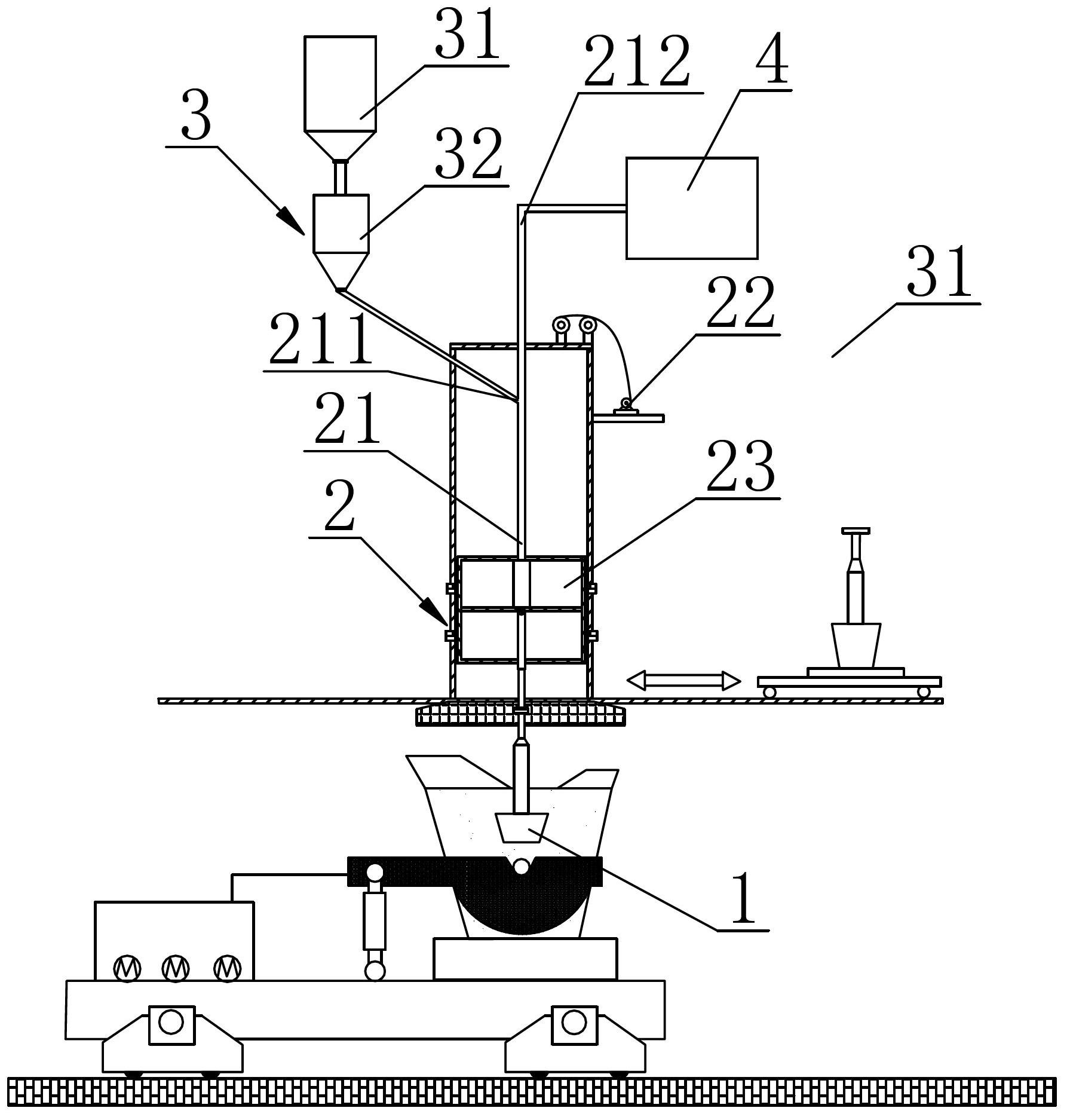

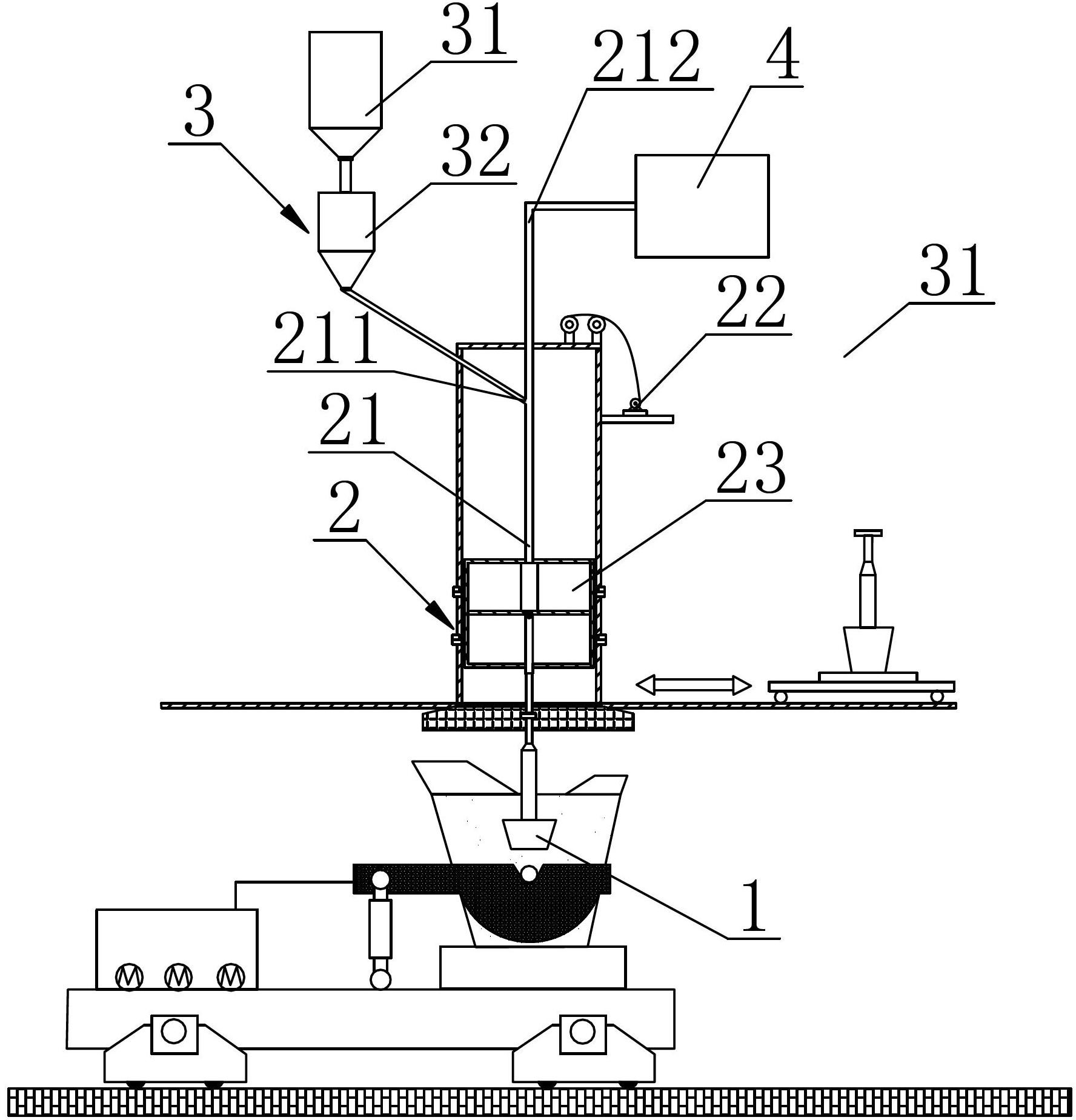

KR (knotted reactor) powder spraying, stirring and desulfurizing device and method

A technology of stirring desulfurization and powder spraying, which is applied in the field of KR powder spraying stirring desulfurization device, can solve the problems of distortion of the main pipe, the gun core cannot be reused, and the injection pipe cannot be extracted and replaced, so as to reduce the iron loss of slag scavenging and stabilize the desulfurization effect. , Solve the effect of large consumption of desulfurizer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] ⑴Conditions of molten iron before treatment:

[0045] 120 tons of molten iron tank, containing 125 tons of molten iron, the composition of the molten iron before desulfurization pretreatment: Si 0.43%, P 0.105%, S 0.061%, the temperature of the molten iron is 1300°C, and the amount of slag in the molten iron is 0.8%.

[0046] Desulfurization pretreatment target S≤0.015%.

[0047] ⑵Desulfurization treatment process:

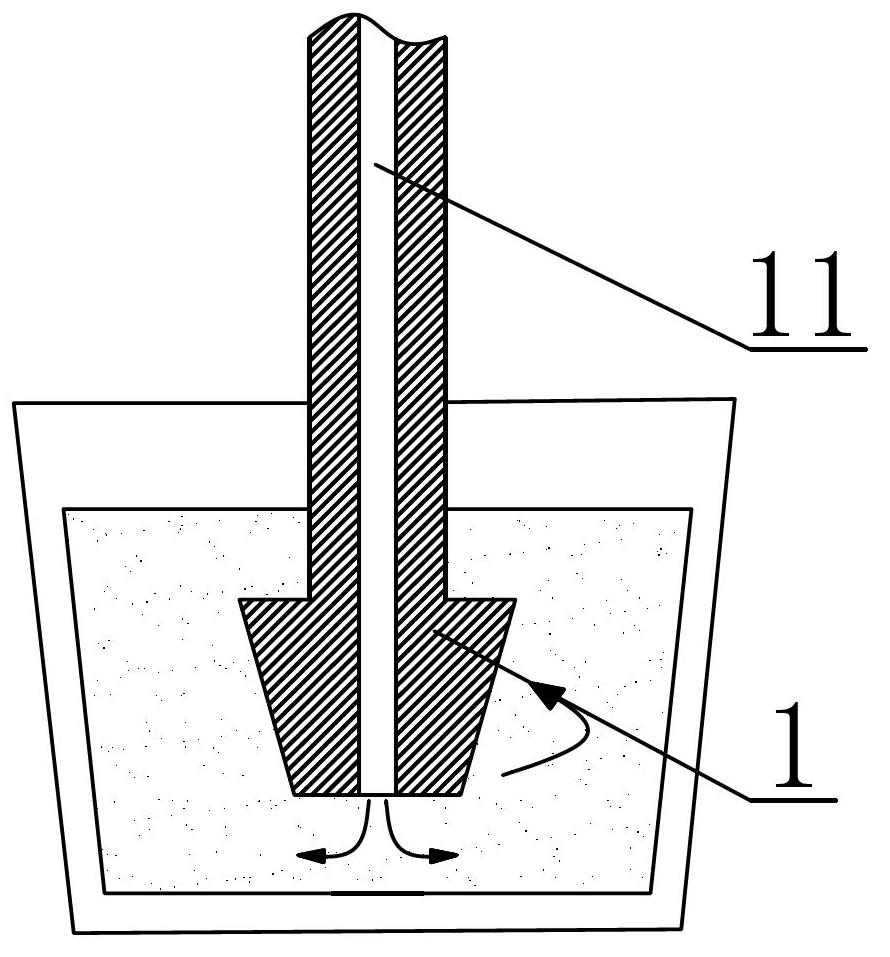

[0048] ① After the molten iron tank enters the desulfurization station, gradually lower the stirring head;

[0049] ②When the stirring head is 5cm away from the molten iron surface, turn on the carrier gas (nitrogen), and the carrier gas flow rate is 30Nm 3 / h, the carrier gas pressure is 0.8MPa;

[0050] ③ After the carrier gas is turned on, bring the desulfurization powder CaO in the silo into the delivery pipeline, and spray it out through the end of the hollow stirring head. Continue to blow nitrogen after the end;

[0051] ④The stirring head start...

Embodiment 2

[0068] ⑴Conditions of molten iron before treatment:

[0069] 120 tons of molten iron tank, containing 120 tons of molten iron, the composition of the molten iron before desulfurization pretreatment: Si 0.32%, P 0.116%, S 0.057%, the temperature of the molten iron is 1310°C, and the amount of slag in the molten iron is 1.0%.

[0070] Desulfurization pretreatment target S≤0.001%.

[0071] ⑵Desulfurization treatment process:

[0072] ① After the molten iron tank enters the desulfurization station, gradually lower the stirring head;

[0073] ② When the stirring head is 3cm away from the molten iron surface, turn on the carrier gas (nitrogen gas) and the flow rate of the carrier gas is 35Nm 3 / h, the carrier gas pressure is 1.0MPa;

[0074] ③ After the carrier gas is turned on, the desulfurization powder CaC in the silo 2 Bring it into the delivery pipeline and spray it out through the end of the hollow mixing head. The desulfurization powder delivery rate is 0.25t / min, the des...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com