Method for linked preparation of sodium aluminate and production of silica-based material by means of high-alumina fly ash low-temperature liquid-phase alkali dissolving

A high-alumina fly ash, low-temperature liquid phase technology, applied in the preparation of alkali metal aluminate/alumina/aluminum hydroxide, silicon oxide, silicon dioxide, etc., can solve the problems of high energy consumption, complicated operation, etc. Achieve the effect of high added value of products, fewer operation steps and less slag amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

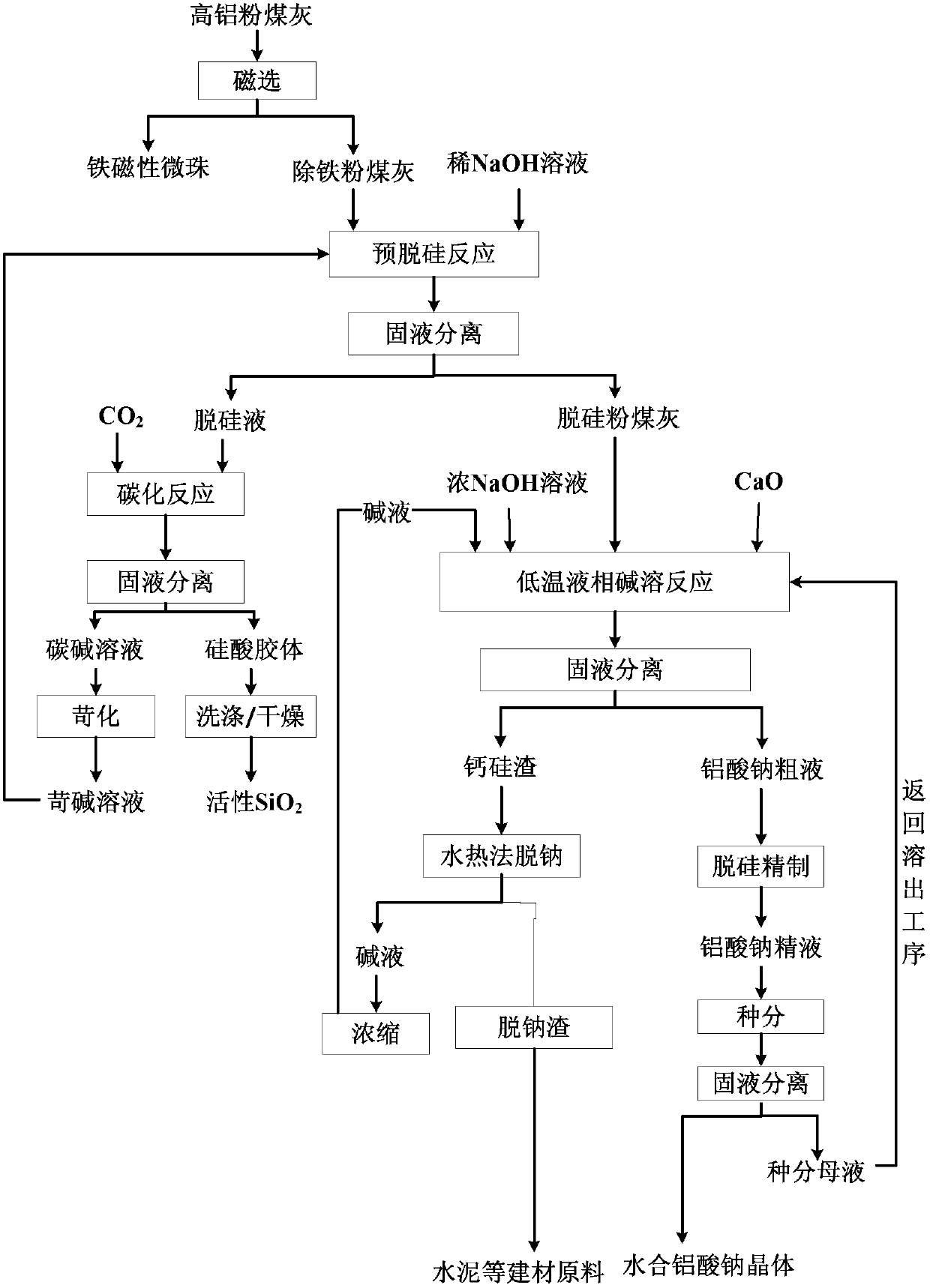

Method used

Image

Examples

Embodiment 1

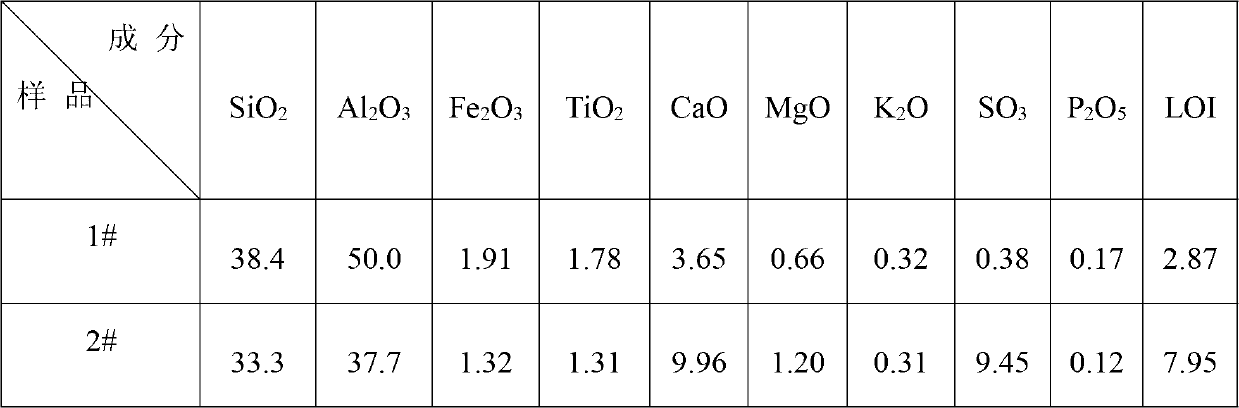

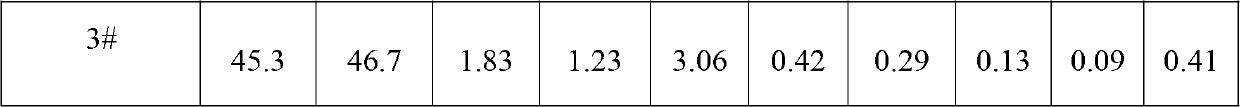

[0031] 1) Use dry magnetic separator to separate iron oxide from 1# high alumina fly ash. The magnetic field strength is 1000-1300 Oersted, and the content of iron oxide in the obtained iron concentrate is close to 45%.

[0032] 2) The high-aluminum fly ash after iron removal and 10% sodium hydroxide solution are uniformly mixed in a ratio of 1:2, put into a high-pressure reactor, and react at 70°C for 0.5h. Filter and separate the reaction product to obtain desiliconization liquid and desiliconization fly ash, SiO 2 The removal rate is 23%.

[0033] 3) The desiliconization solution is kept at 60°C, and 50% (volume concentration) of CO is introduced 2 , with the pH of the solution = 7.5 as the end point. Filter the separated silicic acid colloid, wash and dry to obtain active SiO 2 .

[0034] 4) Desiliconized fly ash, Ca(OH) 2 Mix it with NaOH solution according to a certain ratio, and add it to the autoclave. Among them, NaOH concentration is 45%, Ca(OH) 2 The ratio o...

Embodiment 2

[0039] 1) The magnetic separation process is the same as in Example 1.

[0040] 2) Mix the iron-removing fly ash with 30% sodium hydroxide solution at a ratio of 1:5, add to the reactor, and react at 130°C for 3 hours. The reaction product is separated by filtration to obtain desiliconization liquid and desiliconization fly ash. Among them, SiO 2 The removal rate is 38%.

[0041] 3) The desiliconization solution is kept at 90°C, and 100% (volume concentration) of CO is introduced 2 , with the pH of the solution = 10.5 as the end point. The separated silicic acid colloid was filtered, washed and dried to obtain active SiO 2 .

[0042] 4) Desiliconized fly ash, Ca(OH)2 Mix it with NaOH solution according to a certain ratio, and add it to the autoclave. Among them, NaOH concentration is 65%, Ca(OH) 2 The ratio of calcium to silicon in the desiliconized fly ash is 1.2:1 (molar ratio), the reaction temperature is 300°C, and the reaction time is 3h. After the reaction was co...

Embodiment 3

[0047] 1) The magnetic separation process is the same as in Example 1.

[0048] 2) Mix the iron-removing fly ash with 15% sodium hydroxide solution evenly at a ratio of 1:3, add to the reactor, and react at 110°C for 1.5h. The reaction product is separated by filtration to obtain desiliconization liquid and desiliconization fly ash. Among them, SiO 2 The removal rate is 34%.

[0049] 3) The desiliconization solution is kept at 90°C, and 85% (volume concentration) of CO is introduced 2 , with the pH of the solution = 9.5 as the end point. The separated silicic acid colloid was filtered, washed and dried to obtain active SiO 2 .

[0050] 4) Desiliconized fly ash, Ca(OH) 2 Mix it with NaOH solution according to a certain ratio, and add it to the autoclave. Among them, NaOH concentration is 55%, Ca(OH) 2 The ratio of calcium to silicon in desiliconized fly ash is 0.8:1 (molar ratio), the reaction temperature is 280°C, and the reaction time is 1.5h. After the reaction was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com