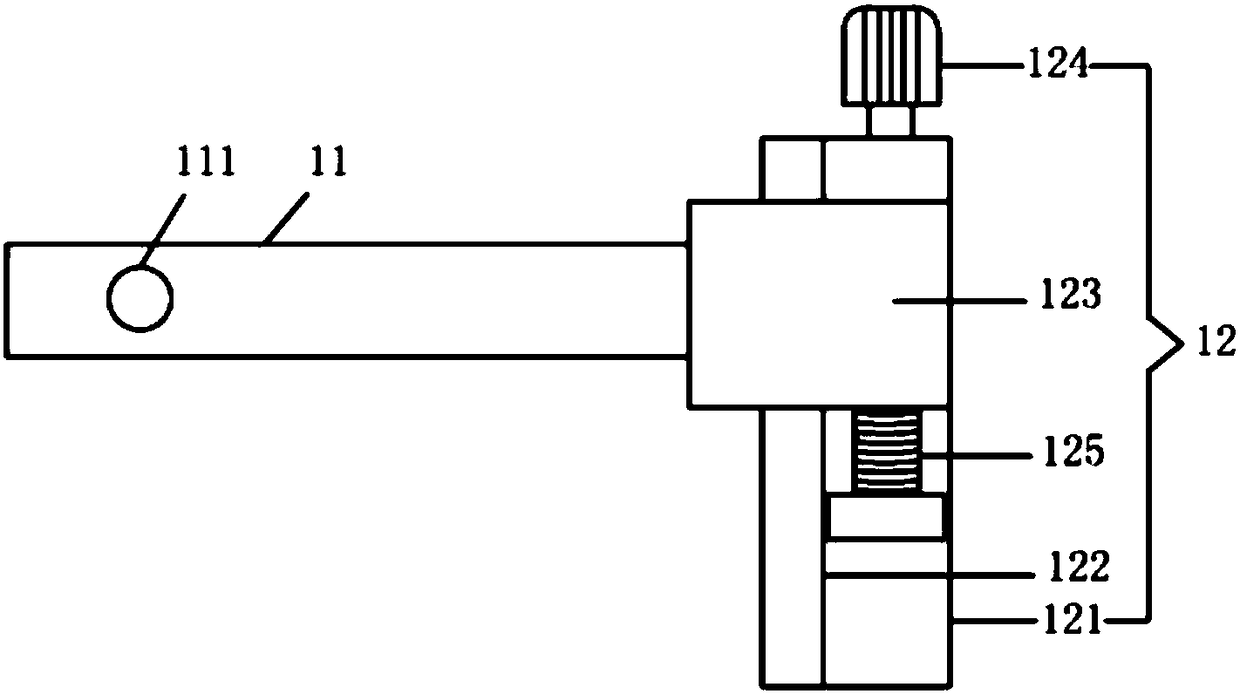

Pouring device of engine main bearing cover

ActiveCN106735139AReduce labor intensitySimple structureMolten metal conveying equipmentsVehicle frameAgricultural engineering

The invention discloses a pouring device of an engine main bearing cover in the technical field of casting equipment. The pouring device comprises a frame. Landing legs are arranged at the two ends of the top of the frame. Wheels are arranged at the bottoms of the landing legs. Frame sliding rails are arranged on the top of the frame. A pouring base is arranged between four sets of pulleys. A pouring ladle is arranged in an inner cavity of the pouring base. A drainage hole is formed in the bottom of the pouring ladle. A blocking block is arranged on the top of the drainage hole, and the top of the blocking block is connected with a vertical rod. The top end of the vertical rod is connected with a cross rod. An elevating device is arranged on the right side of the top of one frame sliding rail. A pouring hose is arranged at the bottom of the pouring base. A trolley is arranged at the bottom of the pouring hose. A conveying motor is arranged on the right wall of the landing leg on the right side. A conveying belt is arranged on the outer wall of the rotation shaft. Safety production is facilitated, the production efficiency is greatly improved, and the labor intensity of workers is relieved. The pouring device is simple in structure, low in cost and convenient to use.

Owner:SHIFANG YONGSEN MACHINERY

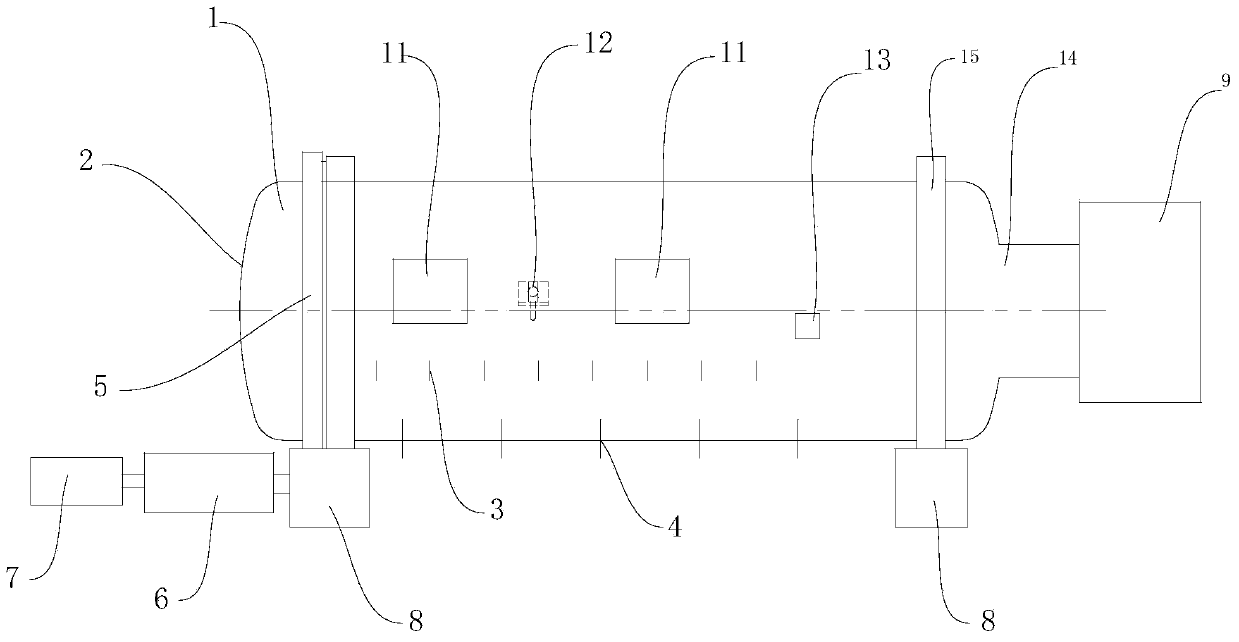

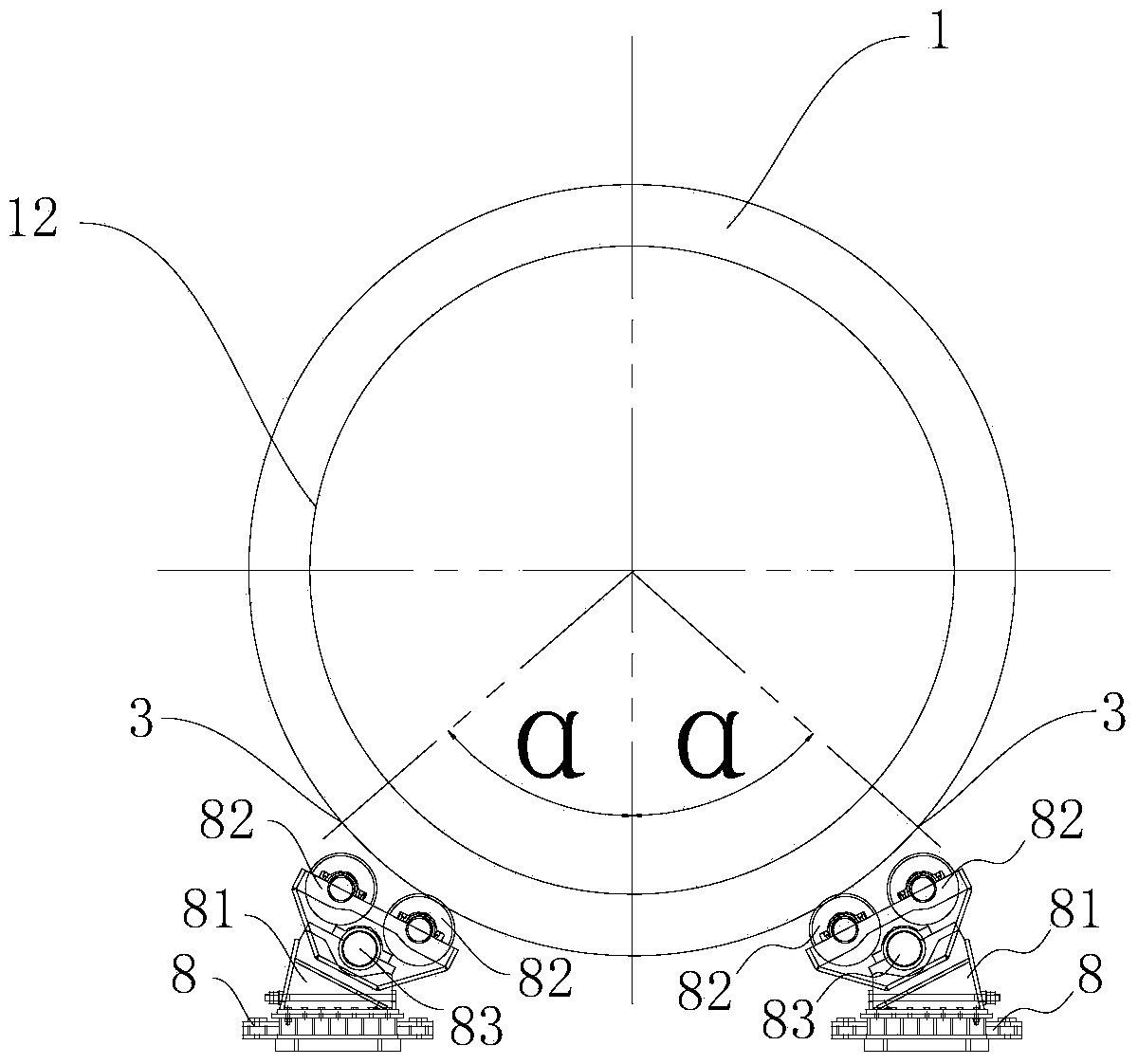

Bottom blowing or side blowing metallurgical furnace for treating scrap copper

InactiveCN103468971AImprove convenienceRapid responseProcess efficiency improvementScrapHeating efficiency

The invention discloses a bottom blowing or side blowing metallurgical furnace for treating scrap copper, which comprises bearings, a horizontal cylindrical furnace body, bottom blowing or side blowing spray guns, a burner and a driving part, wherein the horizontal cylindrical furnace body can be supported on the bearings in a 360-degree rotation manner; feed ports, a copper outlet and a slag hole are formed in the side face of the horizontal cylindrical furnace body, respectively; the horizontal cylindrical furnace body is provided with a smoke outlet and a nozzle port; and reductant-oxidant injection ports and air bricks are formed and arranged at the bottom or the side part of the horizontal cylindrical furnace body. The bottom blowing or side blowing spray guns are used for injecting oxygen-containing gas and natural gas, oil or powdered coal into the horizontal cylindrical furnace body, and inserted into the reductant-oxidant injection ports. A burner is mounted at the nozzle port. The driving part is connected with the horizontal cylindrical furnace body to drive the horizontal cylindrical furnace body to rotate. The bottom blowing or side blowing metallurgical furnace for treating the scrap copper is simple in structure, good in environmental protection property and high in heat efficiency.

Owner:CHINA ENFI ENGINEERING CORPORATION

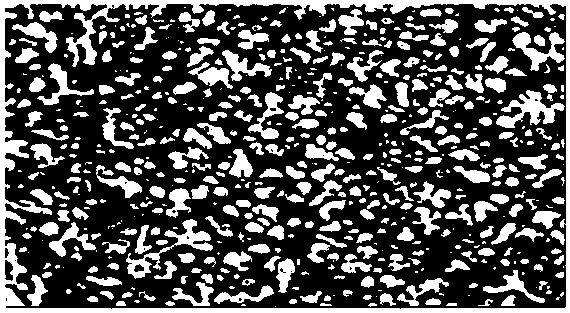

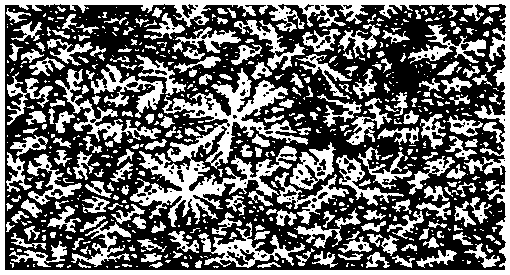

Pressure casting method of filter cavity

ActiveCN109732052AImprove collision strengthImprove liquidityTransportation and packagingCasting cleaning apparatusRotation functionPressure casting

The invention discloses a pressure casting method of a filter cavity. The method comprises the steps that (1), aluminum alloy liquid is transferred into a stirrer internally provided with an electromagnetic inductor and a stirring rod, and the stirring rod penetrates into the stirrer; (2), the stirrer is covered and air inside the stirrer is pumped out; (3), the stirrer is started to stir the aluminum alloy liquid in a closed vacuum condition, so that the aluminum alloy liquid is subjected to electromagnetic stirring in the magnetic field direction of the electromagnetic inductor, mechanical stirring is conducted under the rotation function of the stirring rod, and the aluminum alloy liquid is stirred to be in a semi-solid state to obtain a semi-solid aluminum alloy sizing agent; and (4),the semi-solid aluminum alloy sizing agent obtained in the step (3) is injected into a filter mold, pressure casting molding is conducted with the injection speed of 1.5-2.5 meters / second, the injection specific pressure of 30-80 MPa and the boost pressure of 60-80 MPa, the filter cavity is obtained after pressure is kept for 7-30 seconds, and the temperature of the filter mold is set to be 250-400 DEG C.

Owner:ZHUHAI RUNXINGTAI ELECTRICAL

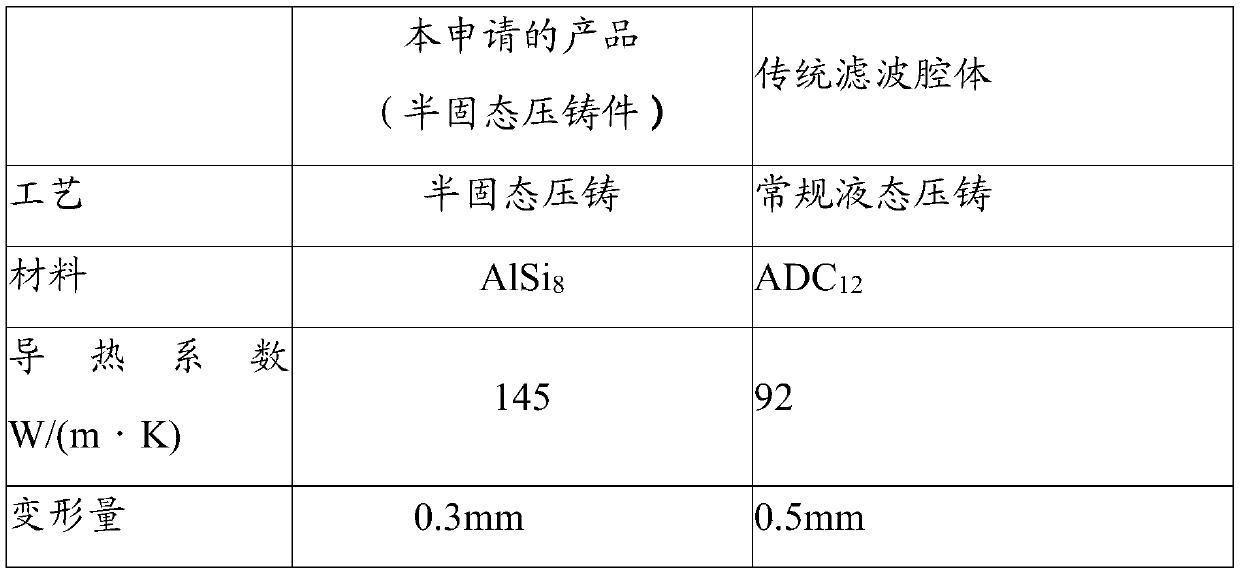

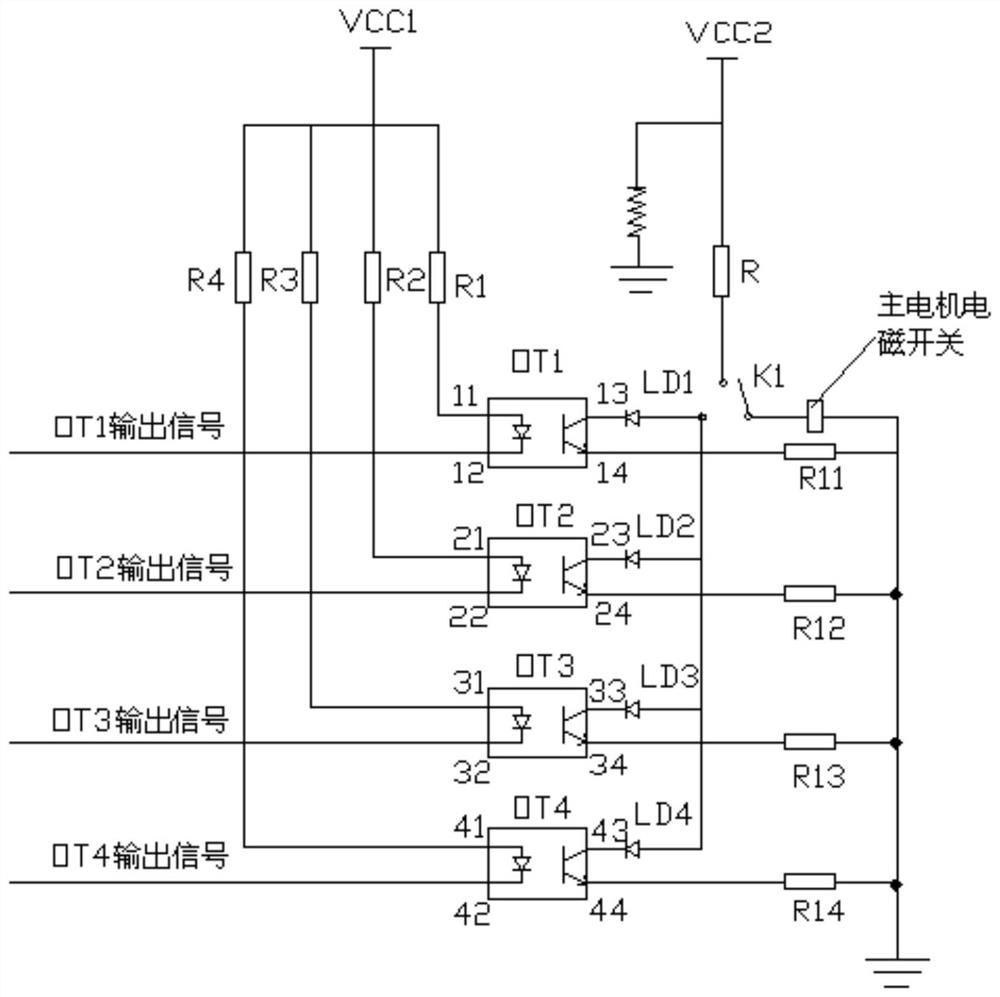

Bottom-blowing flow dynamic control method of top-bottom combined blowing converter

InactiveCN110157848ARealize dynamic controlSolve fixed problemsSteel manufacturing process aspectsIncreasing energy efficiencyEngineeringOxygen content

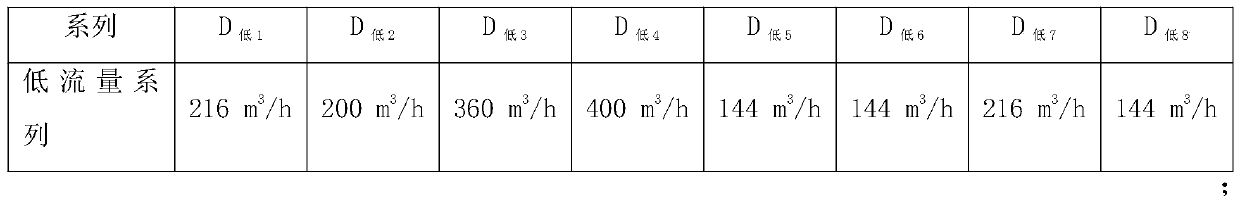

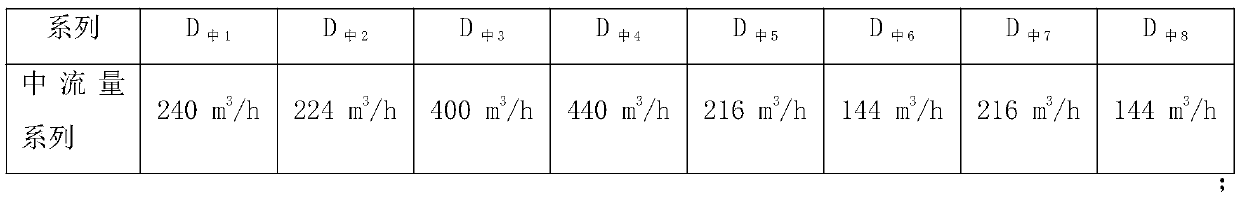

The invention provides a bottom-blowing flow dynamic control method of a top-bottom combined blowing converter. Firstly, three flow series composed of a high-flow series, a medium-flow series and a low-flow series are added based on three bottom-blowing air supply modes, three bottom blowing air supply modes and three flow series are permuted and combined into nine basic bottom-blowing curves, wherein the time coordinate axes of the basic bottom-blowing curves are provided with eight time intervals; in addition, the measured carbon content [C], the oxygen content [O], a molten pool liquid level a, and an end point temperature T of the converter blowing end point of the previous furnace as well as the furnace age of a next furnace to be blown are taken as variable parameters to be substituted into a formula, then the nine basic bottom blowing curves are dynamically corrected through formula calculation, thus the bottom blowing instantaneous flow after dynamic correction is the bottom blowing instantaneous flow of the actual blowing of the next furnace. According to the bottom-blowing flow dynamic control method of the top-bottom combined blowing converter, the problem that the bottom blowing flow is fixed is solved, the dynamic control of the bottom blowing flow is realized, thus reducing the carbon oxygen product at the blowing end point and improving the metallurgical effect of the bottom blowing as well as the quality of the molten steel.

Owner:山东钢铁集团有限公司

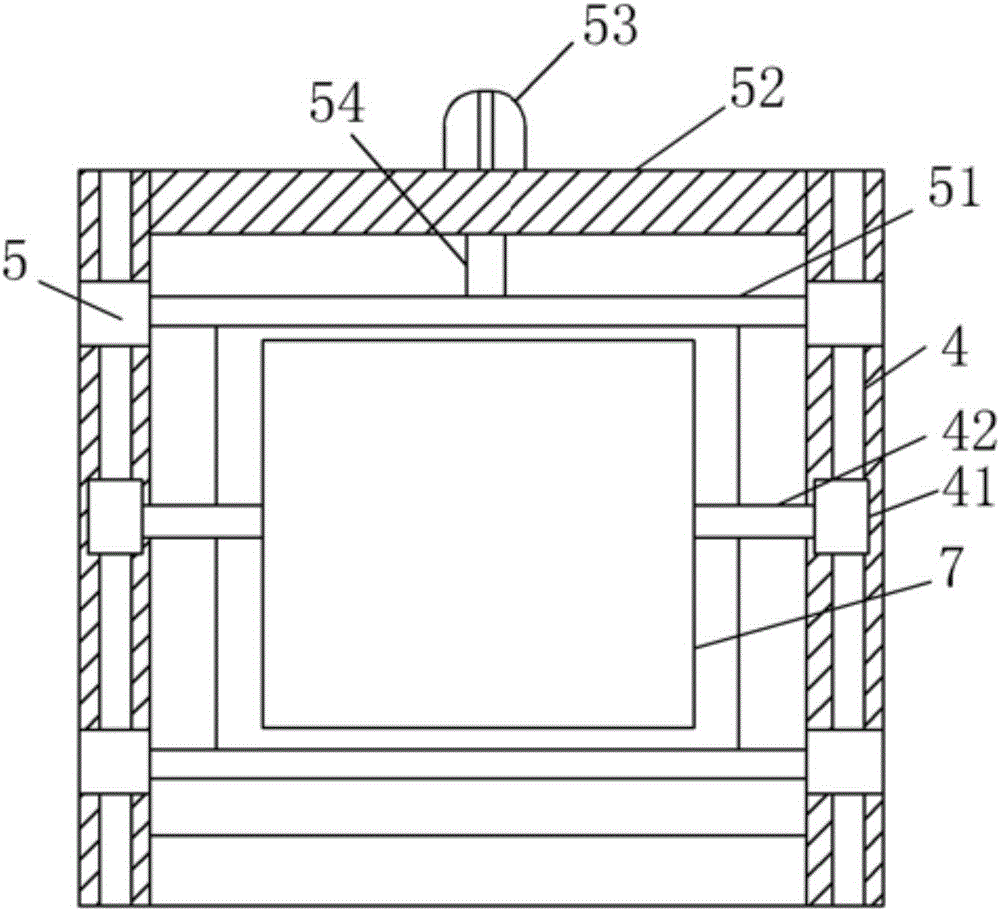

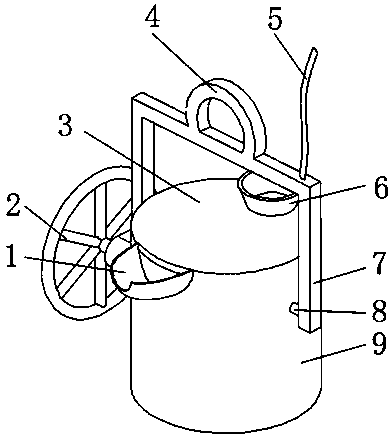

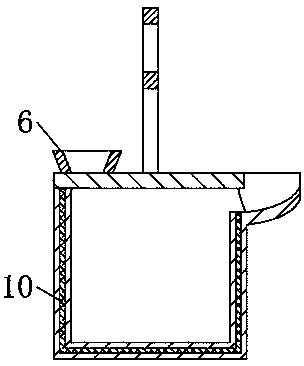

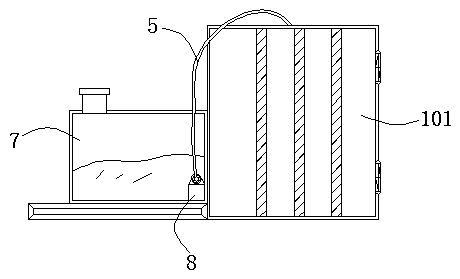

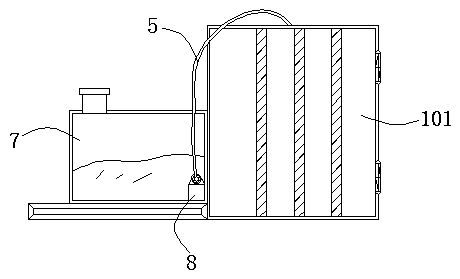

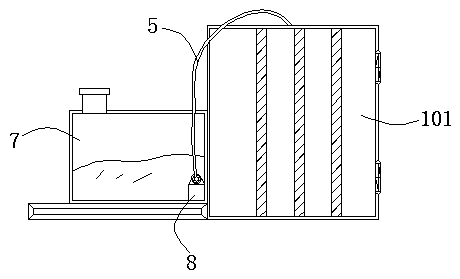

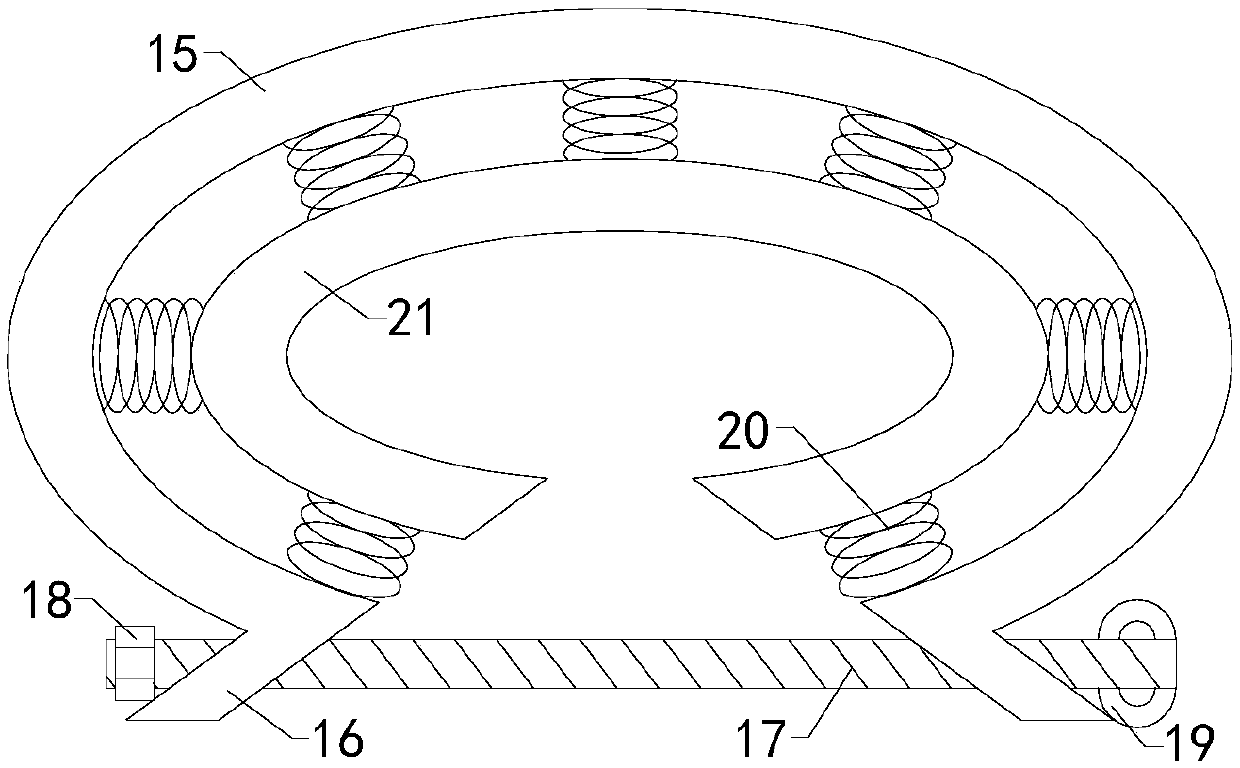

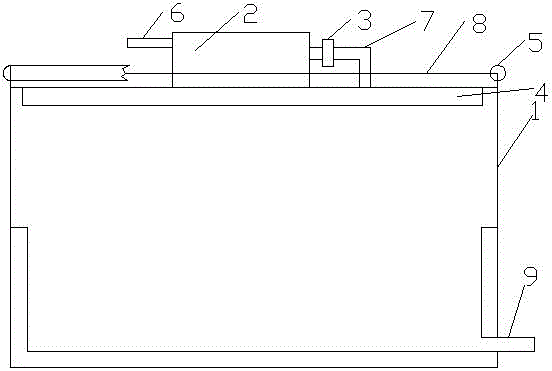

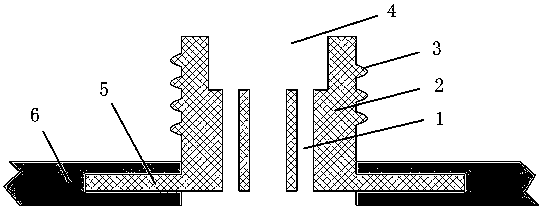

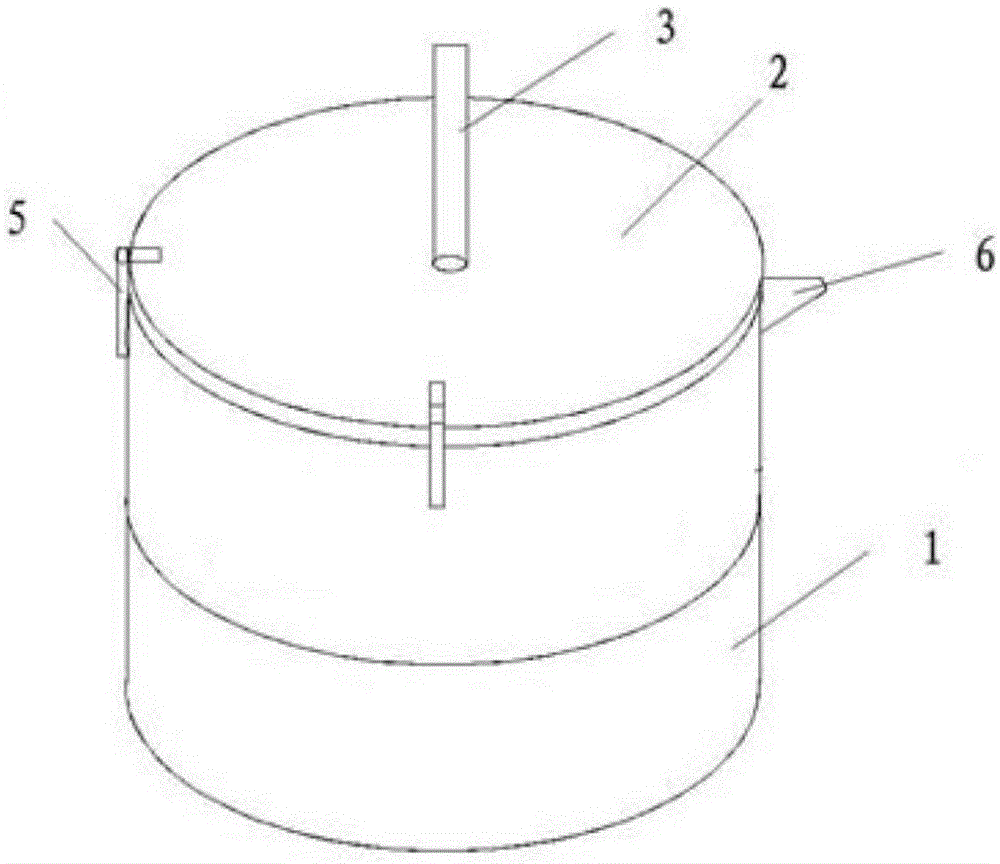

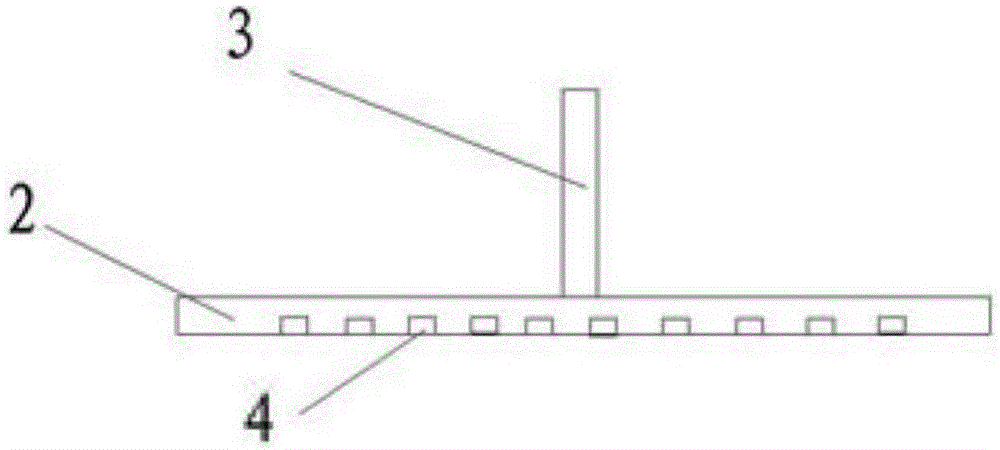

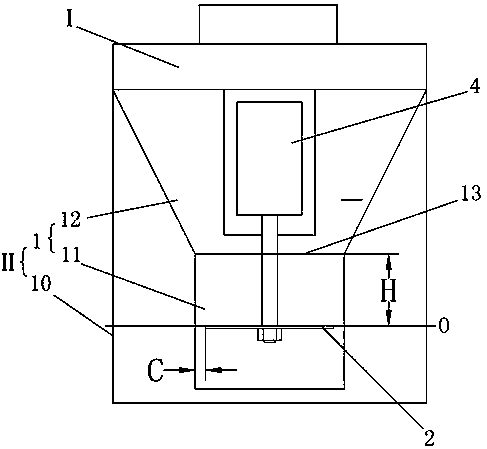

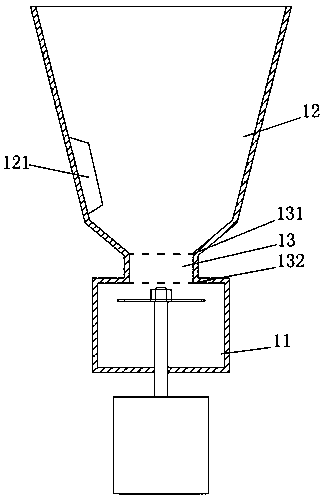

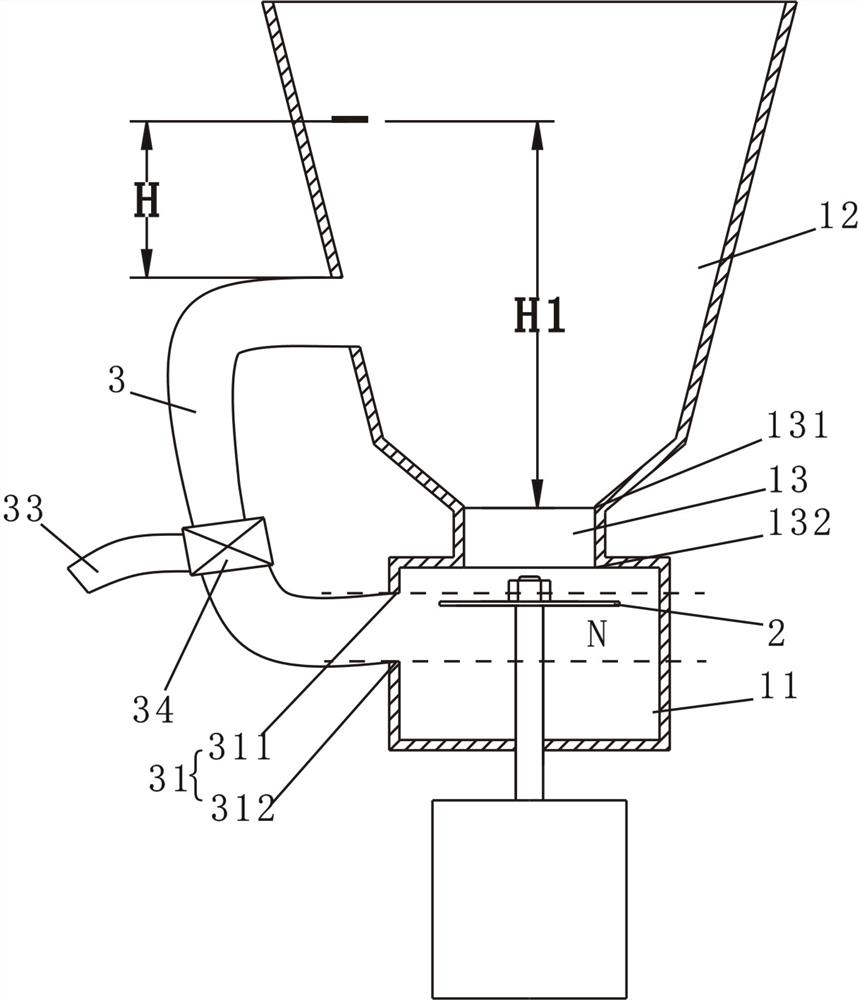

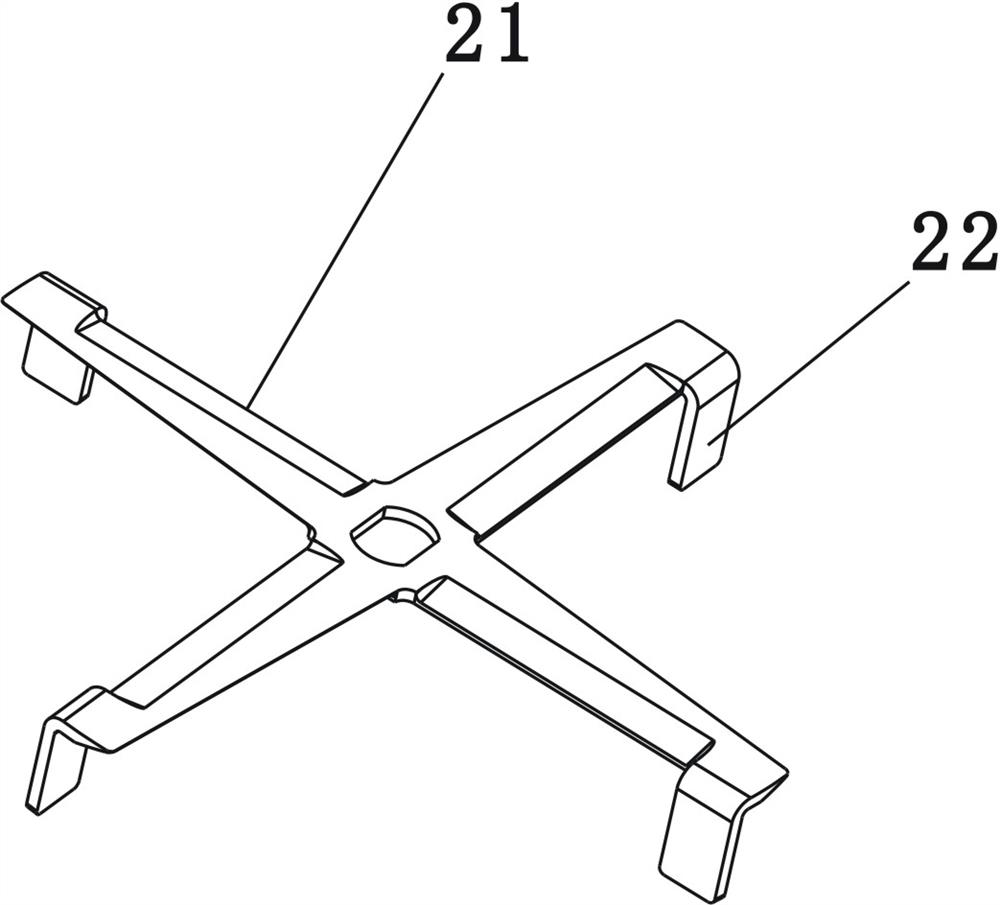

Self-heating heat preservation casting ladle

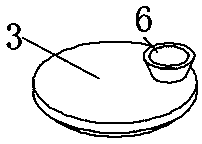

InactiveCN107755678AImprove transport efficiencyNot prone to splashingMelt-holding vesselsInjection portThermal insulation

The invention discloses a self-heating thermal insulation ladle, which comprises a material storage tank, a rotating disk and a connecting frame. Insulation cover, the top surface of the ladle insulation cover is provided with a material injection port, the side wall of the storage tank is rotatably connected to the connecting frame through a rotating shaft, a large gear is sleeved on the periphery of the rotating shaft, and the connecting frame The other end of the rotating adjustment box is connected with the side wall of the storage tank, and the outside of the rotating adjustment box is provided with a rotating disc, which is connected to the pinion through a connecting rod, and the pinion is connected to the large gear Engagement transmission. In the present invention, on the basis of the traditional ladle, a ladle heat preservation cover and a material injection port are set, so that the injection of liquid metal into the ladle is not easy to cause splashing and also plays a role of heat preservation, ensuring the liquid metal The temperature meets the casting requirements.

Owner:泰兴市金鳌机械制造有限公司

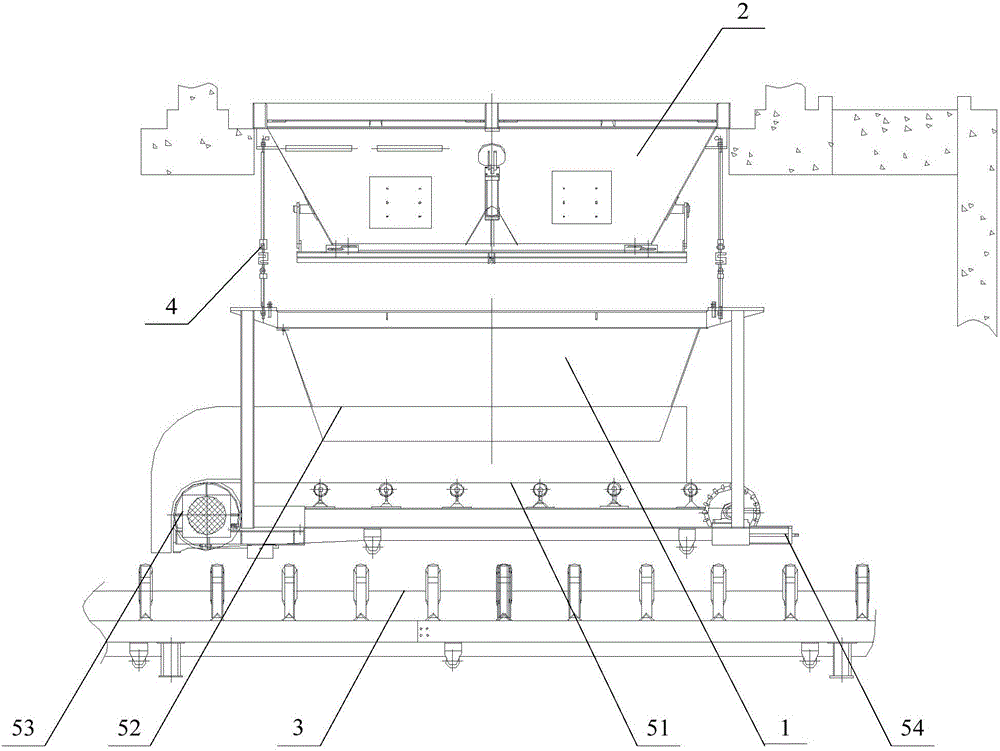

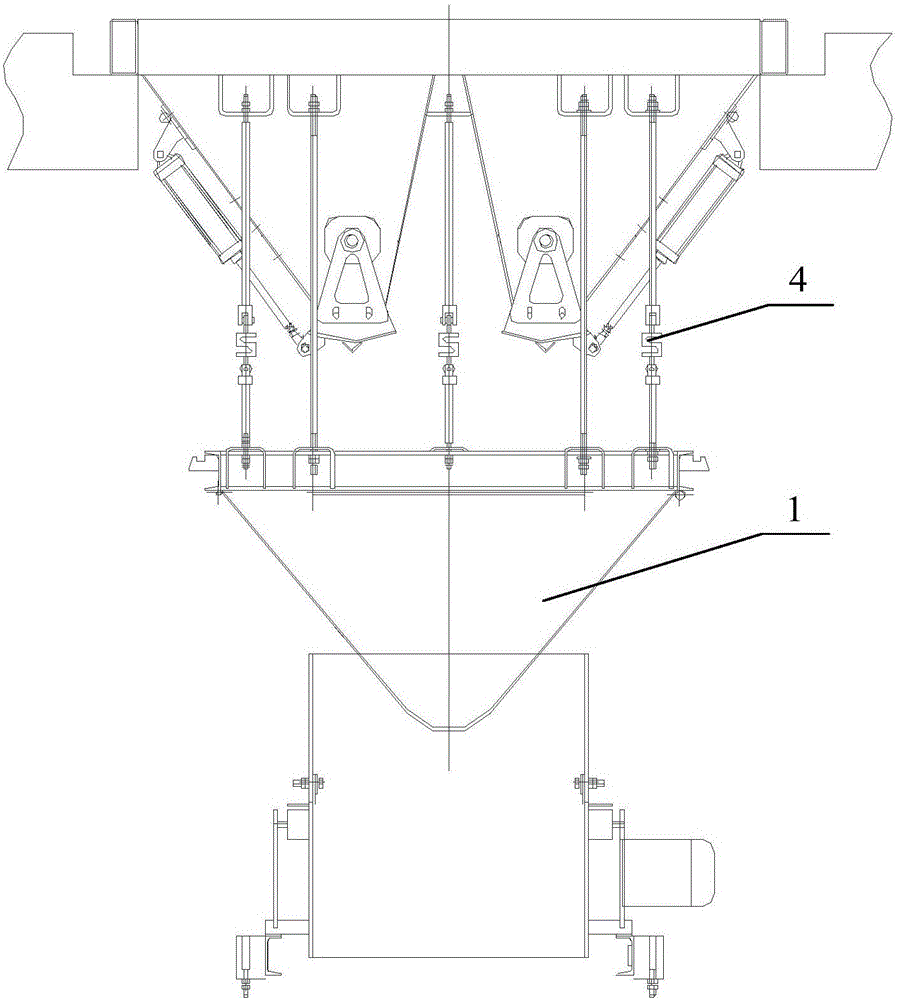

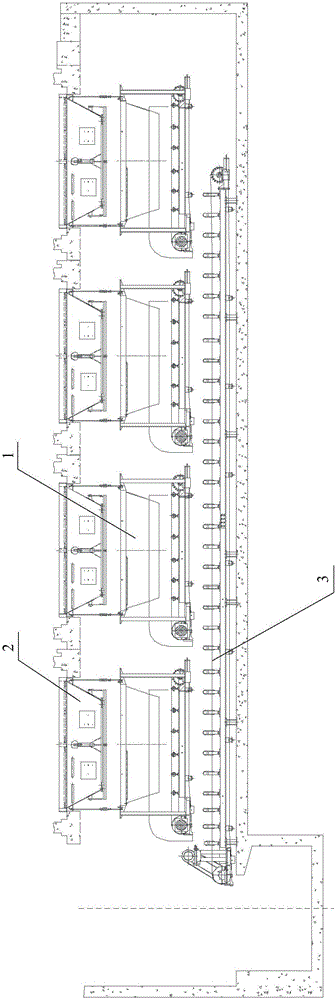

Metering method and device and feeding system with metering device

InactiveCN105865590AReduce shockHigh precisionWeighing apparatus with automatic feed/dischargeLoading/unloadingEngineeringMechanical engineering

The invention discloses a metering device. The metering device comprises a stocker and weighing devices, and further comprises a conveying machine arranged below the stocker. The conveying machine is used for driving materials to be discharged, and when the reduction value of the weight, weighed by the weighing devices, of materials on the convening machine is equal to the preset weight value, discharging is stopped. When the metering device is applied, discharging is even, impacting is small, adjusting and controlling of discharging are convenient, and the accuracy of the metering device is increased. Materials are conveyed and discharged through the conveying machine, impacting of the following device is small, on one hand, abrasion of the following device is not prone to being caused, and the service life of the following device can be prolonged; on the other hand, splashdown of materials is not prone to occurring during discharging, the influence on the environment is reduced while the metering accuracy is further increased, and the labor intensity of cleaning persons is reduced. Multiple materials can be discharged at the same time, and production efficiency is effectively improved. The invention further discloses a feeding system comprising the metering device and a metering method.

Owner:BEIQI FOTON MOTOR CO LTD

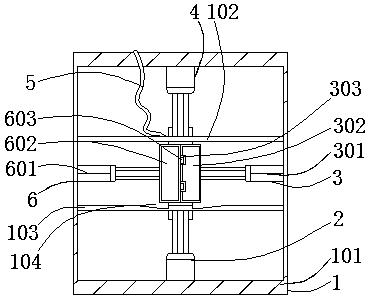

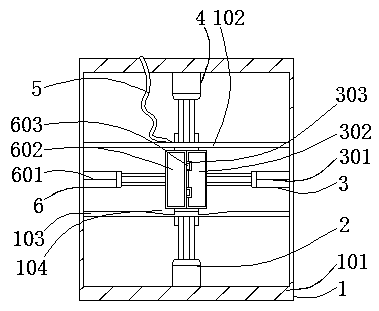

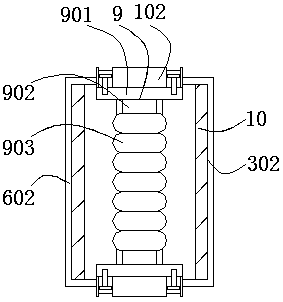

Spraying device for spring processing

ActiveCN111545394ANot prone to splashingAffect spraying work efficiencyLiquid surface applicatorsCoatingsEngineeringBrush

The invention discloses a spraying device for spring processing and relates to the technical field of spring processing. The spraying device comprises a bearing mechanism and a second clamping mechanism, wherein a first electric push rod is installed on the bottom end of the inner side of the bearing mechanism; a first clamping mechanism is disposed on one side of the middle of the inner wall of the bearing mechanism; the second clamping mechanism is placed on the other side of the middle of the inner wall of the bearing mechanism; and a third electric push rod is installed on the top end inside the bearing mechanism. According to the invention, the spraying device for spring processing, which is used for preventing liquid splashing has the beneficial effects that brush bars, a brush pillar and a connecting pipe are disposed, the brush bars are symmetrical relative to the center axis of the brush pillar, and an oil conveying pump is started after spring installation, so that protectiveoil is conveyed along the connecting pipe to the brush bars and the brush pillar; and through flexible effects of the brush bars and the brush pillar, liquid collision on a spring and a splashing phenomenon caused thereby are not easily generated during a spraying operation of inner and outer walls of the spring respectively.

Owner:CHONGQING TECH & BUSINESS UNIV

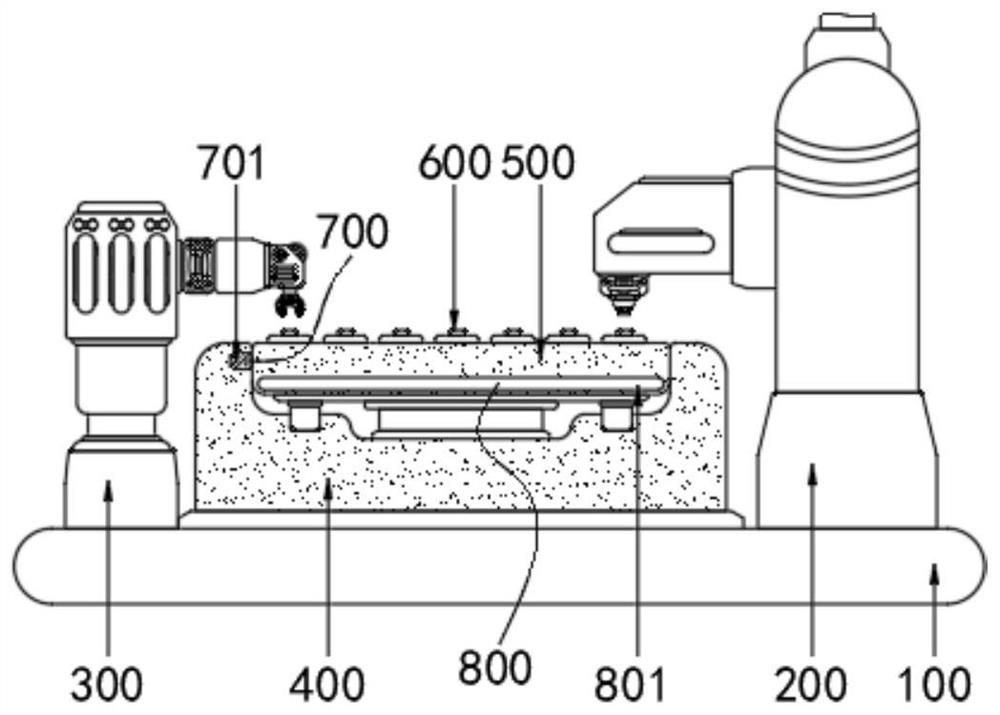

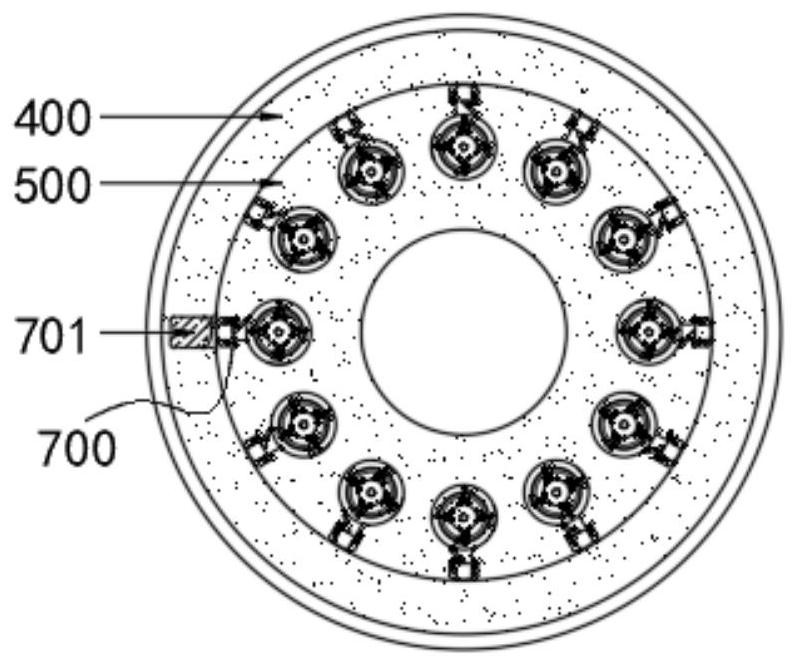

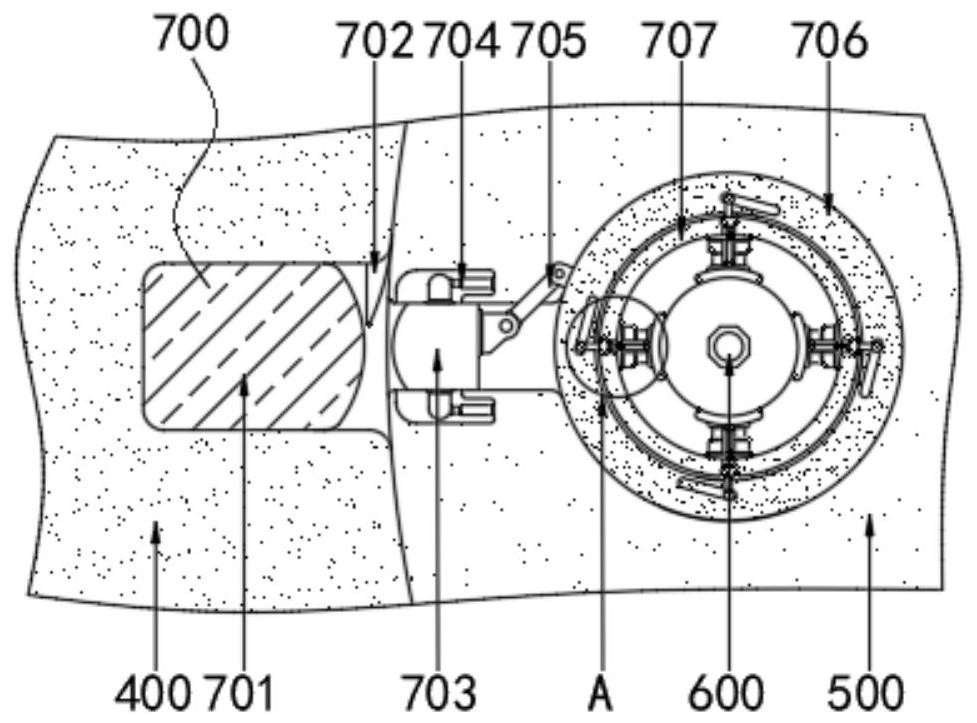

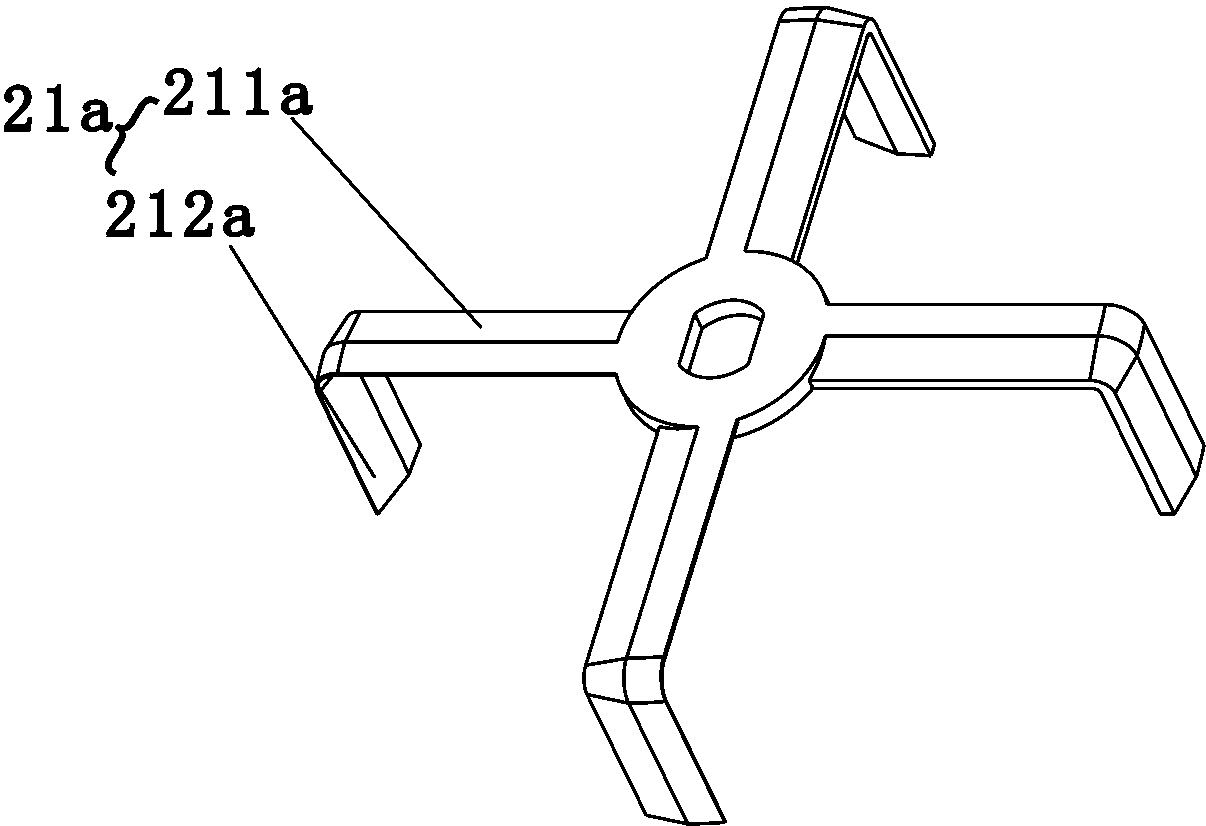

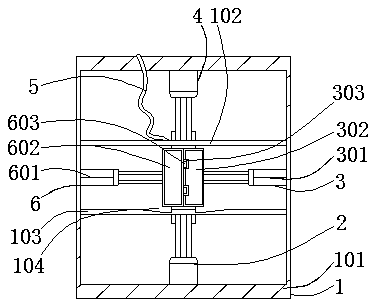

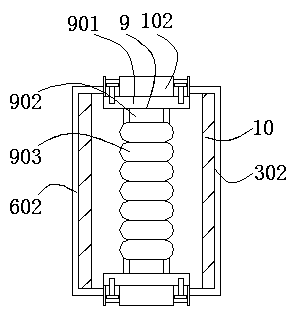

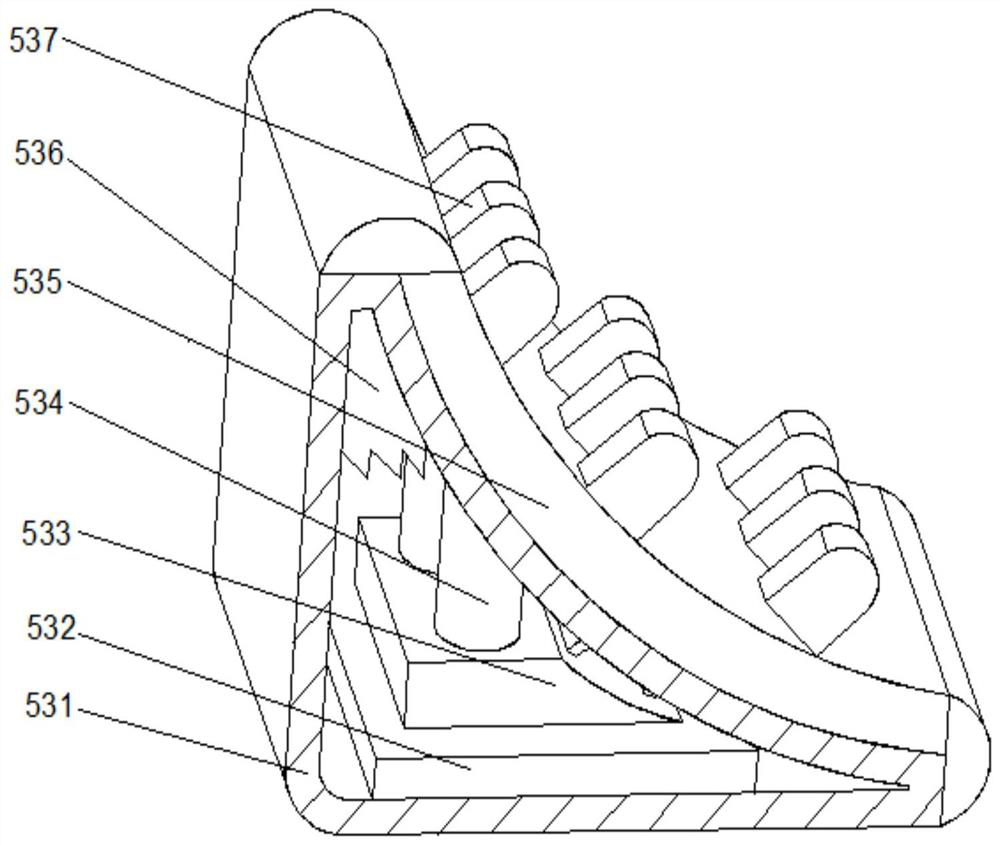

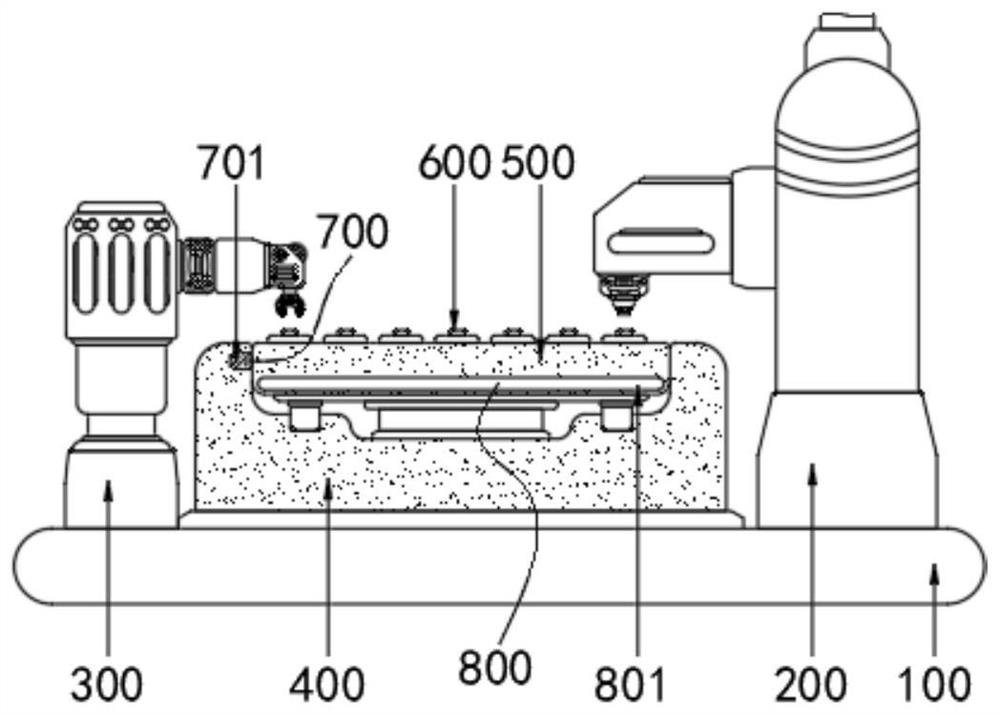

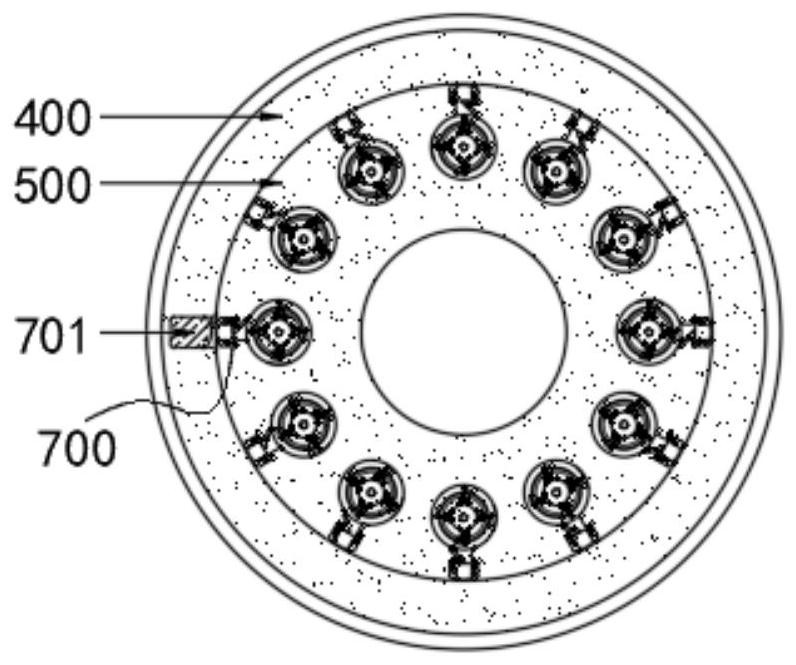

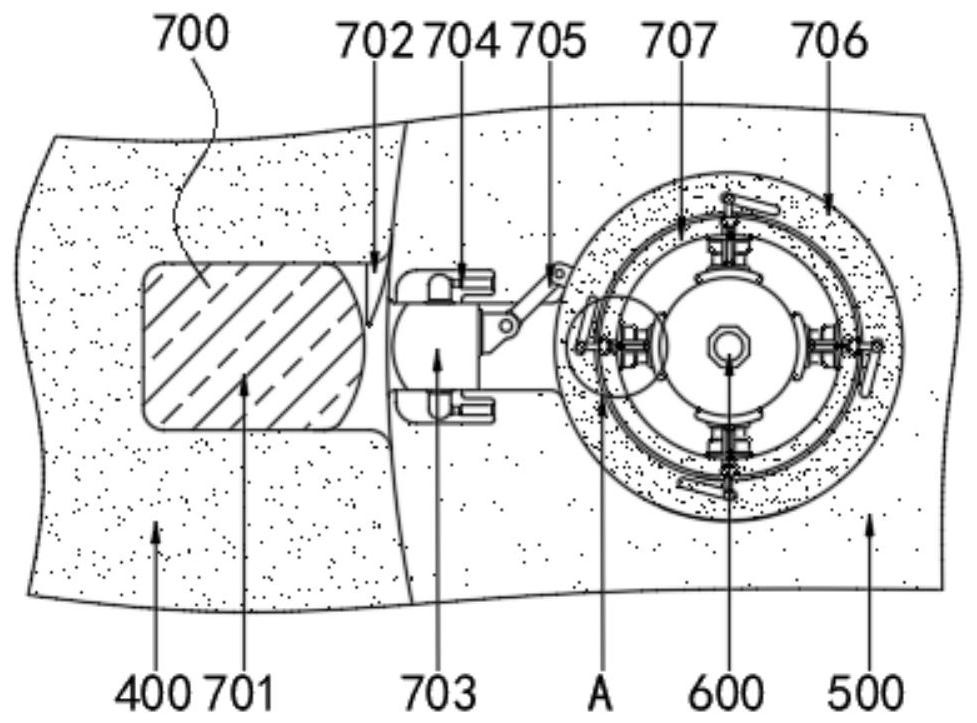

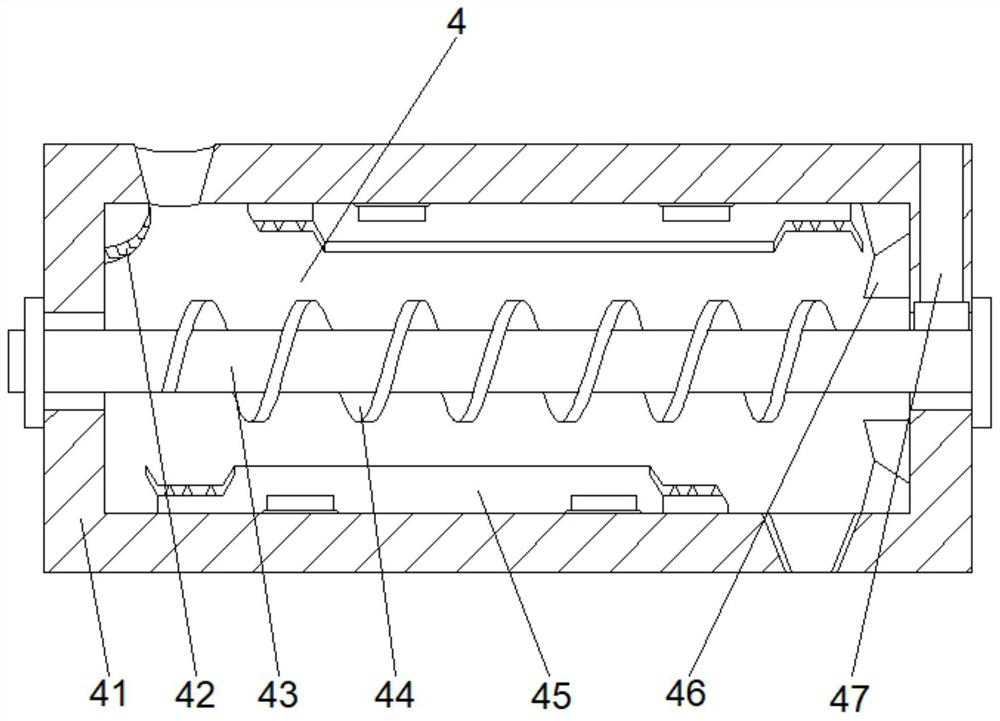

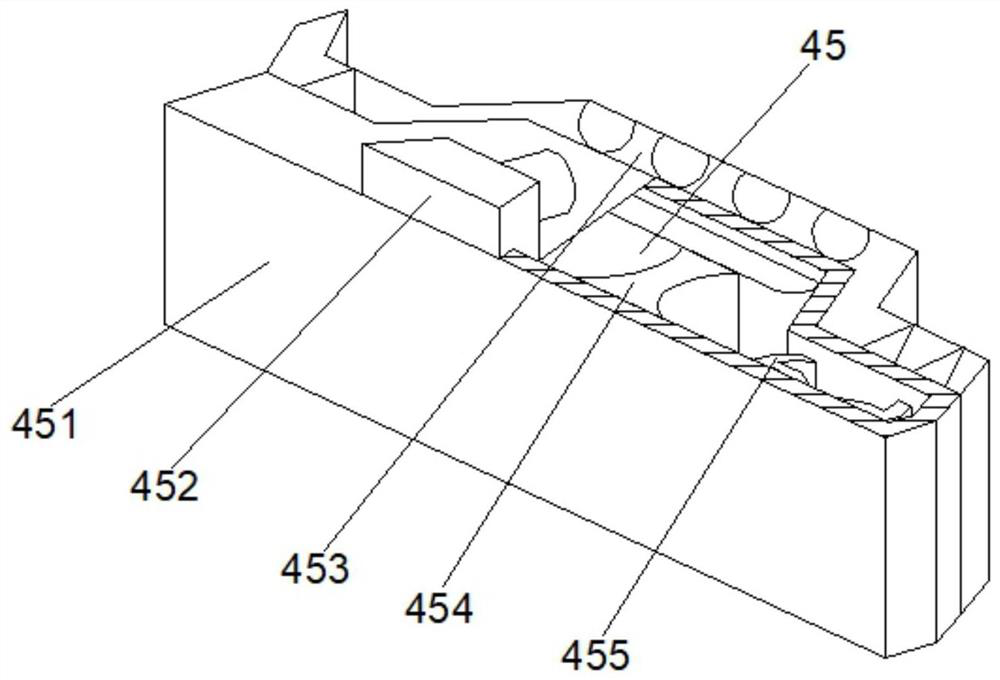

Rotary pouring machine for casting machining

ActiveCN112775419AStable clampingEasy to holdMould handling equipmentsMolten metal conveying equipmentsCircular discElectric machinery

The invention relates to the technical field of casting machining, and discloses a rotary casting machine for casting machining. The rotary casting machine for casting machining comprises a base, a liquid injection column, a mechanical arm, a box body, a rotary disc, a mold, a clamping assembly and a buffer assembly, wherein the top end of the base is fixedly connected with the liquid injection column; the box body is located on the left side of the liquid injection column and fixedly connected with the top end of the base; the top end of the inner wall of the box body is movably connected with the rotary disc; the top end of the inner wall of the rotary disc is movably connected with the mold; the inner wall of the rotary disc is movably connected with the buffer assembly; the left side of the rotary disc is movably connected with the clamping assembly; and a driving motor is arranged in the rotary disc and drives the rotary disc to rotate when running; Compared with traditional manual pouring, the rotary casting machine for casting machining is accurate during casting, the phenomenon that molten metal splashes is not prone to being generated, and the mold does not shake greatly in the initial rising stage, so that the phenomenon that the molten metal in the mold splashes is avoided.

Owner:临沂凯士彼机械有限公司

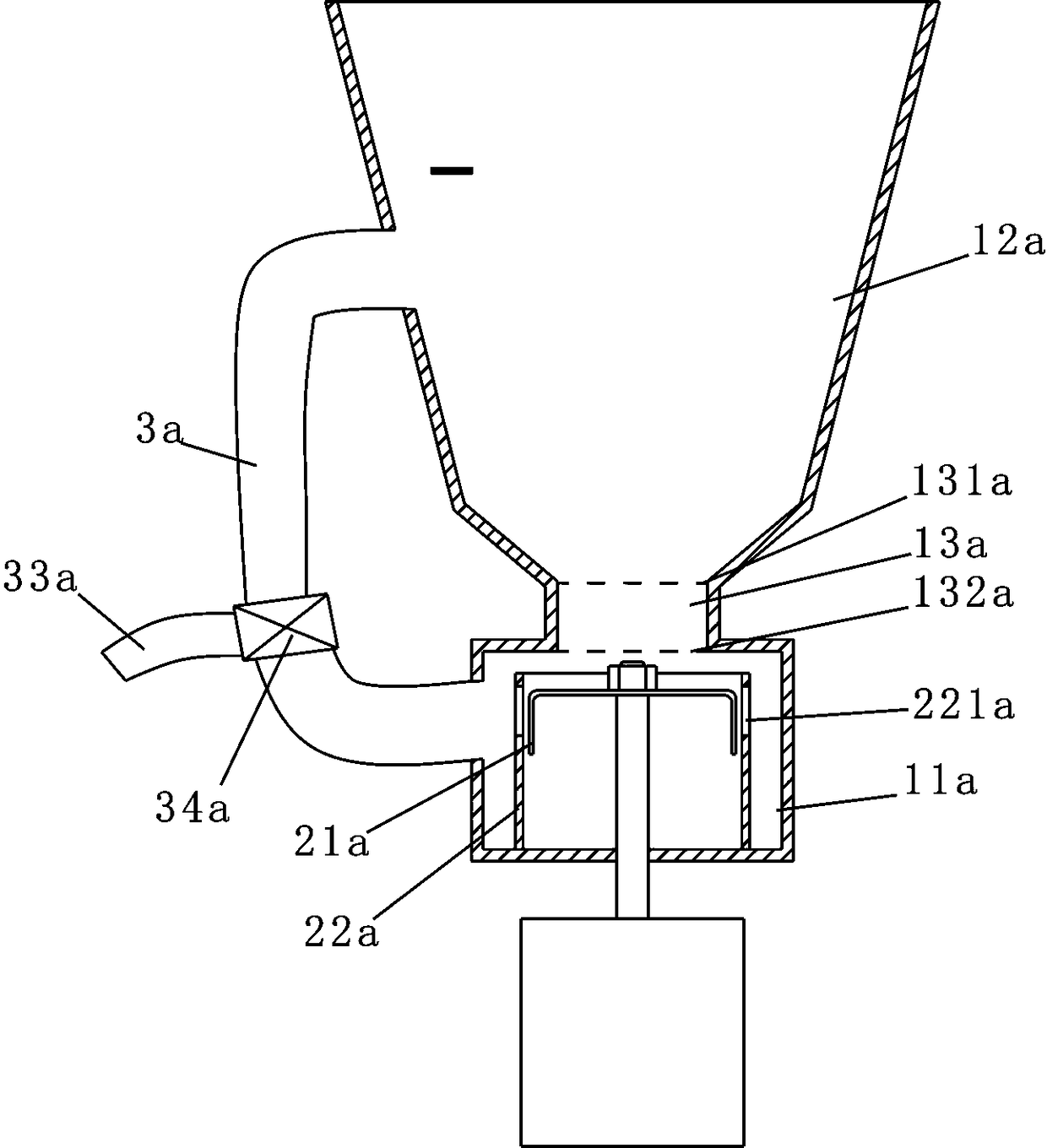

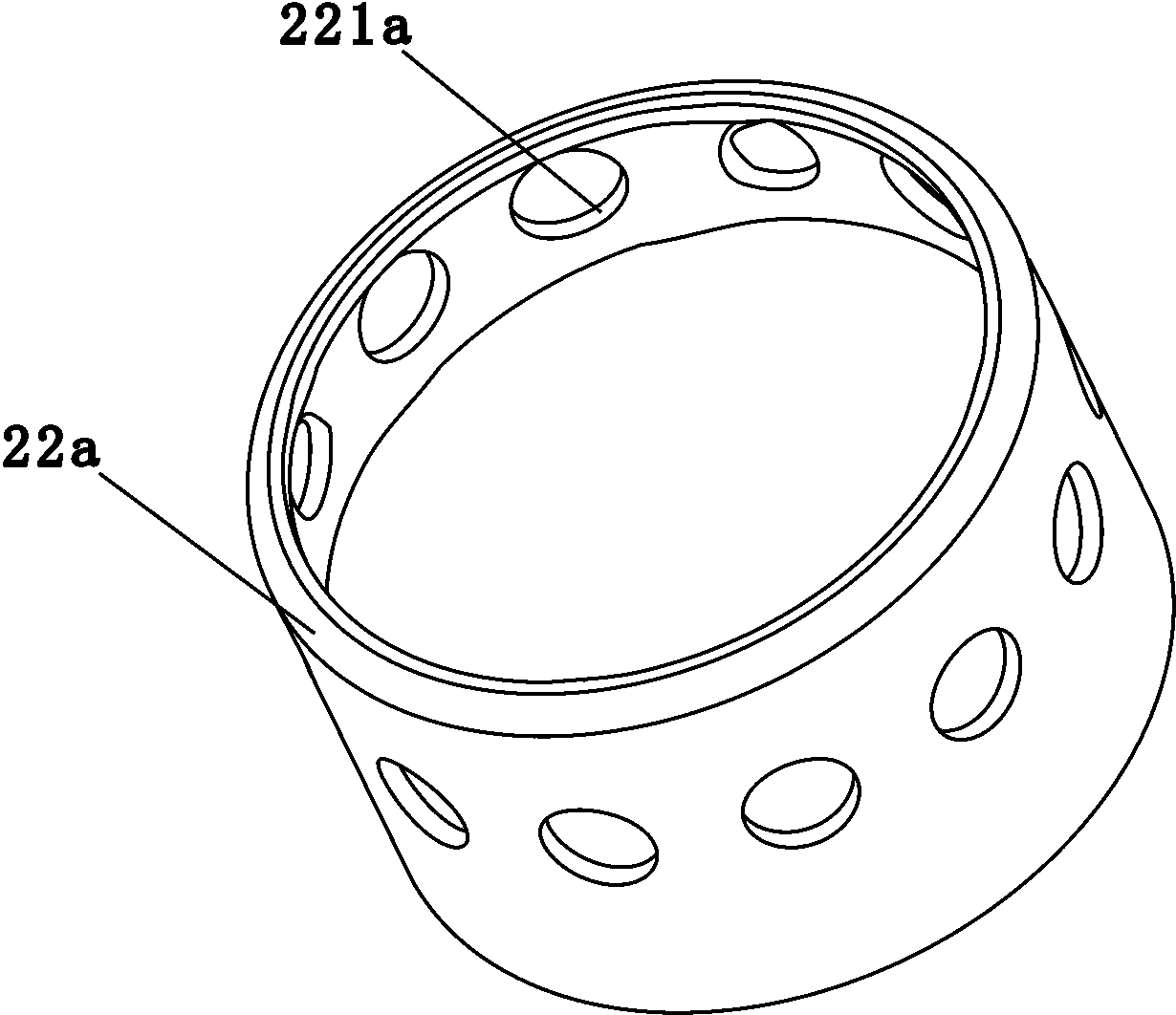

Food processing machine

ActiveCN108309086AImprove efficiencyThe surface of the slurry is smoothKitchen equipmentEngineeringMechanical engineering

The invention relates to a small household electrical appliance in a kitchen, especially a food processing machine. The food processing machine comprises a container and is characterized in that the container comprises a crushing chamber located at the bottom of the container, a backflow chamber arranged on the crushing chamber and a flow gathering opening used for communicating the crushing chamber with the backflow chamber; a crushing blade is arranged in the crushing chamber; the capacity of the crushing chamber ranges from 22 mL to 380 mL; the side wall of the backflow chamber is equippedwith a water level marking line; the outside located outside the container is equipped with a circulating pipeline connecting the crushing chamber with the backflow chamber; an inlet of the circulating pipeline is located in the crushing chamber; an outlet of the circulating pipeline is located in the backflow chamber and the outlet of the circulating pipeline is no higher than the water level marking line. Compared with the prior art, the food processing machine is simple in structure and relatively low in cost and capable of effectively reducing bubbles. Additionally, the machine can crush material in a concentrated manner at great crushing efficiency. No bulky material appears. Additionally, the machine is convenient to clean.

Owner:JOYOUNG CO LTD

Liquid anti-splashing spraying device for spring machining

ActiveCN110394271ANot prone to splashingAffect spraying work efficiencyLiquid surface applicatorsCoatingsMachiningEngineering

The invention discloses a liquid anti-splashing spraying device for spring machining, and relates to the technical field of spring machining. The device comprises a bearing mechanism and a second clamping mechanism. A first electric push rod is installed at the bottom end of the inner side of the bearing mechanism, a first clamping mechanism is arranged at one side of the middle of the inner wallof the bearing mechanism, the second clamping mechanism is arranged at the other side of the middle of the inner wall of the bearing mechanism, and a third electric push rod is installed at the top end inside the bearing mechanism. The liquid anti-splashing spraying device for spring machining has the beneficial effects that by arranging brush strips, a brush column and a connecting pipe, the brush strips are symmetric about the central axis of the brush column, after a spring is installed, an oil conveying pump is turned on, preservative oil is conveyed to the brush strips and the brush column along the connecting pipe, and due to the flexible effect of the brush strips and the brush column, the phenomena that when the inner and outer walls of the spring are sprayed, liquid collides withthe spring, and splashing is caused can be avoided.

Owner:济源市兴联实业有限公司

A spraying device for anti-splash of liquid used in spring processing

ActiveCN110394271BNot prone to splashingAffect spraying work efficiencyLiquid surface applicatorsCoatingsMechanical engineeringPhysics

The invention discloses a spraying device for spring processing and relates to the technical field of spring processing. The spraying device comprises a bearing mechanism and a second clamping mechanism, wherein a first electric push rod is installed on the bottom end of the inner side of the bearing mechanism; a first clamping mechanism is disposed on one side of the middle of the inner wall of the bearing mechanism; the second clamping mechanism is placed on the other side of the middle of the inner wall of the bearing mechanism; and a third electric push rod is installed on the top end inside the bearing mechanism. According to the invention, the spraying device for spring processing, which is used for preventing liquid splashing has the beneficial effects that brush bars, a brush pillar and a connecting pipe are disposed, the brush bars are symmetrical relative to the center axis of the brush pillar, and an oil conveying pump is started after spring installation, so that protectiveoil is conveyed along the connecting pipe to the brush bars and the brush pillar; and through flexible effects of the brush bars and the brush pillar, liquid collision on a spring and a splashing phenomenon caused thereby are not easily generated during a spraying operation of inner and outer walls of the spring respectively.

Owner:济源市兴联实业有限公司

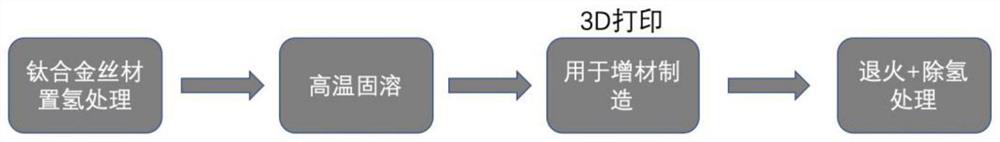

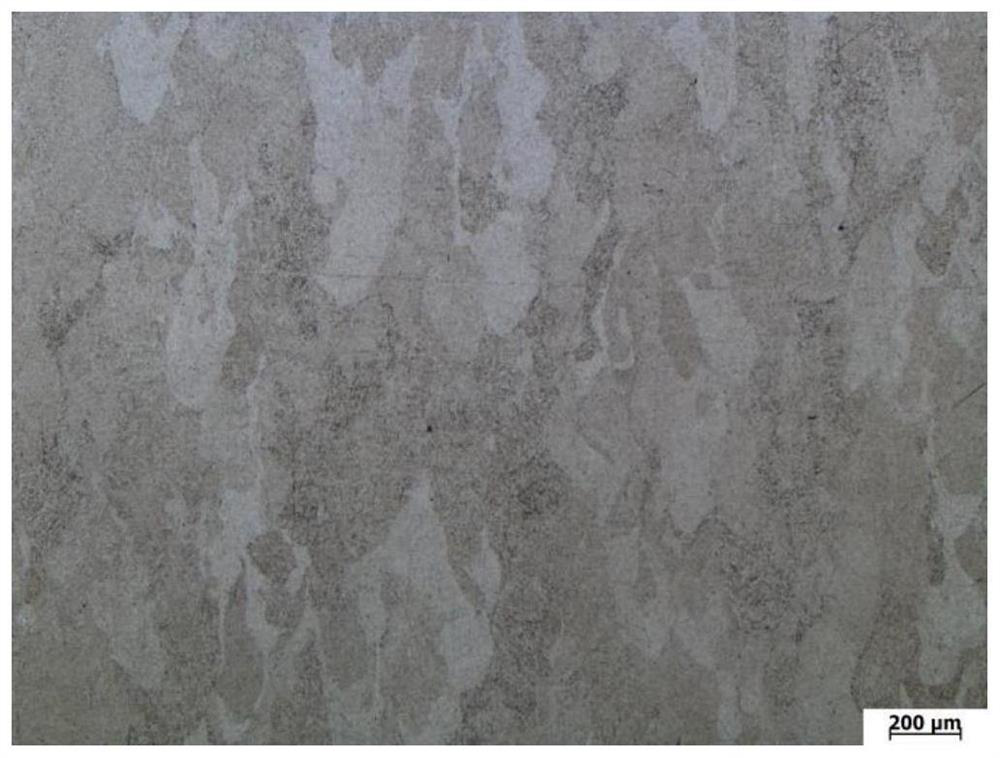

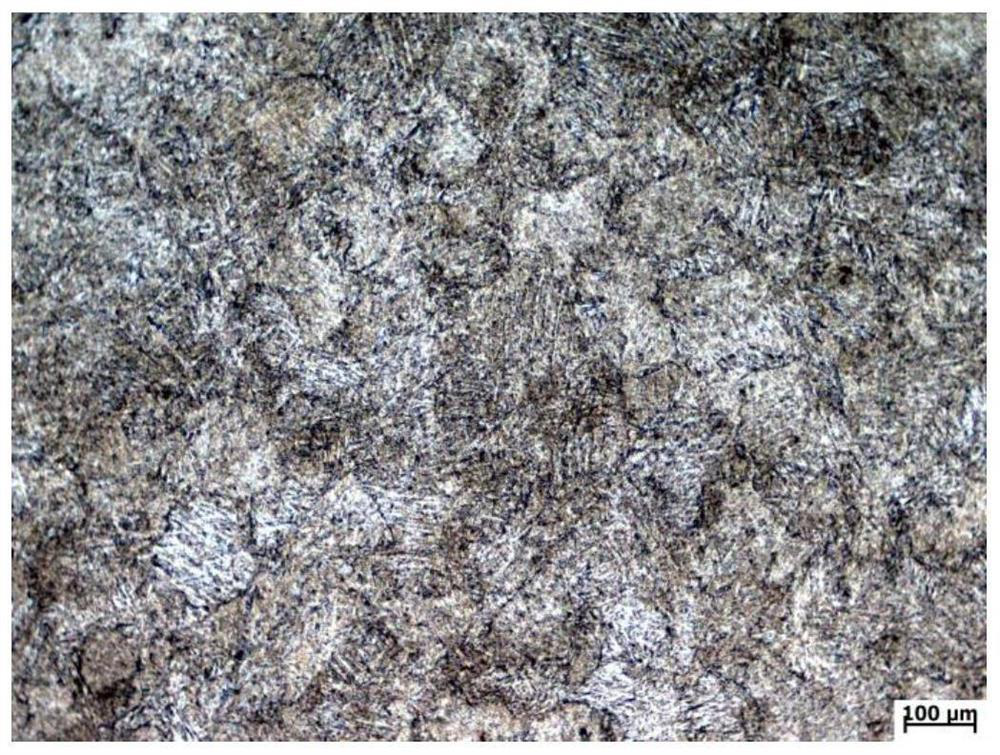

Process for improving titanium alloy wire additive manufacturing metallurgical structure

ActiveCN113430474AImprove organizationImprove performanceAdditive manufacturing apparatusFurnace typesSolution treatmentHydrogen treatment

The invention provides a process for improving a titanium alloy wire additive manufacturing metallurgical structure. The process comprises the following steps of carrying out hydrogenation treatment on a titanium alloy wire, namely introducing hydrogen in a certain percentage of the weight of the titanium alloy wire into a hydrogenation heat treatment furnace, keeping the temperature for a certain time, and cooling to room temperature to obtain a hydrogenation titanium alloy wire; carrying out high-temperature solid solution treatment on the titanium alloy wire subjected to hydrogenation; enabling the titanium alloy wire obtained after high-temperature solid solution treatment to be used for additive manufacturing, and obtaining a titanium alloy workpiece through printing of a wire feeding additive manufacturing process; and enabling the titanium alloy workpiece to be subjected to annealing and dehydrogenation treatment. According to the method, the front titanium alloy wire is subjected to hydrogenation treatment to obtain the hydrogenation titanium alloy wire, and the hydrogenation titanium alloy wire is subjected to solid solution treatment, so that shaping of the hydrogenation printing wire special for additive manufacturing is improved; and the titanium alloy wire obtained after solid solution is used for additive manufacturing to obtain the titanium alloy workpiece, and finally the manufactured titanium alloy workpiece is subjected to dehydrogenation heat treatment and annealing, so that the microscopic structure of the titanium alloy workpiece obtained through wire feeding additive manufacturing is refined and improved.

Owner:NANJING UNIV OF TECH

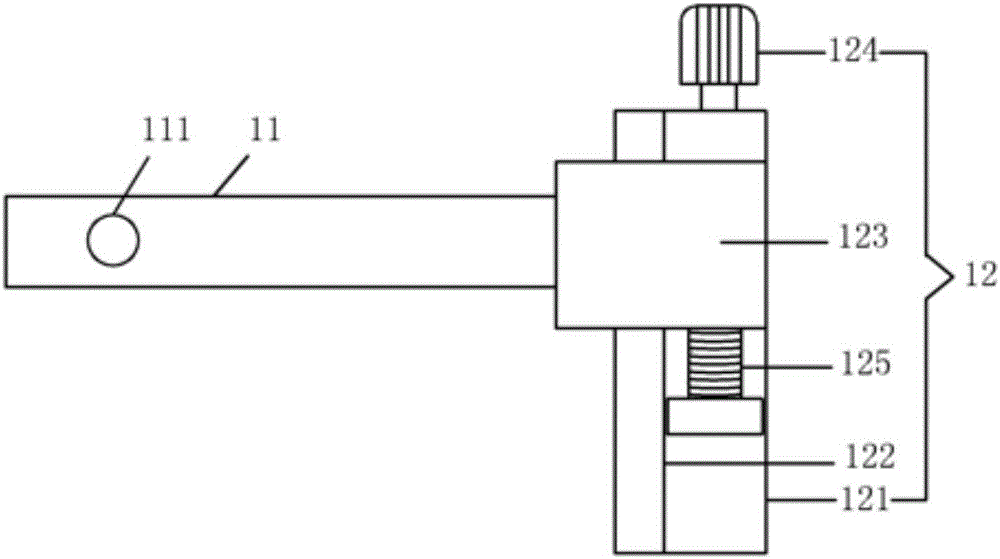

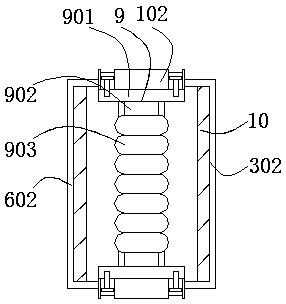

Auxiliary device for detecting permeation coefficient of finished products for concrete production

InactiveCN107860698AReduce wasteImprove stabilityPermeability/surface area analysisBall bearingThreaded pipe

The invention relates to the technical field of concrete water permeability detection accessory devices, in particular to an auxiliary device for detection of water permeability coefficient of finished products used in concrete production, which can reduce the waste of water resources and improve its environmental protection during water spraying treatment, and the lower collection box is opposite to the leakage. When the water is collected, the leaked liquid is not easy to splash, which improves its practicability; and the clamp can be easily adjusted according to the size of the finished concrete product, thereby improving its adaptability; including the top plate, bottom plate, left side plate, right side plate, Four sets of supports, two sets of rods, clamps and lower collection box; also includes an upper collection box, the upper cover is screwed on the upper collection port, and the upper liquid pipe is connected to the left side of the upper collection box; it also includes a support platform 1. Two sets of lower threaded tubes and two sets of lower threaded rods. There are lower placement grooves on the left and right sides of the top of the bottom plate, and lower ball bearings are arranged inside the two sets of lower placement grooves; the clamp includes a hoop body, two sets of Stoppers, bolts and nuts.

Owner:盐城市双强管桩有限公司

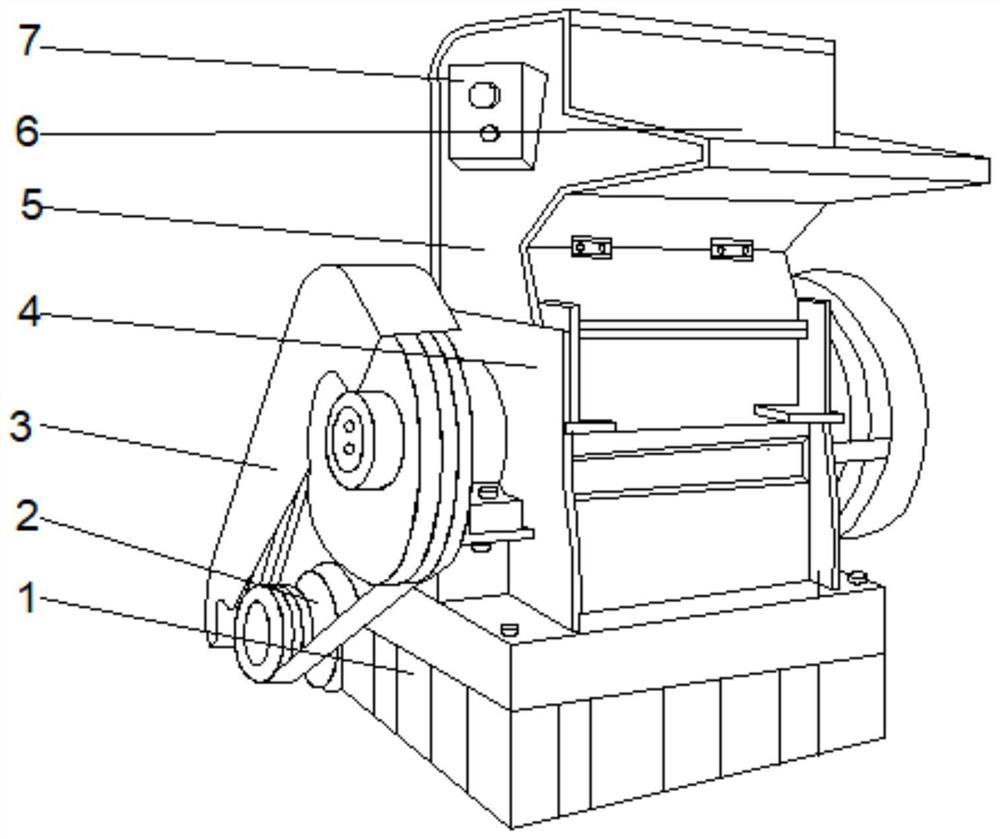

Building waste material crushing device

InactiveCN112808408ANot prone to splashingNot easy to damageUsing liquid separation agentGrain treatmentsElectric machineArchitectural engineering

The invention discloses a building waste material crushing device which comprises a base. Motors are fixedly connected to the two sides of the back face of the base. A protecting cover is arranged on the top of each motor. A device body is fixedly connected to the top of the base. A crushing device body is fixedly connected to the device body. A feeding opening is formed in the middle portion of the front face of the crushing device body. A controller is fixedly connected to the middle position of the top of the left side of the crushing device body. The invention relates to the technical field of building equipment. According to the building waste material crushing device, by arranging a breakage device, an auxiliary mechanism, an adjuster and a baffle, waste material parts obtained after smashing of the breakage device are collected with the help of the auxiliary mechanism, thus waste materials in the crushing process are not splashed easily, the device is convenient to fix in the crushing process, and the phenomenon of shaking does not occur easily. When the crushed waste materials fall off, the interior of the device is not damaged easily, appearing of dust is prevented, breakage and deformation of the surface due to long-time impact are avoided, and the service life of the device is further prolonged.

Owner:张旭亮

Pet cage convenient to disinfect

The invention discloses a pet cage convenient to disinfect. The pet cage comprises a pet cage body and a disinfecting device arranged on the pet cage body, wherein a bottom plate at the bottom of the pet cage body is of a closed structure, and a seal baffle is arranged on the portion, located on the bottom plate at the bottom of the pet cage body, of a rail of the pet cage body; the disinfecting device comprises a liquid storage tank and guide pipes, one end of each guide pipe is connected with the liquid storage tank, the other end of each guide pipe is hung in the pet cage body, and waterstop clamps are arranged on the guide pipes respectively. The pet cage is simple in structure, convenient to use and good in use effect, disinfection can be completed fast, and liquid is not prone to spattering.

Owner:SUZHOU NEW DISTRICT FENGQIAO PURIFICATION EQUIP FACTORY

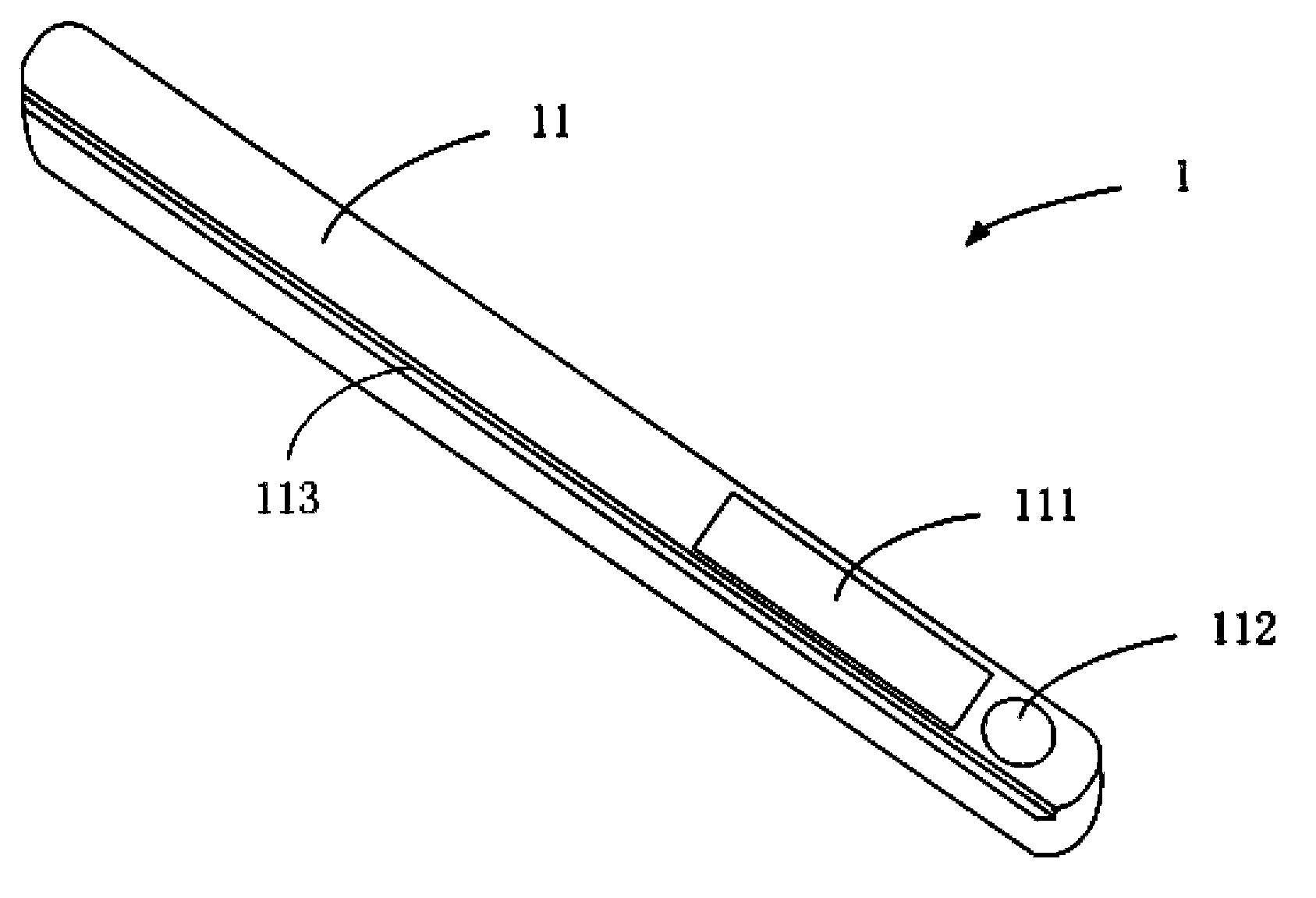

Novel lead-free tin soldering bar

InactiveCN103659036ALess slagImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaSlagSolderability

The invention provides a novel lead-free tin soldering bar which comprises a rectangular cylindrical body. A rectangular groove and a circular groove are formed in one side face of the rectangular cylindrical body. At least one of the longest edges of the rectangular cylindrical body is removed, so that an opening is formed. After the novel lead-free tin soldering bar is melted, slag-out amount is smaller than that of common soldering tin, good oxidation resistance is achieved, viscosity is low after melting, fluidity is good, solderability is high, environment is protected, the novel lead-free tin soldering bar is suitable for a wave soldering procedure, meanwhile, wettability, electric conductivity and thermal conductivity are good, tinning is easy, the inner stress of the tin soldering bar is released, stability is achieved during a soldering process, and the phenomenon of splashing cannot happen easily.

Owner:KUNSHAN SANHAN TIN

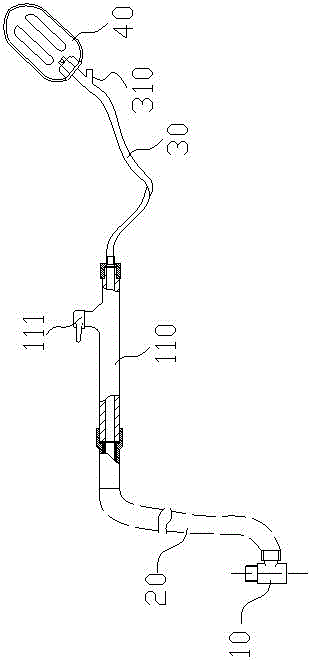

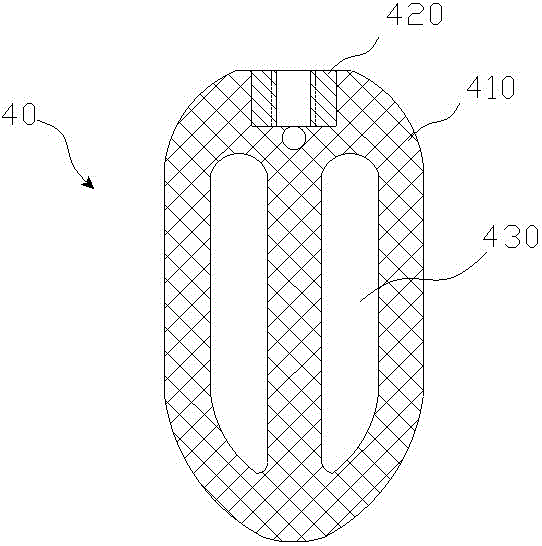

Pet cage with flushing device

InactiveCN105850757AEasy to rinseNot prone to splashingAnimal housingGrooming devicesWater storage tankEngineering

The invention discloses a pet cage with a flushing device, comprising a pet cage body, a water storage tank, a control water valve, a spray head and a waterproof cloth, the water storage tank is fixedly arranged on the top of the pet cage body, and the water storage tank is A water inlet pipe and an outlet pipe are provided, and a control water valve is arranged on the outlet pipe, and the outlet pipe is correspondingly connected to a nozzle, and the nozzle is arranged in a flat plate structure and is fixedly arranged on the top of the pet cage body. The waterproof cloth is rolled on the top edge of the pet cage body. The invention has a simple structure, is convenient for pets to wash, is not prone to liquid splashing, and has good use effect.

Owner:SUZHOU NEW DISTRICT FENGQIAO PURIFICATION EQUIP FACTORY

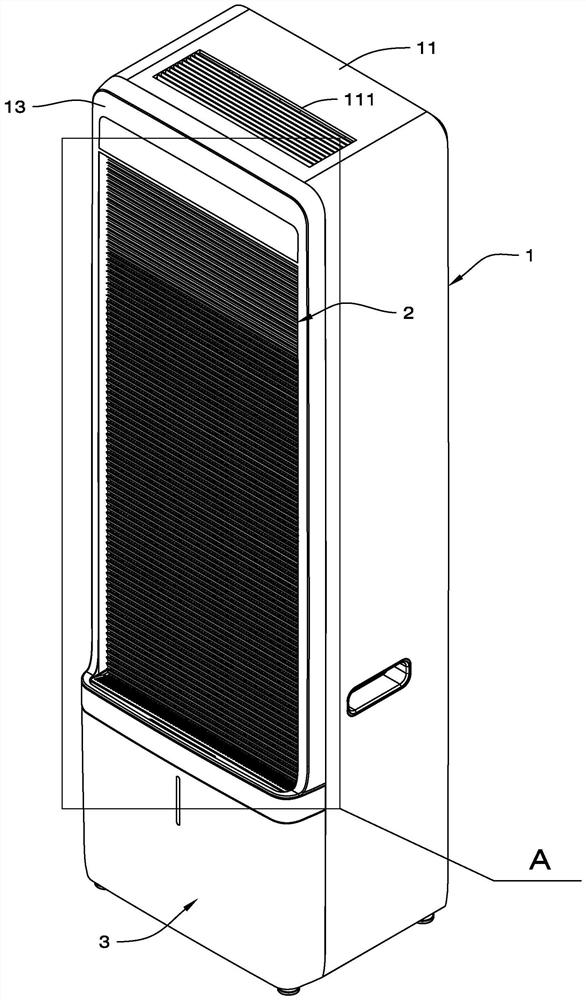

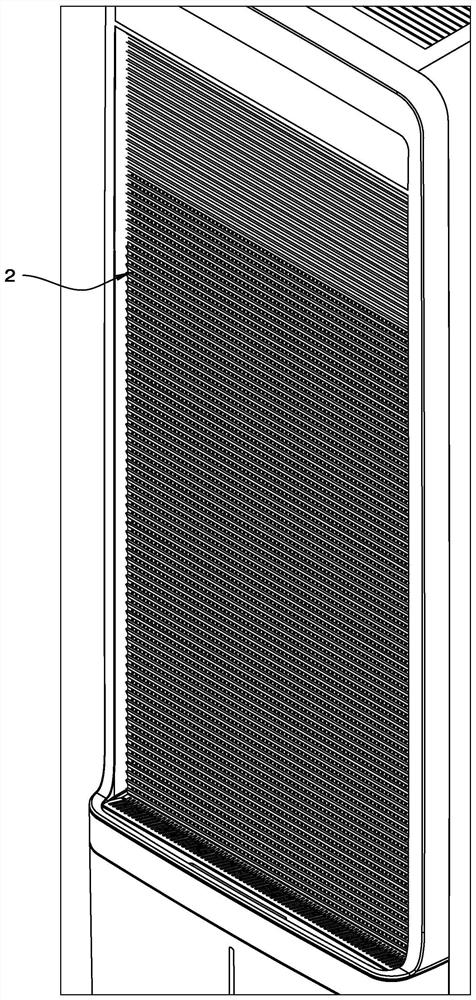

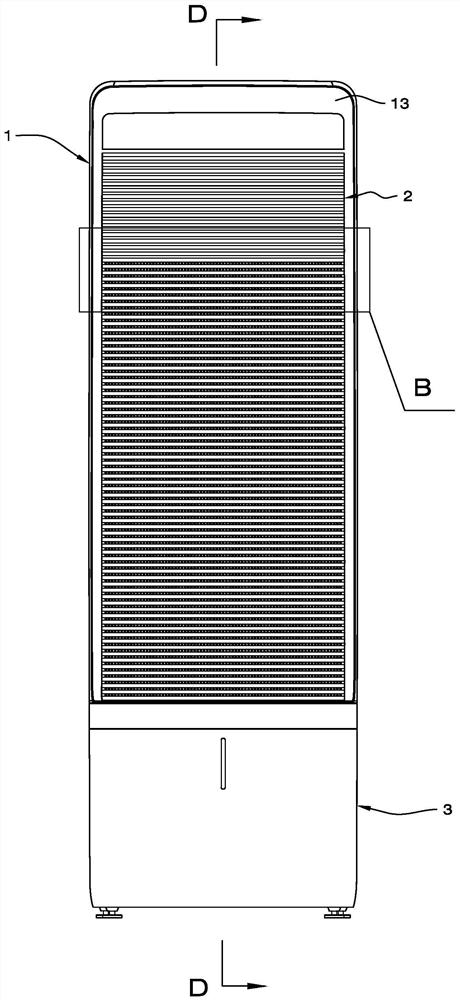

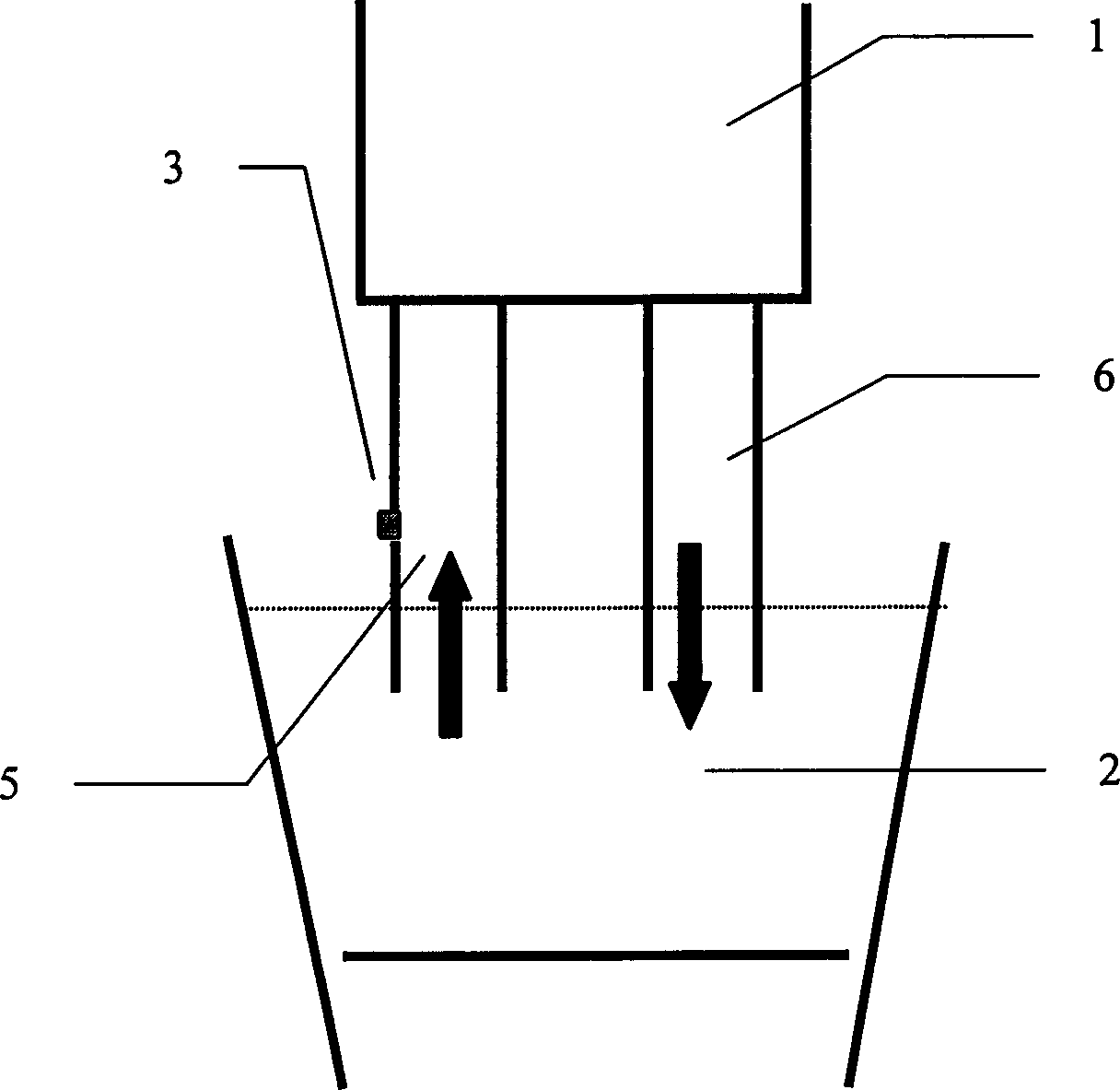

air cleaner

ActiveCN106885312BEasy to use and maintainNot prone to splashingCombination devicesMechanical apparatusAir cleaningEngineering

Owner:北京三利通电器有限公司

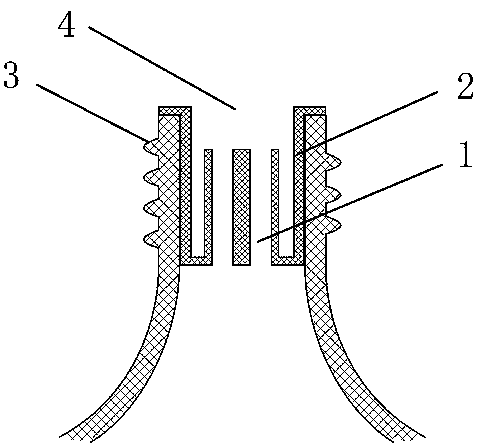

Vacuum deaeration refining process and equipment

The present invention provides one kind of vacuum deaeration refining process and equipment. Soaking pipes in the bottom of the vacuum chamber are inserted into molten steel inside the molten steel container, driving gas is introduced into the ascending soaking pipe and the molten steel flows from the molten steel container, through the ascending soaking pipe, the vacuum chamber and the descending soaking pipe before returning to the molten steel container circular. The present invention features that there is magnetic field generator installed outside at least one soaking pipe to produce electromagnetic force in the same direction to that of the circular molten steel and this results in increased circulating molten steel amount and high refining efficiency.

Owner:BAOSHAN IRON & STEEL CO LTD +1

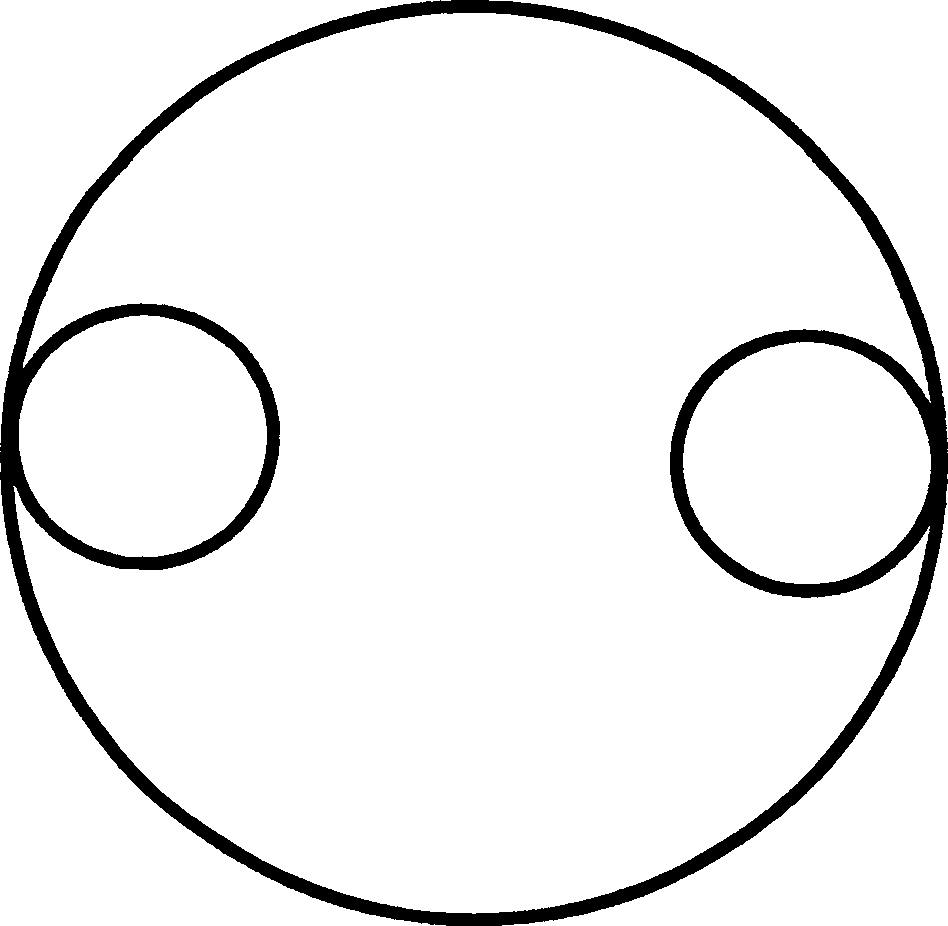

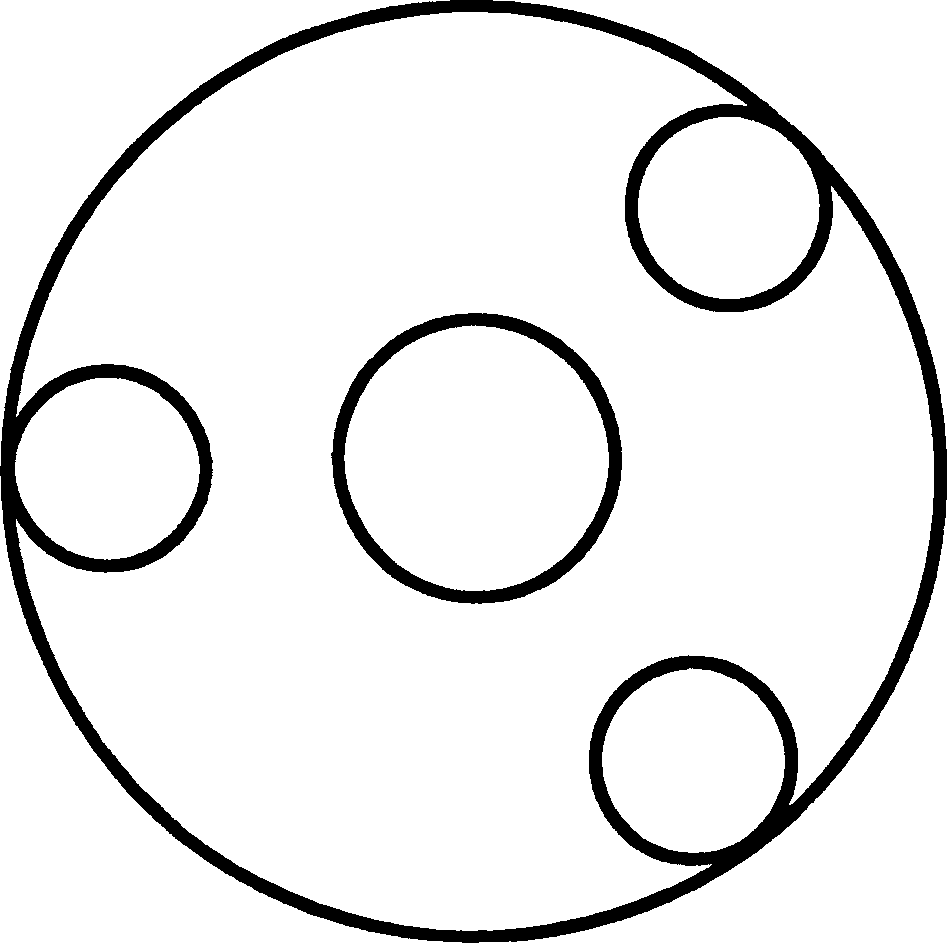

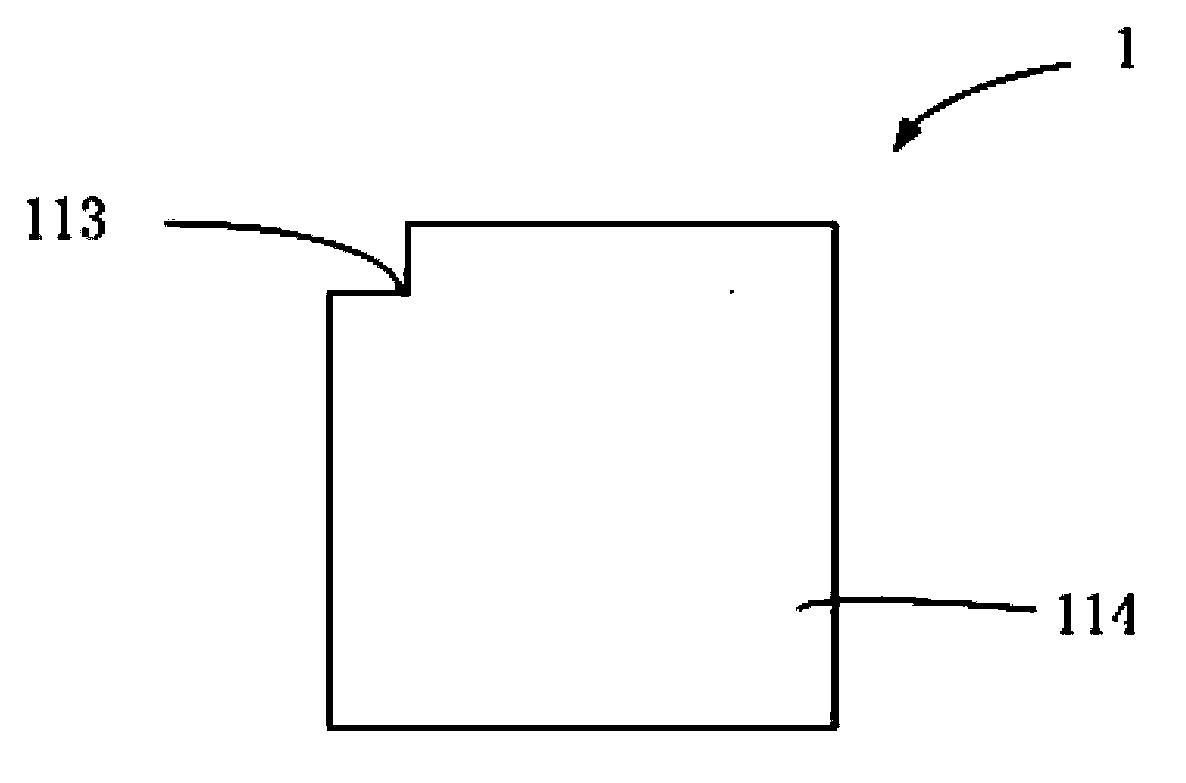

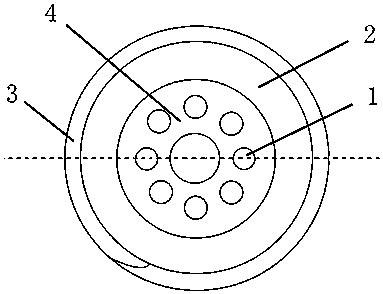

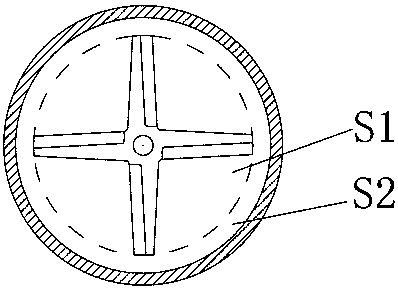

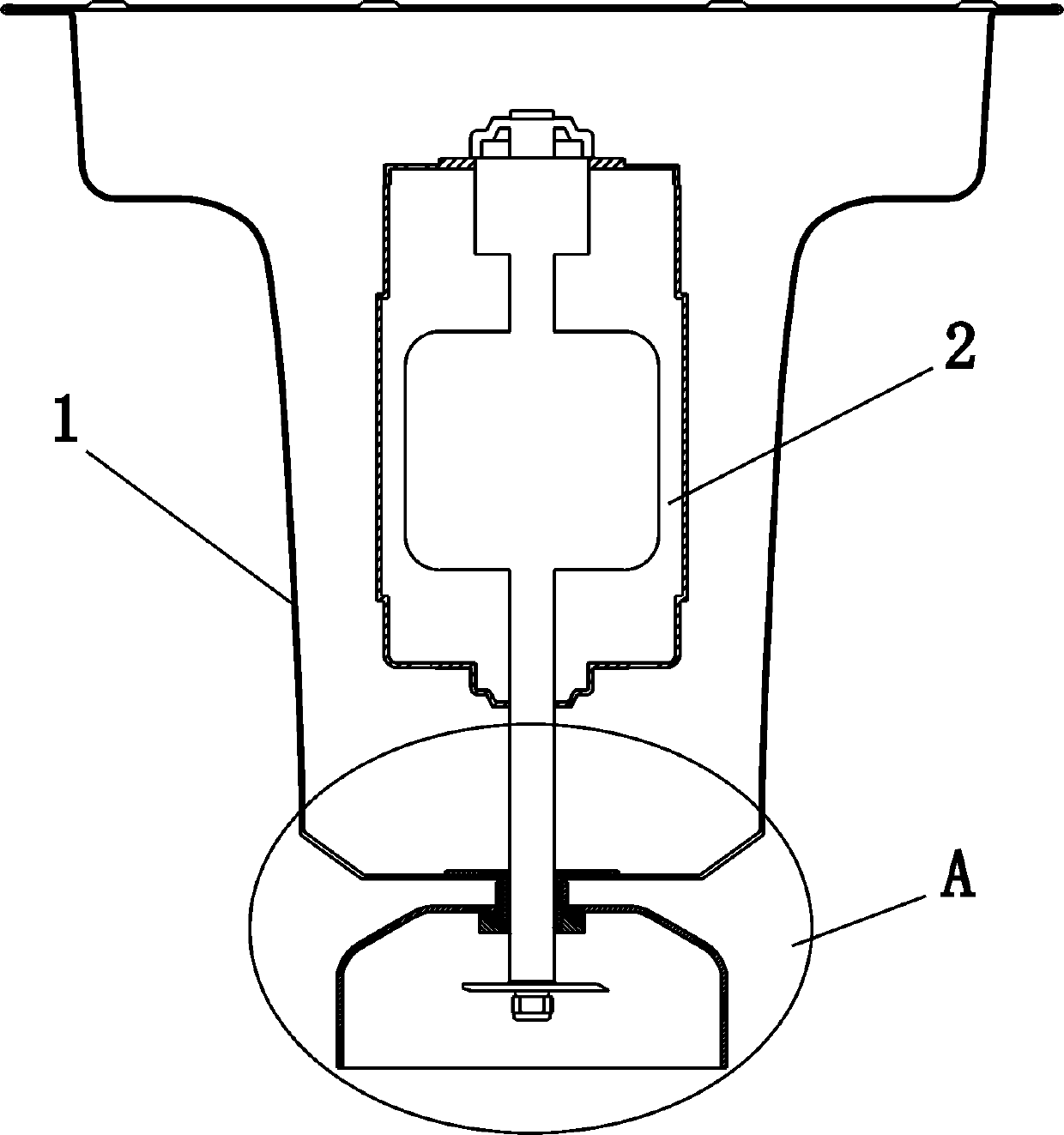

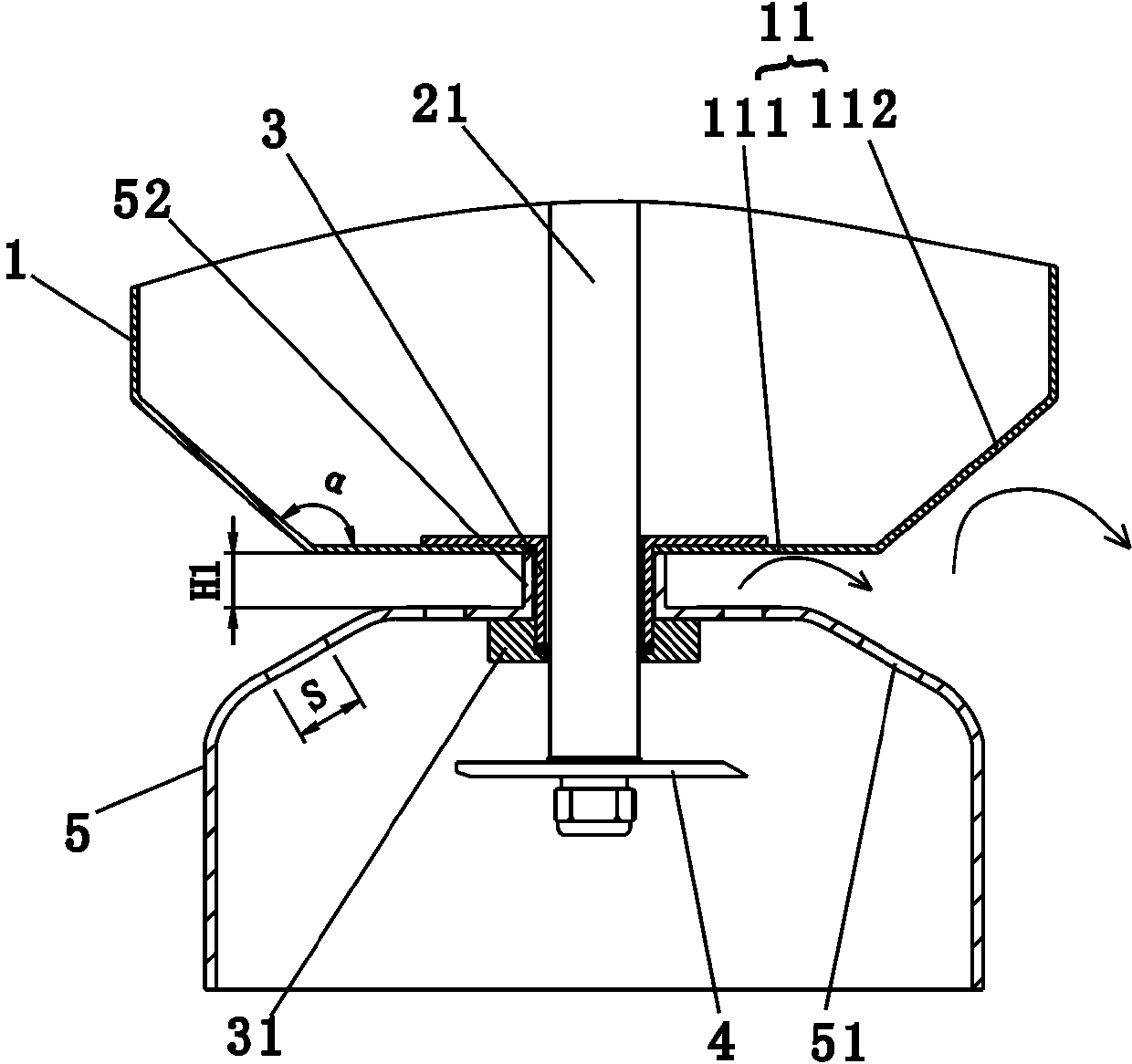

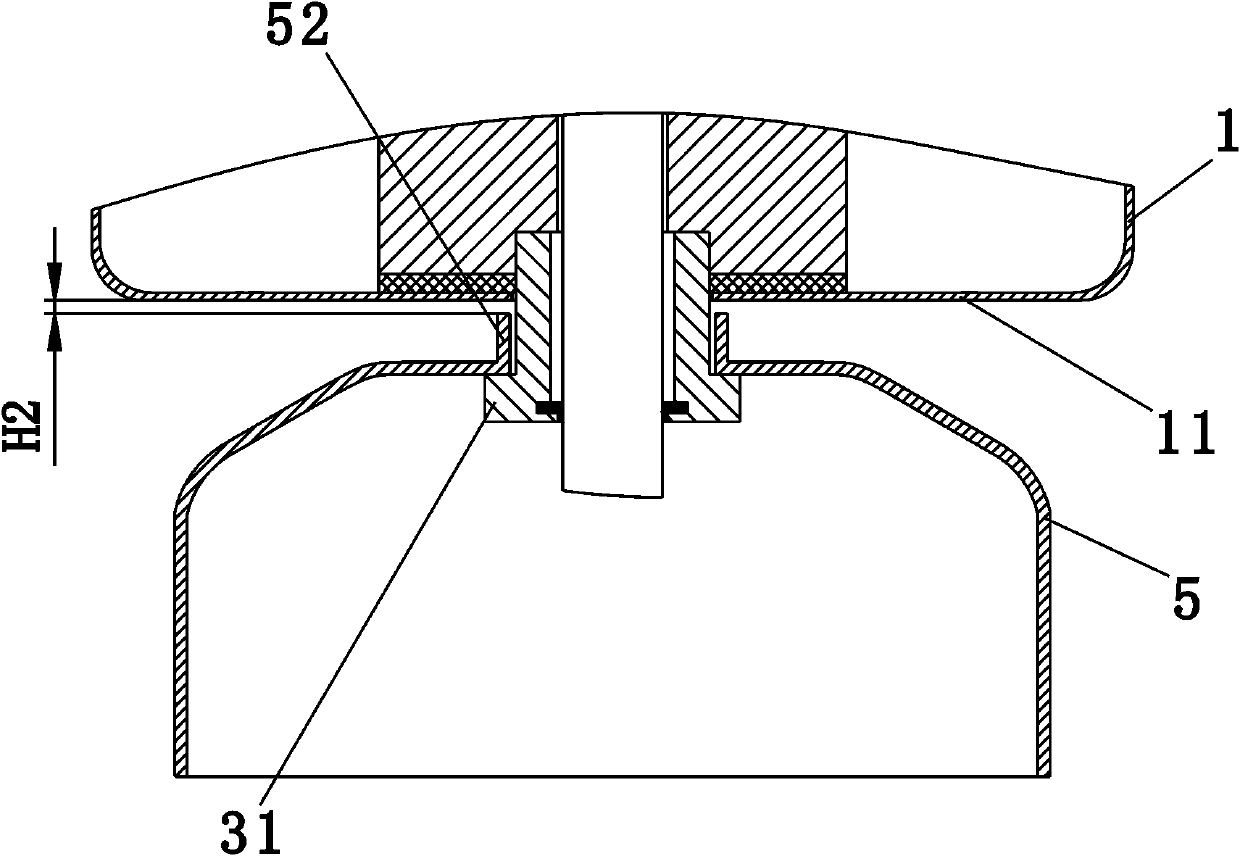

Container port capable of enabling the flow rate of liquid outlet to be uniform

The invention relates to a container port capable of enabling the flow rate of a liquid outlet to be uniform. The container port capable of enabling the flow rate of the liquid outlet to be uniform ismainly used for solving the problems of unstable flow rate of liquid at the outlet of a container, easy splashing and low pouring efficiency when the container with one port pours liquid. The container port is a multi-channel container port comprising a plurality of tubular channels (1) and channel supports (2). According to the container port capable of enabling the flow rate of the liquid outlet to be uniform, a container port structure with the tubular channels is designed, physical characteristics of the tubular channels are fully utilized, stable liquid channels and gas channels can be established in the process of pouring liquid, and the whole pouring process is uniform, stable and efficient. By adopting the container, when liquid is poured, the pouring posture of the container doesnot need to be carefully controlled, the flow rate at the liquid outlet is relatively uniform, different outlet flows can be designed, and rapid pouring can be realized.

Owner:王世焘

Novel vegetable washing basin

The invention discloses a novel vegetable washing basin which comprises a vegetable washing basin body and an inner basin body. The vegetable washing basin body is movably connected with the inner basin body. The top end of the inner basin body is connected with a water diversion pipe. The upper portion of the inner wall of the inner basin body is provided with a plurality of water outlet structures. The top end of the side wall of the vegetable washing basin body is provided with a movable buckle structure. The inner basin body and the vegetable washing basin body are in sealed connection through the buckle structure. The vegetable washing basin body is provided with a conical water outlet structure. The novel vegetable washing basin has the advantages that by means of the water diversion pipe and the water outlet structures on the inner basin body, high-pressure water flow in a tap water pipe can be transformed to small water flow, water splashing is not likely to be caused, cleanness and tidiness of the vegetable washing environment are ensured, and the novel vegetable washing basin is simple in structure, good in cleaning effect, convenient to assemble, disassemble and clean, convenient to replace and high in popularization value.

Owner:宋涛

Toilet

Owner:永春县产品质量检验所福建省香产品质量检验中心国家燃香类产品质量监督检验中心福建

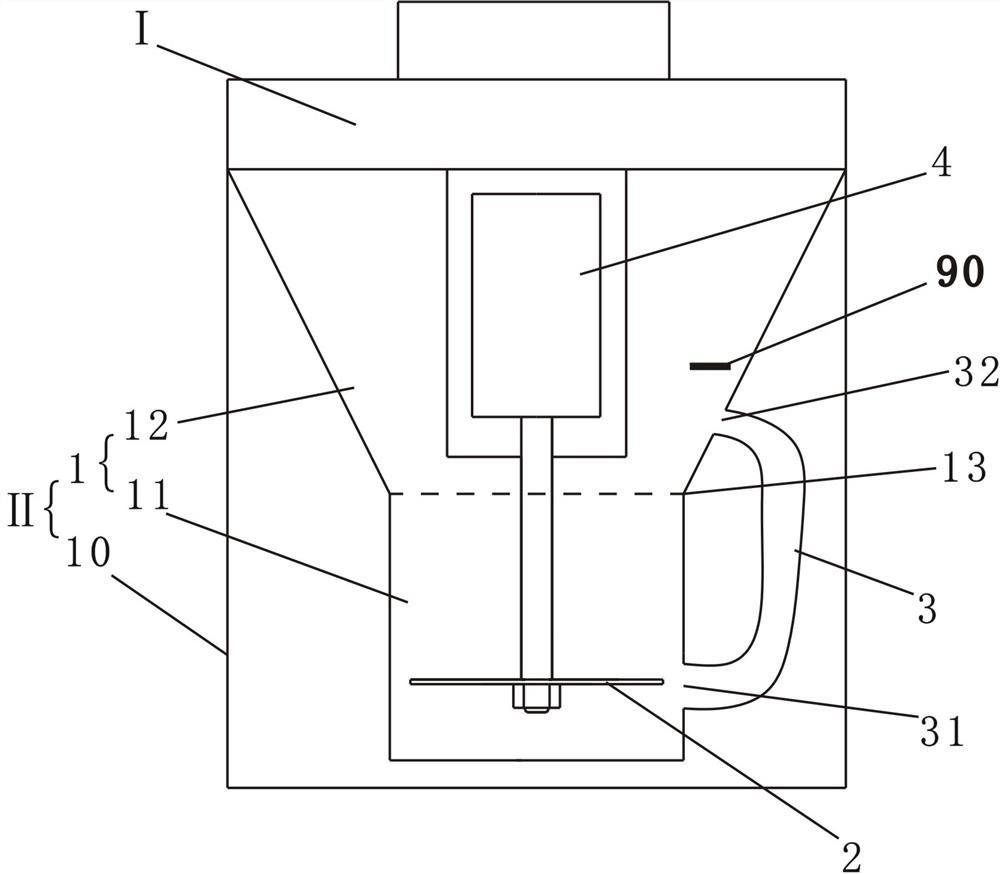

A rotary pouring machine for casting processing

ActiveCN112775419BStable clampingEasy to holdMould handling equipmentsMolten metal conveying equipmentsCircular discElectric machinery

The invention relates to the technical field of casting processing, and discloses a rotary pouring machine for casting processing, which includes a base, a liquid injection column, a mechanical arm, a box, a rotary disc, a mold, a clamping assembly and a buffer assembly. The top is fixedly connected with the liquid injection column, the box is located on the left side of the liquid injection column and is fixedly connected with the top of the base, the top of the inner wall of the box is movably connected with the rotary disc, and the top of the inner wall of the rotary disc is movably connected with the mould. The inner wall of the rotary disc is flexibly connected with the buffer assembly, the left side of the rotary disc is flexibly connected with the clamping component, and the rotary disc has a built-in drive motor, which rotates with the rotary disc when the drive motor is running; the casting processing Compared with traditional manual pouring, the rotary pouring machine is more accurate and less prone to splashing of molten metal during pouring. The mold will not shake a lot in the early stage of rising, so that the molten metal inside the mold will not produce splashing.

Owner:临沂凯士彼机械有限公司

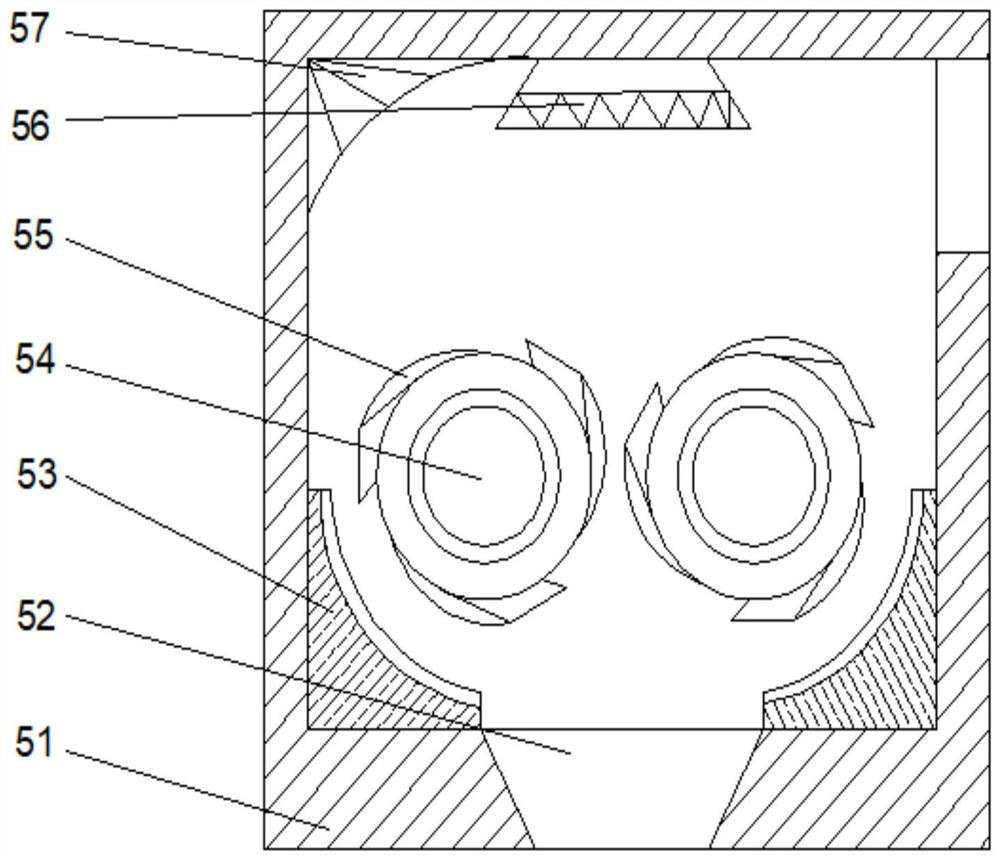

Food processing machine

ActiveCN108309085ALiquid level stabilityNot prone to splashingKitchen equipmentSlurryMechanical engineering

The invention relates to a kitchen small household appliance, in particular to a food processing machine. A crushing device for the food processing machine comprises a container, and is characterizedin that the container comprises a crushing cavity, a mixing cavity and a flow gathering opening; the crushing cavity is positioned at the bottom of the container; the mixing cavity is arranged above the crushing cavity; the flow gathering opening is used for communicating the crushing cavity and the mixing cavity; a crushing cutter blade is arranged in the crushing cavity; a downward pressing partfor driving the slurry to move towards the crushing cavity is arranged on the crushing cutter blade; the volume of the crushing cavity is 22 to 380 mL. The material can be concentrated in the small space crushing cavity; in addition, the crushing cutter blade is arranged in the crushing cavity, so that most materials can be concentrated in the crushing cavity to be crushed. Compared with the prior art, the kitchen small household appliance has the advantages that the structure is simple; the cost is low; in addition, the crushing device can be used for concentrated crushing on the materials;the crushing efficiency is high; the block formation phenomenon cannot occur; the cleaning is convenient.

Owner:JOYOUNG CO LTD

a food processor

ActiveCN108309086BNot easy to escapeHigh efficiency of centralized crushingKitchen equipmentThermodynamicsProcess engineering

Owner:JOYOUNG CO LTD

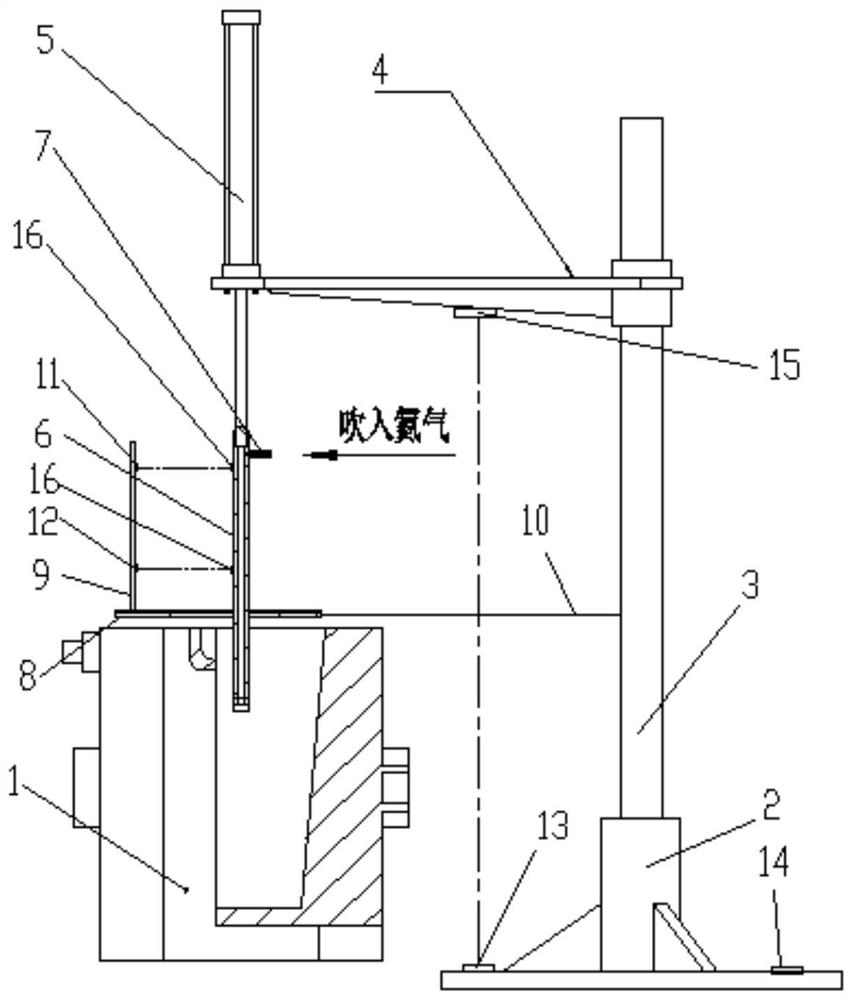

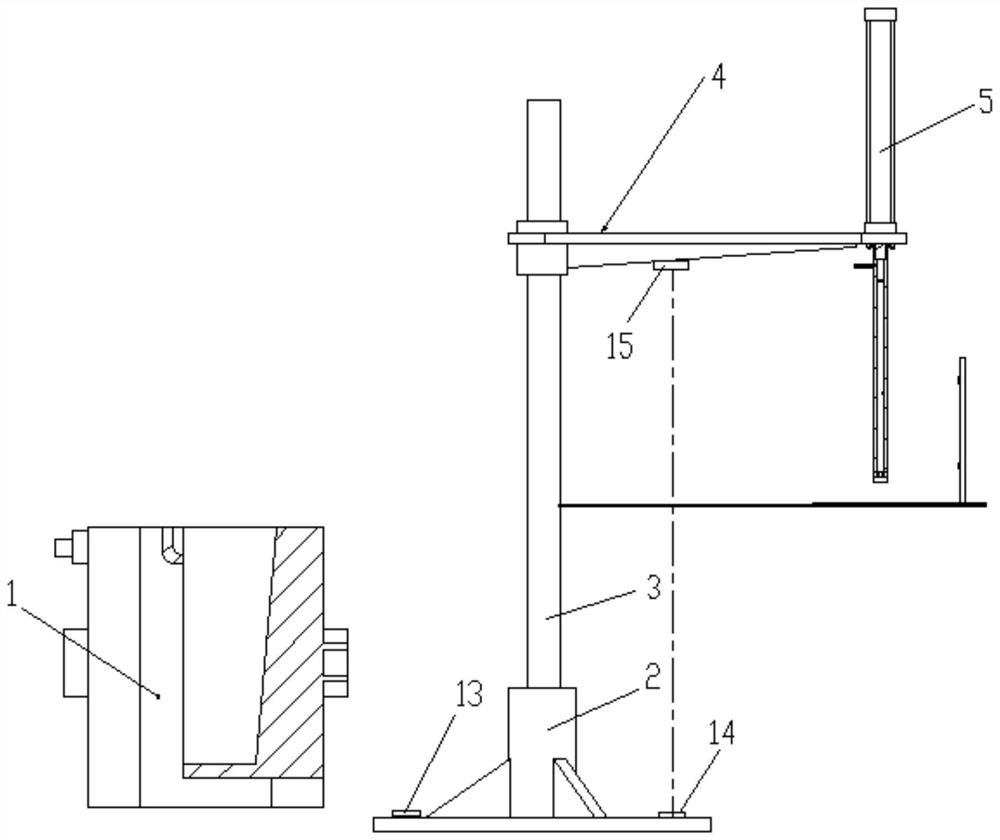

Device for obtaining nitrogen-containing alloy by blowing nitrogen into molten metal

The invention relates to a device for obtaining nitrogen-containing alloy by blowing nitrogen into molten metal. The device comprises a smelting furnace, wherein a supporting base is arranged on the outer side of the smelting furnace, and a stand column is arranged on the supporting base; a supporting arm is arranged on the stand column; an air cylinder is arranged at the front end of the supporting arm; a blowing rod is arranged at the front end of an air cylinder rod; an air inlet is formed in the blowing rod in the horizontal direction; a laser assembly is arranged on a transmitting rod; alight reflecting plate corresponding to the laser assembly is arranged on a measuring rod; a left laser assembly and a right laser assembly are arranged on the supporting base; and a light reflectingplate is arranged on the supporting arm. According to the device for obtaining the nitrogen-containing alloy by blowing nitrogen into the molten metal, the cost is low, the increment of nitrogen elements is linear and stable, the operation is simple and safe, and splashing is not prone to occur; and when chromium nitride is commonly used for increasing nitrogen, due to the burning loss, the amountof the added chromium nitride is not easy to control, and the melting time is prolonged due to multiple times of addition, so that other elements are burnt, and damage or accidents are caused due tothe fact that splashing is prone to occur.

Owner:莱州润昇石油设备有限公司

A pouring device for an engine main bearing cap

ActiveCN106735139BReduce labor intensitySimple structureMolten metal conveying equipmentsEngineeringUltimate tensile strength

Owner:SHIFANG YONGSEN MACHINERY

a soybean milk machine

The invention relates to the small kitchen household electrical appliances, and specifically refers to a soya-bean milk machine comprising a machine head and a machine body; the machine head comprises a machine head upper cover and a machine head lower cover; a motor is arranged in the machine head lower cover; the bottom of the machine head lower cover is provided with a connector extending downwards; the end of a motor shaft is provided with a crushing blade; a diversion cover is arranged below the connector; the crushing blade is arranged in the diversion cover; a diversion hole is arranged on the diversion cover above the crushing blade; the motor shaft drives the crushing blade to rotate so as to pump liquid, and the liquid sprays outside the diversion cover through the diversion hole in the diversion cover; a flow-disturbing surface used for reflecting the liquid is arranged above the diversion hole and on the bottom of the machine head lower cover; in vertical projection from bottom to top, at least partial the diversion hole is above the flow-disturbing surface. In pulping, the soya-bean milk machine can accelerate liquid flow cycle efficiency, and can improve crushing effect; in addition, splash phenomenon hardly happen in making drinks, thus ensuring consumer safety.

Owner:HONGYANG HOME APPLIANCES

Stirring device for food processing

InactiveCN113663548AAvoid situations that are difficult to clean upQuality improvementRotary stirring mixersMixer accessoriesOff-flavourElectric machinery

The invention discloses a stirring device for food processing, which comprises a base, wherein supporting seats are fixedly connected to the two sides of the bottom of the base, a stirring device is fixedly connected to the middle of the right side of the top of the base, a feeding port is formed in the left side of the top of the stirring device, a motor is fixedly connected to the right side of the top of the back surface of the stirring device, and a discharging port is formed in the middle of the right side of the bottom of the base. The invention relates to the technical field of food processing.' According to the stirring device for food processing, the situation that part of materials adhere to gaps in the stirring process and are not easy to clean is avoided, the quality of the materials is improved, a protection block can protect the corners, the stirred materials are conveniently collected, a blocking mechanism is smooth, the materials are not prone to adhering, internal residues can be reduced, the working quality is improved, peculiar smell caused by long-time use of the device is avoided, good protection is achieved, and the stirring time is saved.

Owner:刘光耀

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com