Novel lead-free tin soldering bar

A lead-free tin and electrode technology, applied in welding media, welding equipment, welding/cutting media/materials, etc., can solve problems such as affecting welding quality, spatter, and short circuit between solder joints and solder joints, and achieves low spatter and good heat. The effect of high conductivity and solderability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

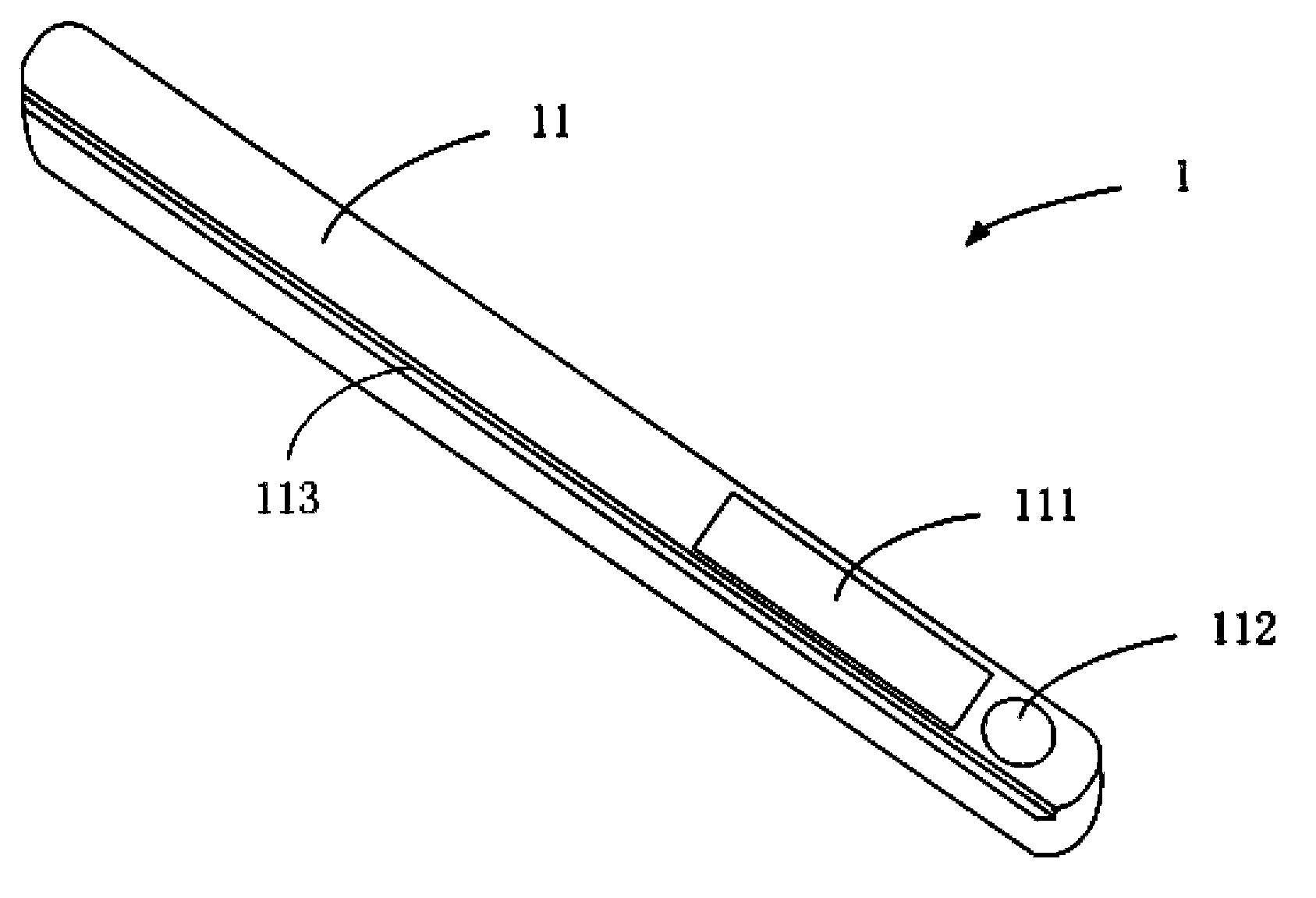

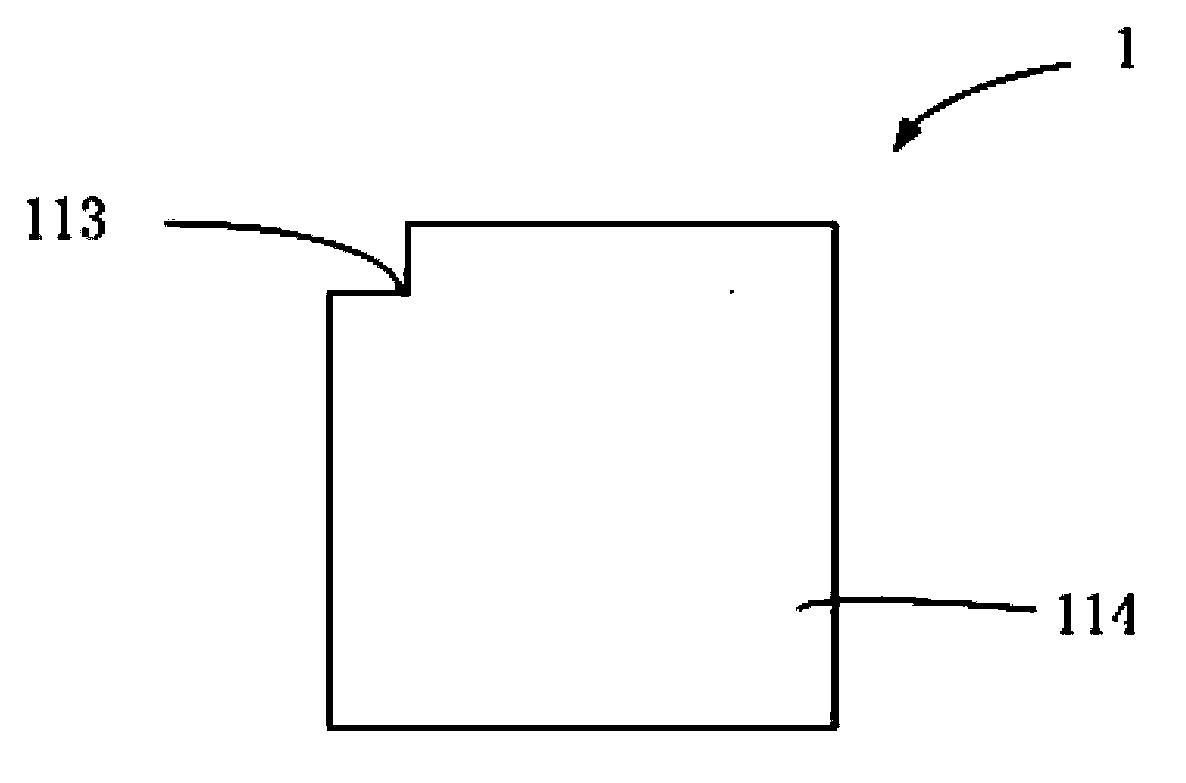

[0013] Please refer to figure 1 , the new lead-free soldering rod 1 provided in this embodiment includes a rectangular column-shaped main body, one of the surfaces of the rectangular column main body includes a rectangular groove 111 and a circular groove 112, the rectangular At least one of the longest edges of the cylindrical body 11 is removed to form the opening 113 . The novel lead-free solder bar 1 of the present embodiment is preferably a wave solder bar, and the wave solder bar can be divided into a lead solder bar and a lead-free solder bar, and the novel lead-free solder bar 1 of the present embodiment does not contain lead and belongs to lead-free The composition of the solder bar can further be tin-copper (Sn-0.7Cu), tin-silver-copper (Sn-0.3Ag-0.5Cu) or tin-silver-copper (Sn-3.0Ag-0.5Cu). In this embodiment, since one of the longest edges of the rectangular columnar main body 11 is removed to form the opening 113, the stress of the new lead-free tin soldering rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com