A kind of molten iron desulfurizer

A technology for desulfurization and mass fraction of molten iron is applied in the field of iron and steel metallurgy auxiliary materials, which can solve the problems of high cost and low desulfurization efficiency, and achieve the effects of suppressing the degree of volatilization, improving the desulfurization rate, and shortening the desulfurization time.

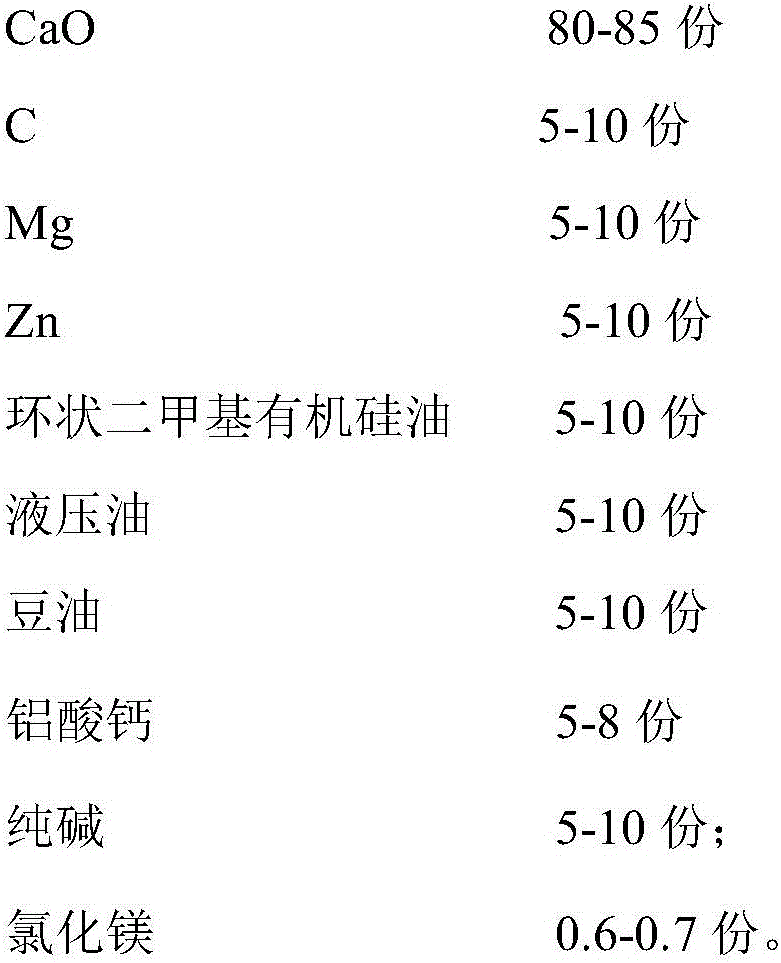

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] The preparation method of desulfurizing agent of the present invention, step is as follows:

[0062] (1) Take 80 parts of CaO for passivation treatment, the process is as follows:

[0063] a. Spraying: Mix 80 parts of water and 80 parts of CaO in a container, and then spray the additive (5 parts of cyclic dimethyl silicone oil, hydraulic oil and soybean oil) on the lime surface, and rotate while spraying Spray and mix in the same way;

[0064] Among them, the raw material parameters are as follows: lime containing CaO ≥ 70-88%, its S ≤ 0.05%, activity ≥ 250ml / 4N (HCl), loss of ignition < 0.5%, angle of repose < 35°, after passivation treatment, particle size 0.01 to 0.1mm.

[0065] b. Heat preservation: heat preservation at 100~1050°C for 4 minutes to make the additive boil and completely volatilize and be absorbed by slaked lime to form a protective film;

[0066] (2) After mixing the following ingredients with the materials prepared in step (1), dry pretreatment: ...

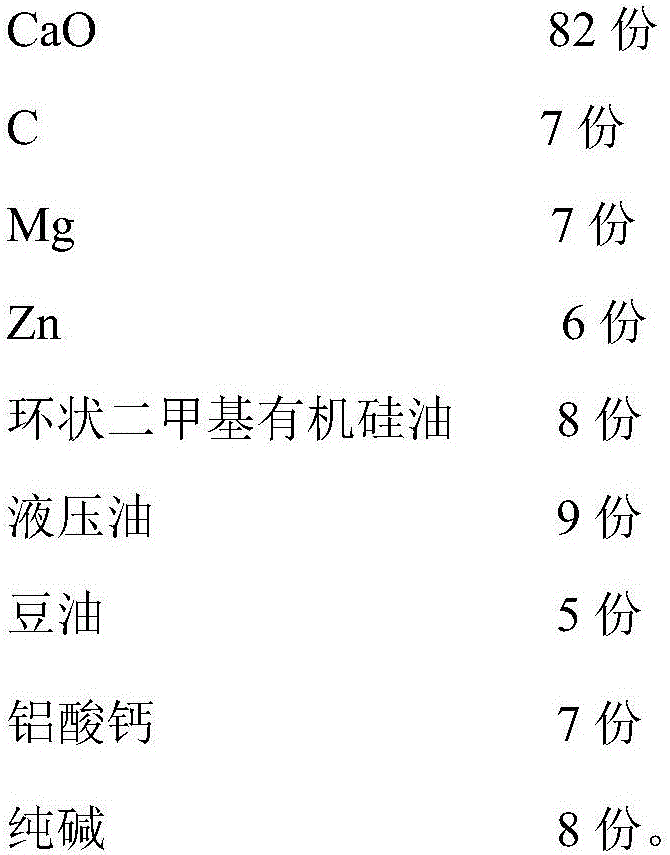

Embodiment 2

[0077] The preparation method of desulfurizing agent of the present invention, step is as follows:

[0078] (1) Take 82 parts of CaO for passivation treatment, the process is as follows:

[0079] a. Spraying: Mix water and CaO in a mass ratio of 1:1 in a container, then spray the additive on the lime surface, and spray and mix evenly while spraying; wherein, the additive is cyclic dimethyl silicone oil 8 parts, hydraulic oil 9 parts, soybean oil 5 parts;

[0080] b. Heat preservation: heat preservation at 100~1050°C for 4 minutes to make the additive boil and completely volatilize and be absorbed by slaked lime to form a protective film;

[0081] (2) After mixing the following ingredients with the materials prepared in step (1), dry the pretreatment;

[0082] C 7 copies

[0083] Mg 7 parts

[0084] Zn 6 parts

[0085] Calcium aluminate 7 parts

[0086] 8 parts of soda ash,

[0087] Then pour the passivation solution into the above materials, stir until the materials are...

Embodiment 3

[0091] The preparation method of desulfurizing agent of the present invention, step is as follows:

[0092] (1) Take 85 parts of CaO for passivation treatment, the process is as follows:

[0093] a. Spraying: Mix water and CaO in a mass ratio of 1:1 in a container, then spray the additive on the lime surface, and spray and mix evenly while spraying while rotating; wherein, the additive is cyclic dimethyl silicone oil 10 parts, hydraulic oil 10 parts, soybean oil 10 parts mixed;

[0094] b. Heat preservation: heat preservation at 100~1050°C for 4 minutes to make the additive boil and completely volatilize and be absorbed by slaked lime to form a protective film;

[0095] (2) After mixing the following ingredients with the materials prepared in step (1), dry the pretreatment;

[0096] C 10 copies

[0097] Mg 10 parts

[0098] Zn 10 parts

[0099] Calcium aluminate 8 parts

[0100] 10 parts of soda ash.

[0101] Among them, soda ash contains more than 90% Na 2 CO 3 , S w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com