Process of efficiently recovering copper from lead matte according to oxygen pressure acid leaching and vortex electrolysis techniques

A technology of swirl electrolysis and oxygen pressure acid leaching, which is applied in the direction of photography technology, photography auxiliary technology, process efficiency improvement, etc., can solve the problems of affecting the purity of cathode copper, long production cycle, low leaching rate, etc., and achieve the reduction of black copper plate and the amount of black copper slag, the leaching rate is increased, and the effect of increasing income

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

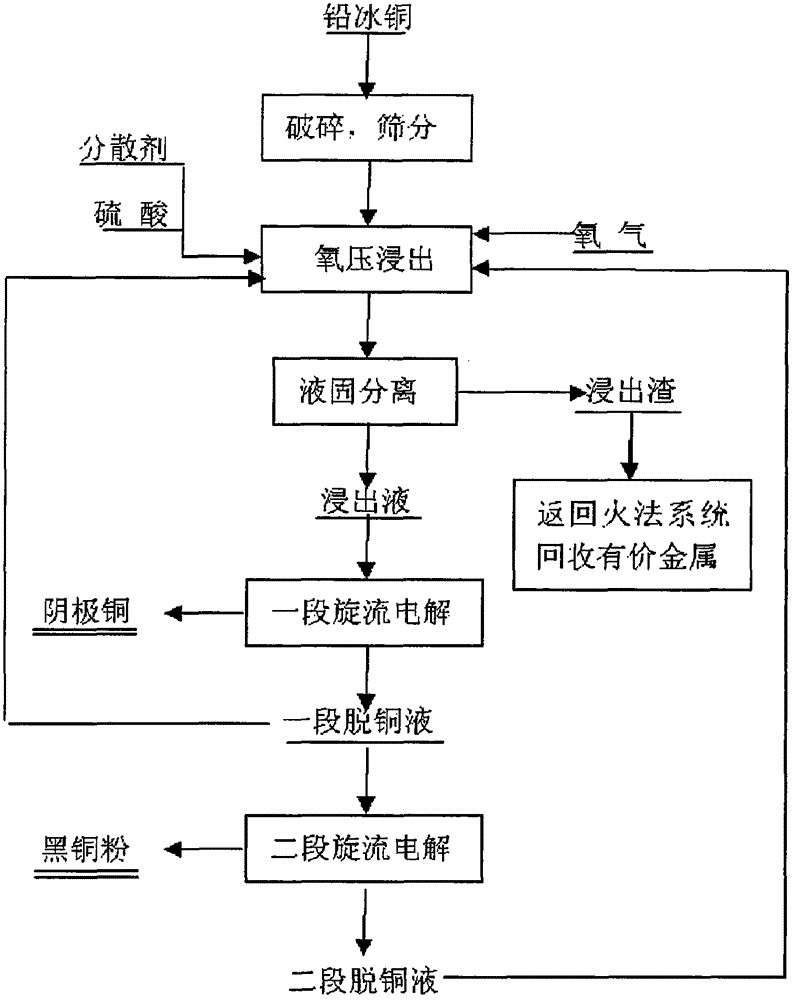

Method used

Image

Examples

Embodiment 1

[0031] Lead matte (Cu: 34.68% Fe: 18.52% S: 16.59% Pb: 17.26% As: 0.9428% Ag: 0.1835%) is crushed, ground, after passing through a 100-mesh sieve, take 1000g of powder and dilute sulfuric acid and 20g Add the dispersant to the autoclave after slurry preparation, control the oxygen pressure of the autoclave to 1.4MPa, the liquid-solid ratio to 4:1mL / g, the concentration of sulfuric acid to 200g / L, the temperature to 150°C, and the stirring speed to 700r / min. The time is 2 hours. After the leaching reaction is completed, the pulp is extracted from the autoclave, filtered, and the filter residue is returned to the pyro-method lead smelting system to recover valuable metals such as lead and silver. Take 5L of the filtrate and add it to the cyclone electrolysis system, control the current intensity to 20A, and the current density to 500A / m 2 , the temperature is room temperature, the electrolyte flow rate is 500L / h, and the electrolysis time is 2h. After electrolysis, the cathode ...

Embodiment 2

[0033] Lead matte (Cu: 32.59% Fe: 21.79% S: 14.95% Pb: 19.96% As: 1.354% Ag: 0.2235%) is crushed, ground, after passing through a 180 mesh sieve, take 1000g of powder and dilute sulfuric acid and 20g Add the dispersant to the autoclave after slurry preparation, control the oxygen pressure of the autoclave to 1.2MPa, the liquid-solid ratio to 5:1mL / g, the concentration of sulfuric acid to 210g / L, the temperature to 150°C, and the stirring speed to 600r / min. The time is 2.5 hours. After the leaching reaction is completed, the ore pulp is extracted from the autoclave, filtered, and the filter residue is returned to the pyro-method lead smelting system to recover valuable metals such as lead and silver. Take 5L of the filtrate and add it to the cyclone electrolysis system, control the current intensity to 20A, and the current density to 500A / m 2 , the temperature is room temperature, the electrolyte flow rate is 600L / h, and the electrolysis time is 2h. After electrolysis, the cat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com